Hydrolysis-resistant aliphatic-aromatic copolyester and preparation method thereof

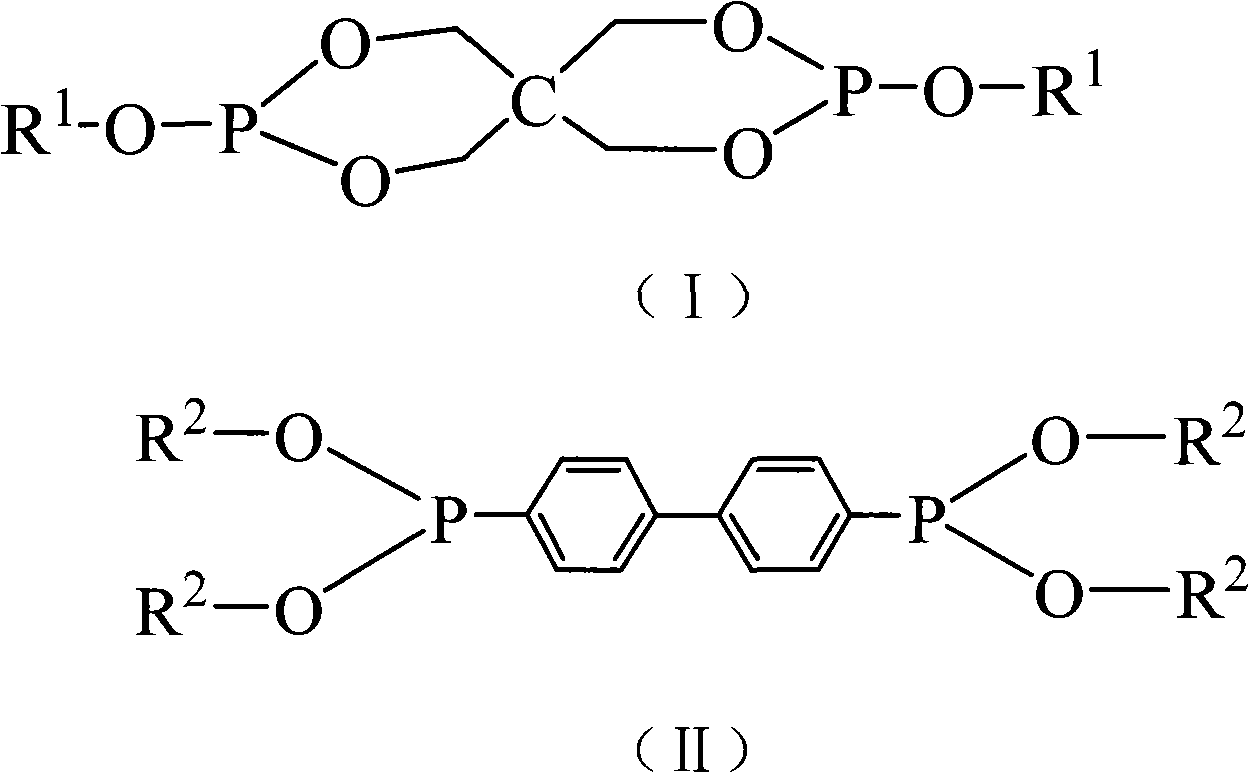

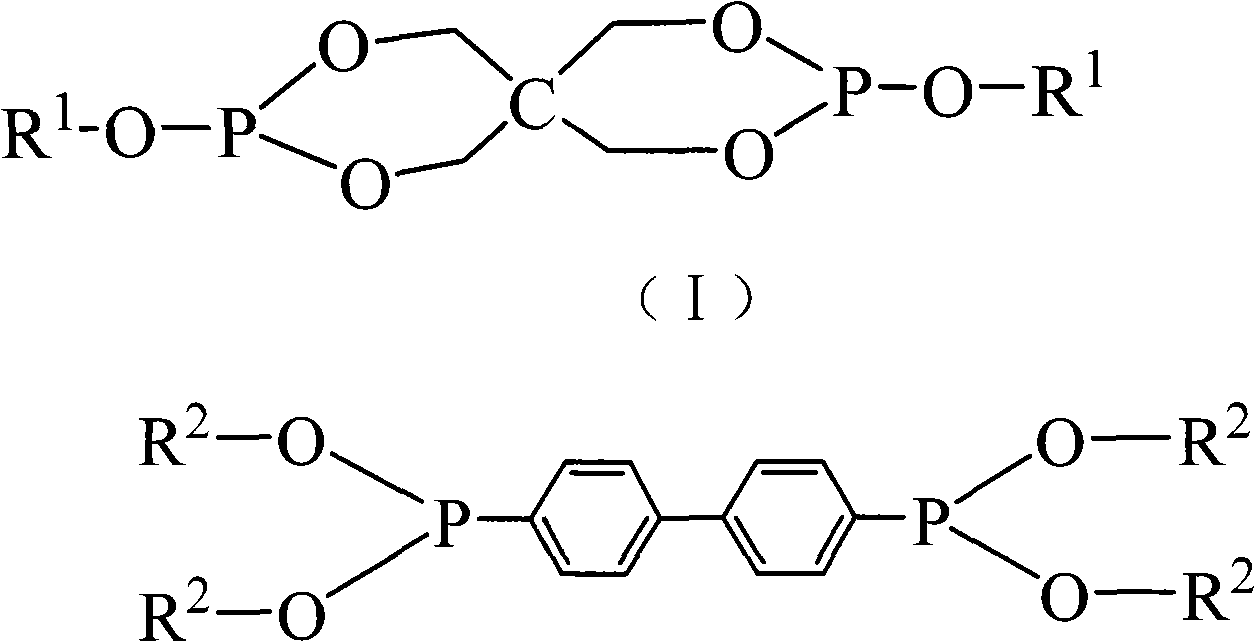

An aromatic polyester and aromatic technology, which is applied in the field of designing the preparation of hydrolysis-resistant and degradable copolyester, can solve problems such as difficulty in further recovery, and achieve the effects of good hydrolysis stability, avoiding addition and simplifying the process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Add 200kg of 1,5-pentanediol and 175kg of dimethyl terephthalate into the reactor, under the protection of nitrogen, raise the temperature to 185°C, add 319g of n-butyl titanate, and maintain the temperature in the reactor at 180°C; 130kg of 1,5-pentanediol and 161kg of azelaic acid were reacted at 170°C for 4 hours.

[0042] Then, the above two esterified products were mixed together, and 100 g of antioxidant was added, and the temperature was raised to 210° C., and reacted in a low vacuum (90 KPa) for 1 hour. After the temperature reaches 230°C, react for 30 minutes, then start to slowly raise the temperature to 245°C, gradually increase the vacuum degree, so that the pressure in the kettle reaches 1KPa, keep the temperature constant, and keep the pressure in the kettle below 80Pa, react for 3.5 hours, turn the reactor Nitrogen was flushed inside, and 50g of sodium carbonate and 300g of vinyltrimethoxysilane were added to obtain a hydrolysis-resistant degradable polye...

Embodiment 2

[0045] Add 190kg of 1,4-butanediol and 175kg of dimethyl terephthalate into the reactor, under the protection of nitrogen, raise the temperature to 185°C, add 319g of n-butyl titanate, and maintain the temperature in the reactor at 180°C; 130kg of 1,4-butanediol and 210kg of adipic acid were reacted at 170°C for 4 hours.

