Patents

Literature

67results about How to "Good hydrolytic stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

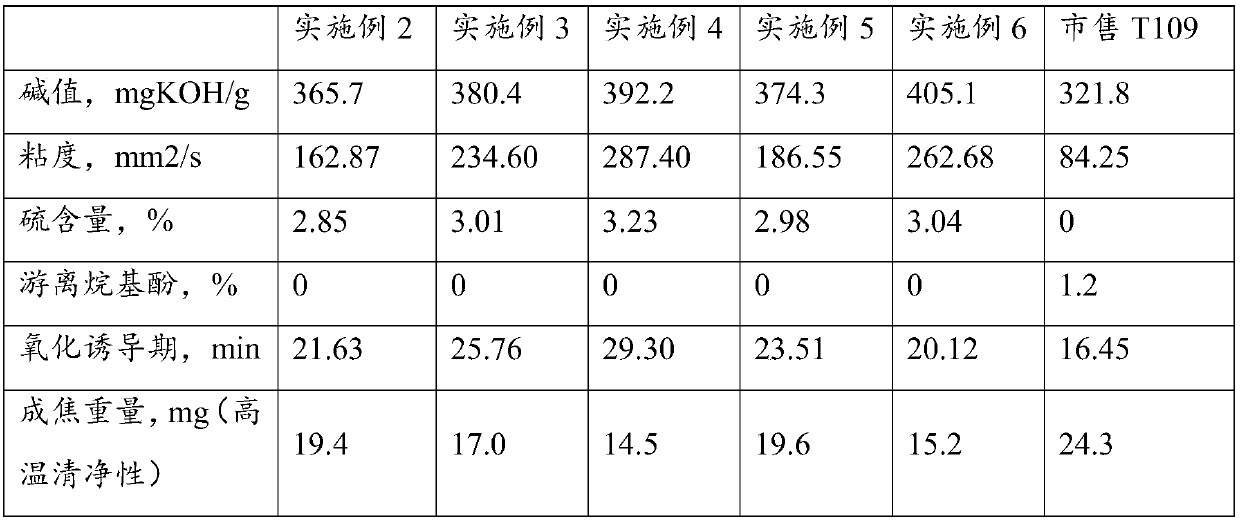

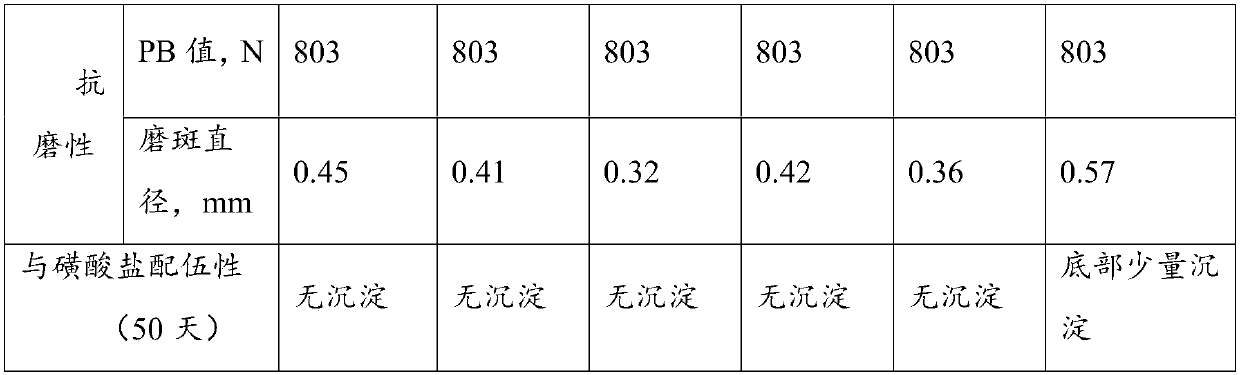

High basic value (TBN400) sulfurized calcium alkyl and preparation method thereof

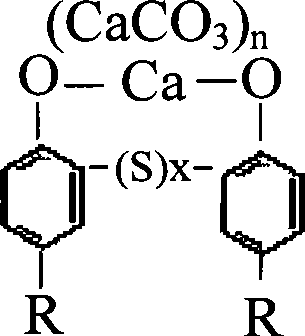

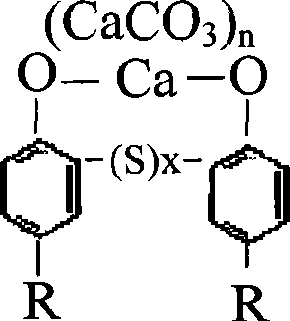

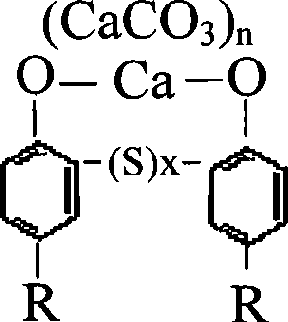

ActiveCN101423483AWide range of usesImprove performanceAdditivesHydropoly/poly sulfide preparationChemical structureCarboxylic acid

The invention relates to high base number (TBN400) vulcanized alkyl phenol calcium and a preparation method thereof. The vulcanized alkyl phenol calcium has a chemical structure as right. The preparation method is as follows: in a system containing solvent and diluent oil, alkyl phenol compound, shielded phenol compound, calcium oxide and / or calcium hydroxide and sulfur are subjected to sulfonation / neutralization reaction at a temperature of between 60 and 180 DEG C to generate phenolate intermediate; balanced calcium oxide and / or calcium hydroxide are added into the mixture, carbon dioxide is introduced, and the mixture is subjected to carbonation reaction; and alkyl polylol is added into the mixture at the sulfonation / neutralization reaction or respectively at the sulfonation / neutralization reaction and the carbonation reaction to participate in the reaction, long-chain carboxylic acid is added into the mixture at the sulfonation / neutralization reaction or respectively at the sulfonation / neutralization reaction and the carbonation reaction to participate in the reaction, and products are obtained through refining. The vulcanized alkyl phenol calcium has the characteristics of high base number, low viscosity, low precipitation number, good heat storage stability, and the like, and has excellent combination property, does not cause environmental protection problem during use, and belongs to an environment-friendly product, and adopts a one-stage process, has mild reaction conditions, and is easy to filter.

Owner:JINZHOU DPF TH CHEM CO LTD

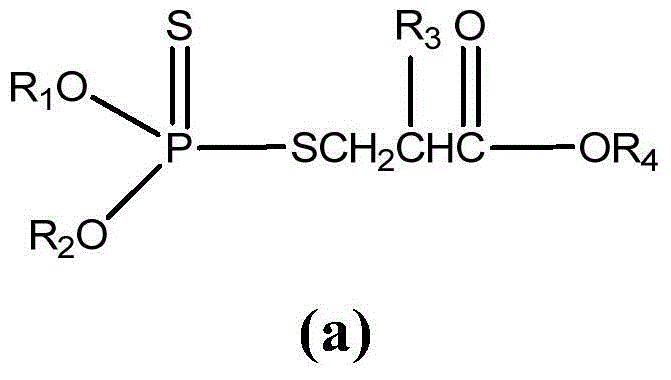

Phosphorothioate type antiwear agent

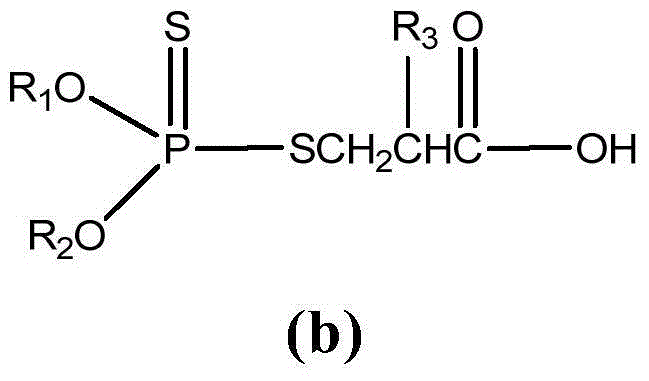

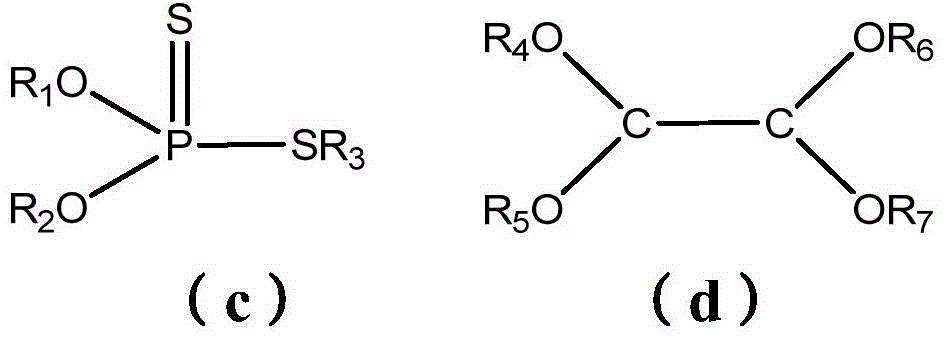

ActiveCN106317109AImprove rust resistanceImprove wear resistanceGroup 5/15 element organic compoundsAdditivesFiltrationAlkoxy group

The invention relates to a phosphorothioate type antiwear agent, and in particular relates to a compound of formula I, wherein R1 and R2 are independently selected from C1-12 straight or branched chain alkyl groups, R3 and R4 are each independently selected from the group consisting of H, C1-12 straight or branched chain alkyl groups, C1-12 straight or branched chain alkyloxy groups, and the C1-12 straight or branched chain alkyl groups and the C1-12 straight or branched chain alkyloxy groups are optionally mono-substituted or polysubstituted by substitutes selected from the group consisting of a halogen, C1-4 alkyl groups, halogen-substituted C1-4 alkyl groups, C1-4 alkoxy groups, halogen-substituted C1-4 alkoxy groups, hydroxyl groups, cyano groups, nitro groups, amino groups or trifluoromethyl groups. The compound as a hydraulic oil or lubricating oil additive exhibits excellent rust resistance, good antiwear property, thermal stability, filtration and hydrolytic stability.

Owner:XCMG CONSTR MACHINERY

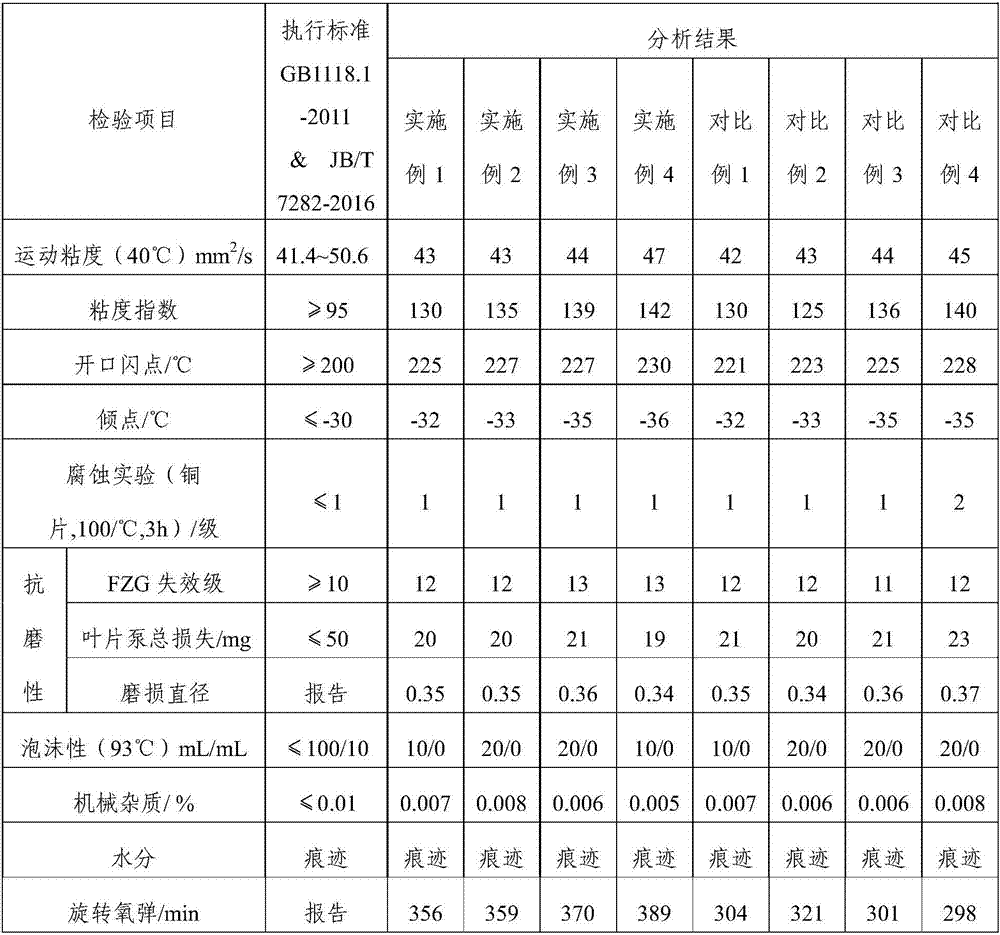

High-pressure anti-wear hydraulic oil

InactiveCN111363608AGood demulsibilityImprove rust resistanceLubricant compositionFoaming agentThermal stability

The invention discloses high-pressure anti-wear hydraulic oil, and belongs to the hydraulic oil field. The hydraulic oil comprises the following components in percentage by mass: 95-99% of base oil, 1.0%-1.5% of an extreme pressure anti-wear agent, 0.1-0.3% of a friction modifier; 0.4-1.0% of an antioxidant, 0.1-0.5% of an antirust agent, 0.1-0.5% of a metal deactivator, 0.02-0.1% of a detergent dispersant, 0.001-0.005% of an anti-foaming agent, and 0.1-0.5% of a demulsifying agent. Compared with the prior art, the hydraulic oil has the advantages of good viscosity-temperature performance, extreme pressure abrasion resistance, oxidation resistance stability, hydrolysis stability and thermal stability, and is not prone to aging and deterioration; the service life is prolonged, a friction pair can be normally lubricated under high-pressure and high-speed harsh conditions, and abrasion is reduced. The foam generated under the condition of violent mechanical stirring in the operation process can be quickly eliminated; air mixed in the oil can be released in a short time, and a static pressure can be accurately, sensitively and stably transmitted.

