Patents

Literature

194results about How to "Design faster" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

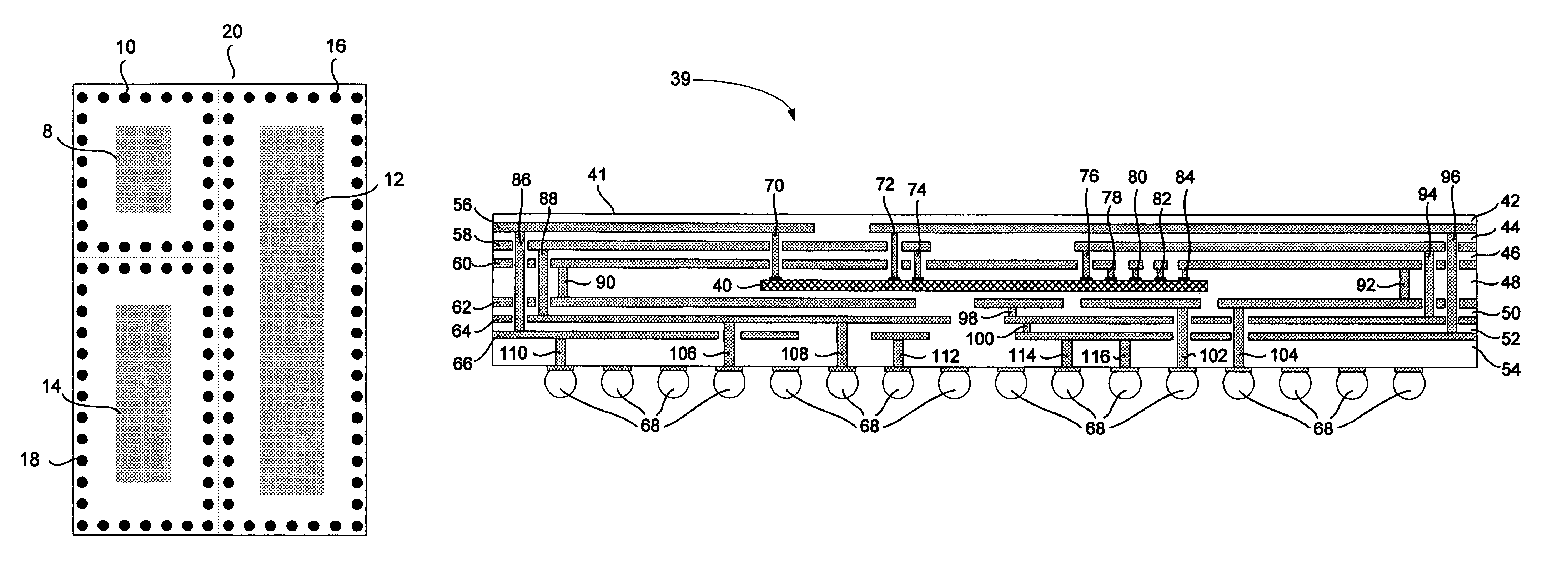

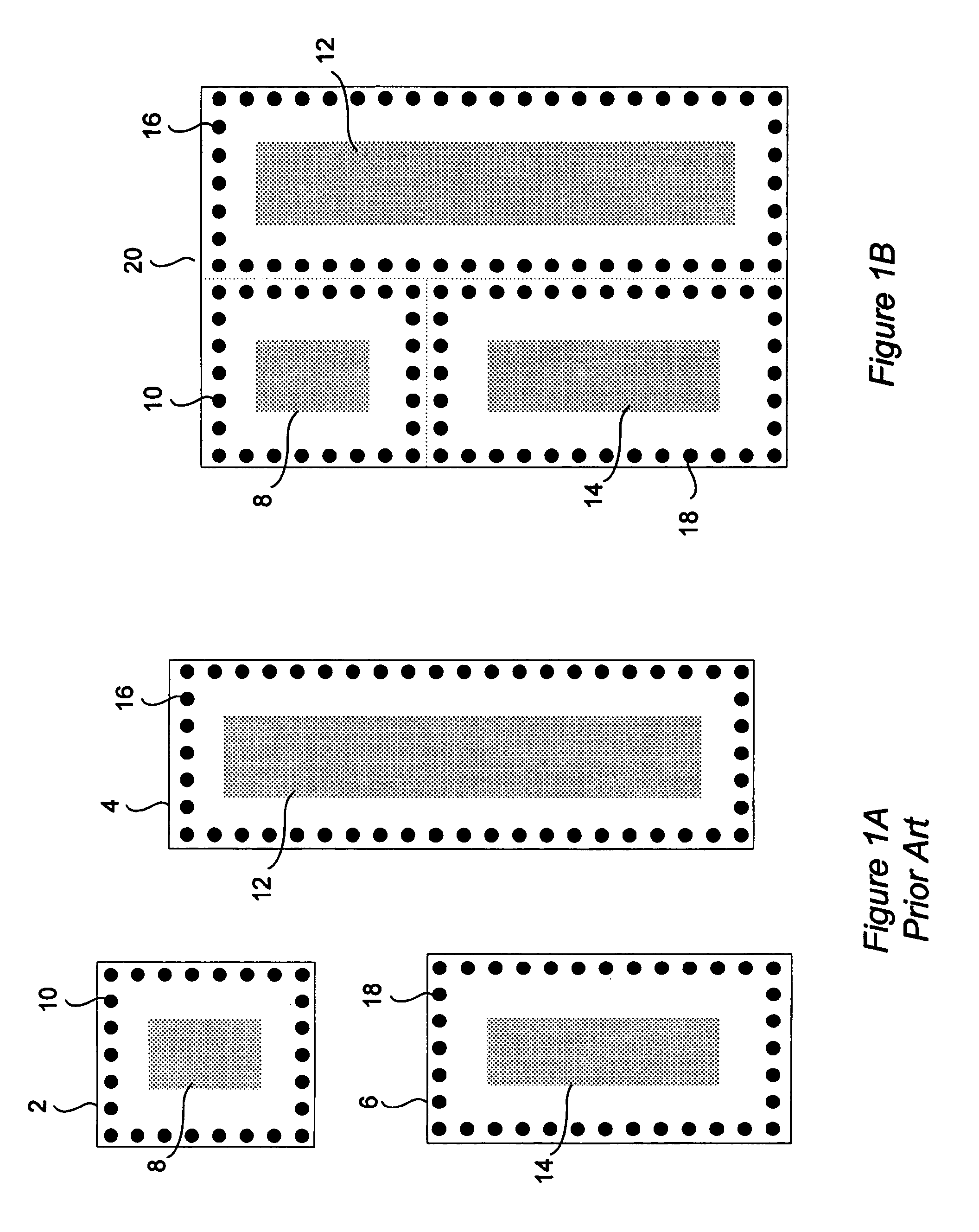

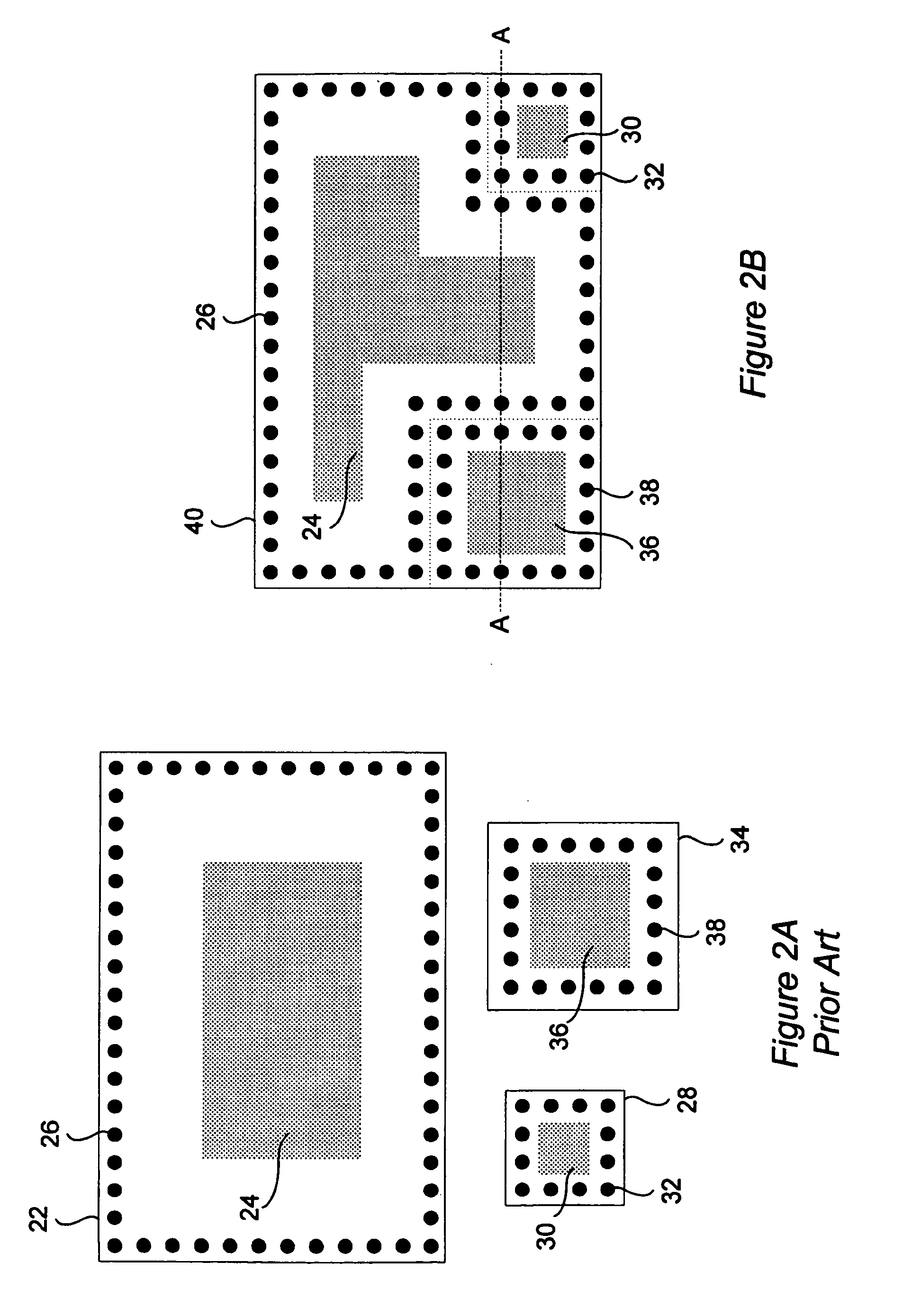

Semiconductor package

InactiveUS7327006B2Shorten the timeIncrease the areaSemiconductor/solid-state device detailsSolid-state devicesSemiconductor packageEngineering

A semiconductor package includes a combination die embedded in a base. The combination die includes a plurality of functional blocks, where the functional blocks are insulated from one another on the combination die. Each functional block has plural die connectors. The base includes insulating layers conductive layers and vias. Each conductive layer has parts removed to form a pattern. The base is provided with a plurality of external connectors. A conductive path, made from a part of at least one of the conductive layers and at least one of the vias, connects one of the die connectors to a respective one of the external connectors.

Owner:NOKIA CORP

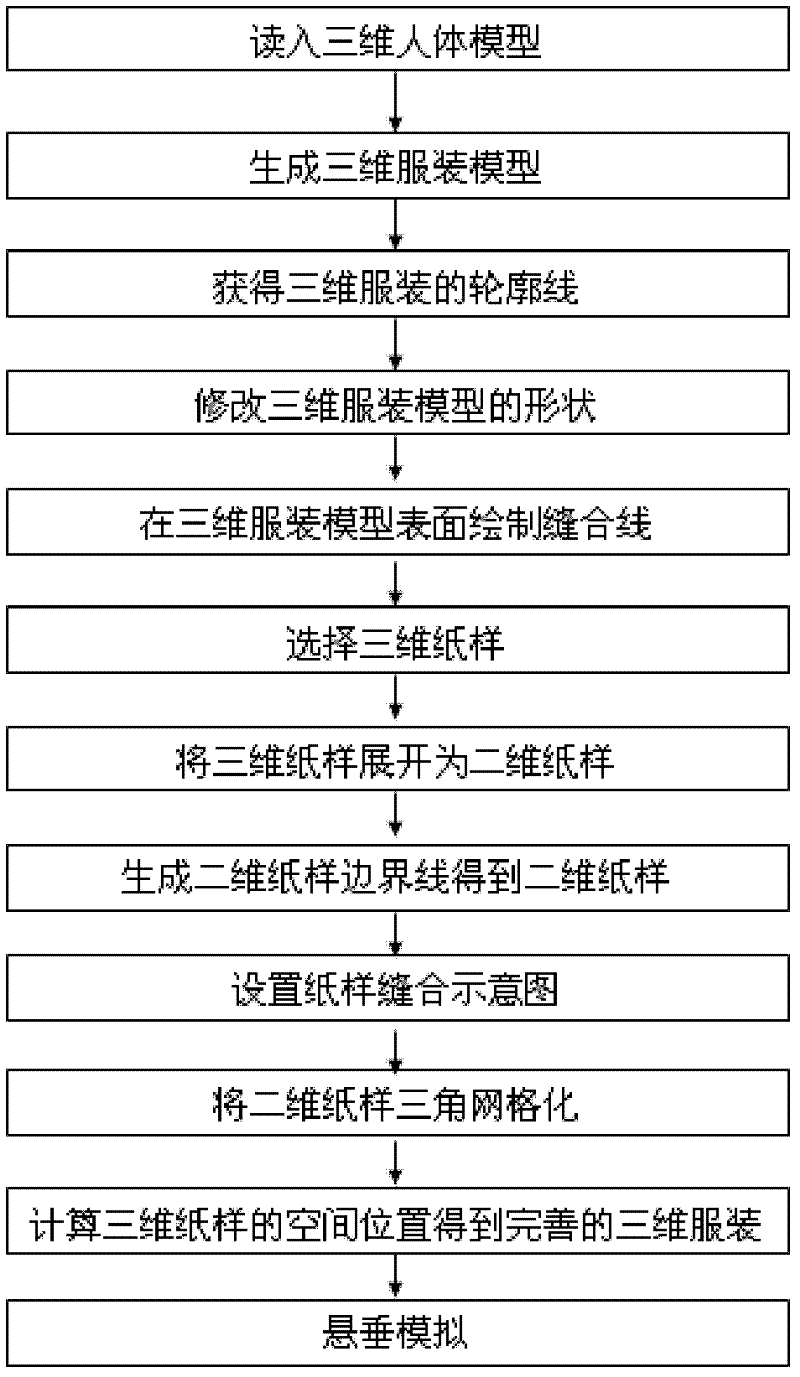

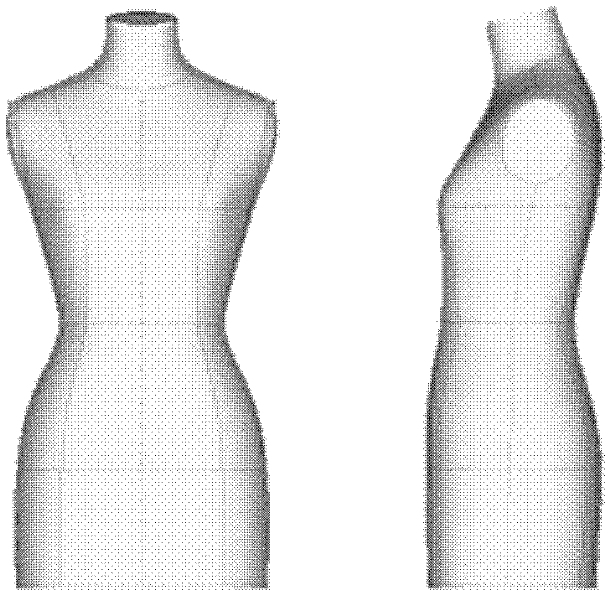

Three-dimensional garment modeling and pattern designing method based on draping

ActiveCN102332180AShorten the timeReduce excess spaceImage data processingManufacturing computing systemsLine segmentSuture line

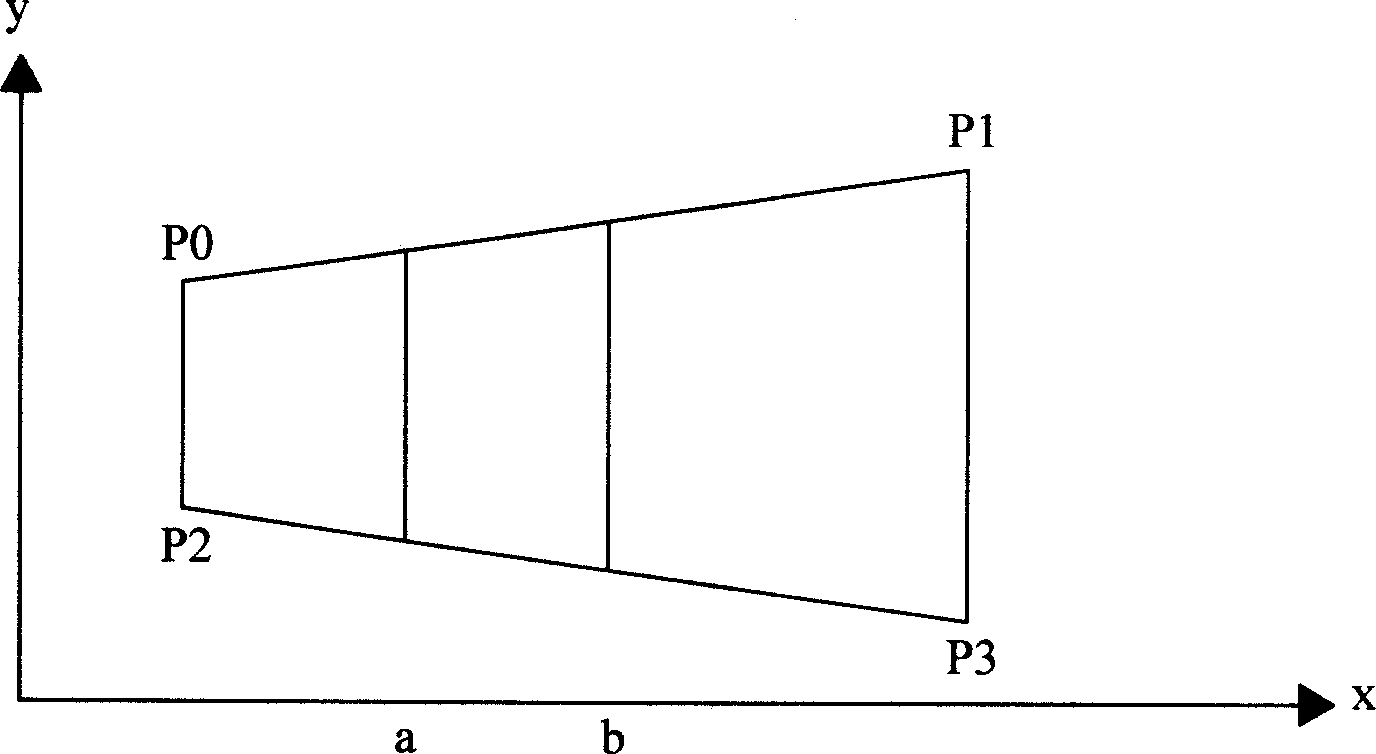

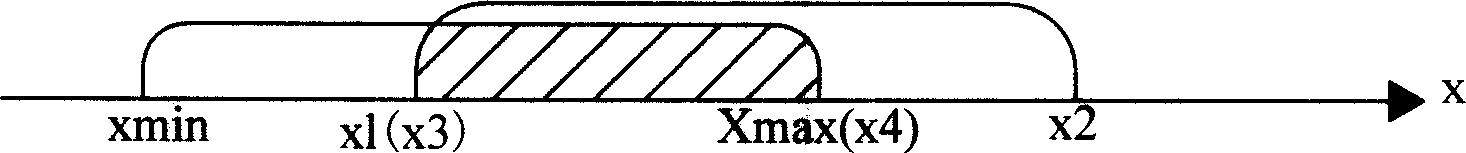

The invention discloses a three-dimensional garment modeling and pattern designing method based on draping. The method comprises the following steps of: reading a three-dimensional human model represented by a triangular grid to generate a three-dimensional garment model; generating a contour line of the three-dimensional garment model, and modifying the shape of the contour line; drawing suture lines on the surface of the three-dimensional garment model to divide the surface of the three-dimensional garment model into a plurality of areas of which each is a three-dimensional pattern; selecting a three-dimensional pattern, generating the three-dimensional grid corresponding to the three-dimensional pattern, converting the three-dimensional grid into a two-dimensional garment pattern, and setting a suture schematic drawing of the two-dimensional garment pattern; re-discretizing a boundary line of the two-dimensional garment pattern into a polygon consisting of straight line segments with uniform lengths, and triangulating the two-dimensional garment pattern; and computing the position of the triangulated two-dimensional garment pattern in a three-dimensional space to obtain a final three-dimensional garment model, and finally simulating hanging effects of three-dimensional garments. The method is high in speed and relatively higher in accuracy.