[0046] Then, the above two esterified products were mixed together, and 100 g of phosphorous acid was added, and the temperature was raised to 210° C., and reacted in a low vacuum (90 KPa) for 1 hour. After the temperature reaches 230°C, react for 30 minutes, then start to slowly raise the temperature to 245°C, gradually increase the vacuum degree, so that the pressure in the kettle reaches 1KPa, keep the temperature constant, and keep the pressure in the kettle below 80Pa, react for 3.5 hours, turn the reactor Nitrogen was flushed inside, and 50 g of ethylene glycol carbonate and 180 g of γ-(2,3-epoxy)propanetrimethoxysilane were added to obtain a hydrolysi...

Embodiment 3

[0049] Add 190kg of 1,4-butanediol, 175kg of dimethyl terephthalate, and 1200g of trimesic acid into the reaction kettle. Under the protection of nitrogen, raise the temperature to 185°C, add 319g of n-butyl titanate, and maintain the reaction kettle The internal temperature is 180°C; 130kg of 1,4-butanediol and 210kg of succinic acid are reacted at 170°C for 4 hours.

[0050] Then, the above two esterified products were mixed together, and 100 g of phosphorous acid was added, and the temperature was raised to 210° C., and reacted in a low vacuum (90 KPa) for 1 hour. After the temperature reaches 230°C, react for 30 minutes, then start to slowly raise the temperature to 245°C, gradually increase the vacuum degree, so that the pressure in the kettle reaches 1KPa, keep the temperature constant, and keep the pressure in the kettle below 80Pa, react for 3.5 hours, turn the reactor Nitrogen gas was flushed inside, and 50 g of five-membered cyclic carbonate of soybean oil and 250 g ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Crystallization temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com