Anti-microbial and anti-corrosion industrial cleaning fluid

A cleaning liquid and anti-corrosion technology, applied in the direction of detergent compounding agent, detergent composition, organic cleaning composition, etc., can solve the corrosion and damage of metal pipes and screens, reduce equipment heat exchange and filtration efficiency, and speed up equipment Purchasing replacement cycle and other issues to achieve the effect of good acid-base stability, reduced cleaning costs, and excellent skin compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

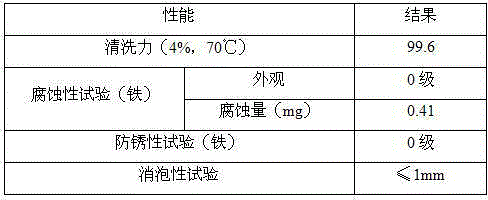

Examples

Embodiment 1

[0025] The industrial antibacterial and corrosion-resistant cleaning solution in this embodiment consists of the following components in parts by mass: 10 parts of ethoxyaminopropyl polydimethylsiloxane, 20 parts of triazine-s-triazine, 20 parts of hexamethylene Diamine tetramethylene phosphonic acid, 10 parts of ethylhexyl alcohol polyoxypropylene polyoxyethylene ether, 60 parts of sodium N-acyl sarcosinate, 30 parts of sorbitan palmitate, 30 parts of imidazole hydroxyethyl myristate phylloline, 20 parts of sodium N-acyl sarcosine, 10 parts of potassium lauryl ether phosphate, 10 parts of bisoctyl zinc salt of sulfur phosphorus, and 100 parts of deionized water.

[0026] Above-mentioned cleaning solution preparation method is as follows:

[0027] (1) Divide the above-mentioned deionized water in parts by mass into three equal parts, namely deionized water A, deionized water B and deionized water C, and heat them up to 60°C;

[0028] (2) Add the above mass fractions of ethoxy...

Embodiment 2

[0033] The industrial antibacterial and corrosion-resistant cleaning solution in this embodiment is composed of the following components in parts by mass: 15 parts of ethoxyaminopropyl polydimethylsiloxane, 25 parts of triazine-s-triazine, 25 parts of hexamethylene Diamine tetramethylene phosphonic acid, 15 parts of ethylhexyl alcohol polyoxypropylene polyoxyethylene ether, 65 parts of sodium N-acyl sarcosinate, 35 parts of sorbitan palmitate, 35 parts of imidazole hydroxyethyl myristate phylloline, 30 parts of sodium N-acyl sarcosine, 15 parts of potassium laureth phosphate, 15 parts of bisoctyl zinc salt of sulfur phosphorus, and 150 parts of deionized water.

[0034] Above-mentioned cleaning solution preparation method is as follows:

[0035] (1) Divide the above-mentioned deionized water in parts by mass into three equal parts, namely deionized water A, deionized water B and deionized water C, and heat them up to 70°C;

[0036] (2) Add the above mass fractions of ethoxy a...

Embodiment 3

[0041] The industrial antibacterial and corrosion-resistant cleaning solution in this embodiment consists of the following components in parts by mass: 20 parts of ethoxyaminopropyl polydimethylsiloxane, 30 parts of triazine-s-triazine, 30 parts of hexamethylene Diamine tetramethylene phosphonic acid, 20 parts of ethylhexyl alcohol polyoxypropylene polyoxyethylene ether, 70 parts of sodium N-acyl sarcosinate, 40 parts of sorbitan palmitate, 40 parts of imidazole hydroxyethyl myristate phylloline, 40 parts of sodium N-acyl sarcosine, 20 parts of potassium lauryl ether phosphate, 20 parts of bisoctyl zinc salt of sulfur phosphorus, and 200 parts of deionized water.

[0042] Above-mentioned cleaning solution preparation method is as follows:

[0043] (1) Divide the above-mentioned deionized water in parts by mass into three equal parts, namely deionized water A, deionized water B and deionized water C, and heat them up to 80°C;

[0044] (2) Add the above mass fractions of ethoxy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com