Owner:杭州力孚信息科技有限公司

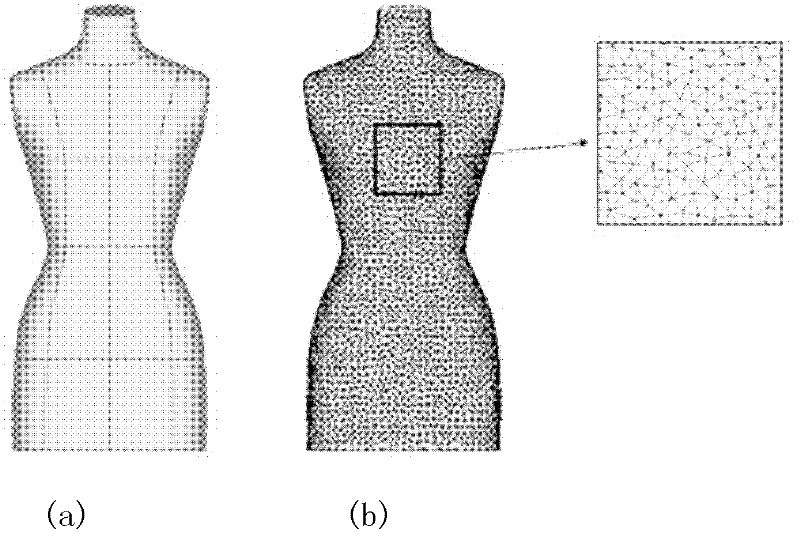

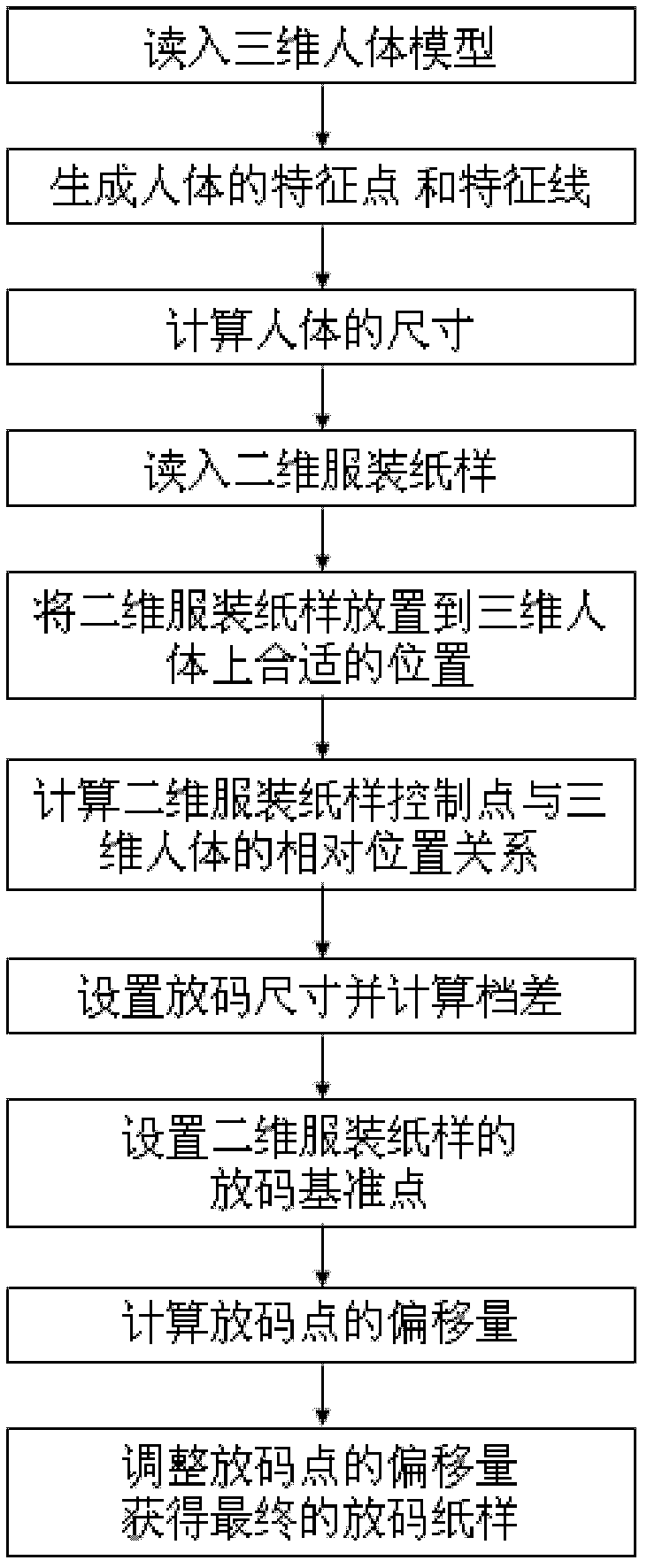

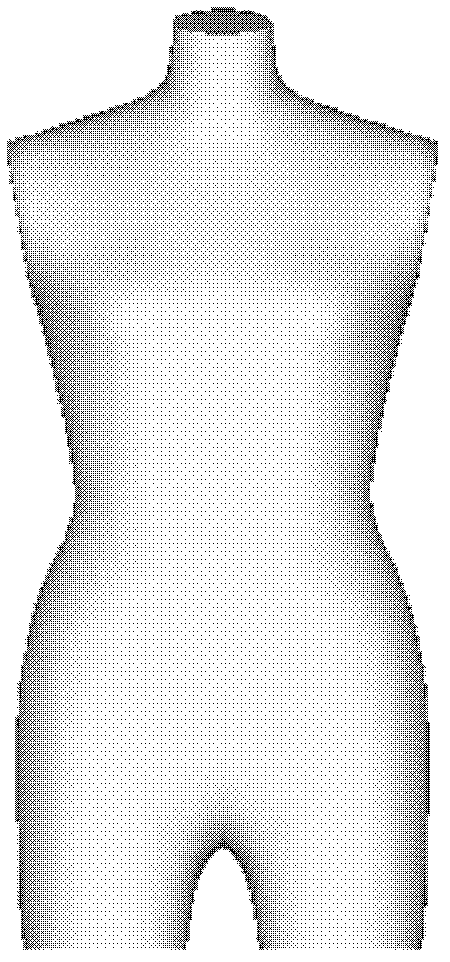

3D (three-dimensional) apparel grading method based on human body characteristics

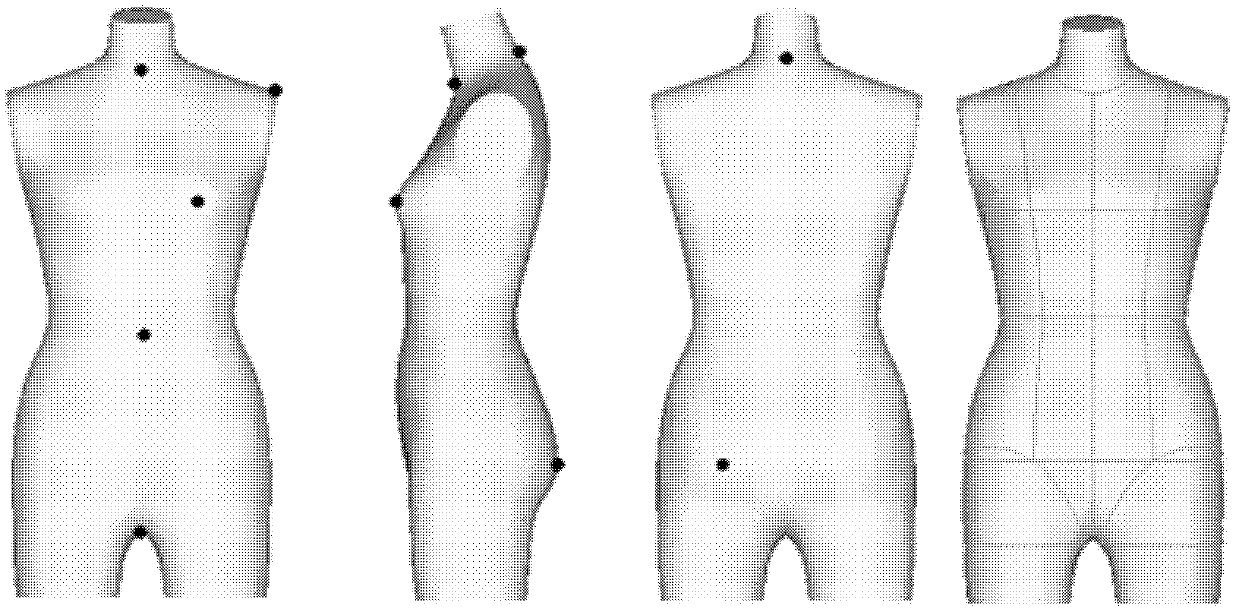

ActiveCN102708231ALower requirementFit closelySpecial data processing applicationsData pointHuman body

The invention relates to a 3D (three-dimensional) apparel grading method based on human body characteristics. The 3D apparel grading method comprises the steps of reading a 3D human body model; generating characteristic points and characteristic lines of the 3D human body model; calculating the size of the 3D human body model; reading a 2D (two-dimensional) apparel pattern; putting the 2D apparel pattern at the proper position on the 3D human body model to obtain the 3D spatial position of the 2D apparel pattern; calculating the relative position relationship of the boundary control points of the 2D apparel pattern and the 3D human body model; setting a grading size of the 3D human body model and calculating the grading differences; setting the grading datum points of the 2D apparel pattern; calculating the grading offsets of the boundary control points of the 2D apparel pattern, and updating the boundary shapes of the 2D apparel pattern; and adjusting the grading quantities of certain special control points according to the design requirement of the apparel pattern to obtain a final grading apparel pattern. According to the method, the design speed is fast, the efficiency is high, the degree of automation is high, the design process of the apparel is accelerated greatly and the design quality of the apparel is improved.

Owner:杭州力孚信息科技有限公司

Charging design method of solid rocket engine

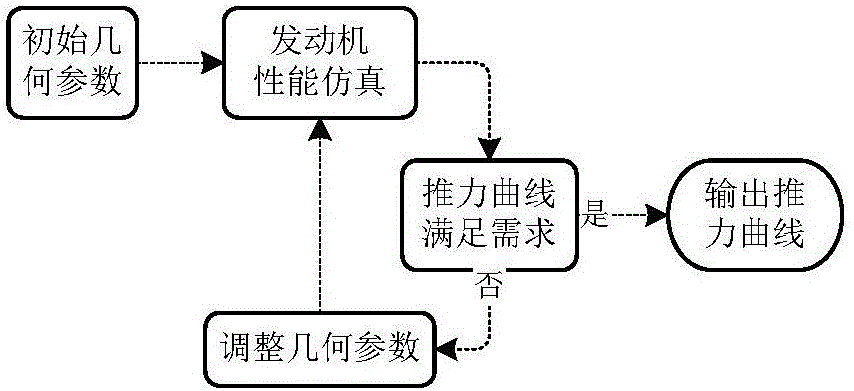

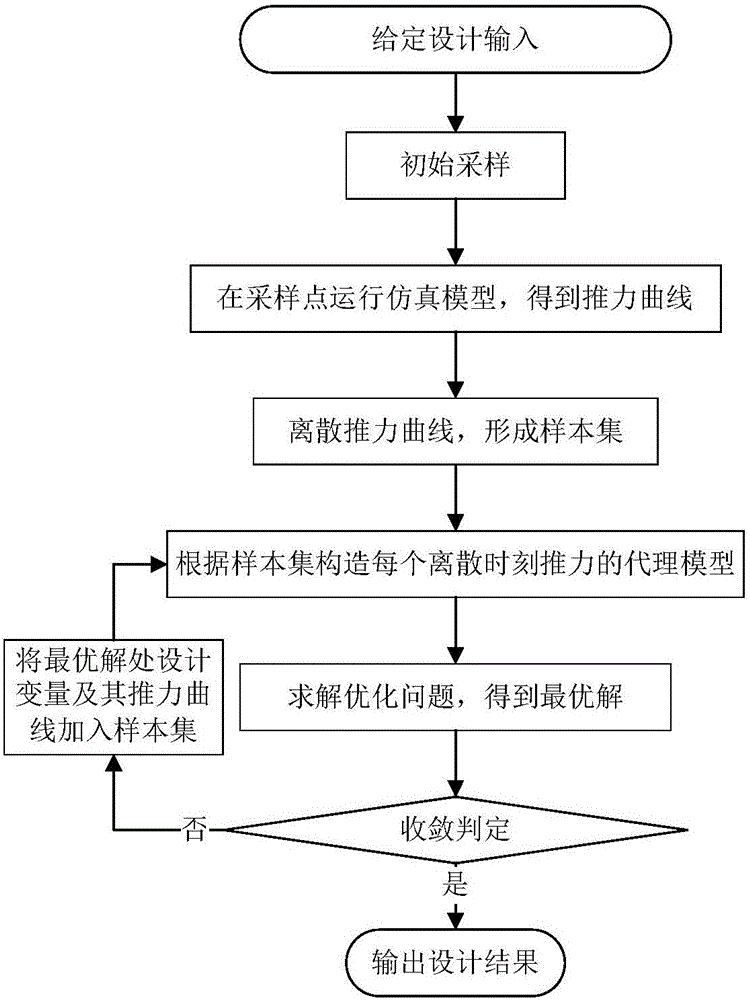

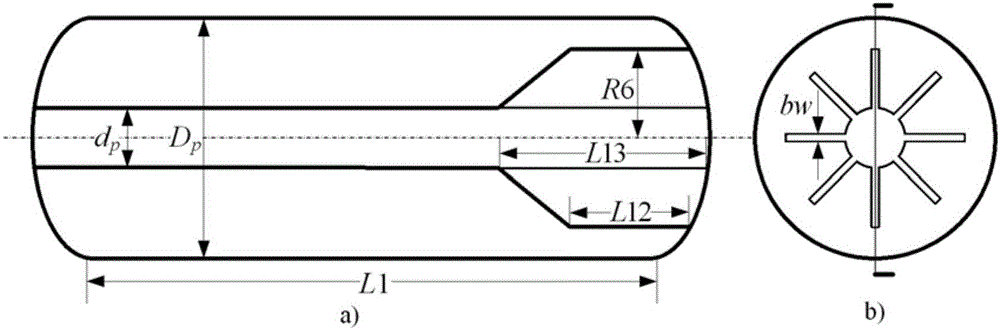

ActiveCN105956281AEffectively describe the law of changeReduce precisionDesign optimisation/simulationSpecial data processing applicationsRocketLeast squares

The invention provides a charging design method of a solid rocket engine. An agent model is used as a basis to directly carry out approximation on a thrust curve, and the thrust curve, instead of the agent model of a least square deviation between the thrust curve and a design index, is constructed to effectively describe a change rule of the thrust along with time so as to obviously reduce the simulation frequency of a high-precision burning surface and a trajectory. The agent model can better describe the change rule of the thrust curve, effectively guides subsequent search in a subsequent design, and can obviously improve the charging design efficiency of the solid rocket engine.

