Hydraulic transmission dual-purpose oil and preparing method thereof

A hydraulic transmission, dual-purpose technology, applied in the petroleum industry, lubricating compositions, etc., can solve the problem of not having the dual functions of hydraulic oil and transmission oil, ignoring the high-temperature oxidation resistance of the oil, and the color of the oil becoming darker and viscous, etc. problem, to achieve the effect of excellent high temperature oxidation resistance, good demulsibility, and high viscosity index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

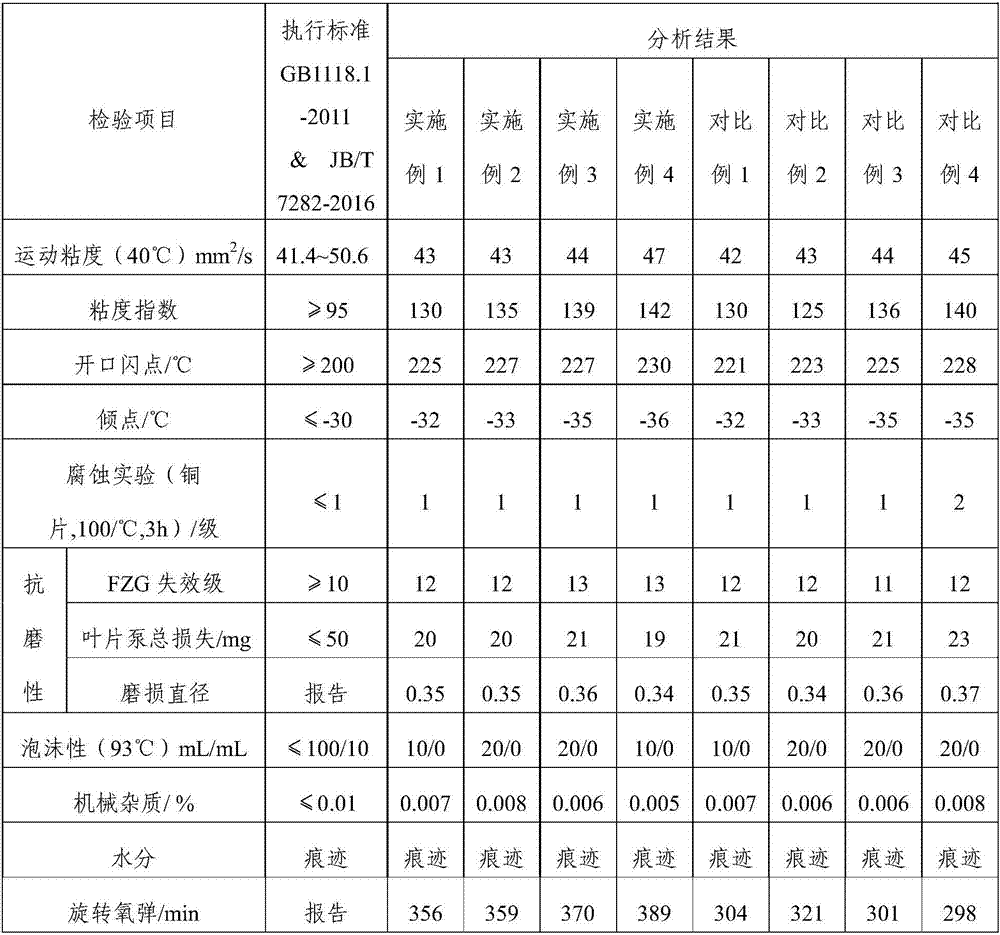

Examples

Embodiment 1

[0023] This embodiment provides a dual-purpose oil for hydraulic transmission, including the following raw materials in parts by weight: 97 parts of 250N type III base oil, 1.5 parts of zinc dialkyl dithiophosphate (ZDDP), 1.5 parts of N,N-dithiophosphate 0.5 parts of sec-butyl-p-phenylenediamine (44PD) and 1 part of polyalkyl benzyl sulfide (T324).

[0024] This embodiment also provides a preparation method of the above hydraulic transmission dual-purpose oil: first add 250N type III base oil to the reactor, heat it to 60°C, then add the rest of the raw materials, and pulse the gas until they are evenly mixed.

Embodiment 2

[0026] This embodiment provides a dual-purpose oil for hydraulic transmission, including the following raw materials in parts by weight: 96 parts of 250N type III base oil, 1.5 parts of zinc dialkyl dithiophosphate (ZDDP), 1.5 parts of N,N-dithiophosphate 0.5 parts of sec-butyl-p-phenylenediamine (44PD), 0.08 parts of dodecenylsuccinic acid (T746), 1.5 parts of polyalkyl benzyl sulfide (T324), 0.2 parts of benzotriazole fatty acid ammonium salt (T406), 0.1 part of polymethacrylate (T602HB), 0.0001 part of methyl silicone oil (T901) and 0.05 part of condensate of amine and epoxy compound (T1001). The preparation method is the same as in Example 1.

Embodiment 3

[0028] This embodiment provides a dual-purpose oil for hydraulic transmission, including the following raw materials in parts by weight: 99 parts of 250N type III base oil, 1.3 parts of zinc dialkyl dithiophosphate (ZDDP), 1.3 parts of N,N-dithiophosphate 0.4 part of sec-butyl-p-phenylenediamine (44PD), 0.07 part of dodecenyl succinic acid (T746), 1 part of polyalkyl benzyl sulfide (T324), 0.2 part of benzotriazole fatty acid ammonium salt (T406), 0.3 part of polymethacrylate (T602HB), 0.001 part of methyl silicone oil (T901) and 0.03 part of condensate of amine and epoxy compound (T1001), the preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com