Ship side thruster hydraulic oil

A technology of side thruster and hydraulic oil, applied in the petroleum industry, lubricating composition, etc., can solve problems such as harsh working environment, achieve no irritating odor, excellent anti-rust performance, outstanding anti-wear performance and oxidation stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The following components are blended according to mass percentage:

[0019] components

[0020] The sum of the above components is 100%.

Embodiment 2

[0022] The following components are blended according to mass percentage:

[0023] components

[0024] The sum of the above components is 100%.

Embodiment 3

[0026] The following components are blended according to mass percentage:

[0027] components

Content (mass percentage)

The mass ratio is 50% pentaerythritol ester and 50% polya-olefin composite

92.0%

The mass ratio of 50% borated phosphate and 50% tricresyl phosphate compounded

3.0%

Condensate of amine and epoxy compound

0.5%

50% 2,6-di-tert-butyl-p-cresol and 50% N-phenyl-a-naphthylamine composite

1.0%

Benzotriazole derivatives

0.5%

Thiadiazole Derivatives

1.0%

0.003%

Combination of 50% benzotriazole and 50% sodium petroleum sulfonate by mass

0.997%

Friction modifiers are phosphate esters

1.0%

[0028] The sum of the above components is 100%.

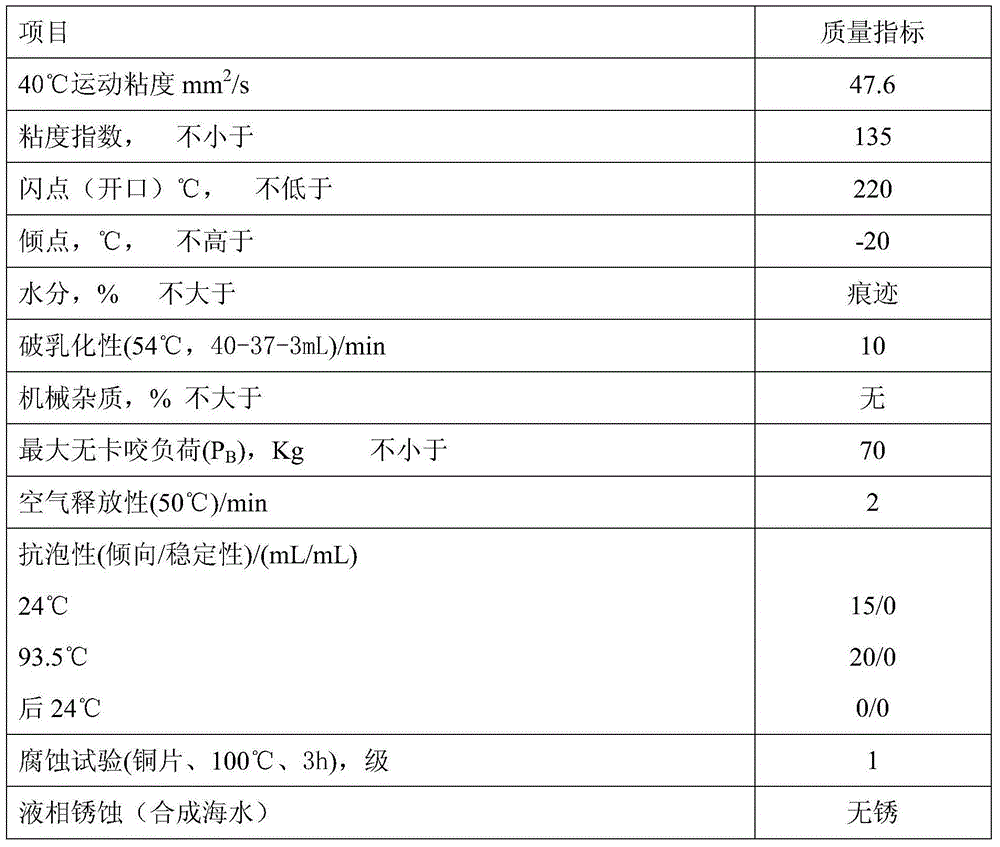

[0029] The main physicochemical index of embodiment 3 product is:

[0030]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com