Owner:NAT UNIV OF DEFENSE TECH

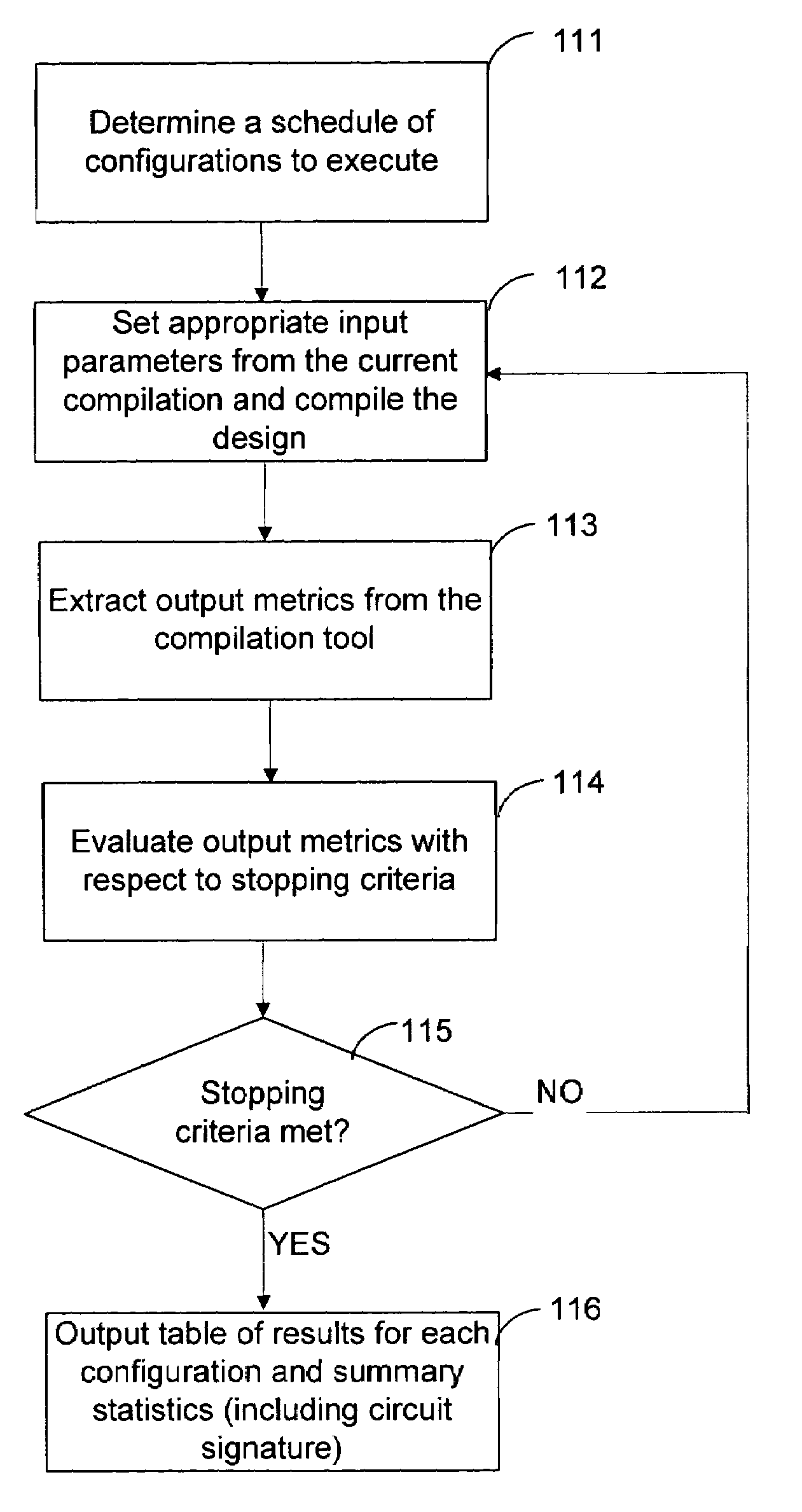

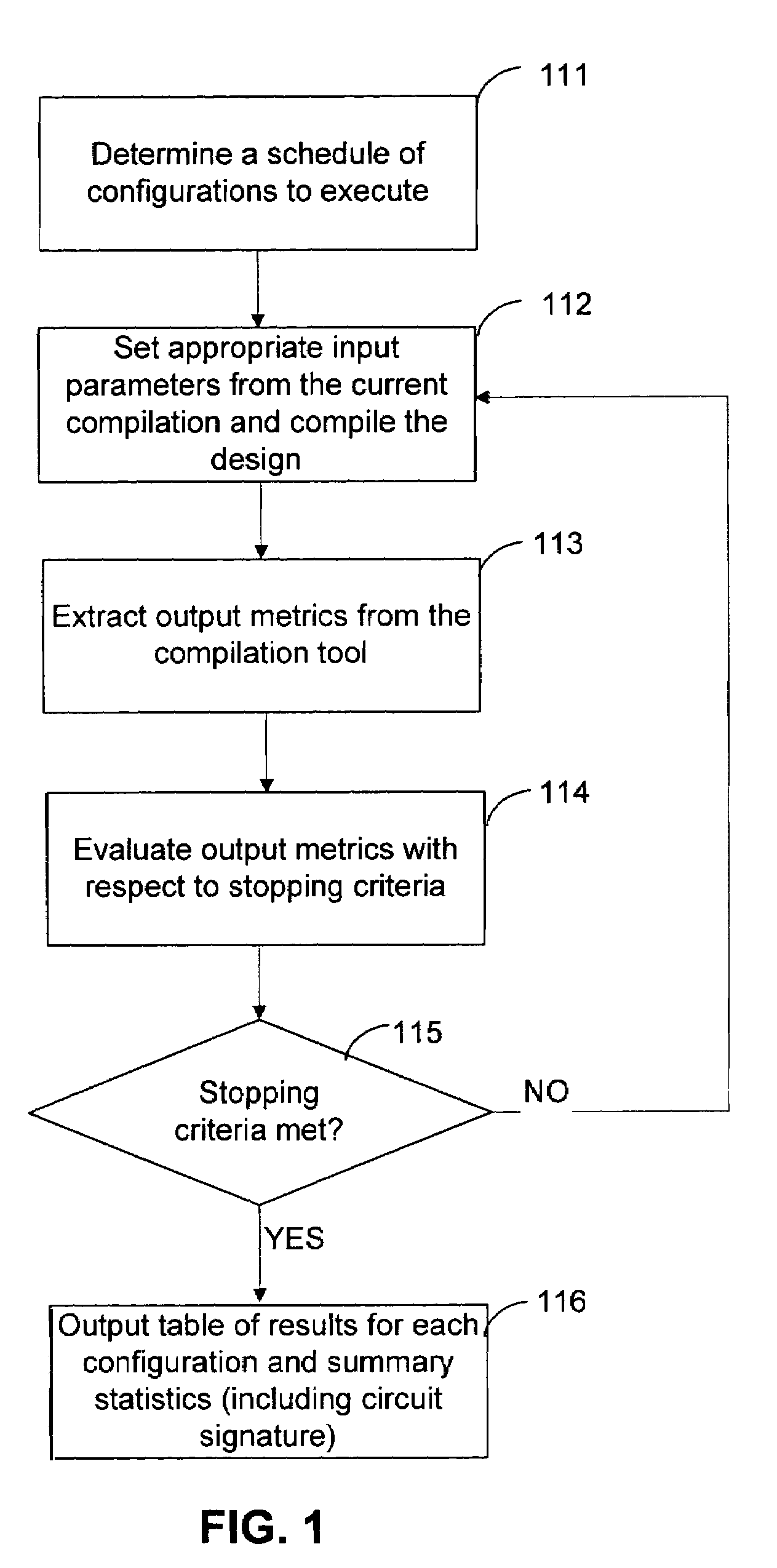

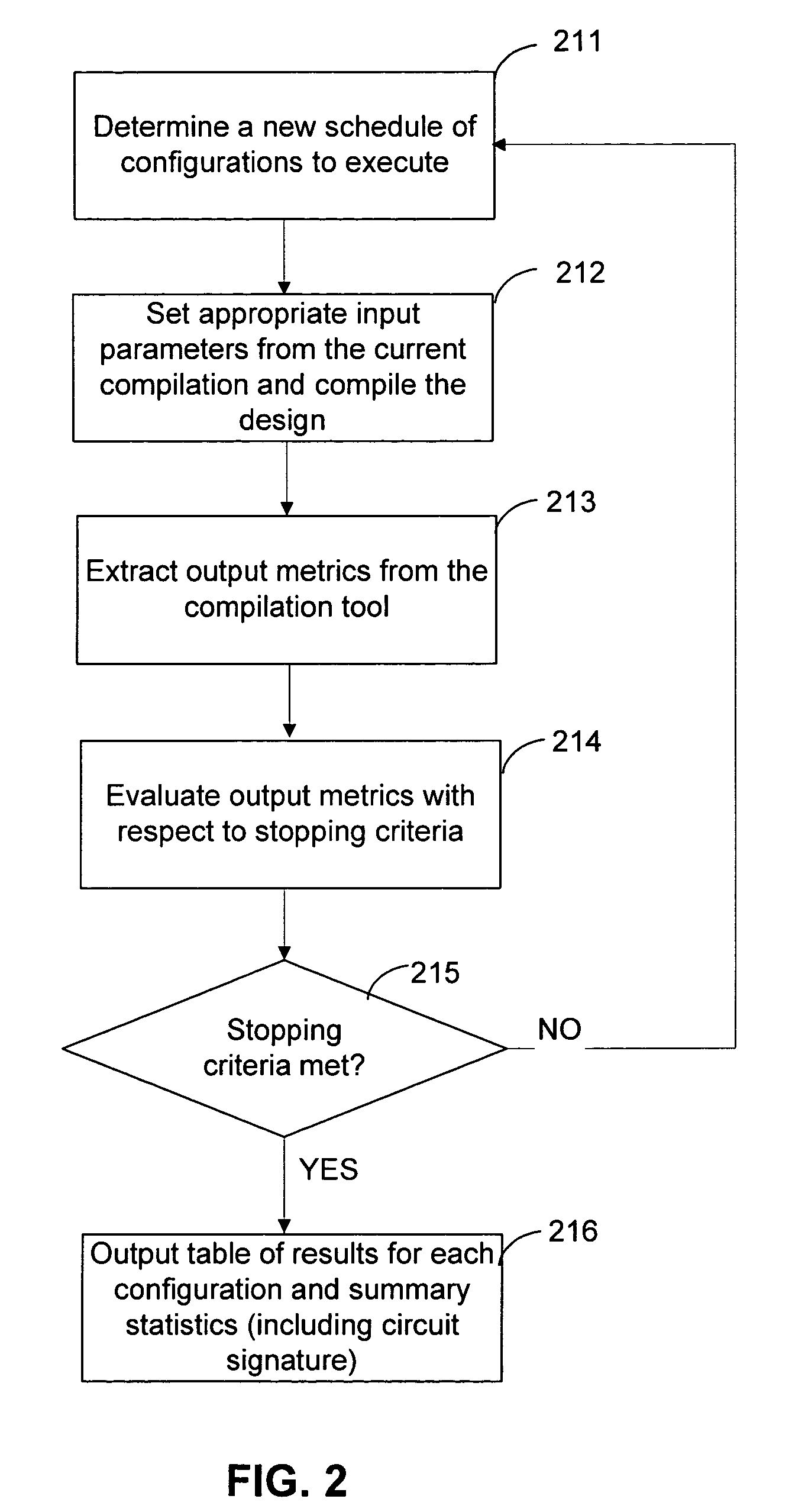

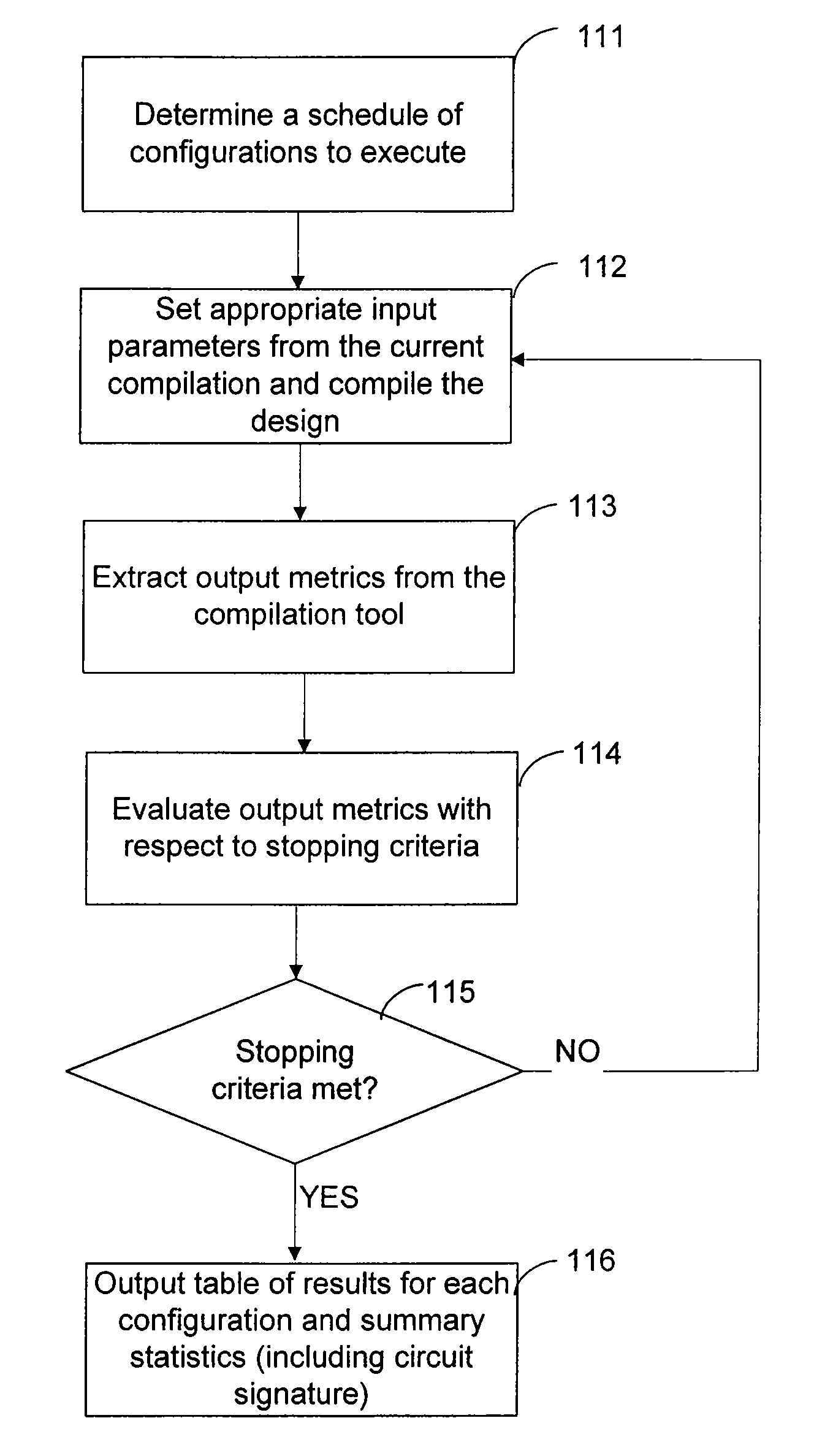

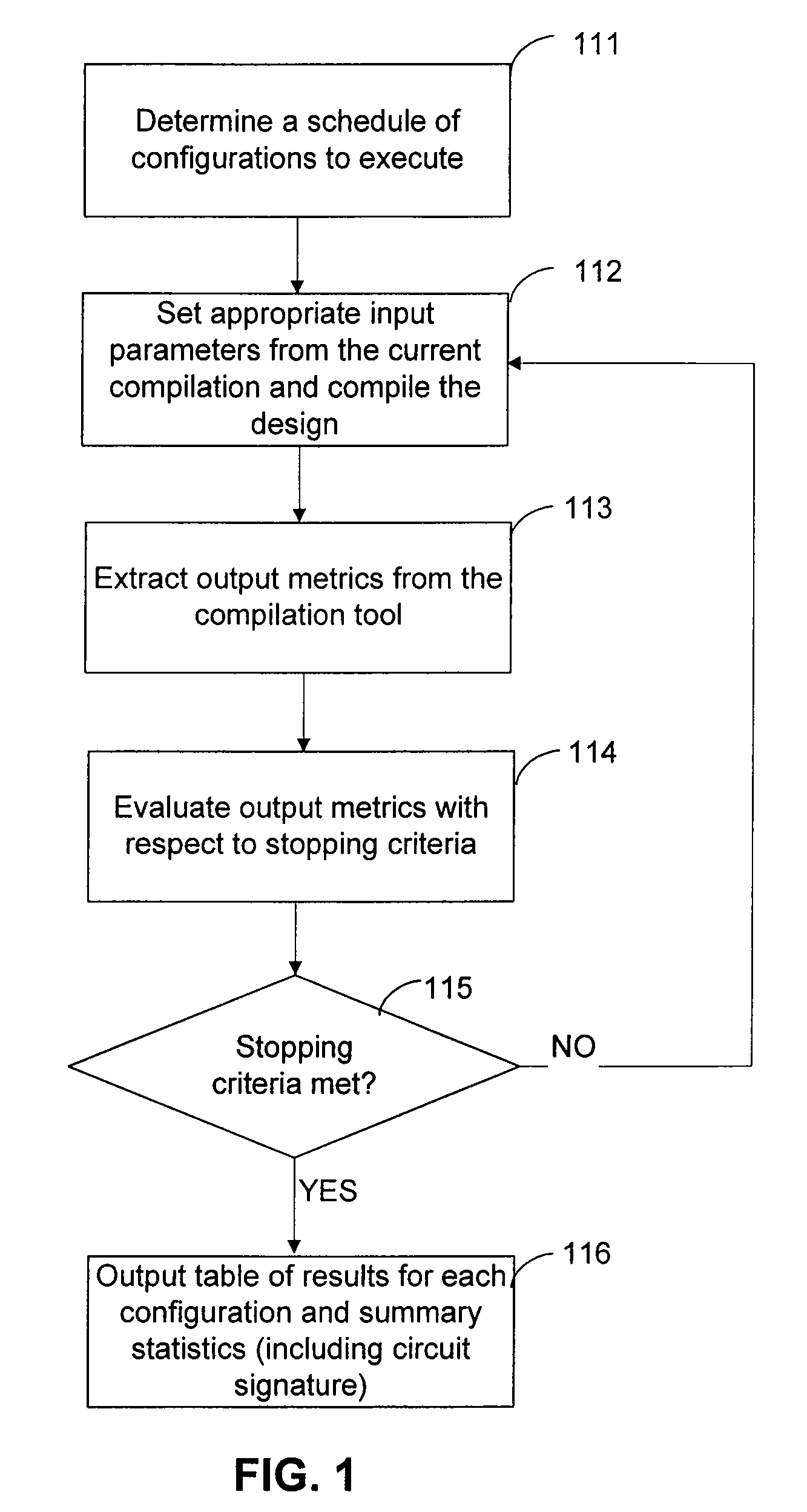

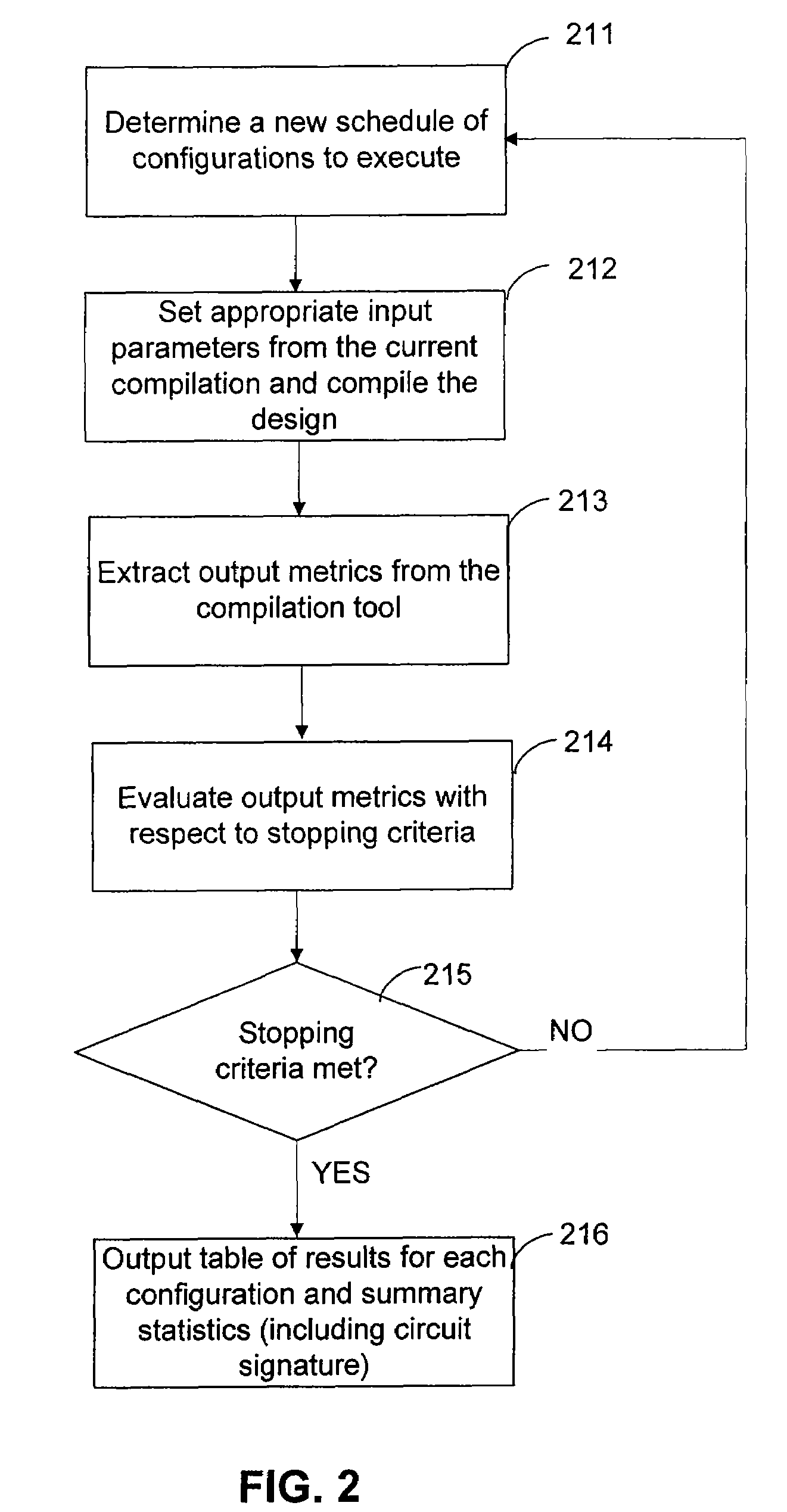

Techniques for automated sweeping of parameters in computer-aided design to achieve optimum performance and resource usage

InactiveUS7181703B1Design fasterDesign big and slowCAD circuit designSoftware simulation/interpretation/emulationComputer Aided DesignTrade offs

Techniques for optimizing the placement and synthesis of a circuit design on a programmable integrated circuit are provided. The performance of a circuit design is analyzed after it has been compiled with different values for selected input parameters. The input parameter values that produce the best results for an output metric are then chosen to synthesis and place the circuit design on the programmable integrated circuit. In one embodiment, the values of the output metrics are averaged for all test compiles that share the same input parameters, but different seeds. In another embodiment, the compile with the best output metrics, as determined by the user, are selected. These techniques allow a user to automatically trade off compile-time to get a better-optimized circuit.

