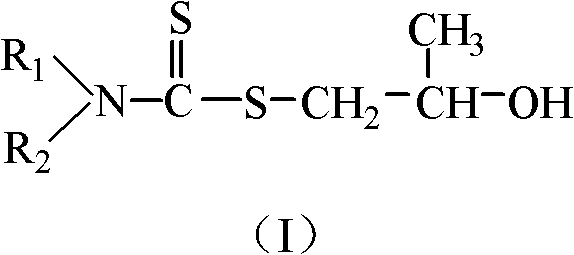

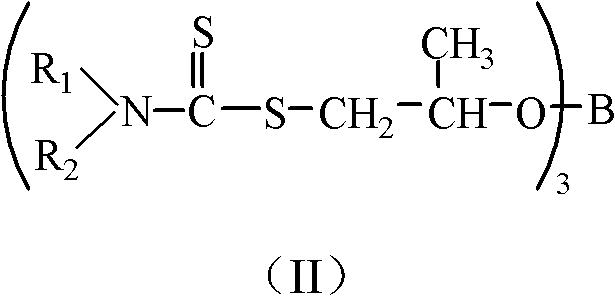

Preparations and applications of dialkyl dithiocarbamate hydroxy derivative and borate thereof

A technology of hydroxy derivatives and alkanes, which is applied in the field of preparation and application of dialkyldithiocarbamic acid hydroxy derivatives and borate esters, to achieve good oil solubility, low hydrolysis stability, good anti-friction performance and anti-friction properties. The effect of wear properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Add 0.25 mol of di-n-butylamine and 0.25 mol of triethylamine together into the three-necked flask, and slowly add 0.275 mol of carbon disulfide dropwise under ice-water bath. After about 1 hour, the dropwise addition is completed. Continue to stir for 2 hours, and slowly rise to room temperature, the system becomes It is bright yellow translucent liquid. At room temperature, 0.275mol propylene oxide was added dropwise to the reaction system, and the dropwise addition was completed after about 1 hour. After 1 hour of heat preservation, the temperature was raised to 50° C., and stirring was continued for 2 hours. The acid-binding agent triethylamine is evaporated under reduced pressure to obtain di-n-butyldithiocarbamate hydroxy derivative (a);

[0021] Add boric acid and the above product in a molar ratio of 1:3 into a reaction bottle equipped with a water separator, and add an appropriate amount of acidic resin as a catalyst and an appropriate amount of benzene as a wa...

Embodiment 2

[0024] Add equimolar amounts of diisooctylamine and pyridine together into a three-necked flask, and slowly add an excess of 10% carbon disulfide dropwise at room temperature, and control the reaction system not to exceed 45°C by the drop rate, and the dropwise addition is completed within about 2 hours, and continue to stir After 4 hours, the system turned into a bright yellow translucent liquid. At room temperature, add propylene oxide in an equimolar amount to carbon disulfide dropwise to the reaction system. After about 1 hour, the dropwise addition is completed. After 3 hours of heat preservation, the temperature is raised to 60° C., and stirring is continued for 2 hours. The acid-binding agent pyridine is distilled off under reduced pressure to obtain diisooctyl dithiocarbamate hydroxy derivatives;

[0025] Add boric acid and the above product into a reaction bottle equipped with a water separator at a molar ratio of 1:3, and add an appropriate amount of acidic resin as ...

Embodiment 3

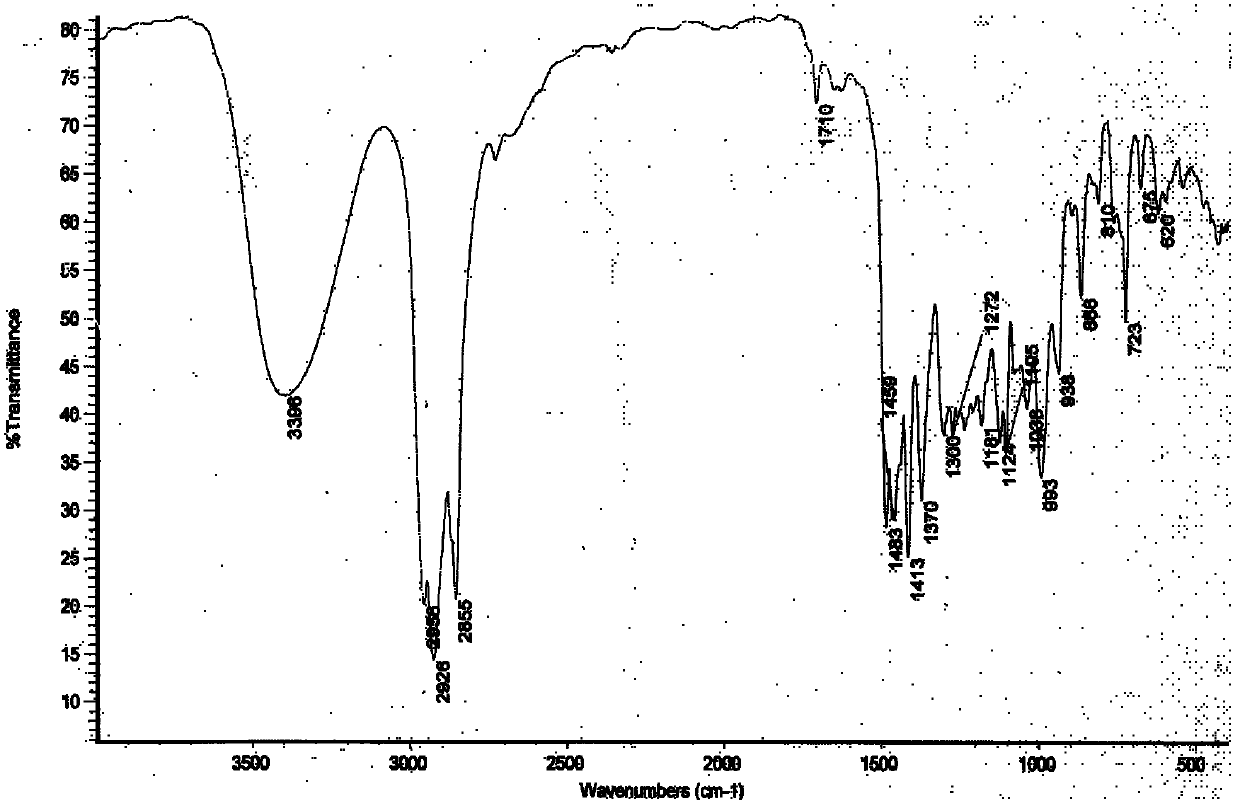

[0028] This example is a tribological performance test.

[0029] Get the borate (b) of di-n-butyldithiocarbamate hydroxy derivative (a) and di-n-butyldithiocarbamate hydroxy derivative that example 1 makes, take commercially available refined rapeseed oil as The anti-wear and anti-friction properties of the synthetic additives were evaluated on the base oil on a four-ball friction and wear testing machine. The test conditions were: the maximum non-seizing load PB and sintering load PD of the sample were measured according to the GB / T3142-82 standard method to evaluate the extreme pressure performance ; Under 392N load, measure the wear spot diameter (WSD) of sample according to SH / T 0189-92 standard method to evaluate antiwear performance; Under 392N load, measure sample according to ASTM D5183-95 (1999) standard method The coefficient of friction (μ) under different loads is used to evaluate the anti-friction performance. The test results are listed in Table 1 and Table 2. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com