Owner:无锡中石油润滑脂有限责任公司

Hydrolysis-resistant aliphatic-aromatic copolyester and preparation method thereof

The invention discloses hydrolysis-resistant aliphatic-aromatic copolyester and a preparation method thereof. The preparation method comprises the following steps of: (1) carrying out ester exchange reaction on aromatic binary acid ester or aromatic binary acid and excessive dihydric alcohol to obtain ester P1; (2) reacting aliphatic binary acid, cyclized aliphatic binary acid, an esterification derivative of aliphatic binary acid or an esterification derivative of cyclized aliphatic binary acid with aliphatic dihydric alcohol to obtain ester P2; and (3) mixing P1 with P2, adding an antioxidant to carry out condensation polymerization, then adding a carbonate mineral and a silane compound, and evenly mixing, thus the hydrolysis-resistant aliphatic-aromatic copolyester is obtained. The aliphatic-aromatic copolyester disclosed by the invention has better hydrolysis stability, properties of a polymer in storing and processing processes can be ensured to be stable, and the property retention rate of the polyester product can be improved; and meanwhile, the polyester product also has degradation performance after the application task of the product is completed, and a hydrolysis-resistant component is added in a synthetic process, thus addition during modification is avoided and process is simplified.

Owner:KINGFA SCI & TECH CO LTD +1

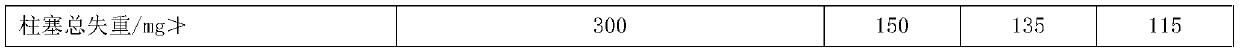

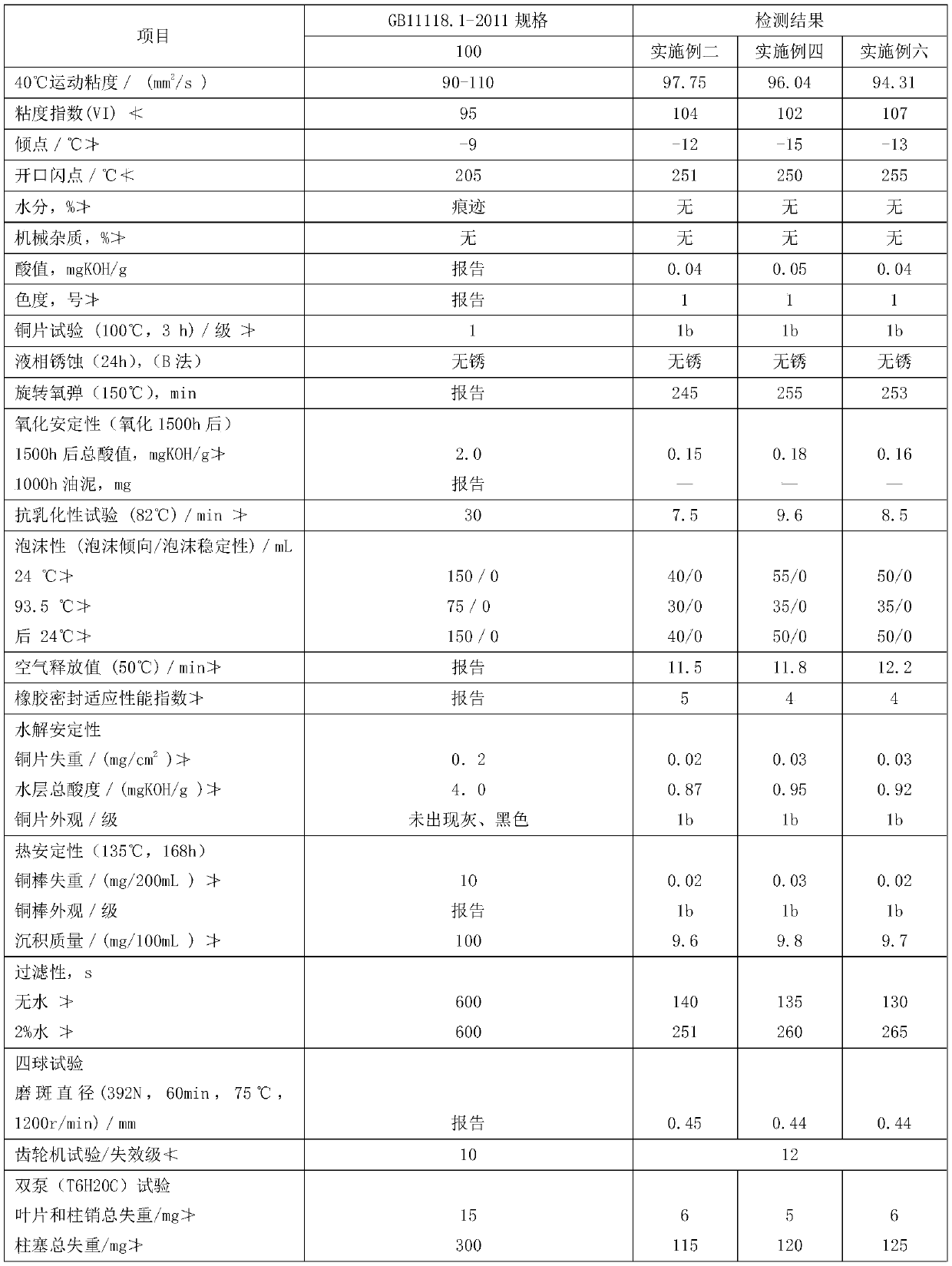

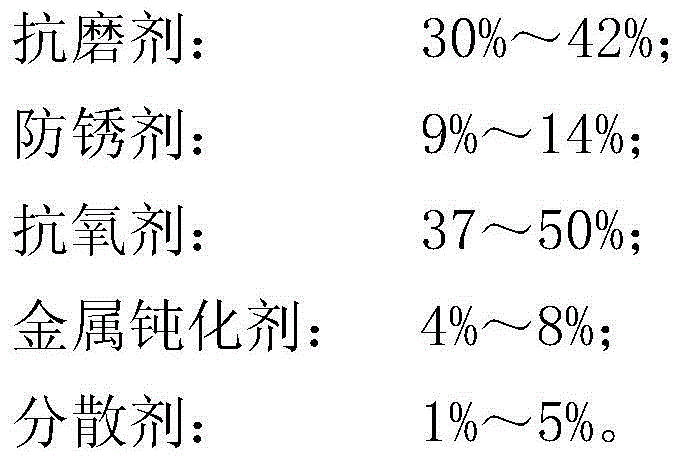

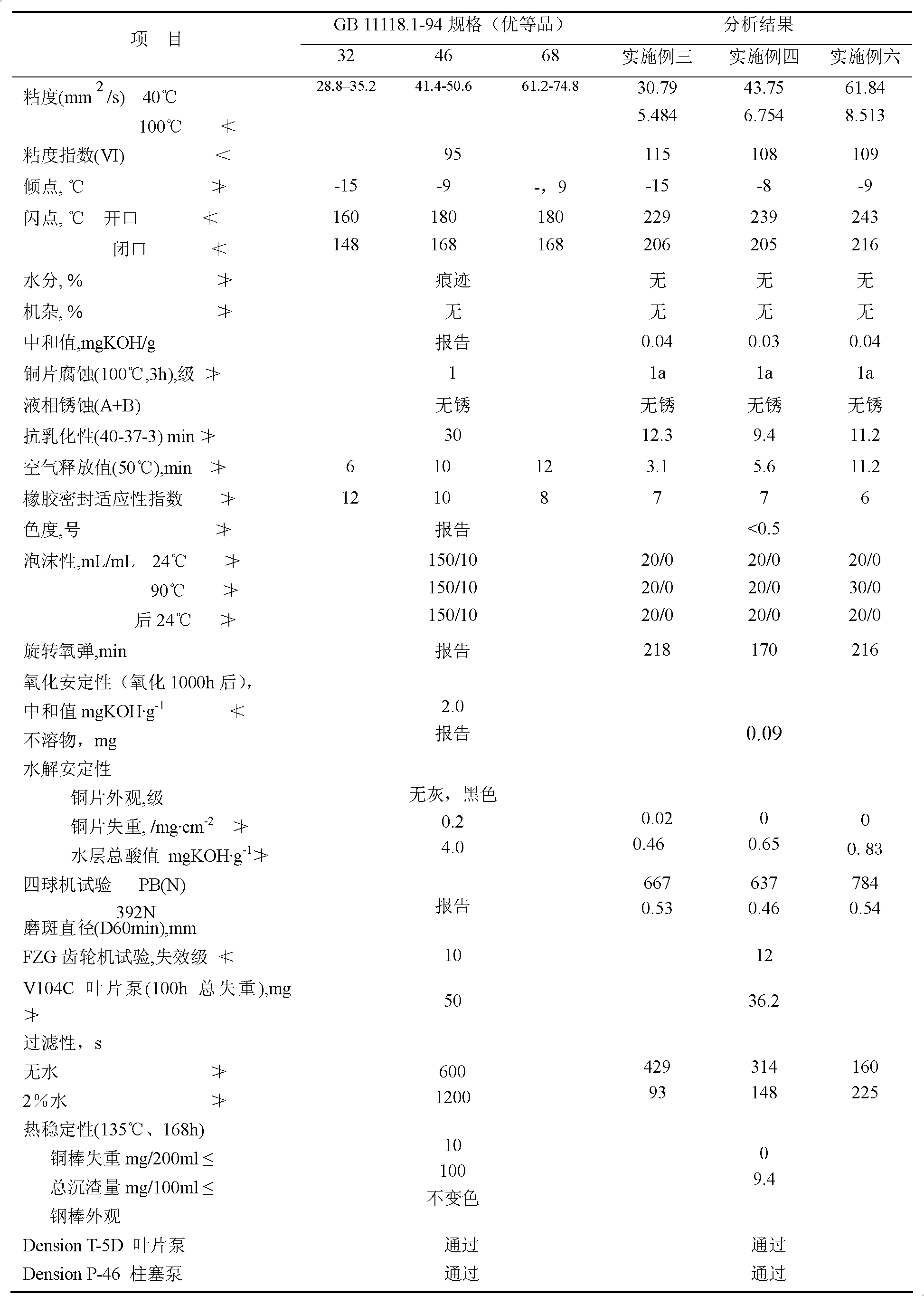

Ash-free hydraulic oil composition

The invention belongs to the technical field of a lubricating composition, and relates to an ash-free hydraulic oil composition. The ash-free hydraulic oil composition comprises the following components by mass percentage: 30-42% of an antiwear agent, 9-14% of an antirust agent, 37-50% of an anti-oxidant, 4-8% of a metal deactivator, and 1-5% of a dispersant. The antiwear agent is a dithio alkyl phosphate and / or a monothio alkyl phosphate. The antirust agent is a compound mixture of a sarcosine derivative and an amino acid derivative or an organic amide. The anti-oxidant is an alkyl group to an aliline or / and a hindered phenol. The metal deactivator is a thiadiazole derivative or a benzotriazol derivative. The dispersant is a polysuccimide derivative. The ash-free hydraulic oil composition has excellent antiwear performance, low greasy filth, and long oxidation life and excellent filterability and hydrolysis stability, and satisfies the GB 11118.1-2011 and Denison HF-0(2011) specification requirements.

Owner:PETROCHINA CO LTD

Preparation method of diisooctyl dithiophosphate zinc salt

ActiveCN107312031AHigh viscosityIncreased zinc contentGroup 5/15 element organic compoundsPhosphoric acidChemistry

The invention provides a preparation method of diisooctyl dithiophosphate zinc salt. The preparation method of the diisooctyl dithiophosphate zinc salt comprises the following steps: performing reaction on isooctanol, phosphorus pentasulfide and zinc oxide to obtain a reaction intermediate system; cooling the reaction intermediate system obtained in the step, adding organic amine and reacting again to obtain the diisooctyl dithiophosphate zinc salt. The organic amine is added in the specific step of the production process to neutralize free thio-phosphoric acid, so the acid value of the product is reduced and the performance of the product is improved; addition of the organic amine can ensure that the T203 product has proper viscosity and zinc content, the diversified requirement of the T203 can be met and the application range is enlarged; meanwhile, the basic salt content of the prepared diisooctyl dithiophosphate zinc salt product is low, the production process of the main body is not changed, an aftertreatment improvement mode is adopted, and the process is simple and suitable for large-scale industrialized production.