Owner:ALTERA CORP

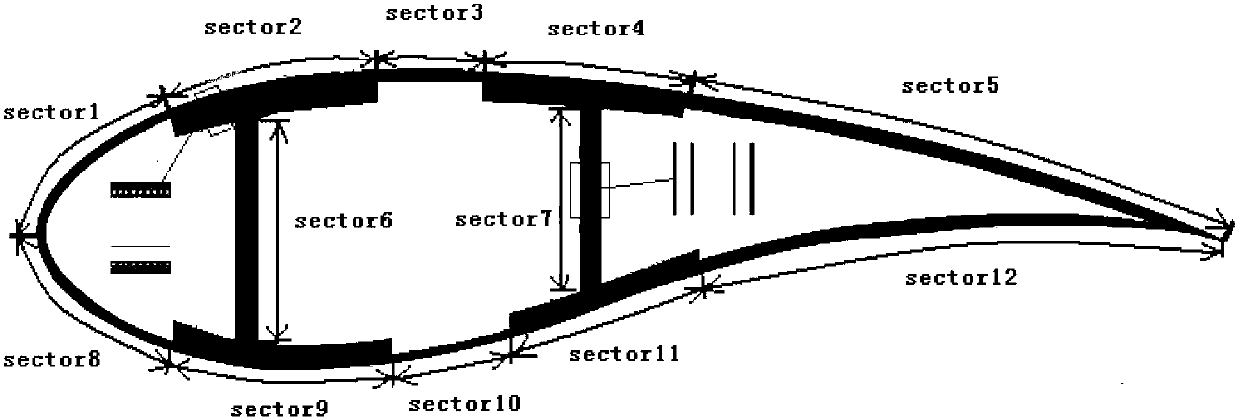

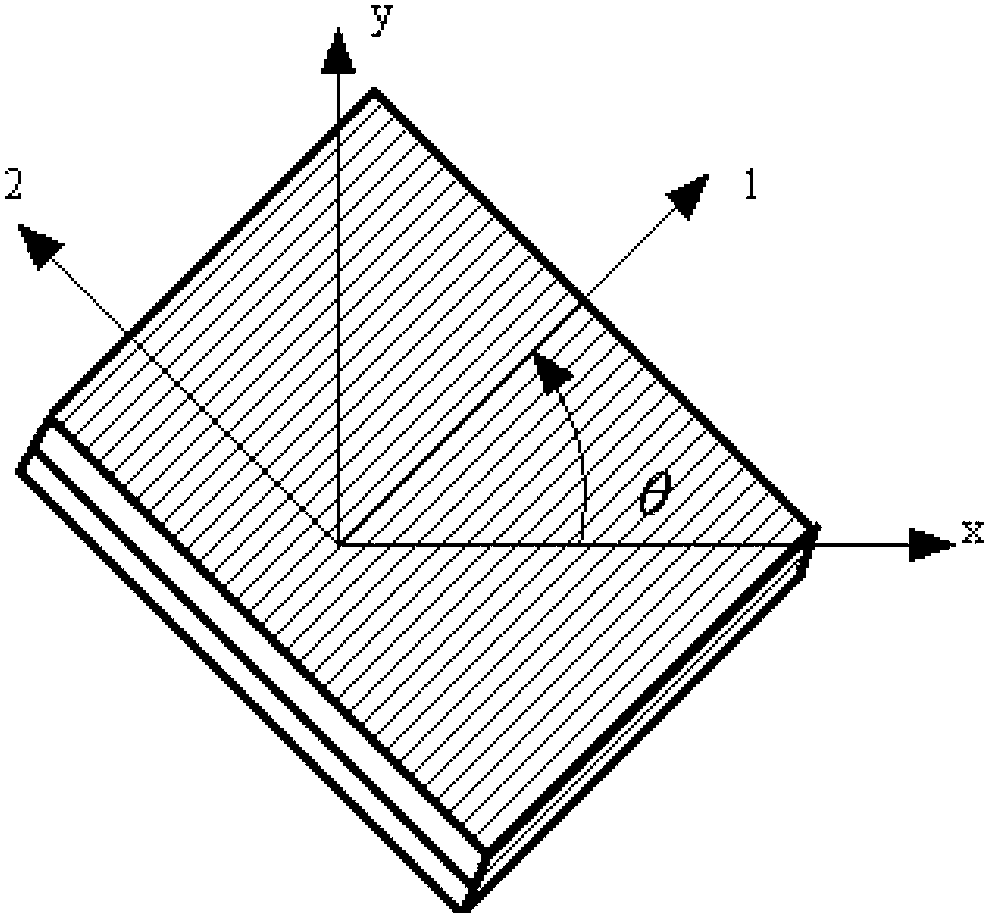

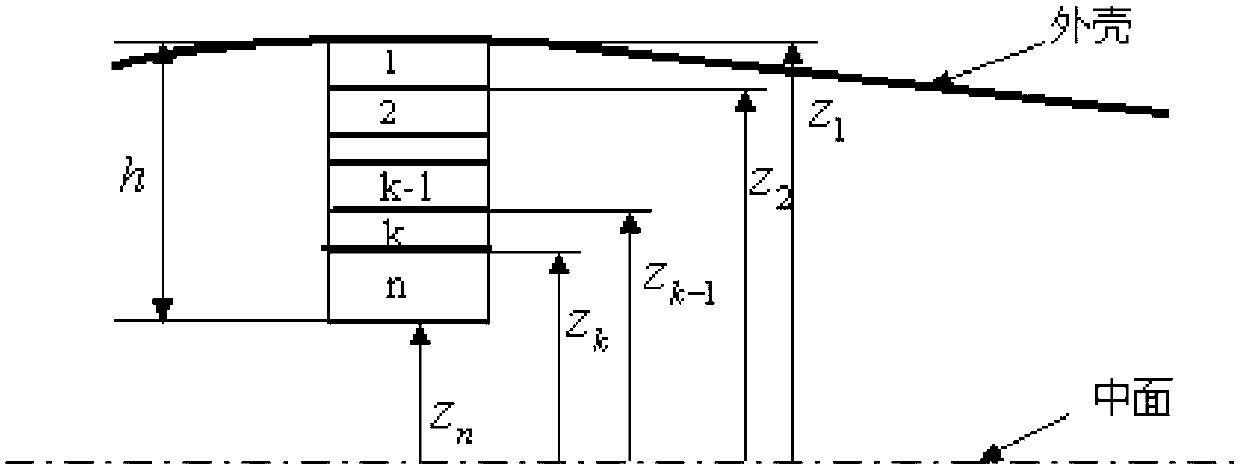

Optimization design method for blade layering of wind turbine with horizontal shaft

ActiveCN102750410AChange ply parametersDesign fasterSpecial data processing applicationsDensity distributionEngineering

The invention relates to an optimization design method for blade layering of a wind turbine with a horizontal shaft. The method comprises the steps of: carrying out parametric modeling on the initial layering of a blade to obtain the layering information of the blade spreading toward all sections; calculating the density distribution and the rigidity distribution of the mass line of the blade; calculating the inherent frequency of the blade according to the density distribution and the rigidity distribution of the mass line; calculating the minimum limit safety factor and maximum blade tip offset of the blade according to limit load distribution of all sections of the blade and the structure characteristic parameters of the blade; judging whether the inherent frequency, the minimum limit safety factor and the maximum blade tip offset of the blade meet the constrain conditions; and optimizing the layering of the blade by adopting an intelligent optimization algorithm, to obtain the optimal blade layering scheme. The method has the advantages that the layering of the different blades are optimized, changing the parameter of the layering needing optimization design according to different design targets and requirements, design is fast in speed, the optimized layering can be directly used for producing practical blades, and the like.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

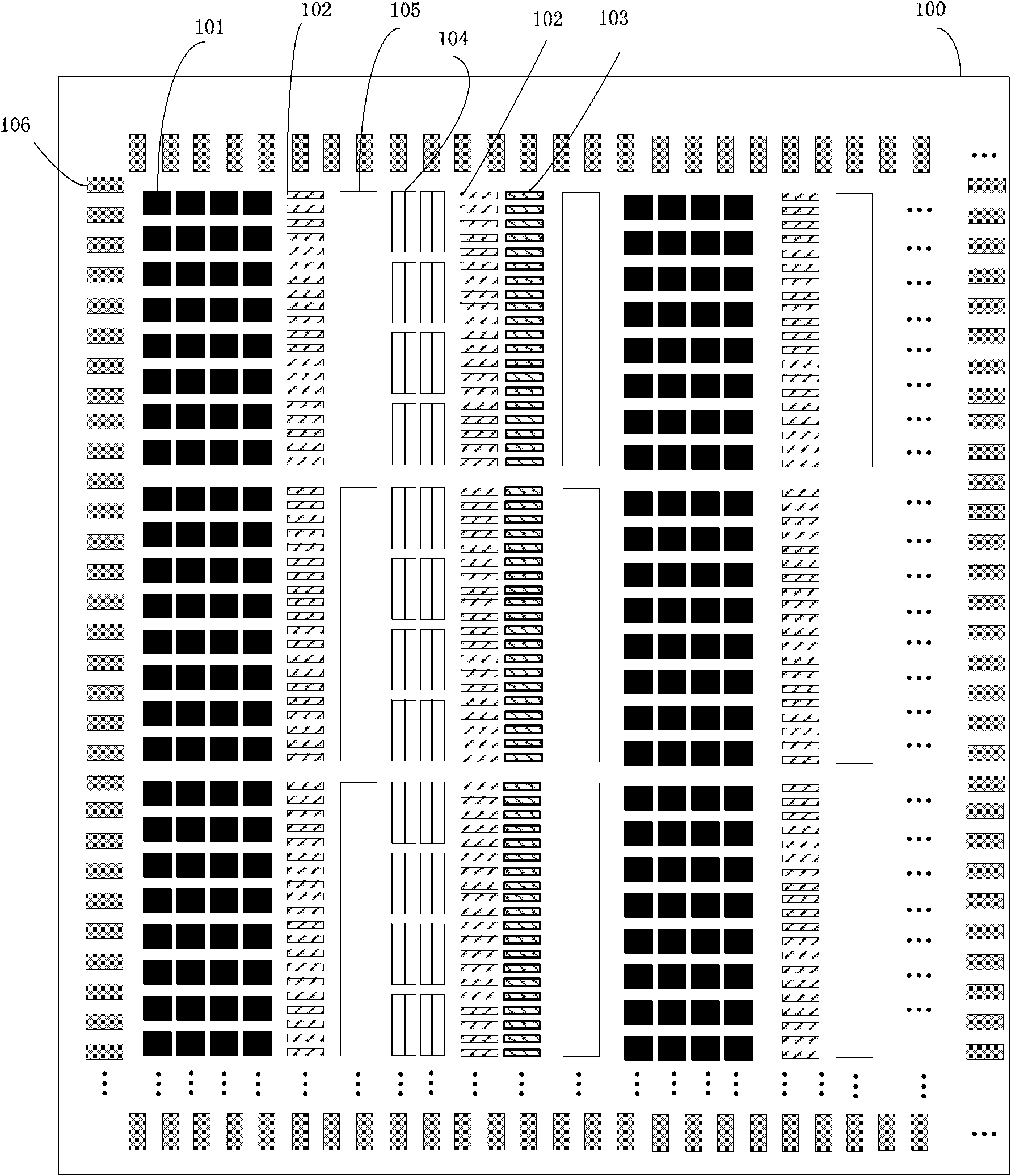

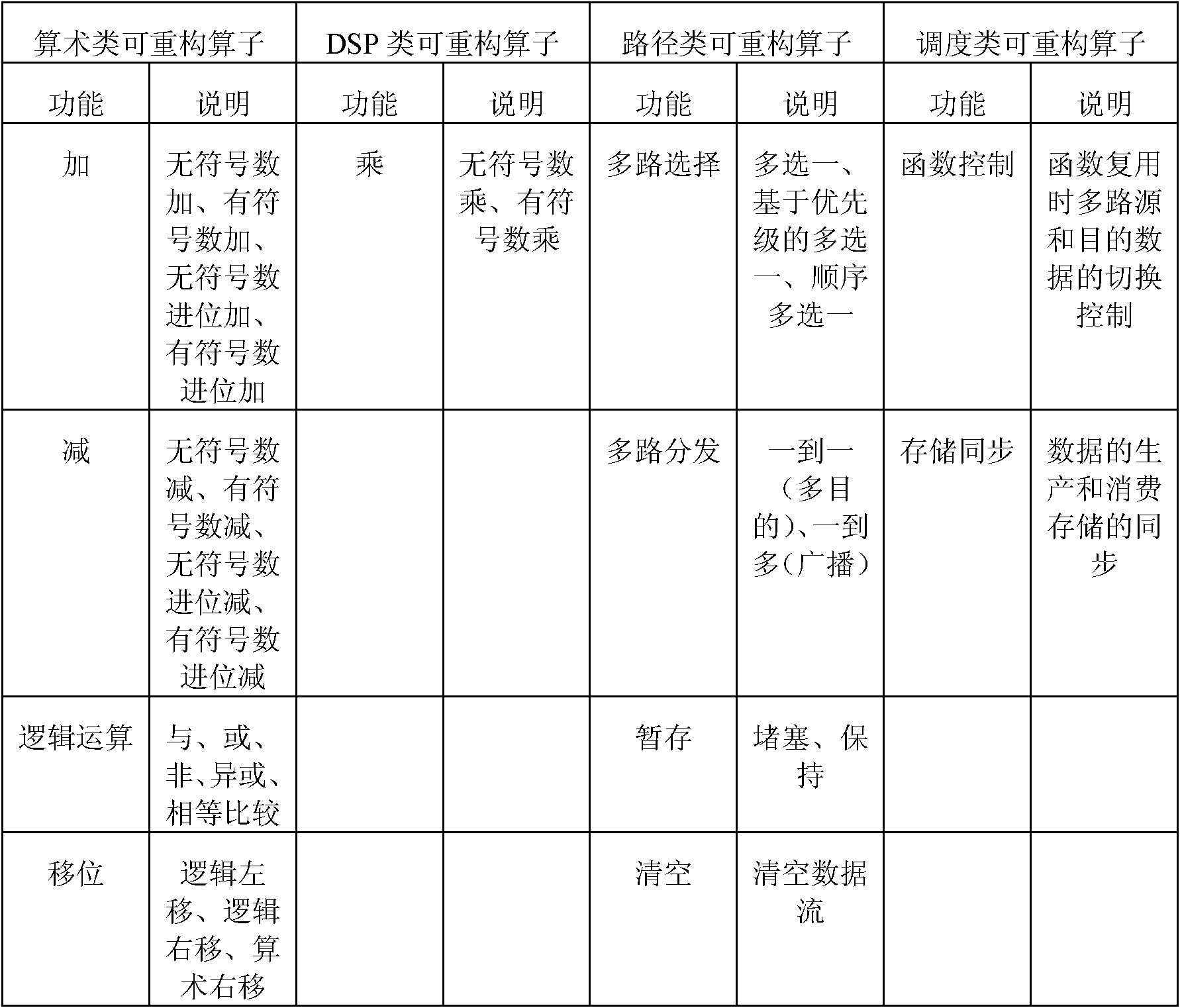

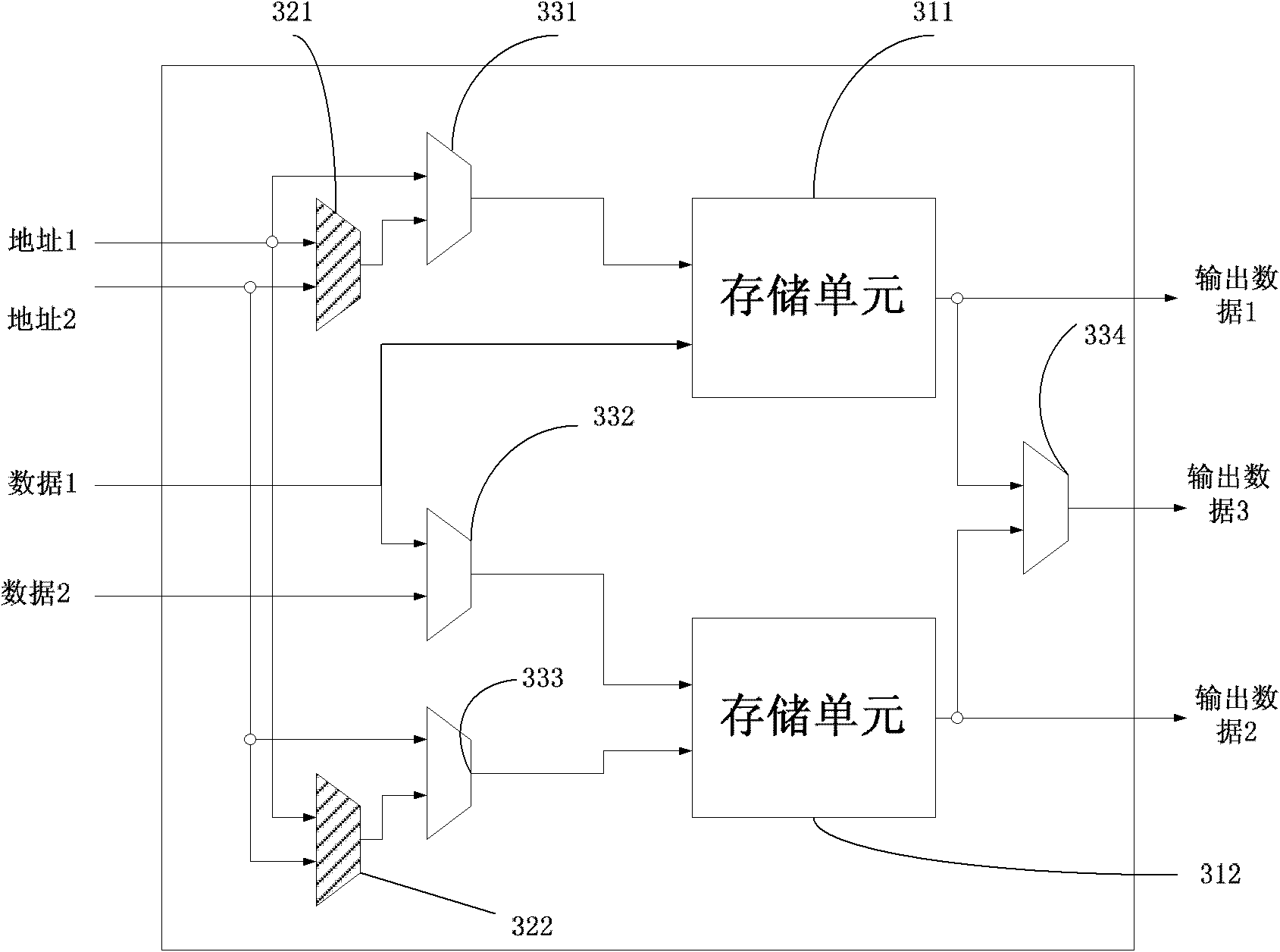

Array structure of reconfigurable operators

InactiveCN102163247AIncreased input description levelDesign fasterSpecial data processing applicationsComputer architectureLogic cell

The invention discloses an array structure of reconfigurable operators, comprising a logic unit for implementing logic function, a connection unit for implementing connection function and an input / output unit for implementing external communication, wherein the logic unit comprises a plurality of reconfigurable operators; the connection unit comprises interconnection resource and configuration nodes with switching characteristic, the reconfigurable operators are interconnected through the interconnection resource, and the connection path between every reconfigurable operator and the interconnection resource is provided with the configuration node. Particular functions are implemented in the array structure by fixing the function of every reconfigurable operator and the connection relationship of all the reconfigurable operators in a manner of programming the array structure, and the array structure includes excellent programmability and expansibility.

