Online monitoring and purifying method and system of oil fume

A technology of oil fume purification and purification system, which is applied in the field of oil fume purification, can solve the problems of not being able to know the actual situation of oil fume emission and having no direct relationship, and achieve the effects of resisting oil fume pollution, prolonging service life, and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

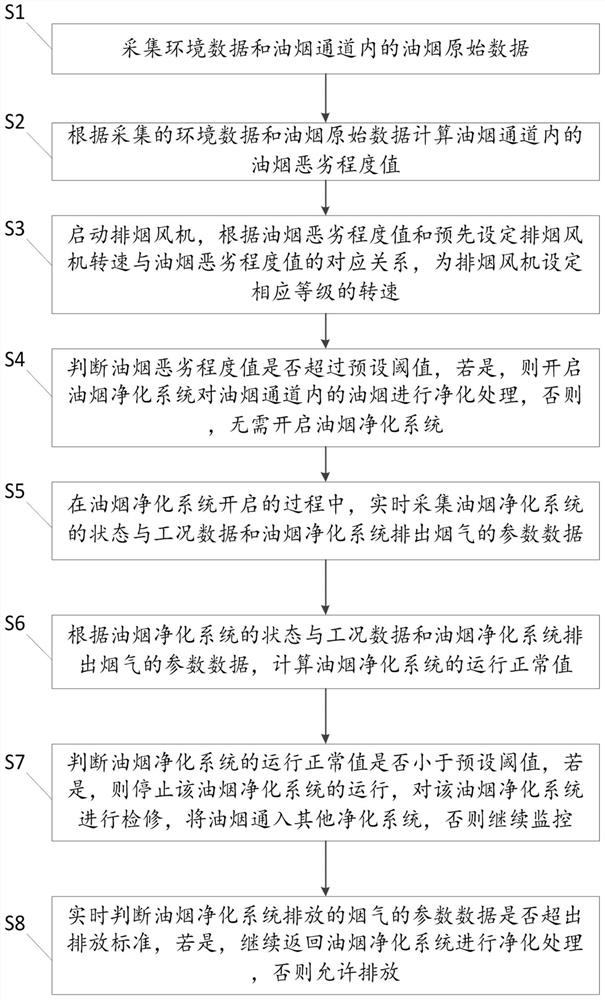

[0027] Such as figure 1 As shown, the present application provides a method for online monitoring and purification of cooking fume, which includes the following steps:

[0028] S1, collecting environmental data and original data of oil fume in the oil fume channel.

[0029] The raw data of oil fume include: oil fume concentration value, oil fume temperature, oil fume humidity, particulate matter concentration value, non-methane total hydrocarbon concentration value.

[0030] Environmental data include ambient temperature, ambient space volume (that is, the size of the surrounding space where oil fumes are generated) and ambient humidity.

[0031] S2. Calculate the severity value of the oil fume in the oil fume channel according to the collected environmental data and the original oil fume data.

[0032] The formula for calculating the severity value of oil fume is:

[0033]

[0034] Among them, E represents the severity value of oil fume; w1 represents the influence weig...

Embodiment 2

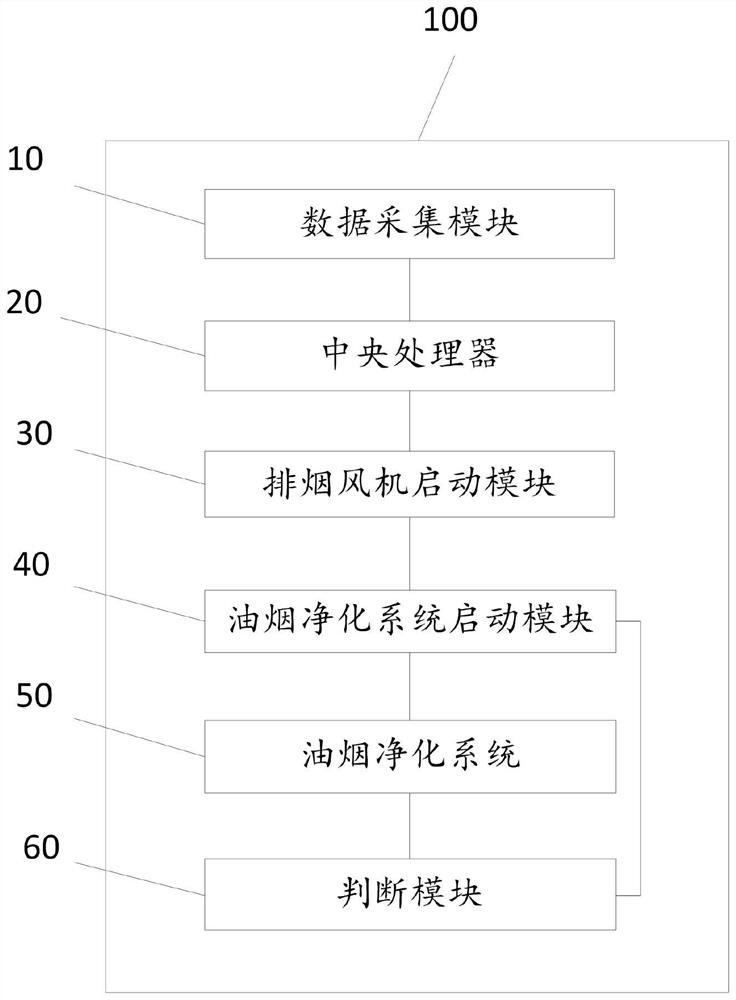

[0064] Such as image 3 As shown, the present application provides an oil fume online monitoring and purification system 100, including:

[0065] The data collection module 10 is used for collecting environmental data and original data of oil fume in the oil fume channel.

[0066] The central processing unit 20 is configured to calculate the severity value of the oil fume in the oil fume channel according to the collected environmental data and the original oil fume data.

[0067] The smoke exhaust fan starting module 30 is used to start the smoke exhaust fan, and set the corresponding grade of rotation speed for the smoke exhaust fan according to the value of the bad degree of oil fume and the corresponding relationship between the preset speed of the smoke exhaust fan and the bad degree of oil fume.

[0068] The oil fume purification system startup module 40 is used to judge whether the severity value of the oil fume exceeds the preset threshold, and if so, the oil fume pur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com