Owner:XINXIANG RICHFUL LUBE ADDITIVE CO LTD

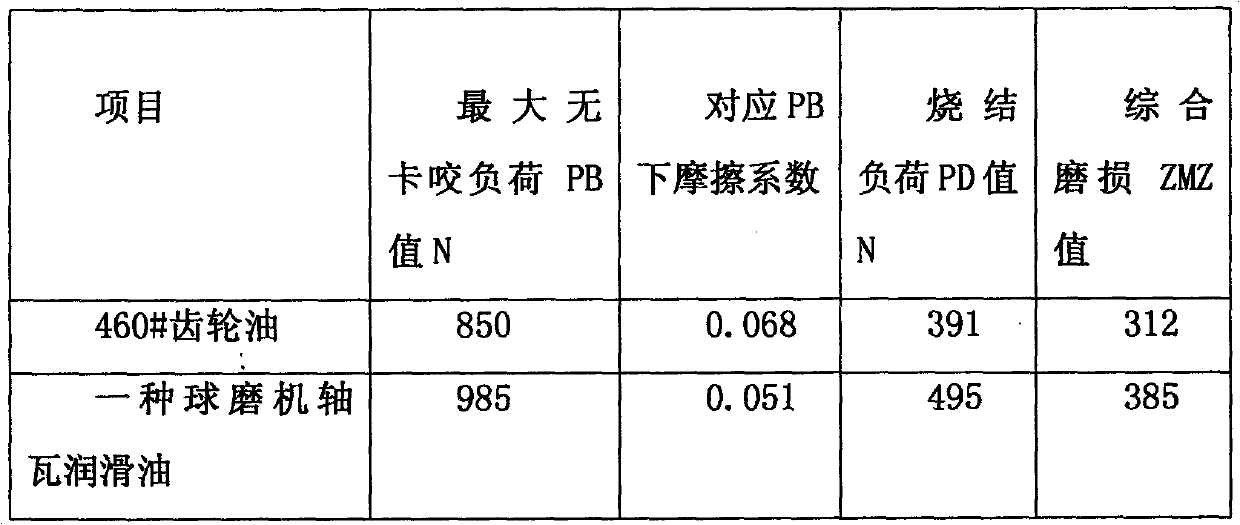

Ball grinding mill bearing bush lubricating oil and manufacturing method thereof

ActiveCN102559347AImprove the lubrication effectReduce the temperatureBase-materialsPolyesterEngineering

Ball grinding mill bearing bush lubricating oil and a manufacturing method thereof solve the problem that a ball grinding mill bearing bush is poor in lubrication in the severe environment. The ball grinding mill bearing bush lubricating oil is formed by using synthetic oil as base oil and refining multiple added efficient composite additives, has the advantages of being abrasion-resisting, high-temperature-resisting, oxidation-resisting, firm in formed film and the like, and can repair wire drawing and reduce abrasion and bearing bush temperature at fastest speed. The work efficiency and the product quality are improved obviously, the repair and maintenance costs are reduced, the service life of a device is prolonged, and energy consumption is reduced greatly. The ball grinding mill bearing bush lubricating oil is composed of, by mass, mineral lubricating oil 49%-69%, polyester synthetic oil 20%-40%, thickening agent 0.05%-0.15%, organic molybdenum composite additive 2.5%-4.5%, T306 additive 1%-3%, T202 antioxygen 0.4%-0.6%, T551 metal deactivator 0.7%-0.9% and T704 antirust additive 0.6%-0.8%, wherein the summation of the components is a hundred percent.

Owner:洛阳正本润滑材料有限公司

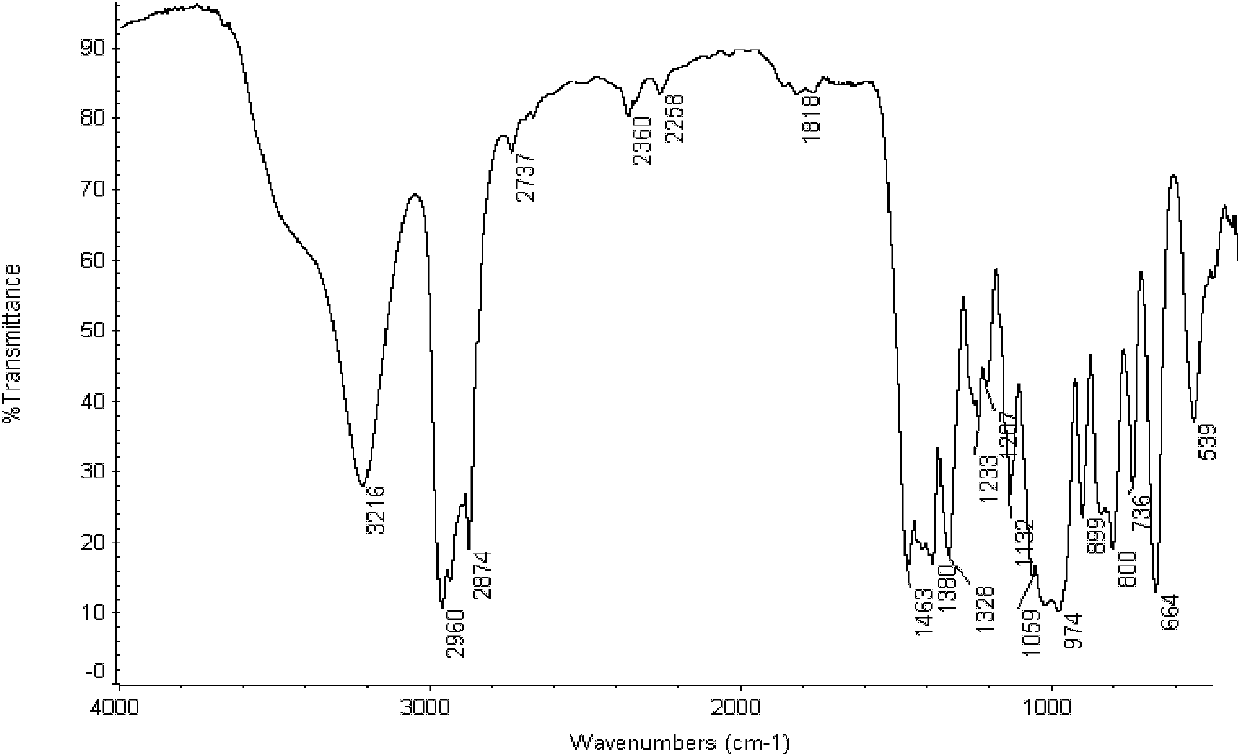

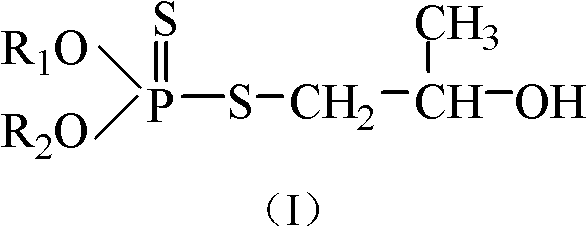

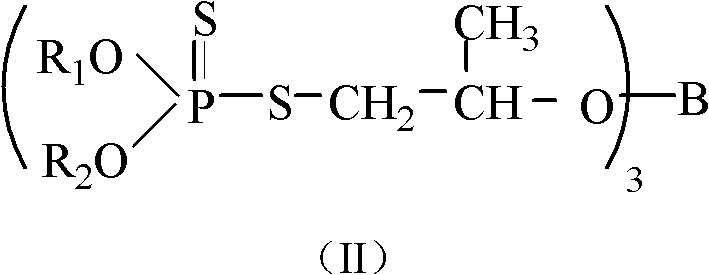

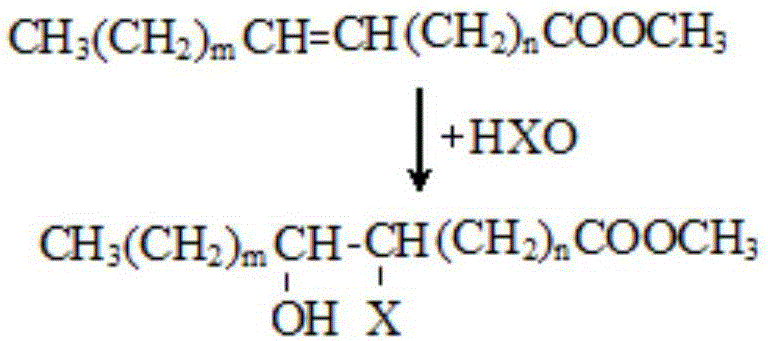

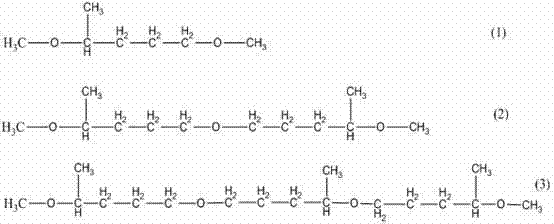

Preparation and application of dialkyl dithiophosphate hydroxyl derivative and boric acid ester thereof

InactiveCN102887918AGood oil solubilityLittle hydrolytic stabilityGroup 5/15 element organic compoundsAdditivesChemistryFriction effect

The invention relates to preparation of a hydroxyl derivative (1) containing dialkyl dithiophosphate and boric acid ester (11) thereof. Both the hydroxyl derivative (1) and the boric acid ester (11) can be taken as environment-friendly lubricating oil additives, can be used for effectively improving the anti-friction quality of environment-friendly basic oil, and have certain anti-friction effects. A preparation method comprises the following steps of: making alcohol react with phosphorus pentasulfide under a certain reaction condition to generate dialkyl dithiophosphate; and reacting with epoxy propane to obtain the hydroxyl derivative containing a dialkyl dithiophosphate group, wherein boric acid ester can be generated by using the hydroxyl derivative and boric acid ester according to an appropriate chemical metering proportion. The method has the advantages of simple process, mild conditions and suitability for industrial production.