Owner:PEKING UNIV SHENZHEN GRADUATE SCHOOL

Techniques for automated sweeping of parameters in computer-aided design to achieve optimum performance and resource usage

InactiveUS7594208B1Reduce measurement errorReduce noiseAnalogue computers for electric apparatusCAD circuit designComputer Aided DesignTrade offs

Techniques for optimizing the placement and synthesis of a circuit design on a programmable integrated circuit are provided. The performance of a circuit design is analyzed after it has been compiled with different values for selected input parameters. The input parameter values that produce the best results for an output metric are then chosen to synthesis and place the circuit design on the programmable integrated circuit. In one embodiment, the values of the output metrics are averaged for all test compiles that share the same input parameters, but different seeds. In another embodiment, the compile with the best output metrics, as determined by the user, are selected. These techniques allow a user to automatically trade off compile-time to get a better-optimized circuit.

Owner:ALTERA CORP

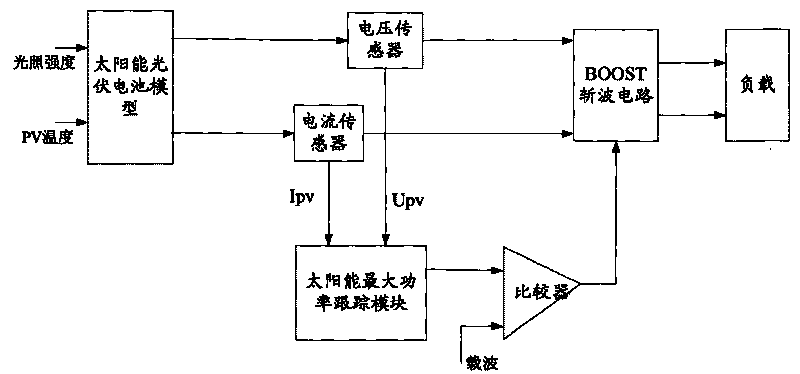

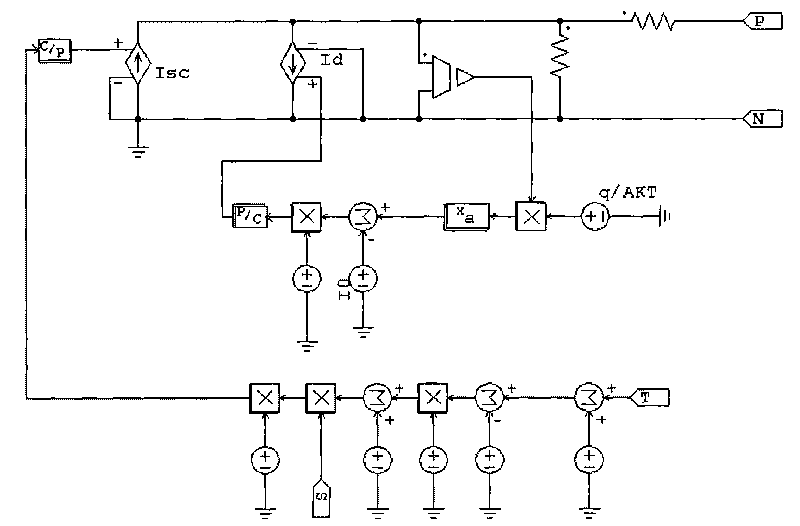

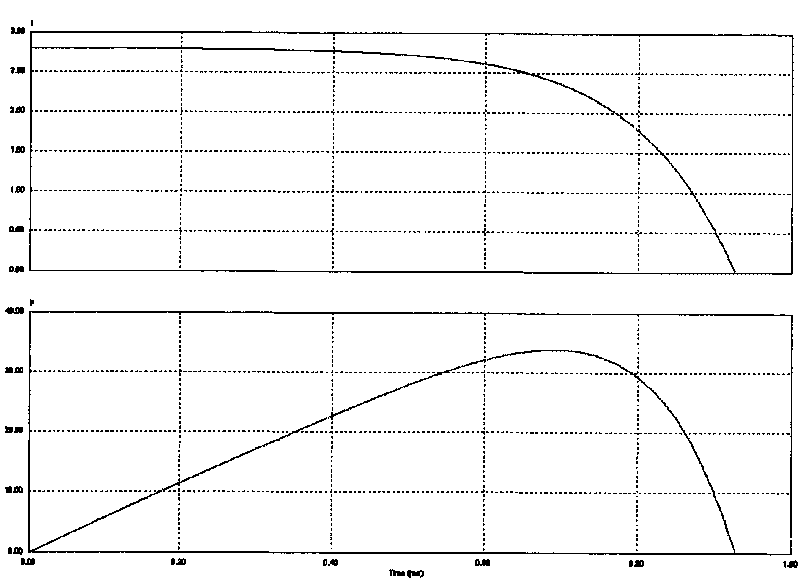

PSIM software-based solar maximum power point tracking algorithm and simulation system

InactiveCN101694676AIncrease flexibilityDesign fasterLight radiation electric generatorSpecial data processing applicationsControl signalCarrier signal

The invention discloses a PSIM software-based solar maximum power point tracking algorithm and a simulation system. The simulation system comprises a solar photovoltaic cell model, a voltage sensor and a current sensor which are sequentially connected with the output end of the solar photovoltaic cell model, a solar maximum power tracking module MPPT.DLL, a comparer and a power conversion circuit, wherein after being respectively detected by the voltage sensor and the current sensor, the real-time voltage and the real-time current generated by the solar photovoltaic cell model are transferred into the solar maximum power tracking module MPPT.DLL to generate a control signal, the control signal and a carrier signal are processed by the comparer to output a PWM waveform signal, and the PWM waveform signal controls the duty factor of the power conversion circuit, thereby controlling the equivalent impedance of load connected with the output end of the power conversion circuit and realizing the maximum power point tracking of the photovoltaic cell.

Owner:广州市圣大电子有限公司

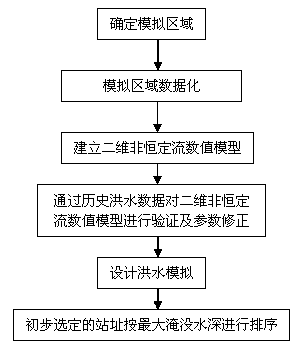

Two-dimensional unsteady-flow numerical model based power engineering location method

ActiveCN103886135AEnsure flood safetyReduce consumptionClimate change adaptationSpecial data processing applicationsDesign floodPower grid

The invention discloses a two-dimensional unsteady-flow numerical model based power engineering location method. On the basis of a plurality of site locations primarily selected according to design requirements of a power grid transmission line, the two-dimensional unsteady-flow numerical model is subjected to verification, parameter modification and design flood simulation by determining a simulation area, digitizing the simulation area and establishing the two-dimensional unsteady-flow numerical model and historical flood data, the site locations primarily selected are sorted according to largest submerged depth, and a primary selection sequence of the site locations is obtained. By the two-dimensional unsteady-flow numerical module flood routing technology, hydrologic characteristics in a certain area and flood hydraulic elements during simulation of flood routing can be truly and objectively reflected, flood control safety of electric power engineering can be guaranteed, construction accuracy can be improved, land source consumption can be reduced, and construction cost can be lowered.

Owner:STATE GRID CORP OF CHINA +3

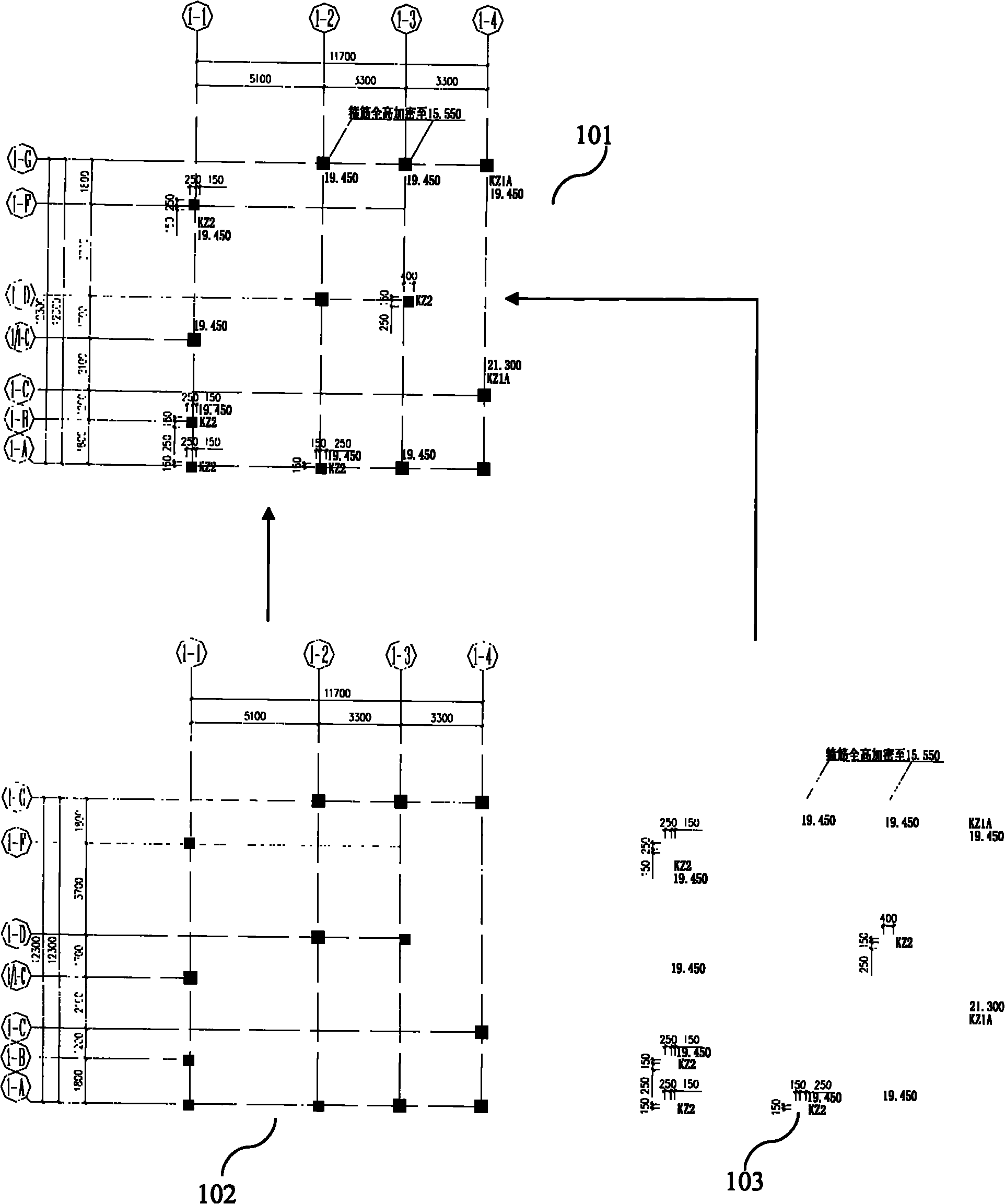

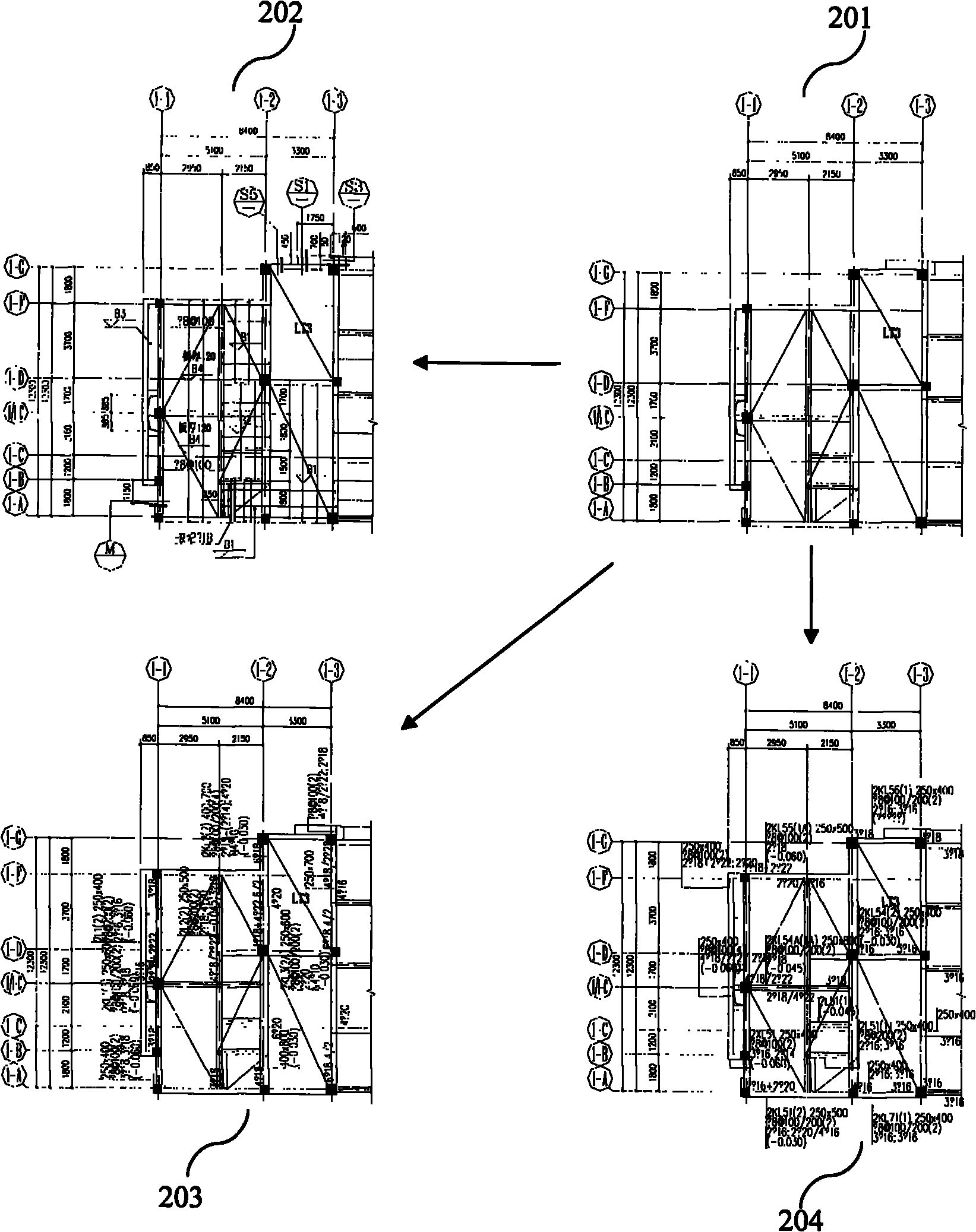

Automatically designable and adjustable engineering graphics system and its building method and using method

InactiveCN1877585AEasy to set upEasy to useSpecial data processing applicationsGraphicsGraphic system

The disclosed method to auto design and adjust engineering graph comprises: building and storing the 2D master control graph with some elements set as the controllable variable parameters and generated variable parameters, and creating the relation formula between parameters as knowledge rule design method; recalling the graph to input new value for controllable parameters and calculate new parameter values by computer, and then auto generating the production graph by a computer. This invention can improve 10-100 times for the design speed compared to the 1-2 months time by common technical staff.

Owner:周红华

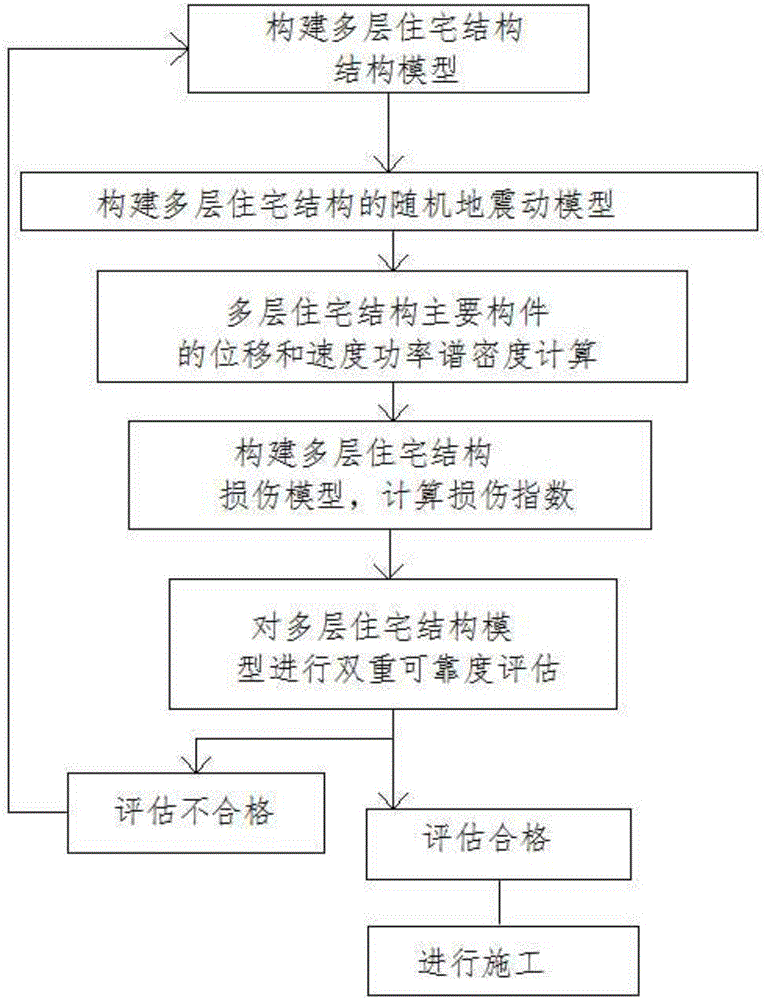

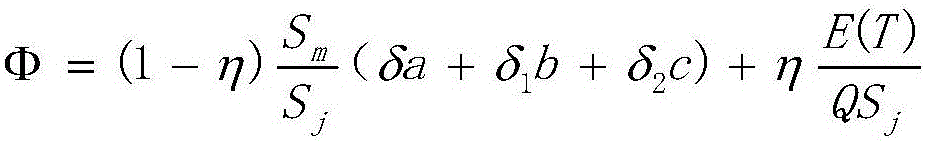

Construction method of multi-storey residential structure

InactiveCN105760628AImprove seismic strengthHigh precisionGeometric CADSpecial data processing applicationsEvaluation resultBuilding construction

The invention discloses a construction method of a multi-storey residential structure. The method comprises the steps of building a model of the multi-storey residential structure, building a stochastic seismic motion model of the multi-storey residential structure, computing the displacement and speed power spectrum densities of main components of the multi-storey residential structure, building a damage model of the multi-storey residential structure, computing a damage index, performing double reliability evaluation on the model of the multi-storey residential structure, and performing construction. The method performs construction according to the model of the model of the multi-storey residential structure which is qualified through evaluation in advance, reasonably performs adjustment in time according to an evaluation result, improves the earthquake-resistant behavior and the safety of structure, improves the efficiency and saves the cost.

