High-pressure anti-wear hydraulic oil

An anti-wear hydraulic oil and extreme pressure anti-wear agent technology, applied in the field of hydraulic oil, can solve problems such as difficulty in meeting oil properties, achieve good demulsibility, prevent wear and sintering, and have low hydrolysis acid value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

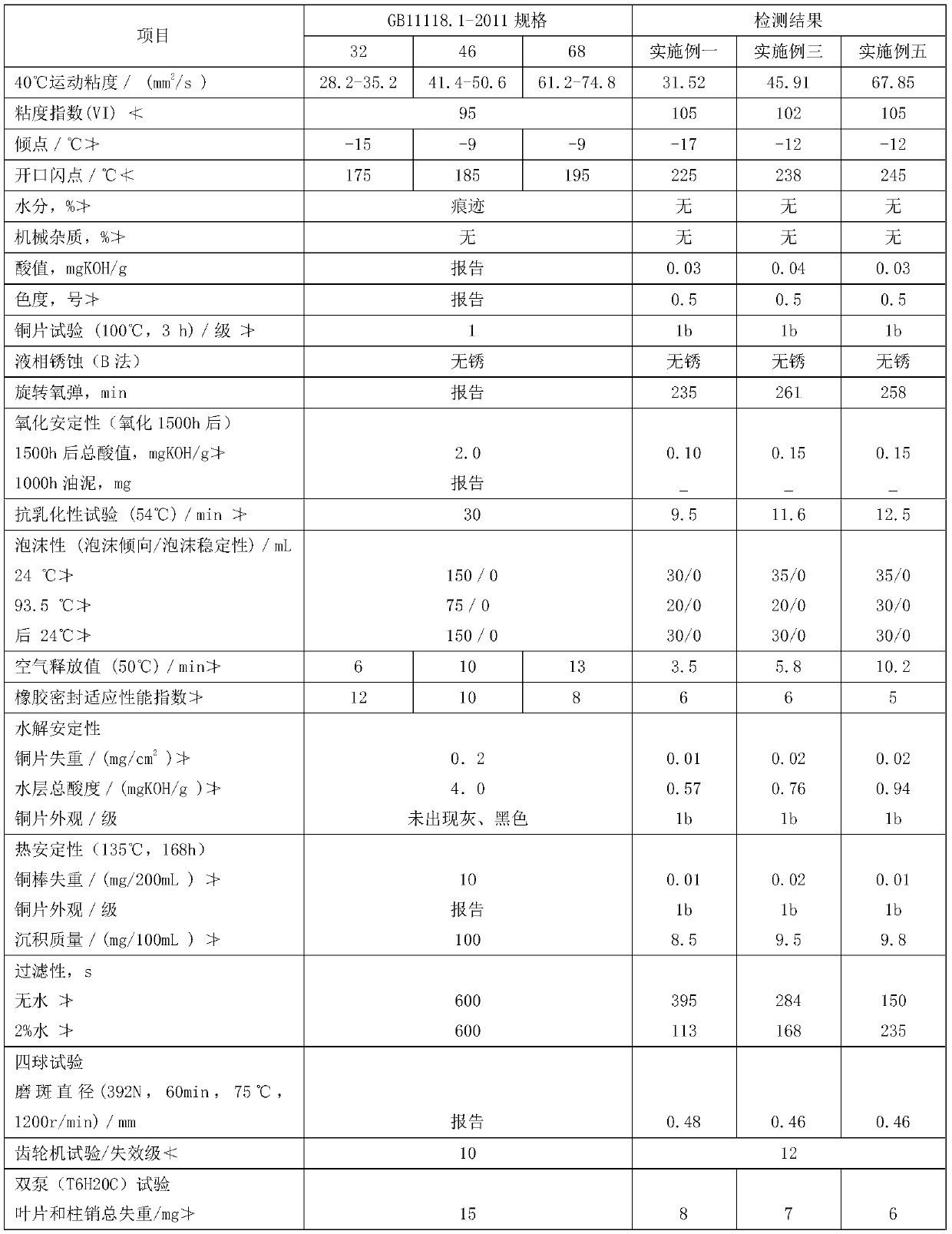

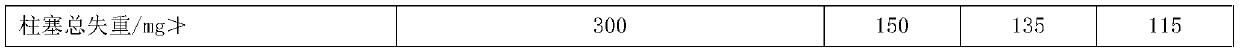

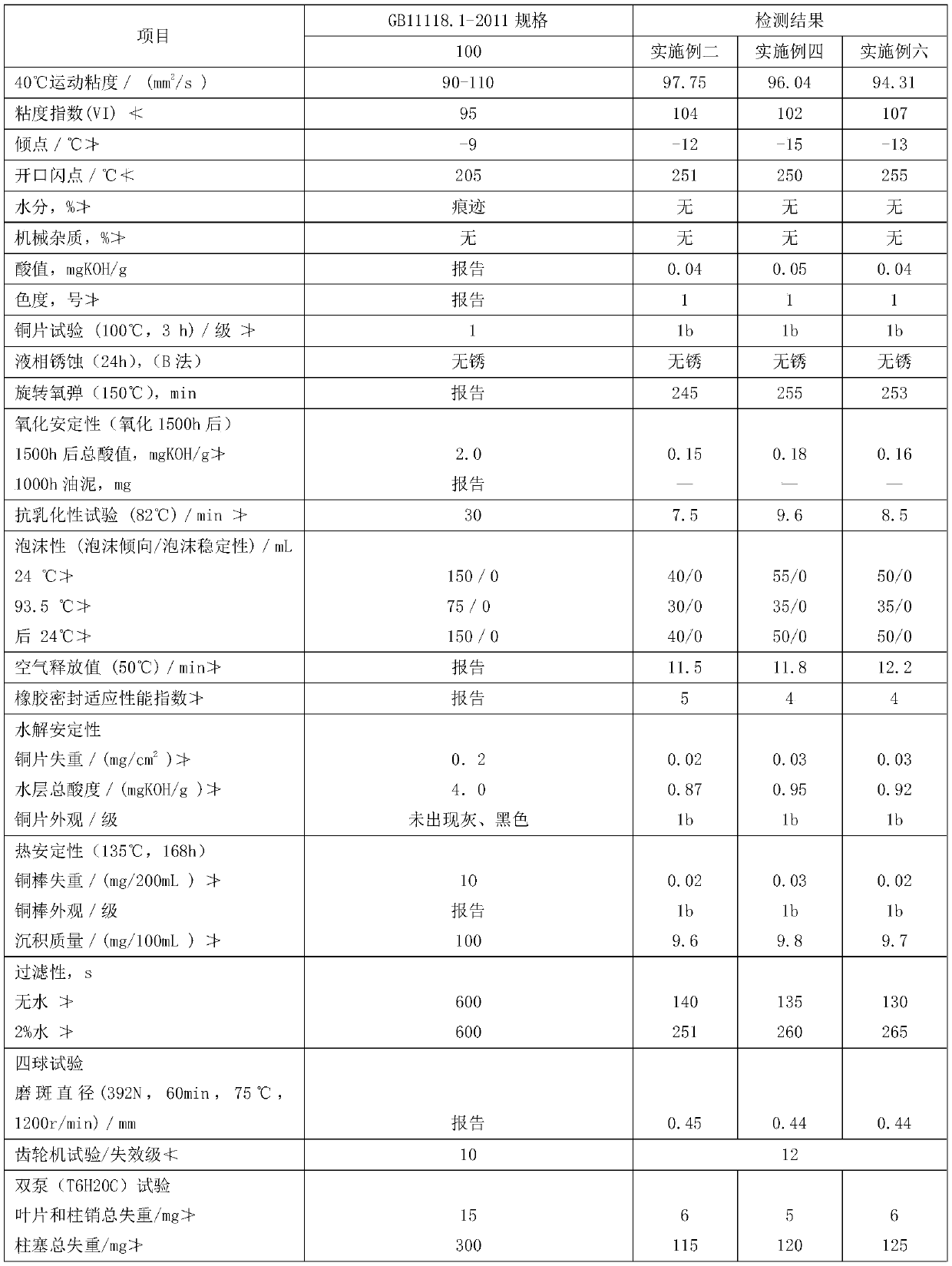

Examples

Embodiment 1

[0024] Example 1: 98% of 150SN base oil, 0.5% of sulfurized isobutylene, 0.5% of phosphorothioate complex ester amine salt, 0.1% of benzotriazole octadecyl ammonium salt, 0.1% of 2,6-di-tert-butyl p-cresol, Alkyl diphenylamine 0.1%, thiadiazole derivatives 0.5%, dodecenyl succinic acid 0.03%, perbasic calcium petroleum sulfonate 0.03%, simethicone 0.001%, condensation of amine and ethylene oxide matter 0.1%.

Embodiment 2

[0025] Example 2: 98.1% of 500SN base oil, 0.35% of sulfurized isobutylene, 0.5% of phosphorothioate double ester amine salt, 0.1% of benzotriazole octadecyl ammonium salt, 0.1% of 2,6-di-tert-butyl p-cresol, Alkyl diphenylamine 0.1%, thiadiazole derivatives 0.4%, barium dinonyl naphthalene sulfonate 0.06%, high base value sulfurized alkylphenate calcium 0.05%, acrylate and ether copolymer 0.001%, amine and ethylene oxide Condensate of alkanes 0.1%.

Embodiment 3

[0026] Example 3: 64% of 150SN base oil, 34% of 500SN base oil, 0.4% of sulfurized isobutylene, 0.6% of phosphorothioate complex ester amine salt, 0.1% of benzotriazole octadecyl ammonium salt, 2,6-di-tert-butylphenol 0.15%, dialkyl diphenylamine 0.15%, thiadiazole derivatives 0.5%, barium dinonyl naphthalene sulfonate 0.05%, high base value sulfurized alkylphenate calcium 0.03%, simethicone 0.0015%, amine and cyclic Condensate of oxyethane 0.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com