Owner:PETROCHINA CO LTD

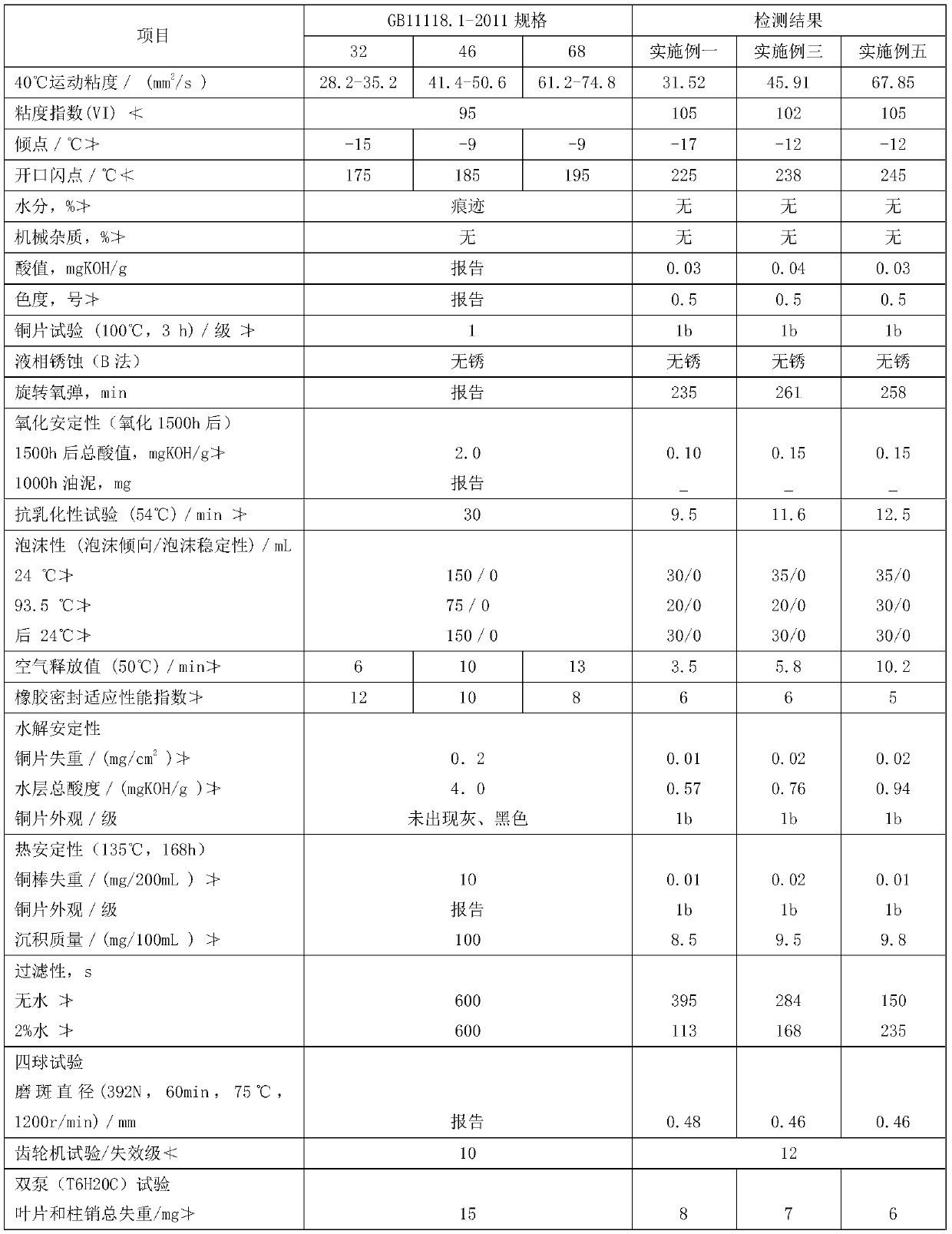

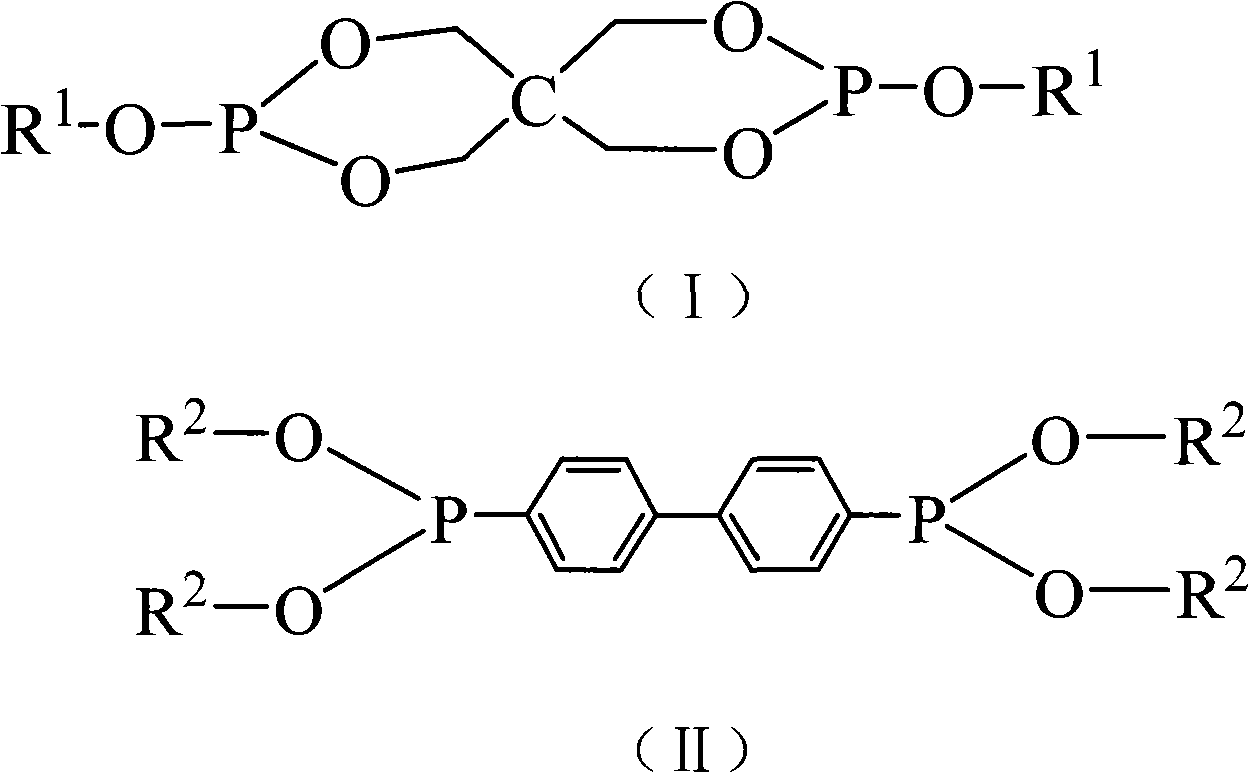

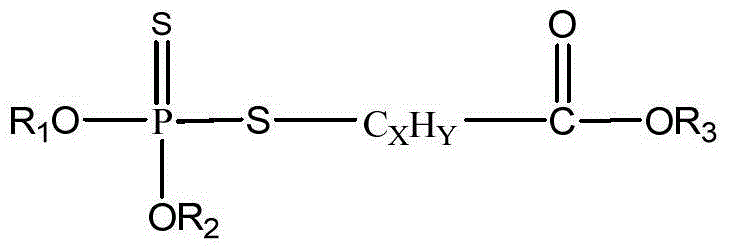

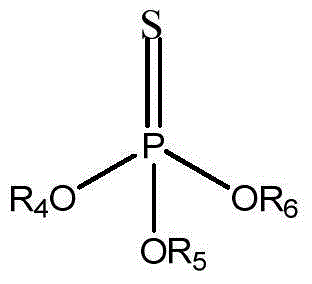

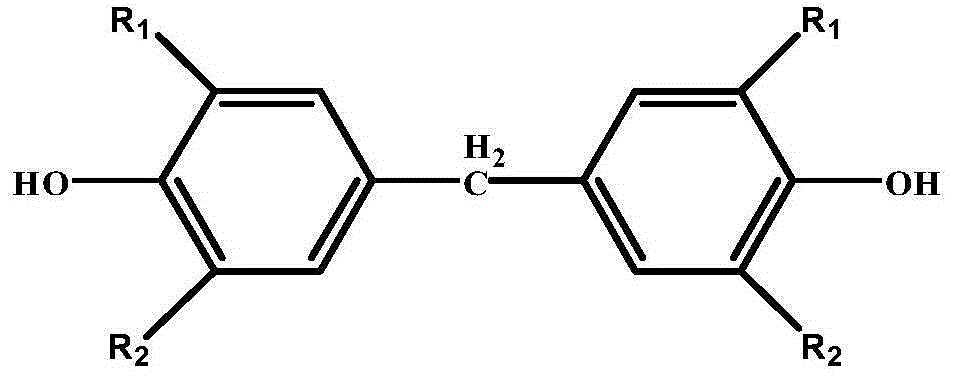

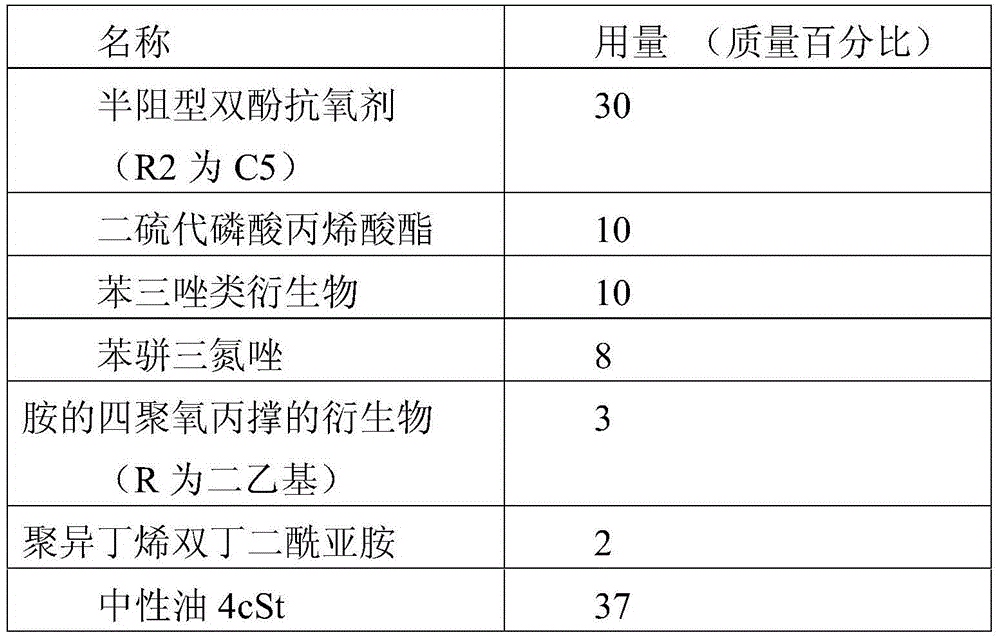

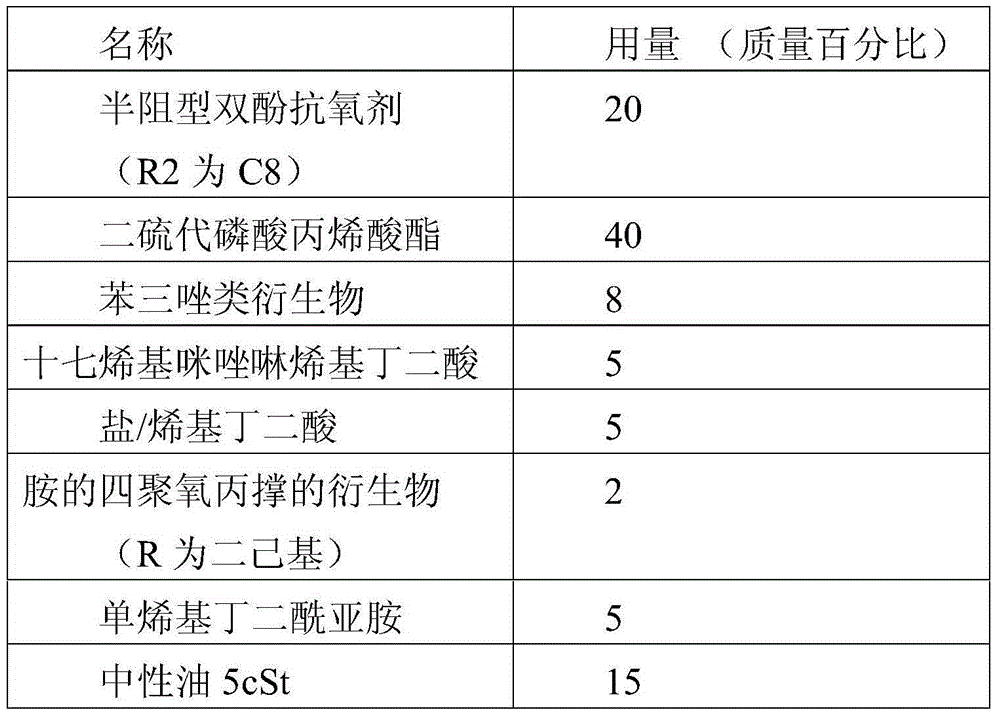

Zinc-free hydraulic oil additive composition

A zinc-free hydraulic oil additive composition includes, by mass, 20-30% of a semi-hindered bis-phenol antioxidant, 10-40% of a dithio-phosphoric acrylate anti-wear agent, 5-10% of a benzotriazole derivative metal passivating agent, 5-10% of an anti-rust agent, 1-3% of an amine tetra-polyoxy trimethylene derivative demulsifier, 1-5% of a dispersant, and the balance being a diluent. The semi-hindered bis-phenol antioxidant has the following structure, wherein R1 is a tert-butyl group and R2 is a C3-C8 straight-chain alkyl group.

Owner:PETROCHINA CO LTD

High-temperature grease and preparation method thereof

InactiveCN103805323AGood oil solubilityStrong extreme pressureLubricant compositionOrganic sulfide compoundAntioxidant

The invention relates to a high-temperature grease and a preparation method thereof. The high-temperature grease comprises the following raw materials in parts by weight: 60-90 parts of base oil, 6-35 parts of thickening agent, 0.5-4 parts of organic sulfide, 0.1-8 parts of rust-inhibiting additive and 0.5-2 parts of antioxidant. The organic sulfide has favorable oil dissolving property, extreme pressure property, oxidation resistance and capability of lowering friction coefficient, does not lose efficacy under high temperature, and effectively avoids great reduction of extrusion property of grease caused by high temperature.