Owner:潘燕

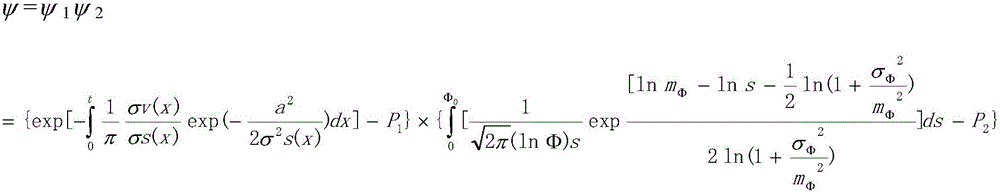

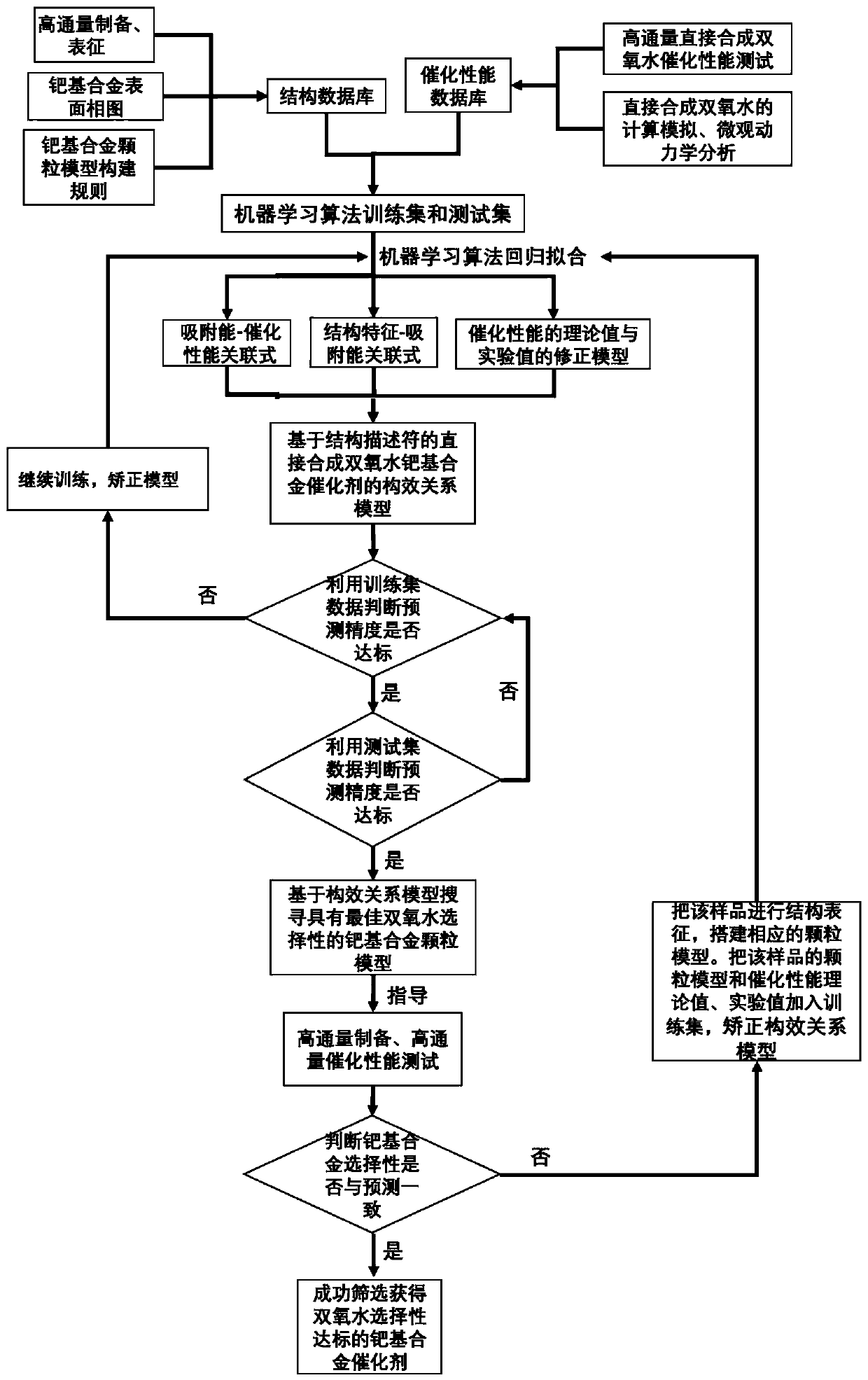

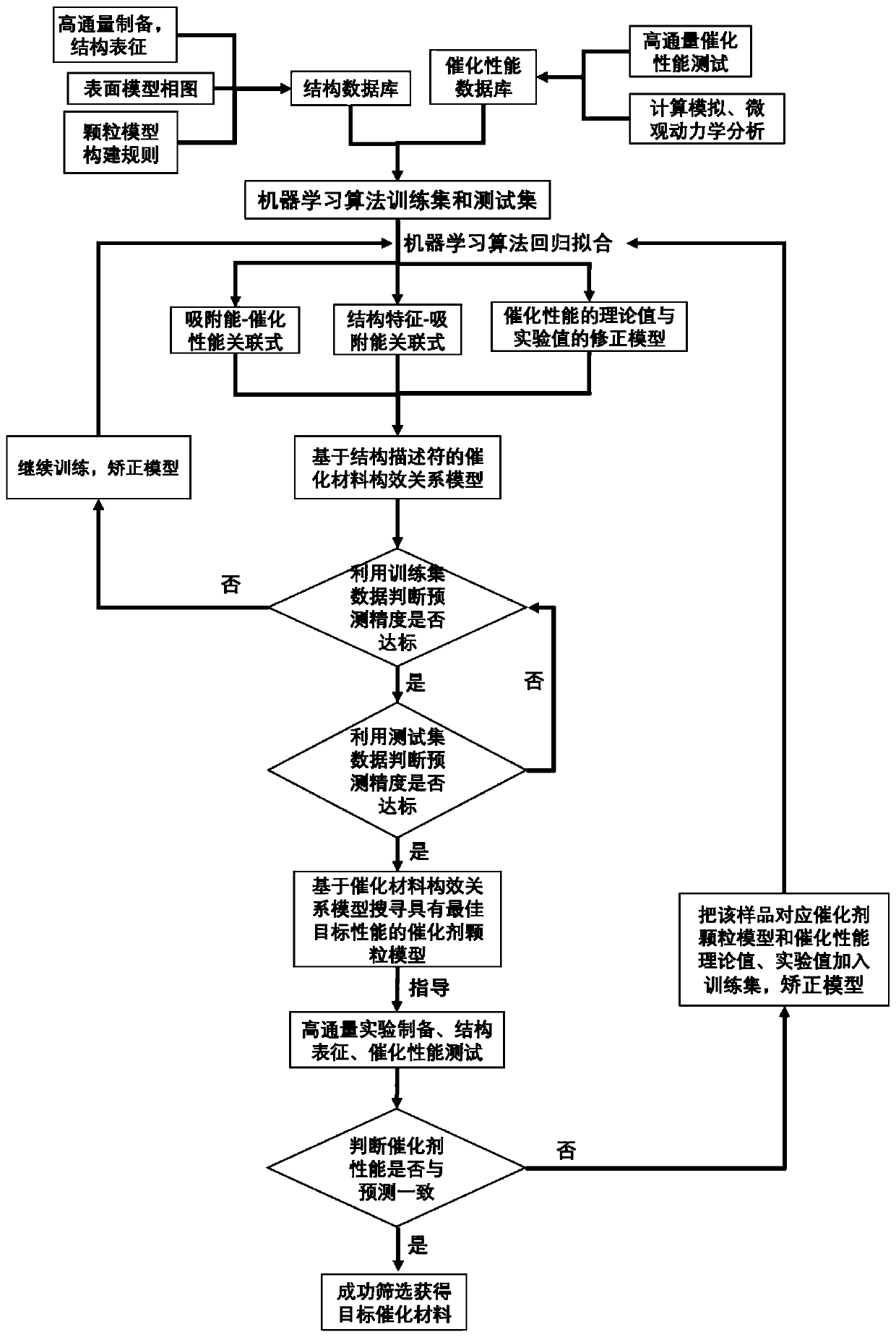

Catalytic material screening method and catalytic material screening system based on high-throughput experiment and high-throughput calculation

ActiveCN111128311AImprove screening accuracySpeed up screeningChemical processes analysis/designComputational theoretical chemistryPtru catalystPhysical chemistry

The invention provides a catalytic material screening method and a catalytic material screening system combining a high-throughput experiment and high-throughput calculation. The method comprises thesteps: screening a to-be-confirmed catalytic material meeting a target catalytic performance by using a catalyst structure-activity relation model constructed based on the data results of a high-throughput experiment and high-throughput calculation; performing high-throughput preparation and high-throughput performance evaluation on the screening result to obtain the experimental result of the to-be-confirmed catalytic material; and comparing the catalytic performance prediction result of the to-be-confirmed catalytic material with the experimental result of the to-be-confirmed catalytic material, and determining that the to-be-confirmed catalytic material is the catalytic material reaching the target catalytic performance under the condition of a predetermined deviation range. According to the scheme, the theoretical calculation simulation result, the existing experiment result and the new catalyst characterization result can form a mutual verification relationship through the catalyst structure-activity relationship model constructed based on the high-throughput experiment and the high-throughput calculation, so that the screening precision and the screening speed of the catalytic material are improved.

Owner:BEIJING UNIV OF CHEM TECH

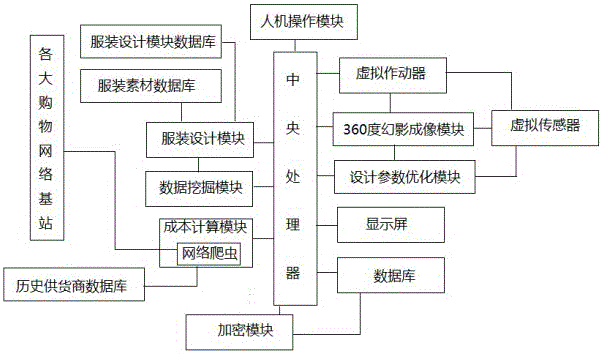

Costume design optimization system

InactiveCN106294981ARealize Simulation OptimizationImprove work efficiencyWeb data indexingData miningThree dimensional simulationSimulation

A costume design optimization system is characterized by comprising a man-machine operation module, a costume design module, a costume design template database, a costume material database, a data mining module, a cost calculation module, shopping network base stations, a historical supplier database, a central processing unit, a 360-degree spectra vision module, a virtual actuator, a virtual sensor, a design parameter optimization module and an encryption module. Three-dimensional simulation of a costume design draft is realized through the 360-degree spectra vision module, the effects at various angles can be observed without making costume, all simulation data are provided by the shopping network base stations, materials are found very conveniently, and the cost price budgeting is very clear; through self-definition by the virtual sensor and the virtual actuator, simulation optimization of design parameters is realized, the optimized design draft can be obtained, and the work efficiency of a designer is greatly improved. The costume design optimization system has the advantages of being scientific, reasonable, high in operability, high in design speed, good in effect and the like.

Owner:NORTHEAST DIANLI UNIVERSITY

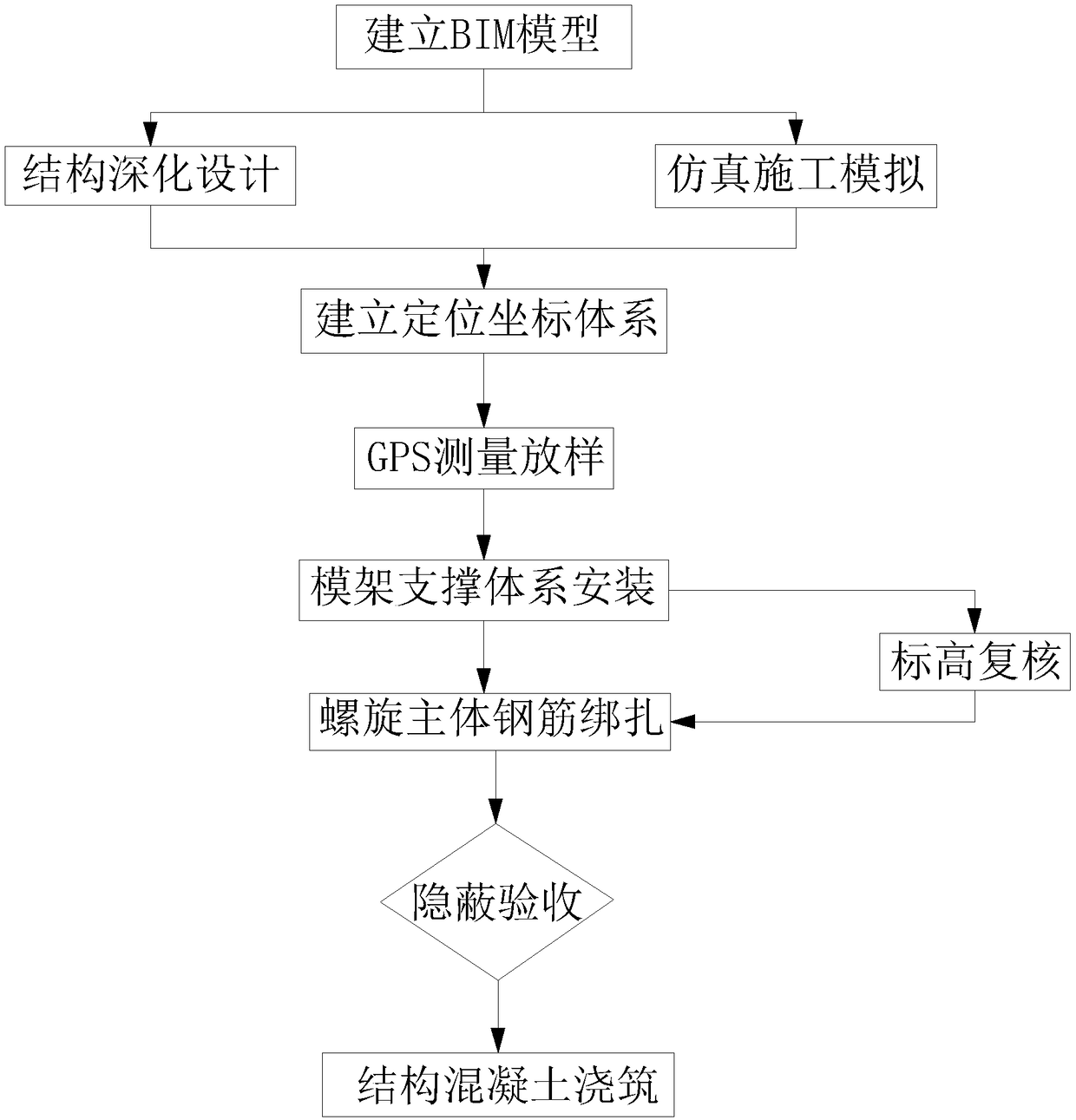

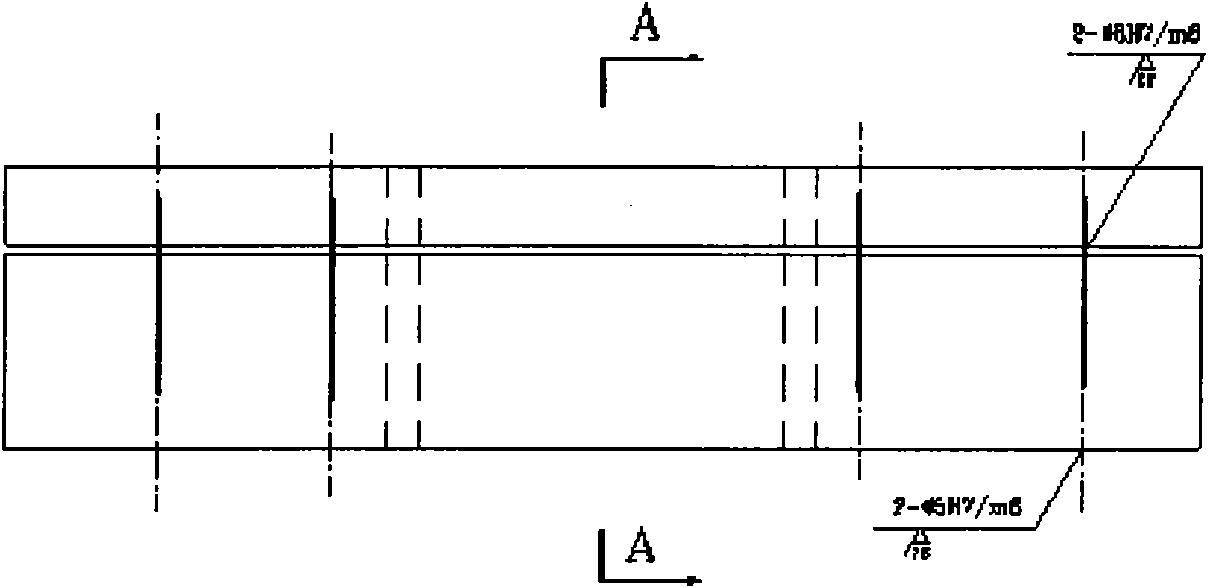

Construction method of spiral-rising-type reinforced concrete structure based on BIM

InactiveCN108416162ADesign fasterHigh precisionGeometric CADBuilding material handlingSupporting systemReinforced concrete

The invention discloses a construction method of a spiral-rising-type reinforced concrete structure based on BIM. A formwork and a supporting system can be automatically generated, the formwork splicing design can be automatically completed, three-dimensional construction simulation can be conducted, intelligent materials are optimized, and the use amount of various materials can be counted and precisely calculated. A BIM software technology is used for conducting three-dimensional modeling on a spiral-rising-type building structure, the splicing size, the supporting system and a safety calculation book of the building structure are determined, and construction workers conduct construction by directly in combination with a three-dimensional model according to a formwork scheme; by using the BIM technology, the speed of designing the formwork is high, the precision of designing the formwork is high, the loss of a supporting rack is reduced, the use efficiency of steel pipes is improved,and the situation is avoided that in the process of calculating the use amount of the materials of the framework and a scaffold, a common artificial design framework is changed, and the materials arewasted due to an unreasonable formwork splicing mode; the energy is saved, the environment is protected, and the engineering construction cost and the construction difficulty are reduced.

