Bio-based dimethoxyl alkane diesel oil and preparation method thereof

A bio-based dimethoxyalkane and dimethoxyl technology, which is applied in the preparation of liquid hydrocarbon mixtures, biofuels, and bio-raw materials, can solve problems such as low calorific value and corrosion, and achieve high calorific value and high calorific value , Good lubrication effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

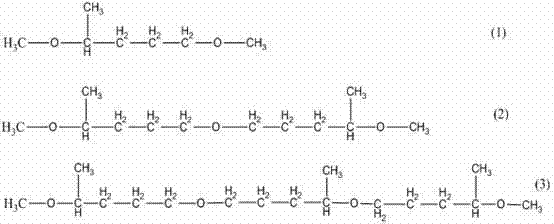

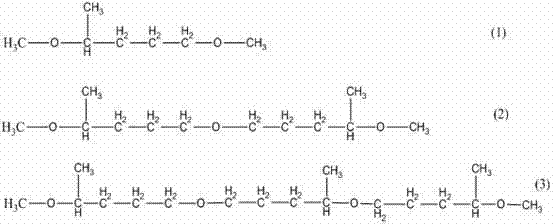

Image

Examples

Embodiment 1

[0023] (1) Preparation of acid-supported catalyst

[0024] 1mol / L of BF 3 The solution was mixed with phosphotungstic acid at 65°C, BF 3 The molar ratio to phosphotungstic acid is 1:0.1. The mixed solution was loaded on activated carbon, in which the carrier accounted for 90% by mass. Dry at 120°C for 12 hours, and bake at 450°C for 3 hours to prepare boron-phosphotungstic acid supported catalyst.

[0025] (2) Product synthesis

[0026] Add 10g of 2-methyltetrahydrofuran and 0.2g of acid-loaded catalyst into a 1L autoclave, feed dimethyl ether gas, the molar ratio of 2-methyltetrahydrofuran to dimethyl ether is 1:10, adjust the nitrogen to keep the reaction kettle The pressure was kept constant, the pressure control range was 1 MPa, the reaction temperature was 160° C., and the reaction was carried out for 4 hours to obtain 12.2 g of the product. Wherein dimethoxyl-1-methylbutane content accounts for 55wt%, bisdimethoxyl-1-methylbutane content is 19wt%, trimethoxyl-1-meth...

Embodiment 2

[0028] (1) Preparation of acid-supported catalyst

[0029] 1mol / L of BF 3 Mix with or silicotungstic acid at 65°C, BF 3 Or the molar ratio of silicotungstic acid is 1:0.1. The mixed solution was impregnated on silica to make a supported catalyst, the impregnation time was 12, and the carrier accounted for 80% by mass. Drying at 120°C for 12h, and calcining at 450°C for 3h, the boron-silicotungstic acid supported catalyst was prepared.

[0030] (2) Product synthesis

[0031] Add 10g of 2-methyltetrahydrofuran and 0.5g of acid-loaded catalyst into a 1L autoclave, feed dimethyl ether gas, the molar ratio of 2-methyltetrahydrofuran to dimethyl ether is 1:20, adjust the nitrogen to maintain the The pressure was kept constant, the pressure control range was 2 MPa, the reaction temperature was 120° C., and the reaction was carried out for 4 hours to obtain 12.3 g of the product. Wherein dimethoxyl-1-methylbutane content accounts for 58wt%, bisdimethoxyl-1-methylbutane content is ...

Embodiment 3

[0033] (1) Preparation of acid-supported catalyst

[0034] 1mol / L of SnCl 2 Solution of silicotungstic acid mixed at 65°C, SnCl 2 The molar ratio with or silicotungstic acid is 1:0.1. The mixed solution was impregnated onto Al2O3 to make a supported catalyst, the impregnation time was 12, and the mass percentage of the carrier was 80%. Dry at 120°C for 12 hours, and bake at 450°C for 6 hours to prepare the tin-silicotungstic acid supported catalyst.

[0035] (2) Product synthesis

[0036] Add 10g of 2-methyltetrahydrofuran and 0.2g of acid-loaded catalyst into a 1L autoclave, feed dimethyl ether gas, the molar ratio of 2-methyltetrahydrofuran to dimethyl ether is 1:20, adjust the nitrogen to maintain the The pressure was kept constant, the pressure control range was 4 MPa, the reaction temperature was 190° C., and the reaction was carried out for 2 hours to obtain 12.5 g of the product. Wherein dimethoxyl-1-methylbutane content accounts for 54wt%, bisdimethoxyl-1-methylbu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com