Novel high-strength dredged soil curing agent

A high-strength, dredging soil technology, applied in the field of curing agents, can solve problems such as difficulty in meeting large-scale projects, low strength of cured soil, and restrictions on the use of cement, and achieve the effects of good hydrolysis stability, improved reaction rate, and shortened curing time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The proportion by weight is: 6 parts by weight of No. 425 ordinary Portland cement, 10 parts by weight of mineral powder, 0.05 parts by weight of binder, 0.02 parts by weight of additive, 0.05 part by weight of silane coupling agent, and hydroxyl-terminated liquid polybutylene 0.1 parts by weight of alkenes, 0.1 parts by weight of diethylaminoethanol, and 0.02 parts by weight of fiber balls. The novel high-strength dredged soil curing agent of this embodiment can be obtained by mixing and stirring the above-mentioned substances evenly. After mixing the curing agent prepared by the above ratio with 80% of the dredged soil, stir evenly and make a mold for curing. After 7 days of curing, the mechanical properties of the soil taken out from the mold will change significantly, and its unrestricted The compressive strength reaches 8.1Mpa, and after 28 days of curing, its unconfined compressive strength can reach 13.2Mpa.

Embodiment 2

[0032] The proportion by weight is: 8 parts by weight of No. 425 ordinary Portland cement, 12 parts by weight of mineral powder, 0.07 parts by weight of binder, 0.04 parts by weight of additive, 0.07 part by weight of silane coupling agent, and hydroxyl-terminated liquid polybutylene 0.12 parts by weight of alkenes, 0.12 parts by weight of diethylaminoethanol, and 0.03 parts by weight of fiber balls. The high moisture content alkali slag curing agent of this embodiment can be obtained by mixing and stirring the above-mentioned substances evenly. After mixing the curing agent prepared by the above ratio with 80% of the dredged soil, stir evenly and make a mold for curing. After 7 days of curing, the mechanical properties of the soil taken out from the mold will change significantly, and its unrestricted The compressive strength reaches 10.6Mpa, and after 28 days of curing, its unconfined compressive strength can reach 16.8Mpa.

Embodiment 3

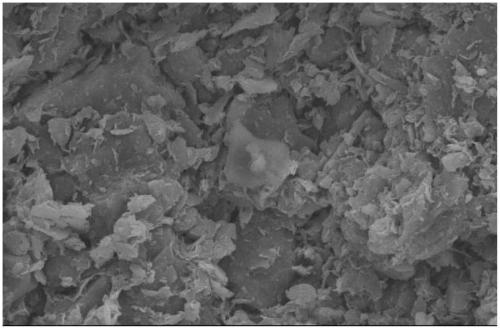

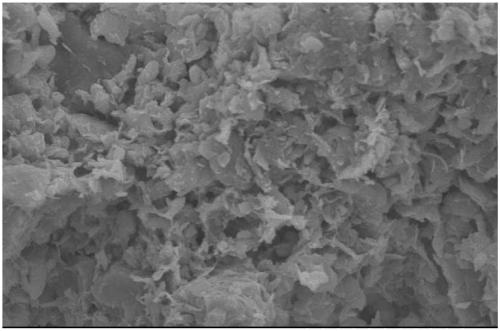

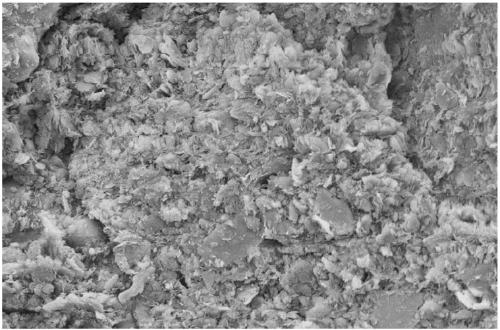

[0034] The ratio by weight is: 10 parts by weight of No. 425 ordinary Portland cement, 14 parts by weight of mineral powder, 0.09 parts by weight of binder, 0.06 parts by weight of additive, 0.09 part by weight of silane coupling agent, and hydroxyl-terminated liquid polybutylene 0.14 parts by weight of alkenes, 0.14 parts by weight of diethylaminoethanol, and 0.04 parts by weight of fiber balls. The high moisture content alkali slag curing agent of this embodiment can be obtained by mixing and stirring the above-mentioned substances evenly. After mixing the curing agent prepared by the above ratio with 80% of the dredged soil, stir evenly and make a mold for curing. After 7 days of curing, the mechanical properties of the soil taken out from the mold will change significantly, and its unrestricted The compressive strength reaches 14.2Mpa, and after 28 days of curing, its unconfined compressive strength can reach 23.8Mpa. Use the EVO18 scanning electron microscope to magnify ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com