Owner:WUXI FEITIAN GREASE

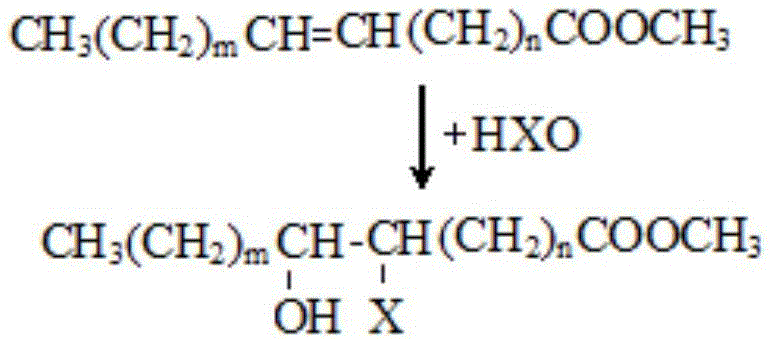

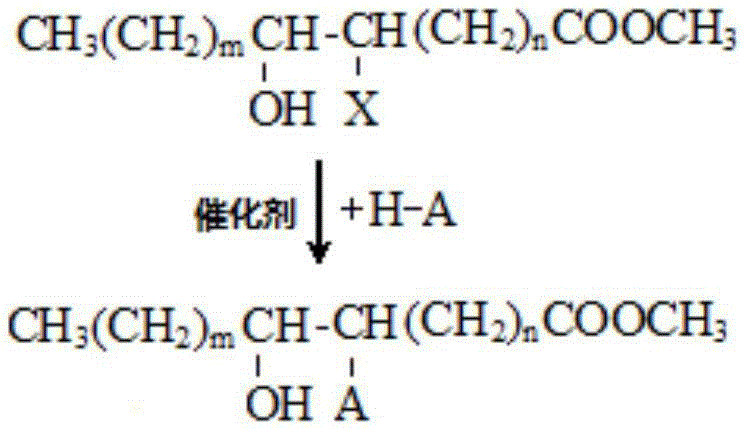

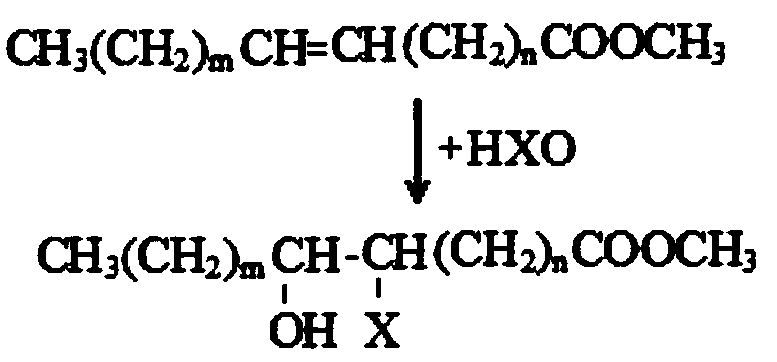

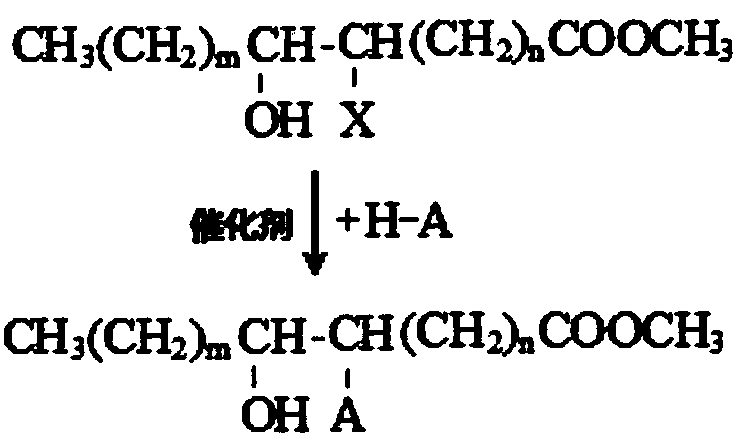

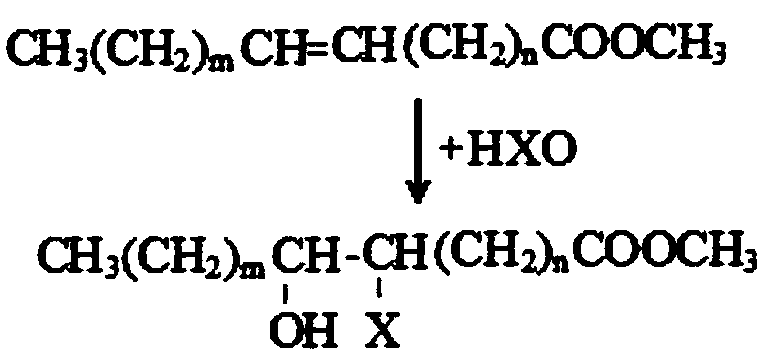

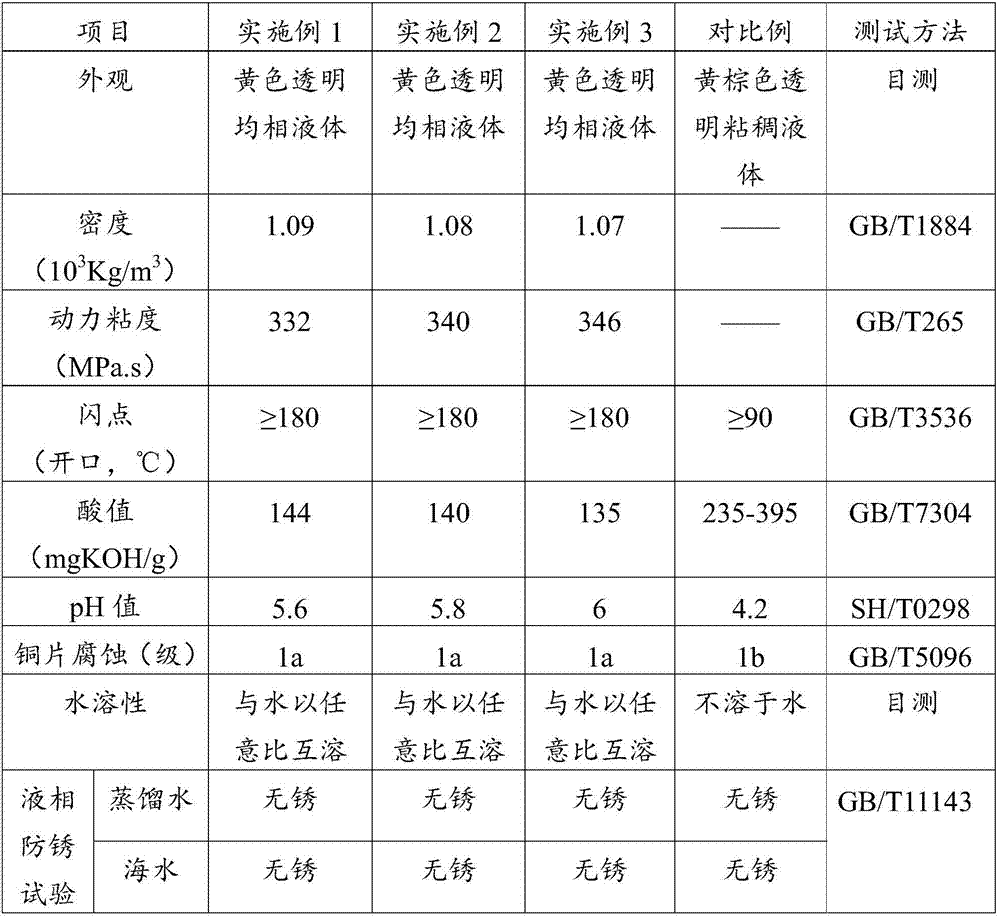

Base oil for metal working fluid and preparation method of base oil

ActiveCN105713700AGood hydrolytic stabilitySimple preparation stepsOrganic chemistryAdditivesMetal working fluidDouble bond

The invention discloses base oil for a metal working fluid (or metal working oil) and a preparation method of the base oil. Plant oil fatty acid methyl ester is taken as a raw material, mercaptothiazole groups are introduced to double bonds, and a plant oil fatty acid methyl ester mercaptothiazole derivative is synthesized to serve as the base oil for the metal working fluid (or metal working oil) or an antiwear agent. By comparison with other plant oil type base oil, the hydrolytic stability of the plant oil fatty acid methyl ester mercaptothiazole derivative is good. The preparation steps are simple, and the reaction conditions are mild.

Owner:四会市格鲁森润滑技术有限公司

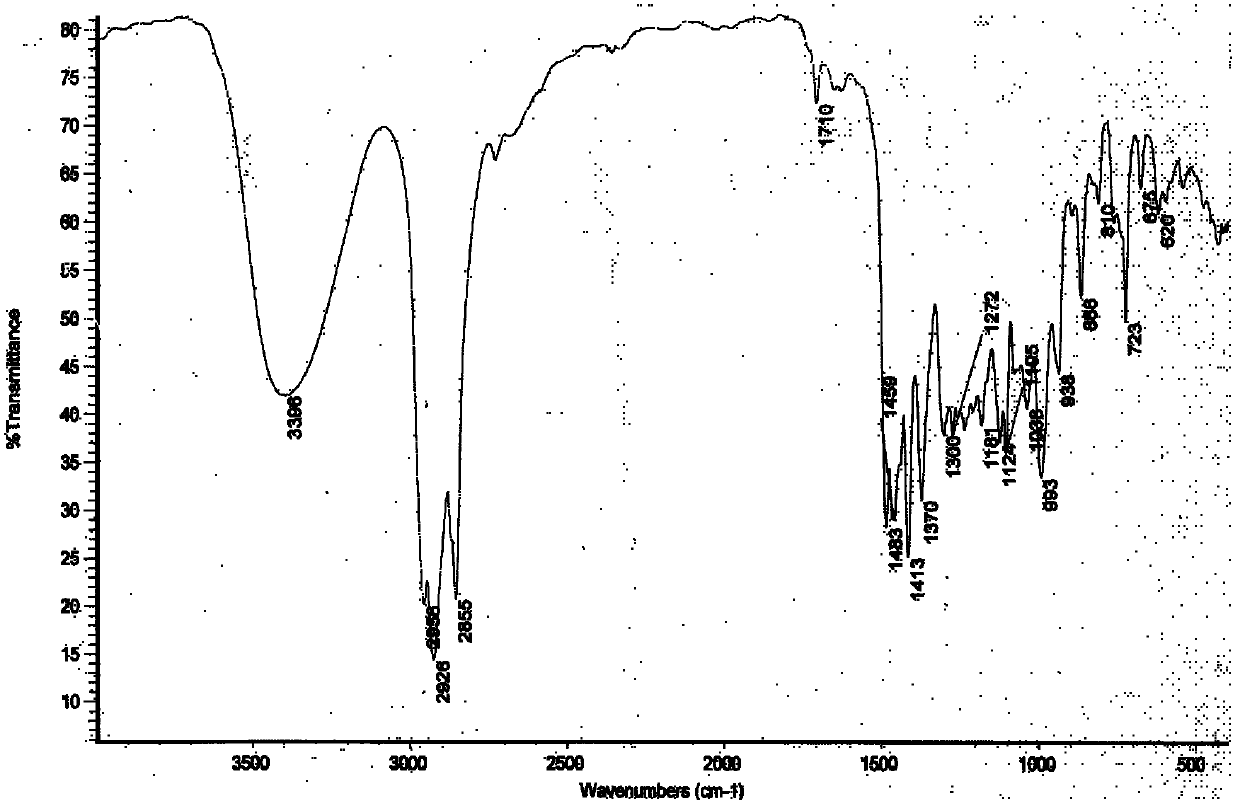

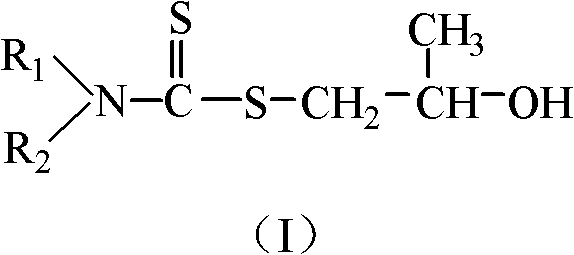

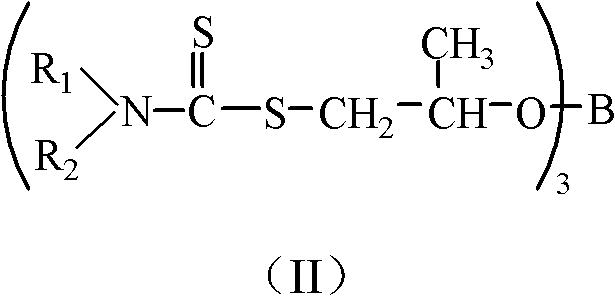

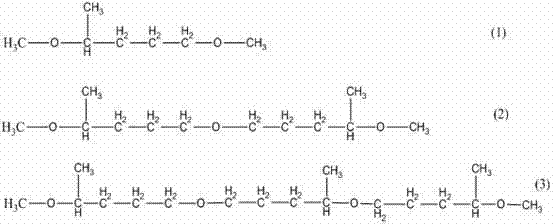

Preparations and applications of dialkyl dithiocarbamate hydroxy derivative and borate thereof

InactiveCN102887846AGood anti-frictionImprove wear resistanceGroup 3/13 element organic compoundsAdditivesBase oilHydroxy group

The invention relates to preparations of dialkyl dithiocarbamate hydroxy derivative (I) and borate (II) of the dialkyl dithiocarbamate hydroxy derivative, both of which can be used as environment-friendly lubricant additives, can effectively improve the antifriction performance of environment-friendly base oils, and play an antiwear role. The preparation method comprises the following steps of: reacting secondary amine and carbon disulfide to generate dialkyl dithiocarbamate in the presence of an acid-binding agent, then reacting with propylene oxide to obtain the hydroxy derivative containing a dialkyl dithiocarbamate functional group; and reacting the latter and borate according to an appropriate stoichiometric ratio so as to generate the borate. The method is simple in process, mild in conditions, and suitable for industrial production.

Owner:PETROCHINA CO LTD

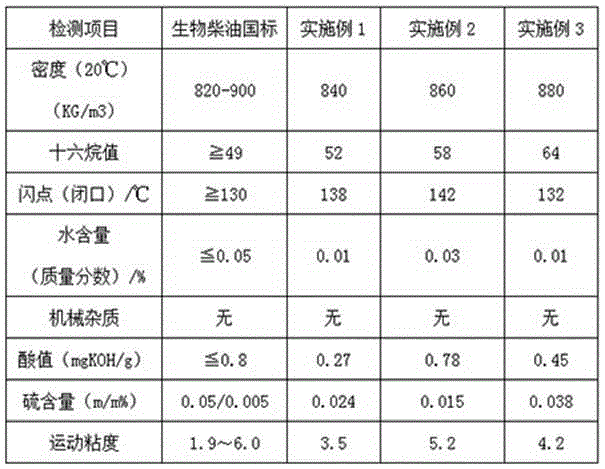

Preparation method of iso-fatty acid methyl ester biodiesel

InactiveCN103740414AAtomic weight increaseWith low coagulationOrganic compound preparationCarboxylic acid esters preparationAlkanePtru catalyst

The invention relates to a preparation method of iso-fatty acid methyl ester biodiesel. The preparation method is characterized in that the iso-fatty acid methyl ester biodiesel is prepared by treating fatty acid methyl ester biodiesel serving as a raw material and gas alkane on an acid supported catalyst through an alkylation process, wherein the using amount of the acid supported catalyst is 2-10 percent by weight of fatty acid methyl ester; the molar ratio of the gas alkane to unsaturated methyl ester in the fatty acid methyl ester is (10-40):1; the pressure control range is 6-8MPa; the temperature is 90-130 DEG C; the reaction time is 2-4 hours. The preparation method has the advantages that the prepared product is low in condensability and excellent in oxidation and hydrolytic stability, the condensation point is lowered by 10-30 DEG C than before reaction, and the oxidation stability is enhanced by over one time; by adopting the product prepared with the method, the defects of the existing biodiesel are overcome, and the product performances are superior to those of commercialized products and the other currently-researched alternative energy sources. The product can become a safe and reproducible high-end synthetic diesel product.