Owner:CHINA MCC17 GRP

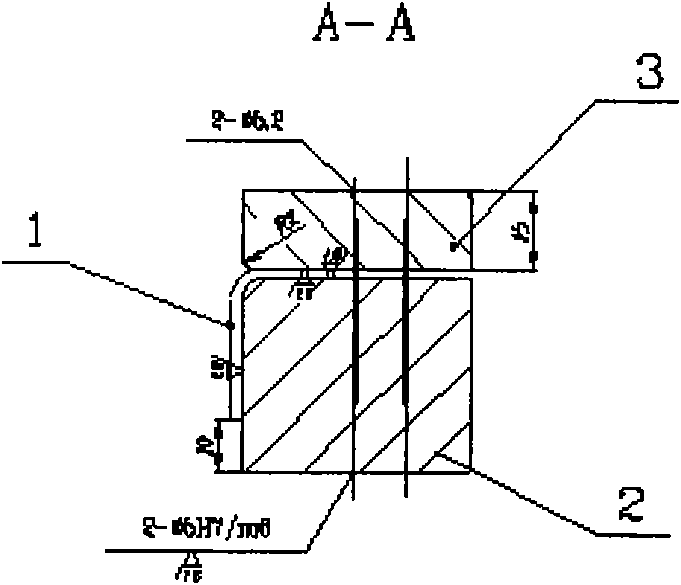

Parametric modeling and labeling method

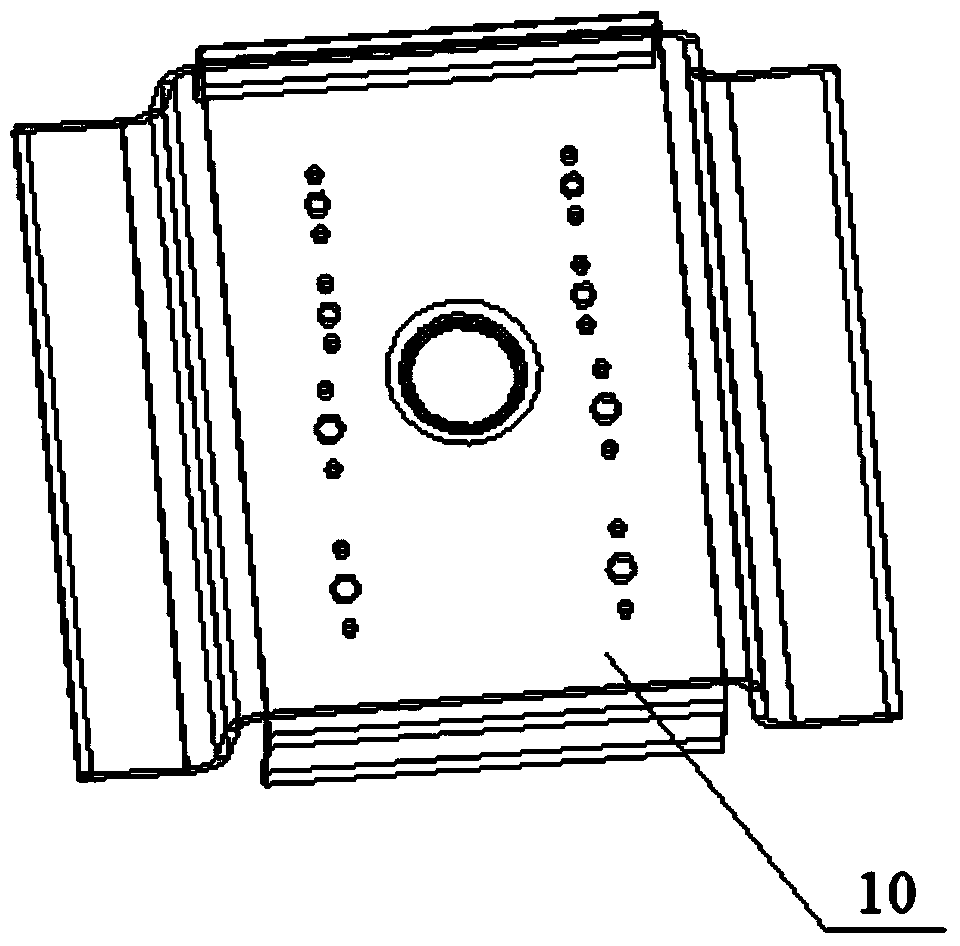

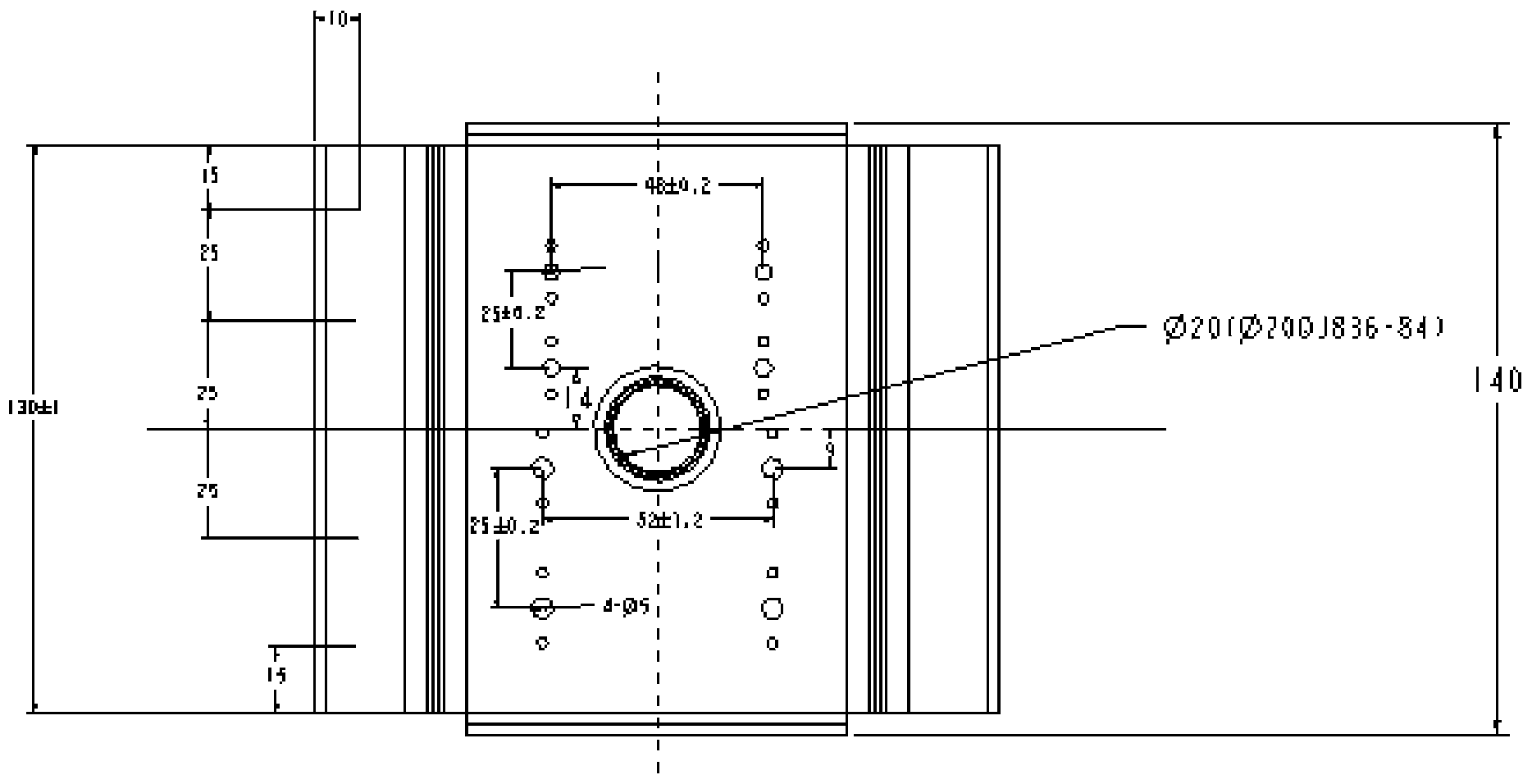

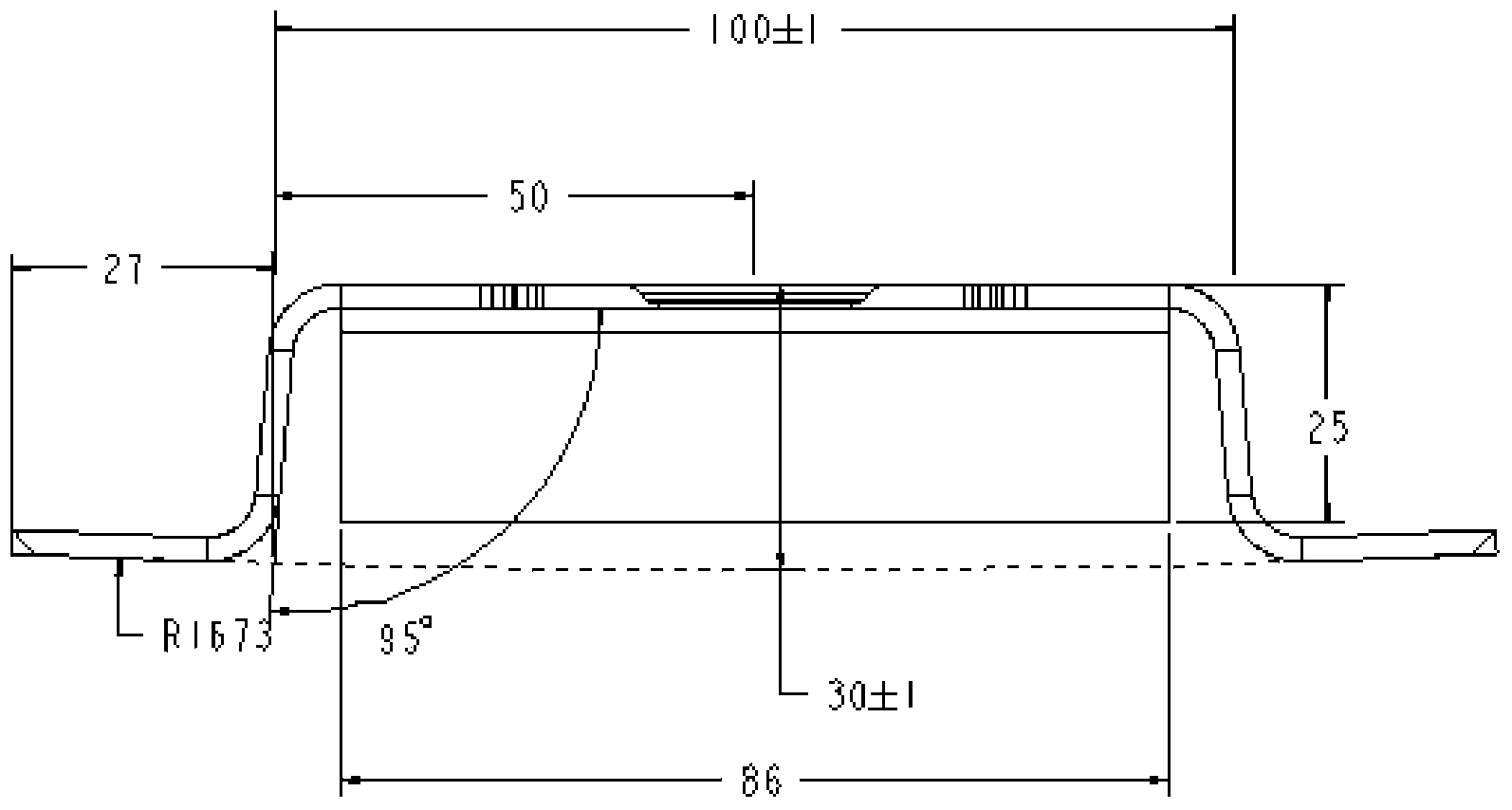

ActiveCN104376152APromote generationGet rid of duplication of workSpecial data processing applicationsQuality by DesignSimulation

The invention provides a parametric modeling and labeling method. The parametric modeling and labeling method comprises the steps that 1, a foundation model of a sheet metal bracket is built, wherein the foundation model structurally comprises turnups, axle holes and fixing holes of the sheet metal bracket; 2, parameters of the foundation model are programmed; 3, a program automatically adjusts the foundation model according to the input sheet metal bracket model parameters, and a sheet metal bracket model is obtained; 4, the sheet metal bracket model is automatically labeled according to the input parameters; 5, a three-dimensional drawing of the sheet metal bracket model is output. The parametric modeling and labeling method has the advantages that through the parametric design, on the basis of the foundation model, modeling and intelligent labeling can be finished rapidly, a new model is generated rapidly to help a designer rapidly finish high-quality design work, repeated labor is avoided, the design and drawing difficulty is lowered, the requirements for product serialization and rapid amendment are met, the design speed of products is increased comprehensively, and the design quality of products is improved greatly.

Owner:BEIJING INST OF ASTRONAUTICAL SYST ENG +1

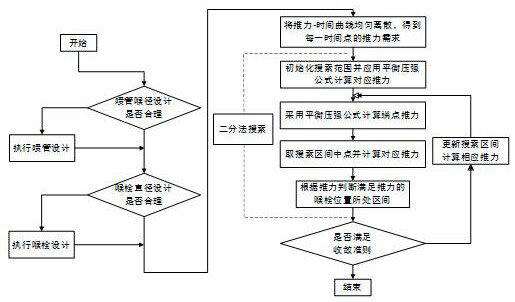

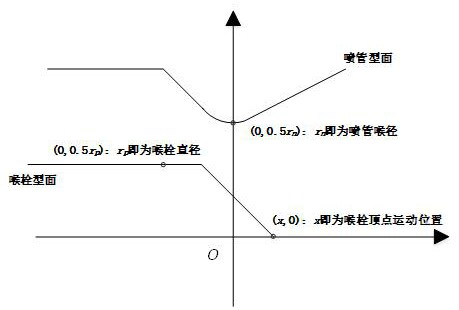

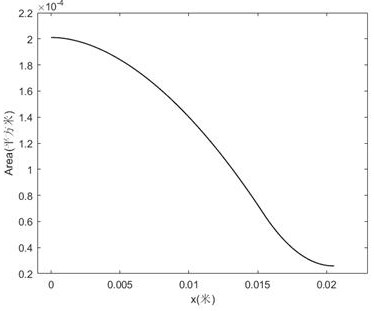

Throat bolt type variable thrust solid engine thrust matching design method

ActiveCN112464387ADesign fasterImprove Thrust Match Design EfficiencyGeometric CADSpecial data processing applicationsThroatControl engineering

The invention discloses a laryngeal bolt type variable thrust solid engine thrust matching design method which comprises the following steps: step 1, acquiring a thrust time curve to be matched and designed, and uniformly dispersing the thrust time curve according to a time step length to obtain required thrust at each time point; step 2, judging whether the size design of the current throat diameter of the spray pipe and the diameter of the laryngeal plug meets the thrust requirement or not, if yes, directly entering the step 3, and otherwise, updating the size design of the throat diameter of the spray pipe and / or the diameter of the laryngeal plug until the thrust requirement is met and entering the step 3; and step 3, based on the minimum adjustable thrust and the maximum adjustable thrust, adopting a bisection method to obtain the laryngeal plug position at each time point, and achieving laryngeal plug movement scheme matching design. The integrated design of the thrust adjustingcapacity and the laryngeal plug movement scheme is achieved, the laryngeal plug movement scheme under the thrust requirement is given, the throat diameter and the laryngeal plug diameter are adjustedaccording to the thrust requirement, the thrust adjusting capacity is improved, and the laryngeal plug type variable thrust solid engine thrust matching design is achieved.

Owner:NAT UNIV OF DEFENSE TECH

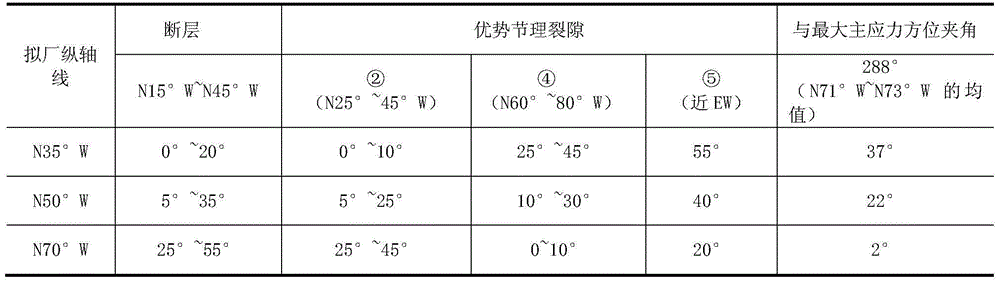

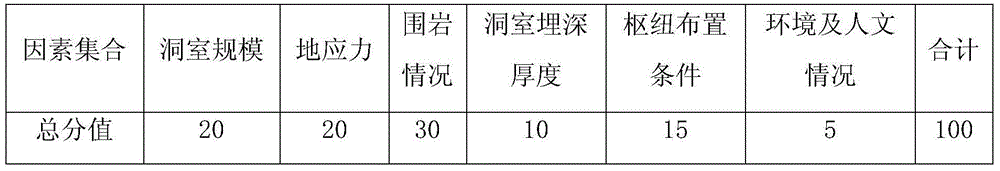

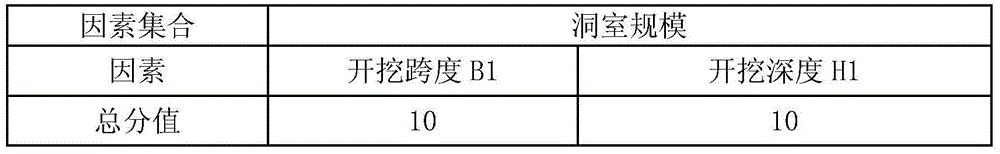

Quick assessment method for site selection of underground powerhouse cavern of hydropower station

The invention discloses a quick assessment method for site selection of an underground powerhouse cavern of a hydropower station, relates to the field of hydraulic and hydroelectric engineering, and provides an assessment method capable of objectively and quickly judging the site selection condition of an underground powerhouse cavern of a hydropower station. The method comprises the following steps: A, summarizing and classifying factors influencing site selection to obtain factor sets; B, endowing each factor set with a total score according to the influence degree on site selection, and distributing the total score of each factor set to factors of the factor set to obtain a total score of each factor; C, determining the actual score of each factor according to the difference between the actual condition and the ideal condition of each factor; and D, calculating the actual score sum of each factor, and judging whether the target address is suitable for building the underground powerhouse cavern according to the difference between the score sum and the total score. By adopting the method, numerous factors involved in site selection of the traditional underground powerhouse cavern are quantified and unified in the same assessment system for assessing via a large amount of existing engineering examples and numerical analysis results.

