Whitening emulsion and preparation method thereof

An emulsion and whitening technology, applied in the field of whitening emulsion and its preparation, can solve problems such as the inability to meet the needs of consumers, and achieve the effects of preventing skin edema, inhibiting the increase of fat cells, and solving skin sagging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Preparation of Whitening Emulsion R-1

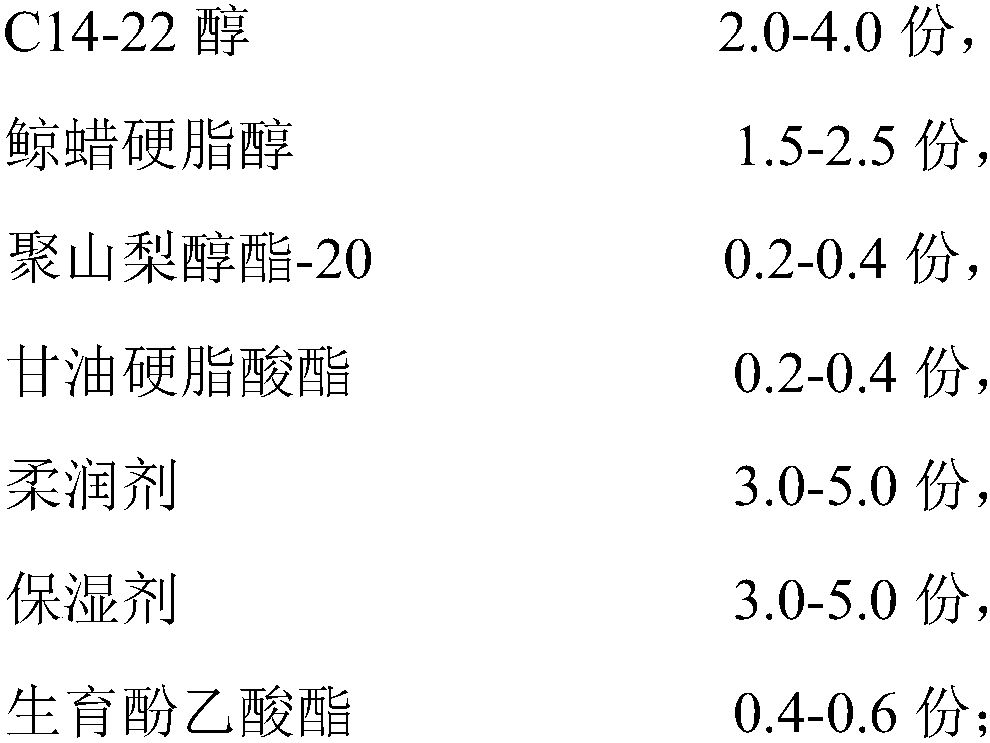

[0038] Table 1 Whitening lotion R-1 formula table

[0039]

[0040]

[0041] S101. Premix component A, component B, component C and component D respectively according to the formula amount, respectively stir them evenly and take them out respectively according to the mass ratio of 1:1:1:1 for later use;

[0042] S102. Heat component A and component B to 80°C respectively, mix, stir and homogenize for 5 minutes;

[0043] S103. Cool down the mixed solution of component A and component B to 48°C, add component C and component D in sequence, stir for homogenization for 2 minutes, continue to stir and cool down to 40°C, and the whitening emulsion R- 1.

Embodiment 2

[0045] Preparation of Whitening Emulsion R-2

[0046] Table 2 Whitening lotion R-2 formula table

[0047]

[0048]

[0049] S201. Premix component A, component B, component C and component D according to the formula amount, respectively, stir them evenly and take them out respectively according to the mass ratio of 1:1:1:1 for later use;

[0050] S202. Heat component A and component B to 83°C respectively, mix, stir and homogenize for 5 minutes;

[0051] S203. Cool down the mixed solution of component A and component B to 50°C, add component C and component D in sequence, stir for homogenization for 2 minutes, continue stirring and cool down to 40°C, and the whitening emulsion R- 2.

Embodiment 3

[0053] Preparation of Whitening Emulsion R-3

[0054] Table 3 Whitening lotion R-3 formula table

[0055]

[0056]

[0057] S101. Premix component A, component B, component C and component D respectively according to the formula amount, respectively stir them evenly and take them out respectively according to the mass ratio of 1:1:1:1 for later use;

[0058] S102. Heat component A and component B to 85°C respectively, mix, stir and homogenize for 5 minutes;

[0059] S103. Cool down the mixed solution of component A and component B to 52°C, add component C and component D in turn, stir for homogenization for 2 minutes, continue to stir and cool down to 40°C, and the whitening emulsion R- 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com