Owner:INNER MONGOLIA JINDI BIOMASS

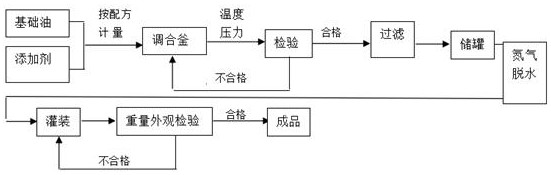

Hydraulic transmission dual-purpose oil and preparing method thereof

ActiveCN108003995AGood high temperature oxidation resistanceHigh viscosity indexLubricant compositionOil processingAntioxidant

The invention provides hydraulic transmission dual-purpose oil and a preparing method thereof, and belongs to the technical field of lubricating oil processing. The hydraulic transmission dual-purposeoil is prepared from, by mass, 96-99 parts of base oil, 0.6-4 parts of antioxidant and 0.5-1.5 parts of extreme-pressure anti-wear additive, wherein the antioxidant is a mixture of an oxidation and corrosion inhibitor and an antioxygen and anti-gum agent. The hydraulic transmission dual-purpose oil has excellent high-temperature oxidation-resistant performance, a high viscosity index, a wide using temperature range and good demulsibility, rust resistance, hydrolytic stability and thermostability, and through the hydraulic transmission dual-purpose oil, mechanical equipment can work normally on the serious work condition.

Owner:河北深思新材料技术有限公司 +1

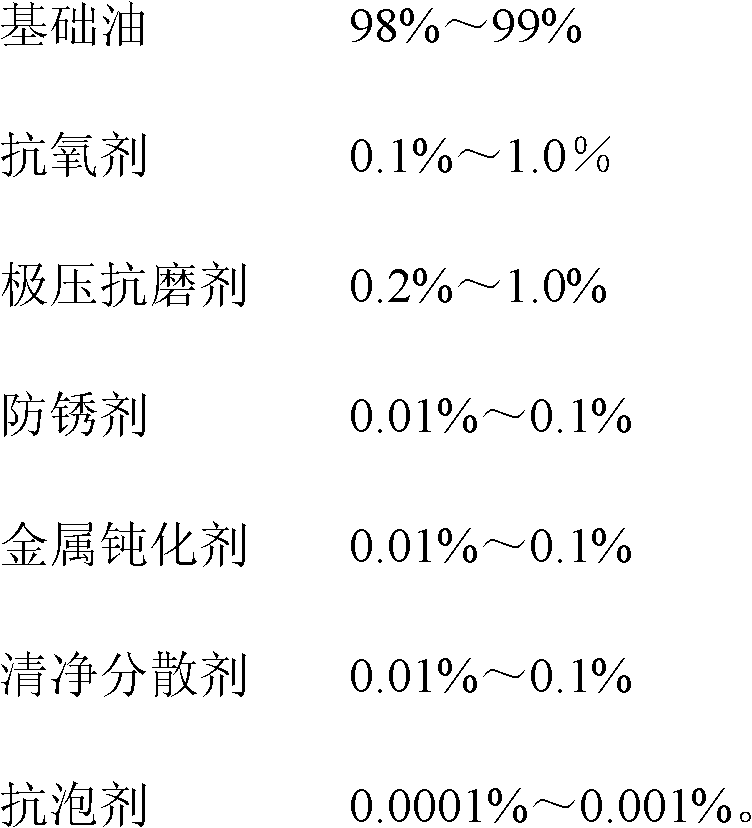

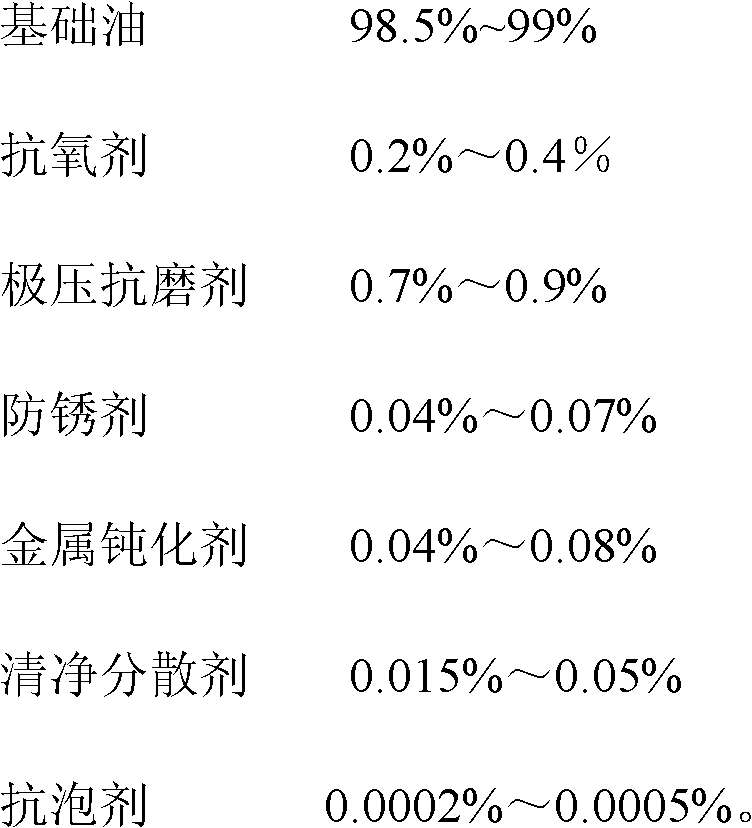

Zinc-free high pressure anti-wear hydraulic oil and preparation method thereof

The present invention discloses zinc-free high pressure anti-wear hydraulic oil. The oil comprises the following components, by mass, 98-99% of base oil, 0.1-1.0% of an antioxidant, 0.2-1.0% of an extreme pressure anti-wear agent, 0.01-0.1% of a rust inhibitor, 0.01-0.1% of a metal passivating agent, 0.01-0.1% of a lustration dispersant and 0.0001-0.001% of an antifoaming agent. The present invention further discloses a preparation method for the zinc-free high pressure anti-wear hydraulic oil. The quality of the hydraulic oil of the present invention meets specification requirements of the anti-wear hydraulic oil superior product in the national standard GB1118.1-94, and can meet specification requirements of the anti-wear hydraulic oil with the highest level Dension HF-0 on the world.

Owner:CHINA PETROLEUM & CHEM CORP

Process for preparing biodiesel

InactiveCN104862084ASimple processEasy to purifyFatty acid isomerisationFatty acid esterificationAlkanePtru catalyst

The invention relates to a process for preparing biodiesel. According to the invention, fatty acid methyl ester biodiesel is adopted as a raw material, and is processed through an alkylation process with gas alkane on an acid-loading catalyst, such that isomeric fatty acid methyl ester biodiesel is obtained. The product provided by the invention has low solidifying point, excellent oxidation stability and excellent hydrolysis stability. The solidifying point is reduced by 10-30 DEG C than that before the reaction. The oxidation stability is improved by more than 1 time. With the product provided by the invention, defects of existing biodiesel are made up. The performance of the product exceeds those of commercial products and other alternative energy sources provided by current researches. The product can become a safe and renewable high-end synthetic diesel product.

Owner:刘敏

A kind of metal processing fluid base oil and preparation method thereof

ActiveCN105713700BGood hydrolytic stabilitySimple preparation stepsOrganic chemistryAdditivesMetal working fluidDouble bond

The invention discloses base oil for a metal working fluid (or metal working oil) and a preparation method of the base oil. Plant oil fatty acid methyl ester is taken as a raw material, mercaptothiazole groups are introduced to double bonds, and a plant oil fatty acid methyl ester mercaptothiazole derivative is synthesized to serve as the base oil for the metal working fluid (or metal working oil) or an antiwear agent. By comparison with other plant oil type base oil, the hydrolytic stability of the plant oil fatty acid methyl ester mercaptothiazole derivative is good. The preparation steps are simple, and the reaction conditions are mild.

Owner:四会市格鲁森润滑技术有限公司

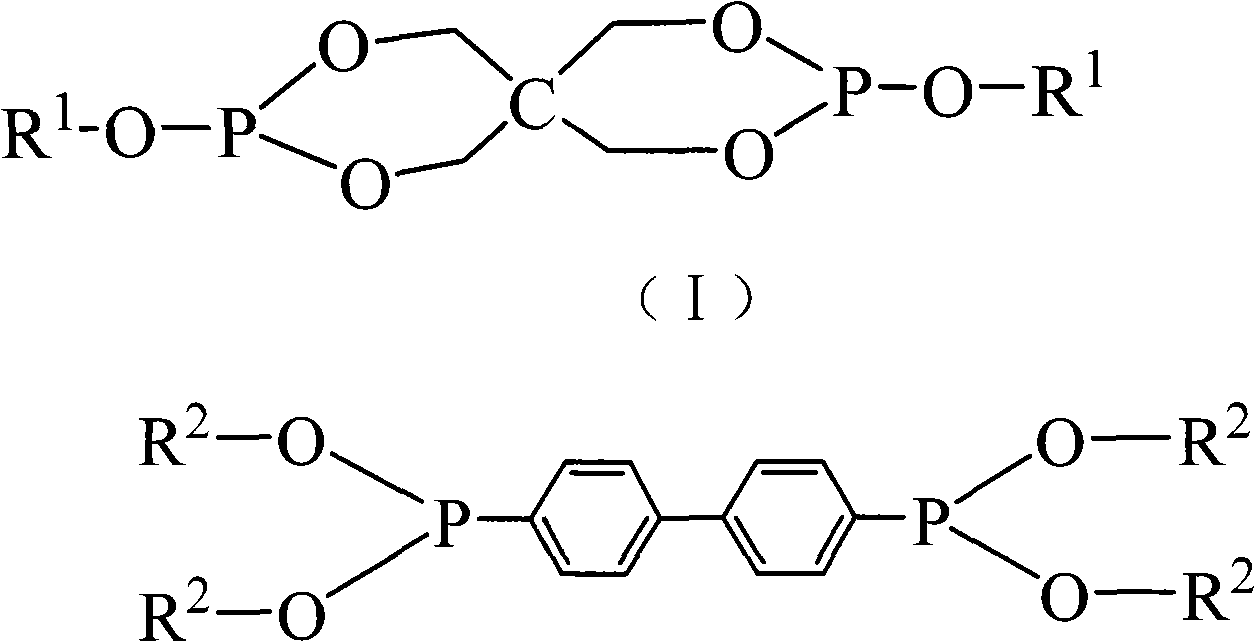

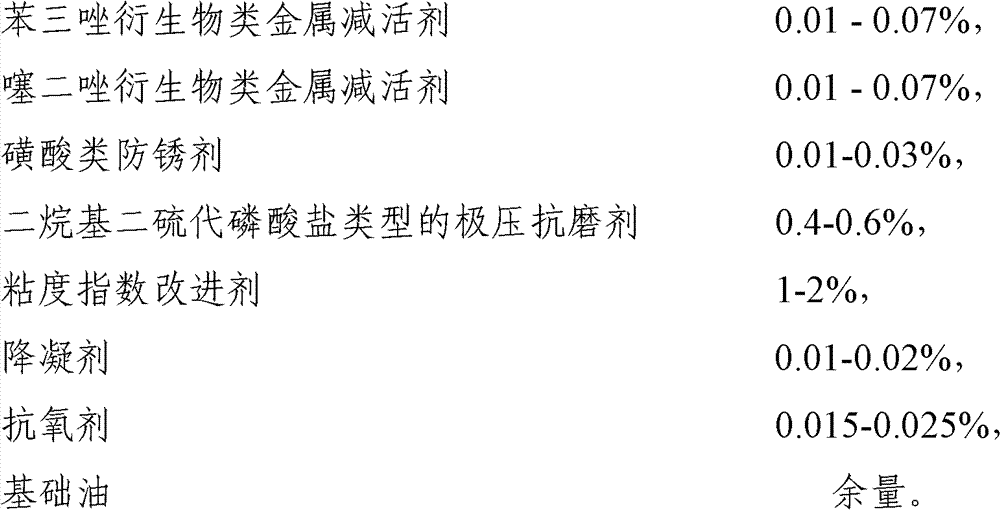

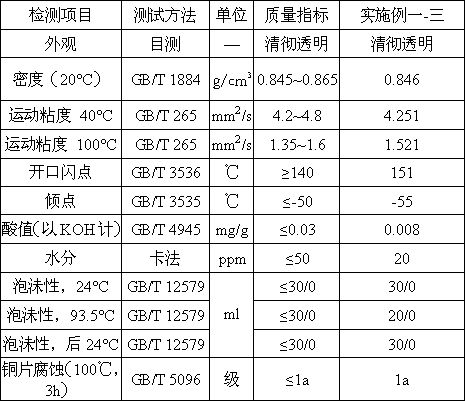

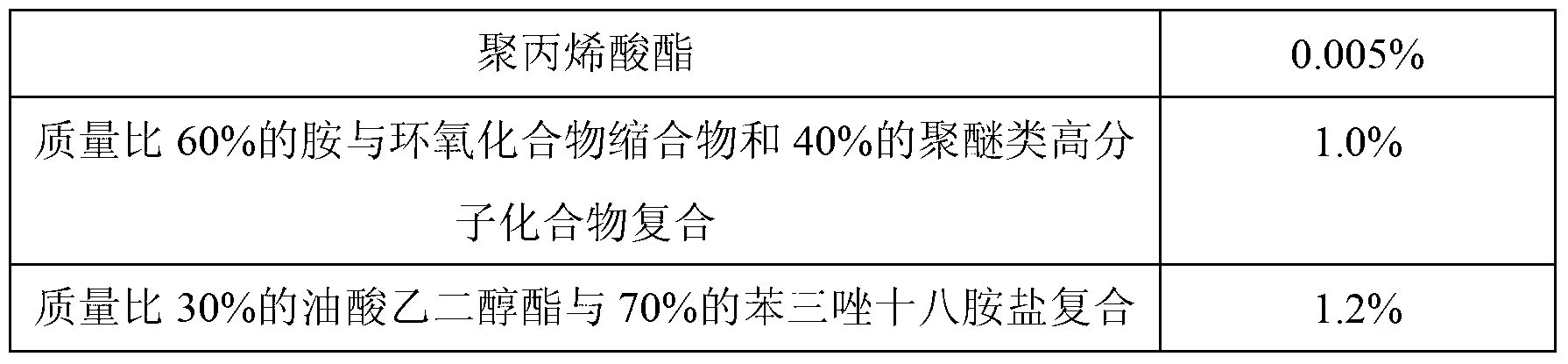

Oil hydrolytic stability enhancer and hydraulic oil composition containing same

ActiveCN103087800AGood hydrolytic stabilityReduce weight lossAdditivesBenzotriazoleTriazole derivatives

The invention provides an oil hydrolytic stability enhancer which is composed of the following components by weight parts: 1-7 parts of a benzotriazole derivative metal deactivator, 1-7 parts of a thiadiazole derivative metal deactivator and 1-3 parts of a sulfonic acid antirust agent. The oil hydrolytic stability enhancer provided by the invention can be used for hydraulic oil compositions so as to improve hydrolytic stability of the hydraulic oil compositions; and the hydraulic oil compositions prepared from the enhancer has characteristics of wear resistance, corrosion resistance, oxidation resistance and demulsification existing in traditional hydraulic oil, and has good hydrolytic stability at the same time.

Owner:CHINA PETROLEUM & CHEM CORP

Trace lubricating oil for high-speed motor bearing and preparation method of trace lubricating oil

InactiveCN102660362AMeet lubrication requirementsDesign fasterAdditivesBase-materialsDibutyl phosphateAlpha-olefin

The invention belongs to the technical field of lubricating oil and particularly relates to trace lubricating oil for a high-speed motor bearing and a preparation method of the trace lubricating oil. The trace lubricating oil is characterized by being prepared from the following raw materials in percentage by weight: 79-90 percent of low-viscosity alpha-olefin, 9-20 percent of octocapric propylene glycol ester and 1-2 percent of dibutyl phosphate, wherein the low-viscosity alpha-olefin is any one of PAO2, PAO4, PAO6, PAO8 or PAO10. Compared with the prior art, the trace lubricating oil disclosed by the invention has the advantages that better lubricating property and extreme pressure anti-wear property are obtained; and by matching with a trace lubricating device, trace amount of lubricating oil can meet the lubricating requirement of the high-speed motor bearing, so that the service life of the high-speed motor bearing is effectively prolonged, the design speed of the high-speed bearing is effectively increased and the important significance for the development of the high-speed motor is realized.

Owner:SHANGHAI JINZHAO ENERGY SAVING TECH

High-impedance soldering flux for single panel of power source charger and preparation method of high-impedance soldering flux

ActiveCN102689110AGood welding performanceGood hydrolytic stabilityWelding/cutting media/materialsSoldering mediaChemistryActive agent

The invention relates to the technical field of soldering flux, in particular to high-impedance soldering flux for a single panel of a power source charger and a preparation method of the high-impedance soldering flux. The high-impedance soldering flux for the single panel of the power source charger consists of the following ingredients in percentage by weight: 1 percent to 5 percent of hydrogenated rosin, 0.1 percent to 0.8 percent of adipic acid, 0.4 percent to 1.2 percent of sebacic acid, 1 percent to 3 percent of succinic acid, 0.5 percent to 2 percent of glycollic acid, 0.1 percent to 0.8 percent of dibromo butylene glycol, 0.5 percent to 2 percent of surface active agents, 2 percent to 7 percent of film forming additives and 80 percent to 92 percent of absolute ethyl alcohol. The high-impedance soldering flux for the single panel of the power source charger has the advantages that the moisture cannot be easily absorbed, so the single panel of the power supply charger is prevented from generating quality problems caused by moisture absorption in rainy humid weather in spring, and in addition, the single panel of the power supply charger has the characteristic of high impedance.

Owner:广东剑鑫科技股份有限公司

Novel ashless wear-resistant hydraulic oil

InactiveCN104673454AImprove Oxidation StabilityGood demulsibilityLubricant compositionTert butyl phenolWear resistant

The invention discloses novel ashless wear-resistant hydraulic oil prepared from the following raw materials in parts by weight: 20-40 parts of base oil, 2-6 parts of dodecenylsuccinic acid, 4-8 parts of polymethacrylate, 2-6 parts of methyl silicone grease, 8-16 parts of triphenyl-thiophosphate, 7-14 parts of alkyl diphenylamine, 3-9 parts of alkyl phenyl propionate, 5-10 parts of a carboxylate derivative, 3-7 parts of a benzotriazole fatty acid amine salt, 7-11 parts of isopropyl palmitate, 5-8 parts of sulfide polyisobutylene and 3-6 parts of tert-butyl phenol. The novel ashless wear-resistant hydraulic oil provided by the invention is good in hydrolysis stability, demulsibility, oil product filterability and thermal oxidation stability and longer in service life.

Owner:QINGDAO KERUN PLASTIC MACHINERY

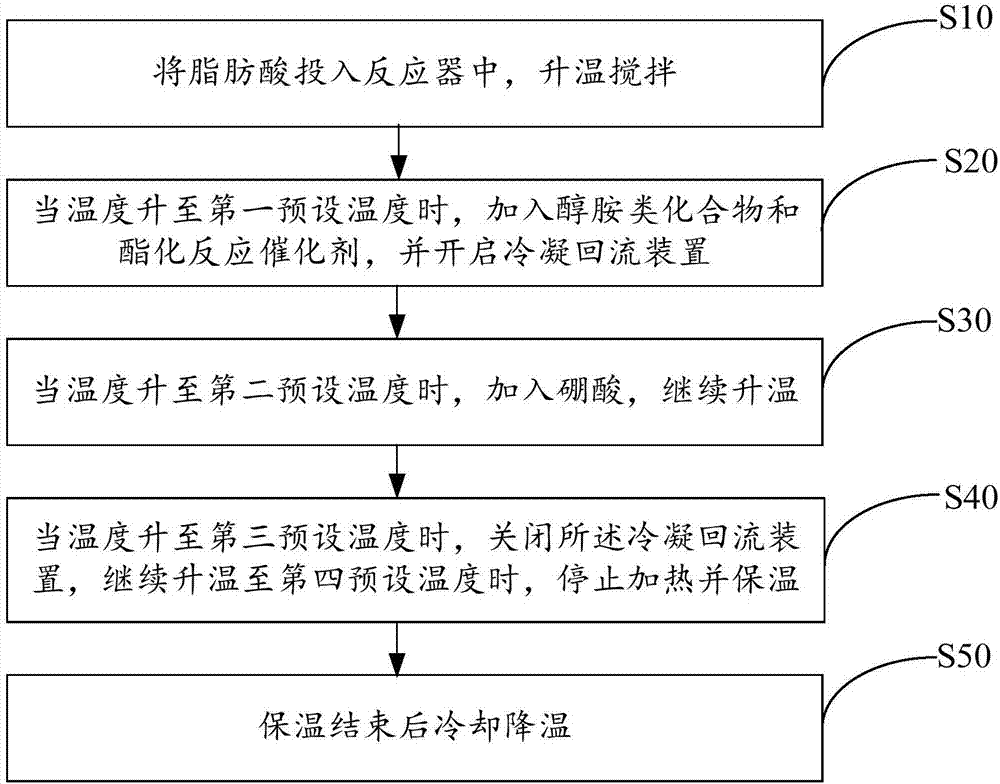

Antirust agent and preparing method thereof

ActiveCN107419274AAnti-rust for a long timeWith anti-wear and anti-friction abilityAdditivesAlcoholBoric acid

The invention discloses an antirust agent and a preparing method thereof. The antirust agent comprises fatty acid, alcohol amine compounds, boric acid and a catalyst; the molar ratio of the fatty acid to the alcohol amine compounds to the boric acid is 5:2:1-1:1:1. The preparing method of the antirust agent comprises the steps that fatty acid is put into a reactor, and heating stirring is carried out; when the temperature rises to the first preset temperature, the alcohol amine compounds and the catalyst are added, a condensate backflow device is started; when the temperature rises to the second preset temperature, boric acid is added, and temperature rising is continuously carried out; when the temperature rises to the third preset temperature, the condensation backflow device is closed, the temperature continuously rises to the fourth preset temperature, heating is stopped, and heat preservation is carried out; after heat preservation is ended, cooling is carried out. The prepared antirust agent is long in antirust effective period, and has the good anti-wear anti-friction capacity, hydrolytic stability and biodegradability.

Owner:WUHAN POLYTECHNIC UNIVERSITY

Novel wear-resistant hydraulic oil

InactiveCN102453597ANormal lubricationDisappear quicklyLubricant compositionTert butyl phenolWear resistant

The invention relates to hydraulic oil, in particular to novel wear-resistant hydraulic oil with good adaptability. The ratio of No.46 base oil to base VGO No.2 oil to benzotriazole fatty acid amine salt to isopropyl palmitate to vulcanized polyisobutene to tert-butyl phenol to silicone oil is (79-95): (60-81): (0.05-0.08): (0.3-1.2): (0.6-1.2): (0.07-0.3): (0.09-0.4). The novel wear-resistant hydraulic oil has good viscosity-temperature performance, extreme pressure wear resistance, anti-oxidation stability, hydrolytic stability and thermal stability, so the aging and the degradation are not easy to occur, the service life is prolonged, the normal lubrication of friction pairs under the rigorous conditions of high pressure and high speed is realized, and the abrasion is reduced. The foam generated under the conditions of violent mechanical stirring in the operation process can be ensured to fast disappear, and in addition, air mixed into the oil can be released in a short time for realizing the accurate, sensitive and stable static pressure transmission.

Owner:孙丽荣

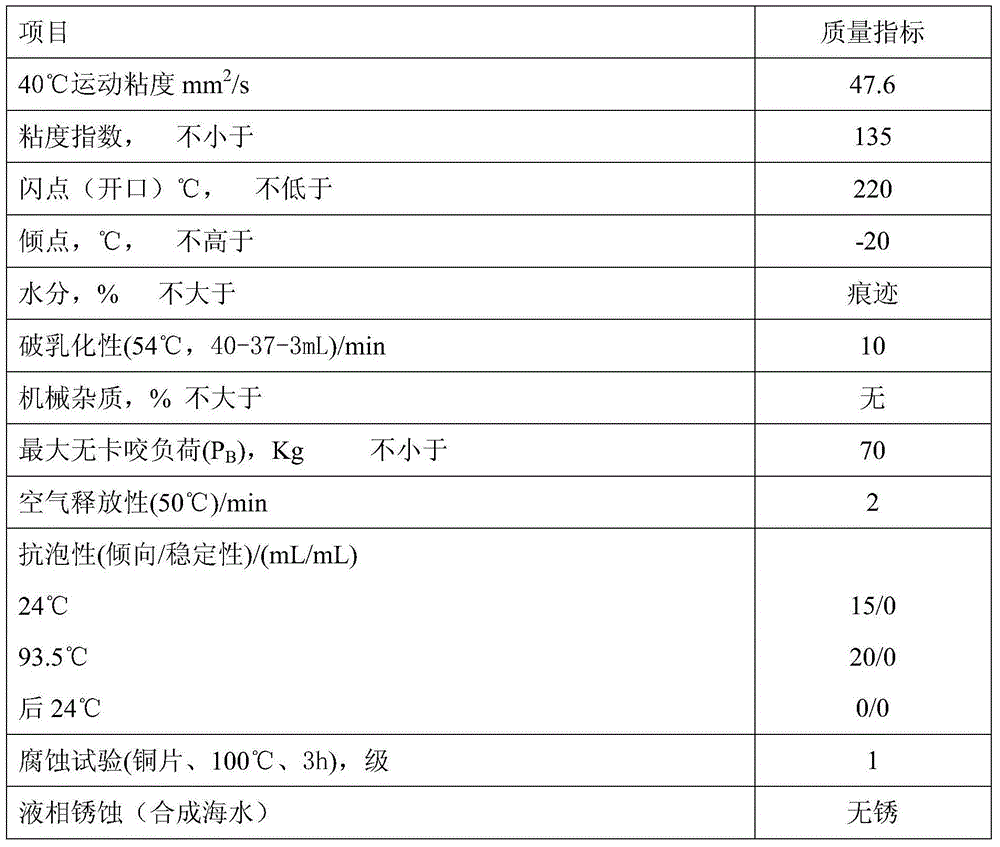

Ship side thruster hydraulic oil

ActiveCN103666682BAgainst pollutionImprove rust resistanceLubricant compositionPentaerythritolEmulsion

The invention discloses ship side thruster hydraulic oil which is formed through the following way: pentaerythritol ester and poly-alpha olefin are compounded, the mixture is used as base oil, and then the base oil is combined with multiple composite additives including an antiwear agent, an antioxygen, an anti-foaming agent, an anti-emulgator, an antirust agent, a metal deactivator, a friction improver and a corrosion inhibition assistant. The ship side thruster hydraulic oil can form a protective film on the surface of a hydraulic kinematic pair, resist pollution of seawater and has excellent anti-rust property, abrasion resistance, hydrolysis stability and emulsion resistance; in addition, the air release property and the anti-foaming property of the ship side thruster hydraulic oil are also excellent.

Owner:GUANGXI UNIV

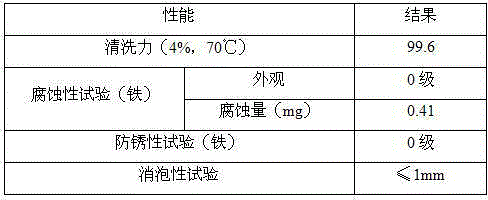

Anti-microbial and anti-corrosion industrial cleaning fluid

InactiveCN105062711AGood thermal stabilityGood hydrolytic stabilityOrganic detergent compounding agentsAmpholytes/electroneutral surface-active compoundsEtherPhosphate

The invention relates to an anti-microbial and anti-corrosion industrial cleaning fluid. The anti-microbial and anti-corrosion industrial cleaning fluid comprises components in parts by mass as follows: 10-20 parts of ethoxyl aminopropyl polydimethylsiloxane, 20-30 parts of sym-triazine, 20-30 parts of HDTMPA, 10-20 parts of oxirane, 2-methyl-, polymer with oxirane, mono(2-propylheptyl) ether, 60-70 parts of N-sodium lauryl sarcosinate, 30-40 parts of sorbitan monopalmitate, 30-40 parts of 1-hydroxyethyl-2-tridecanyl imidazoline, 10-20 parts of potassiam polyoxyethylene laurylether phosphate, 10-20 parts of T203 and 100-200 parts of deionized water. The anti-microbial and anti-corrosion industrial cleaning fluid is suitable for cleaning industrial products, after cleaning, the surfaces are glossy and are not darkened, and the cleaning fluid has no corrosion effect on the surfaces of the industrial products; the cleaning fluid has high degreasing capacity and good cleaning effect, is non-toxic and nonflammable, has the anti-microbial and anti-oxidative effects, is simple and convenient to use and reduces pollution and the cleaning cost.

Owner:龚灿锋

Novel high-strength dredged soil curing agent

The invention provides a novel high-strength dredged soil curing agent. The novel high-strength dredged soil curing agent comprises the following components in parts by weight: 6-12 parts of cement, 8-14 parts of mineral powder, 0.05-0.1 part of a binding agent, 0.02-0.1 part of an additive, 0.05-0.1 part of a silane coupling agent, 0.1-0.15 part of hydroxy-terminated liquid polybutadiene, 0.1-0.15 part of diethylaminoethanol and 0.01-0.05 part of fiber balls. By the novel high-strength dredged soil curing agent, the problem that a large number of dredged sand is difficult to stack and treat in dredging engineering is solved, furthermore, the dredged soil can be cured rapidly and then meets the requirement for the strength of engineering construction, and the cost is saved; according to difference of a construction position, the blending ratio of the curing agent can be adjusted reasonably to achieve the required construction strength, the cost is reduced to a maximum extent, engineering characters of cured soil are improved, and construction safety is ensured; and the using amount of the cement is reduced greatly, an environment is protected, and sustainable development is realized.

Owner:TIANJIN RES INST FOR WATER TRANSPORT ENG M O T

Synthetic refrigerating machine oil and preparation method thereof

InactiveCN112920872AGood low temperatureGood hydrolytic stabilityBase-materialsOil additiveProcess engineering

The invention belongs to the technical field of mechanical lubrication, particularly relates to synthetic refrigerating machine oil and a preparation method thereof, and solves the problems of higher pour point, poor dispersion stability, poor viscosity and the like of refrigerating machine oil in the prior art. The refrigerating machine oil comprises the following raw materials in percentage by weight: 10 to 50 percent of naphthenic base oil, 48 to 88 percent of alkylbenzene oil, 1.5 to 2.5 percent of additive and the balance of defoaming agent. According to the invention, the naphthenic base oil with excellent low-temperature performance and good solubility is adopted; and the alkyl benzene oil with a low pour point and good low-temperature fluidity is adopted as a main raw material, and the alkyl benzene oil and the naphthenic base oil are highly soluble by selecting a reasonable ratio. The obtained refrigerating machine oil is appropriate in viscosity, excellent in low-temperature performance, hydrolytic stability and solubility and good in compatibility with mineral oil and ester oil. The preparation method is simple, adopts a pulse blending treatment technology, and is efficient, energy-saving, easy for industrial production and widely applicable.

Owner:安徽宜度科技有限公司

Bio-based dimethoxyl alkane diesel oil and preparation method thereof

The invention relates to bio-based dimethoxyl alkane diesel oil and a preparation method thereof. The bio-based dimethoxyl alkane diesel oil is characterized by being a mixture comprising dimethoxyl-1-methyl butane, bis-bidimethyl-1-methyl butane and tri-bidimethyl-1-methyl butane, wherein the mixture is prepared by carrying out reaction on 2-methyltetrahydrofuran, produced from a wood fiber biomass, and dimethyl ether on an acid supported catalyst through a condensing process. The diesel oil has the advantages that ether fuel is produced by taking 2-methyltetrahydrofuran produced from the wood fiber biomass as the raw material, the raw material is low in price and easily available, and the product has low condensation point, high heat value, good lubrication and low corrosivity, so that the deficiency of existing ether diesel oil is overcome. Meanwhile, the diesel oil provided by the invention is superior to fatty acid methyl ester biological diesel oil in the aspects of low temperature, oxidation stability and hydrolyzing stability. The diesel oil provided by the invention and petroleum diesel oil can be dissolved in any ratio.

Owner:INNER MONGOLIA JINDI BIOMASS

Preparation process of high-base value sulfurized alkyl salicylate

The invention discloses a preparation process of high-base value sulfurized alkyl salicylate. The preparation process comprising the following steps: firstly taking salicylic acids and long-chain alkenes as initiators, performing alkylation reaction under the action of a polar catalyst to prepare alkyl salicylate and preparing a high-base value (TBN) 350 mgKOH / g) sulfurized alkyl salicylate product through neutralization, vulcanization and high alkalization reactions of the alkyl salicylate. The preparation process disclosed by the invention has the benefits that a continuous synthesis processis adopted, reaction conditions are mild, the product has a higher base value, contains no free phenol and has excellent high temperature detergency, oxidation resistance and abrasion resistance, thereby being a comprehensive, environmentally-friendly and energy-saving product.

Owner:XINXIANG RICHFUL LUBE ADDITIVE CO LTD

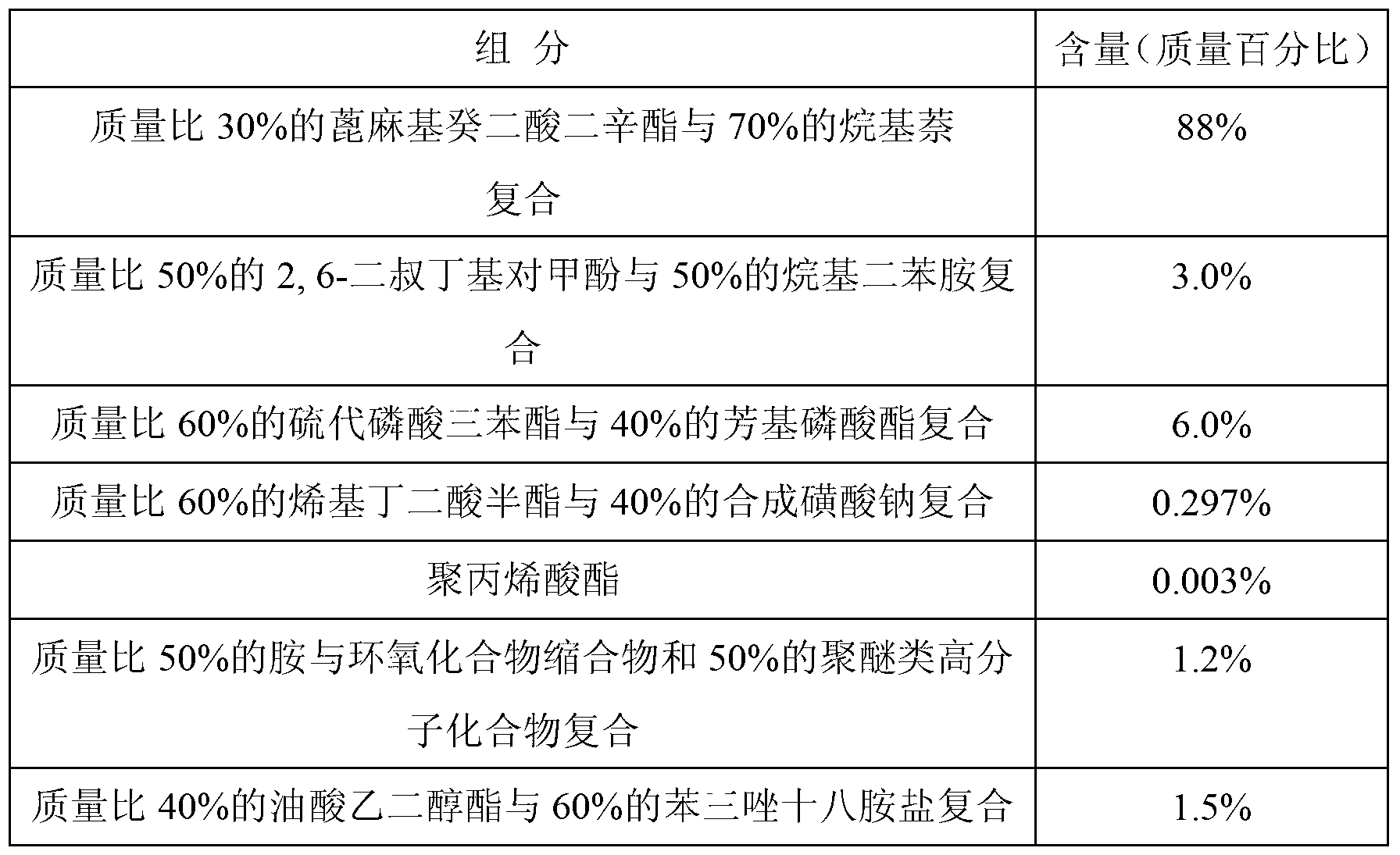

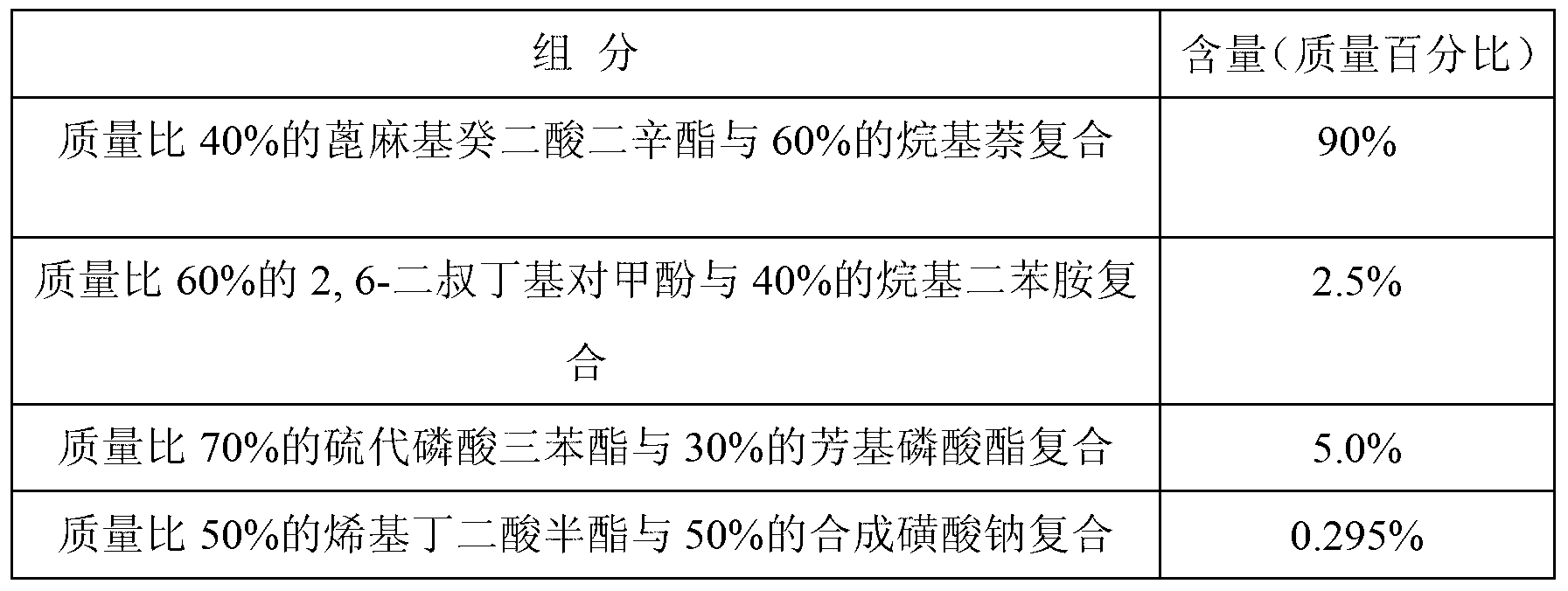

Oil-pressure operating oil for engineering machineries

ActiveCN103254983AEnough thicknessImprove work efficiencyLubricant compositionStatic frictionDioctyl sebacate

The invention discloses an oil-pressure operating oil for engineering machineries. Castor-base dioctyl sebacate and alkyl naphthalene are compounded to serve as base oil. The oil-pressure operating oil is composed of the following components in mass ratio: 88-92% of the base oil, 1.0-3.0% of antioxygen taken as an additive, 3.0-6.0% of extreme-pressure and abrasion resistance agent, 0.2-0.5% of anti-rusting agent, 0.002-0.005% of anti-foaming agent, 0.8-1.2% of anti-emulsifying agent and 1.0-2.0% of oiliness agent. The oil-pressure operating oil composite for the engineering machineries has good combination property, anti-corrosion performance, hydrolytic stability, oxidation stability, anti-emulsifying property, foam resistance, corrosion inhibition performance, water separation performance, abrasion resistance and bearing capacity, guarantees the oil film thicknesses of a steering system and a braking system, decreases the dynamic and static friction coefficients of metallic surfaces, improves the working efficiency and prolongs the services lives of the steering system and braking system of engineering machines.

Owner:GUANGXI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com