Owner:CHINA HYDROELECTRIC ENGINEERING CONSULTING GROUP CHENGDU RESEARCH HYDROELECTRIC INVESTIGATION DESIGN AND INSTITUTE

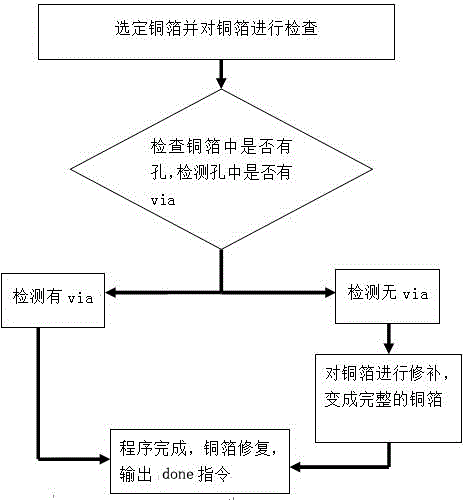

Copper-deficiency automatic supplementing method with no need of repeatedly avoiding copper

InactiveCN105677970ARapid designDesign fasterCAD circuit designSpecial data processing applicationsCopper foilWorkload

The invention discloses a copper-deficiency automatic supplementing method with no need of repeatedly avoiding copper, and relates to the technical field of EDA. On the basis of cadence software, deficient copper of a Shape is automatically supplemented through a Skill program interface of Allegro software; the method comprises the main steps that 1, attribute setting is performed on deficient holes of the Shape; 2, each deficient hole is detected step by step, and whether a via exists in each deficient hole or not is determined; 3, the Shape with the deficient holes needing to be supplemented is determined and selected, and all the deficient holes with no via are supplemented. The method is beneficial to rapidly designing a PCB, redundant workloads brought by manual multistep operations in design are effectively avoided, and the designing speed of the PCB is increased.

Owner:INSPUR GROUP CO LTD

CAD design reusable device based on component-standard floor part structure and method thereof

InactiveCN101923586AEfficient use ofSimple assembly structureSpecial data processing applicationsDuplicate contentComputer Aided Design

The invention relates to a design reusable device in CAD (computer aided design) and a method thereof, which are used for realizing quick establishment and associated modification by using the duplicate content among standard floors and monomers in an architectural drawing. The technology leads the duplicate content to be componentized, and automatically completes assembly of a final drawing from a component to a standard floor part and the like. The device comprises the component, the standard floor part, a graphic element distribution module, a component assembly module and a standard floor part assembly module. The method comprises the following steps: a duplication graphic element is placed into componentization for a user by using an interactive interface provided by the graphic element distribution module; a component is assembled to the standard floor part according to the attribute of the component by using the component assembly module; the component assembled to the standard floor part is subject to reusable adjustment according to the reusable attribute of the component by using a component adjusting module; the standard floor part is assembled to a corresponding host theme standard floor part according to the attribute of a pre-saved standard floor part by using the standard floor part assembly module; and the host theme comprises other themes.

Owner:戴建凤

Computing method for vessel coating area and computer application program for the computation

InactiveCN1702657AReduce tedious workDesign fasterSpecial data processing applicationsApplication softwareCalculation methods

This invention relates to a method for computing ship painting and the computer application program, the computing ship painting method includes moving relevant three-dimensional module out from TRIBON environment, and from which finding the plane board surrounded the cabin room to define the computing range, and computing the plane board area and inside structure part area of cabin room. The computer application program for computing painting area is tapped from VBA program in Excel, open Excel file' painting area computing program', and run macro, dialog box bombs, then put these boards' name into import box of this program, finally the program get the requested area through all kinds of judgment and computing. Comparing to the conventional handwork method, the merit of this invention is that it realize the autoimmunization of ship painting area computing

Owner:BOHAI SHIP HEAVY IND CO LTD

Rapid design method of tyre mould

The invention provides a rapid design method of a tyre mould, which comprises the following steps of: 1) simplifying the expressed mould design pattern, classifying the shape related characteristics of the tyre mould, and drawing and establishing a CAD (computer-aided design) pattern library of the typical structure of various types of tyres; 2) compiling a special tyre designing and manufacturing specification, attaching tyre typical structure legends corresponding to the tyre typical structure pattern library and the pattern of the simplified drawing work order, and classifying and numbering the typical structure legends; and 3) correspondingly selecting a legend number from the typical structure specification according to the product shape, calling the CAD pattern from the typical structure pattern library and filling the CAD pattern into the simplified drawing work order according to the number, and finally filling an order number, a fixture pattern number and other simple information into the work order to finish the design. As the tyre typical structures in the invention are strictly classified, the classes nearly include all tyre structure types and the compiling idea is novel, the tyre mould is convenient and quick to use by designers, the design speed is increased by 6-10 times than that before, and the manual labor and material resources are saved. The invention can greatly shorten the production preparation period, and provides solid technical storage for the development of new products.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

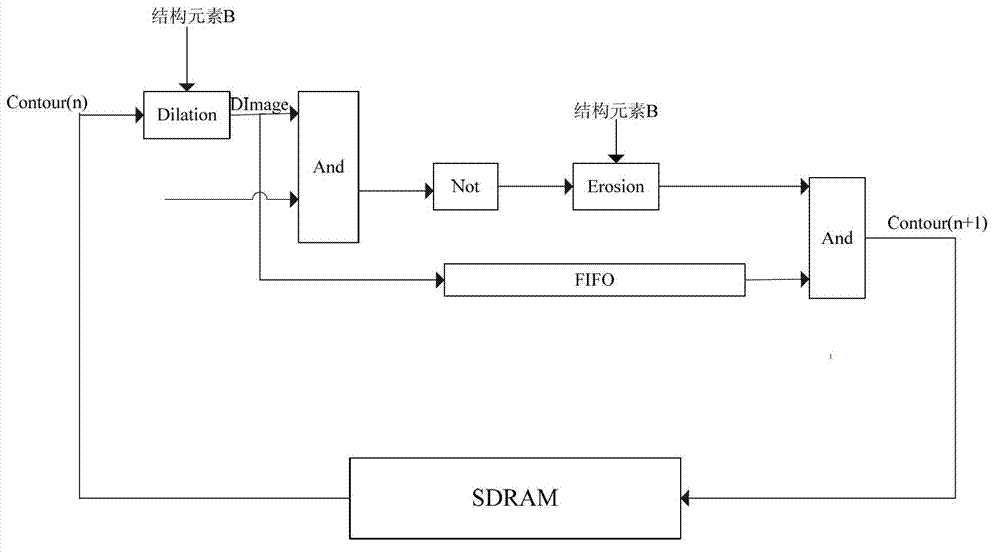

Digital picture contour extraction method

InactiveCN103035010AEasy to useFlexible Data Width OperationImage analysisFloating pointHuman language

The invention provides a digital picture contour extraction method and relates to a digital image processing technique. The method includes the first step of observing a divided image and initiating a curve, the second step of initiating a speed evolvement function and obtaining a speed evolvement image V, the third step of carrying out expansive working on the initiated binary image A obtained from the first step to obtain an image E through expansion, and taking B as a value of a 3*3 structural element, the fourth step of updating a level set function, namely updating the binary image A, and the fifth step of returning to the third step and continuing operation. According to the characteristics of field programmable gate array (FPGA), the contour extraction method based on a form level set is put forward, and floating point arithmetic and parallel calculation for each pixel are needless; the Handel-C language which is quicker and more efficient than a traditional hardware description language is adopted; and circuits with modified structures are adopted in Dilation and Erosion submodules in an image processing submodule, the image is scanned once and image effects of the whole template operation can be obtained.

Owner:XIAMEN UNIV

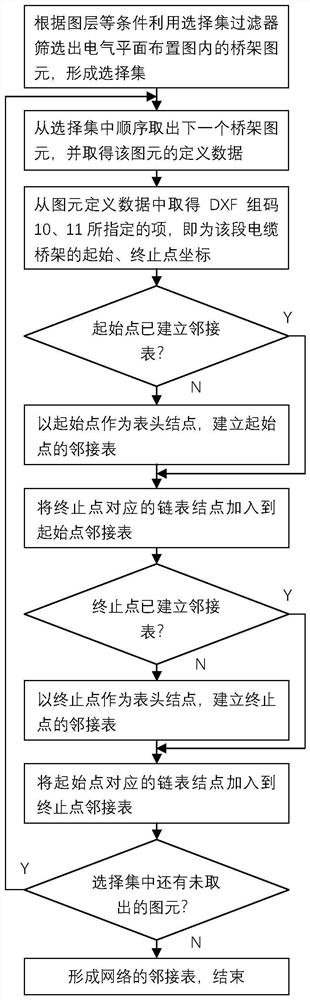

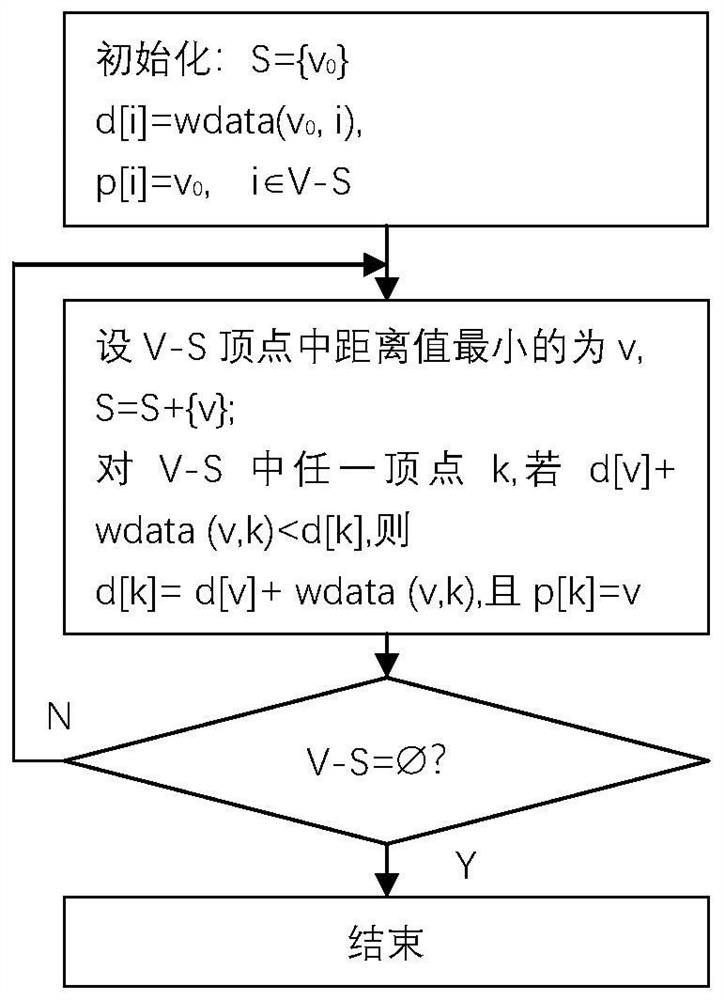

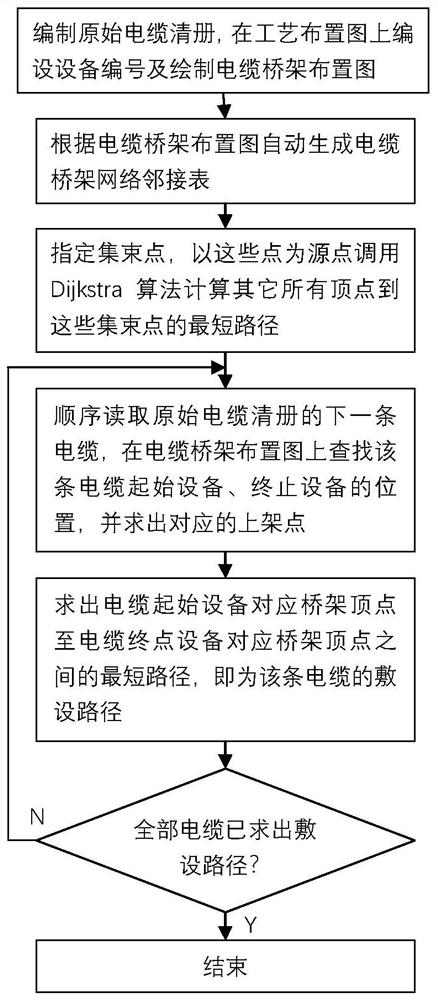

Automatic cable laying method and storage medium

InactiveCN112332306AOvercoming the disadvantages of manually inputting cable tray network dataSmall amount of calculationApparatus for laying cablesCable trayElectric cables

The invention belongs to the field of cable laying, and particularly relates to an automatic cable laying method and a storage medium. The method comprises the steps: preparing an original cable list;drawing an electrical plane arrangement diagram; forming a cable bridge arrangement diagram; generating a cable bridge network adjacency list according to the cable bridge arrangement diagram; calculating the shortest path between vertexes; reading the next cable of the original cable list in sequence; solving a laying path of the cable; and judging whether the laying paths of all cables are solved or not. According to the technical scheme of the invention, the bridge information can be automatically extracted through the cable bridge arrangement diagram, so as to complete the automatic laying of the cable.

Owner:JIANGSU LONG LEAPING ENG DESIGN

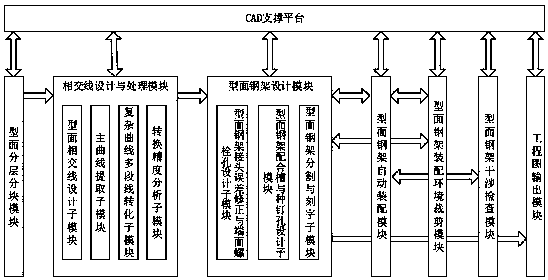

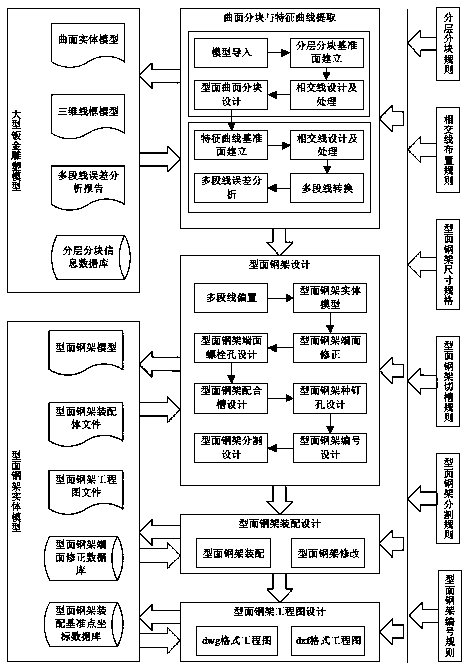

Intelligent design system and method for sheet metal sculpture profile steel frame

ActiveCN107145643AReduce Design WorkloadDesign fasterGeometric CADOrnamental structuresIntelligent designGraphics

The invention discloses an intelligent design system for a sheet metal sculpture profile steel frame. Based on a CAD design platform, firstly a design reference surface is established according to an arrangement rule of the profile steel frame based on a profile curved surface of a sheet metal sculpture; the design reference surface is crossed with the profile curved surface to obtain a design feature curve of the profile steel frame; the feature curve of the profile steel frame is processed to obtain a main curve of the feature curve; the feature curve is converted into multiple line segments by adopting an interpolation method; interface design of the profile steel frame is finished by adopting a curve offset method; physical model design of the profile steel frame is finished by adopting a tensile modeling method; according to the arrangement rule of the profile steel frame, cross section graph design of a matching groove of the profile steel frame is carried out; cutoff design of the matching groove is finished; interference checking is performed by adopting a virtual assembling method; an uncompleted matching groove cutoff position is checked; interference part processing is finished; and finally the design of the profile steel frame is finished. The design speed can be effectively increased and the design workload of designers is greatly reduced.

Owner:SOUTHEAST UNIV

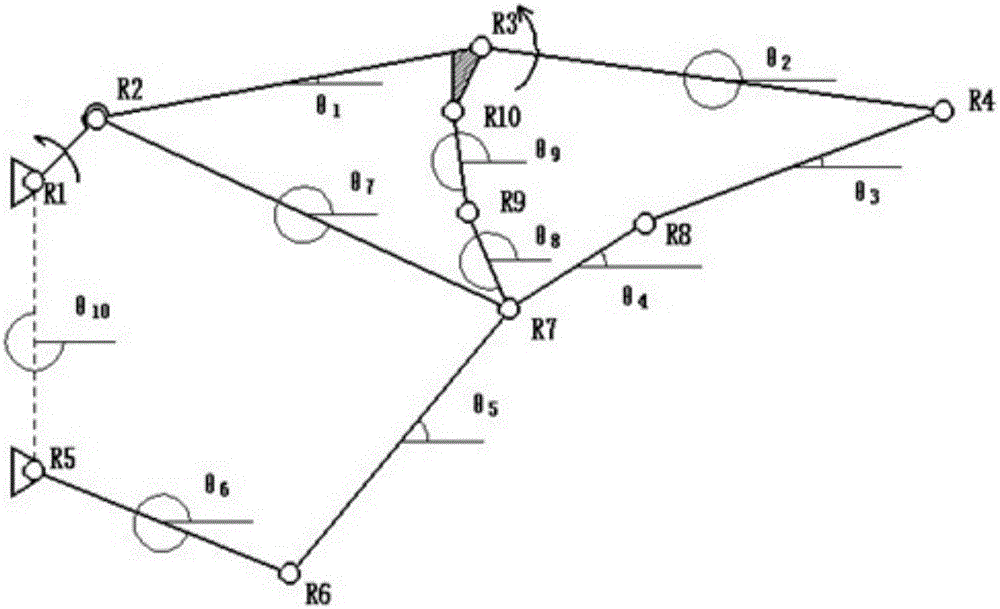

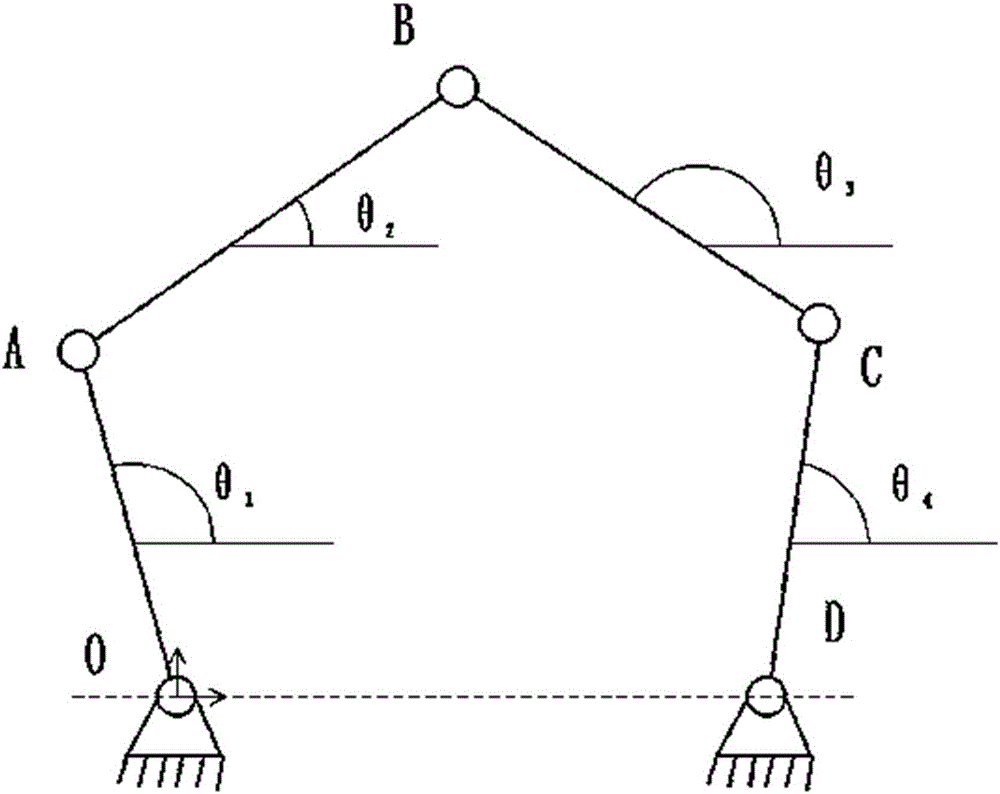

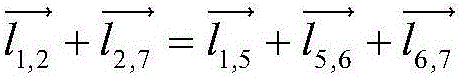

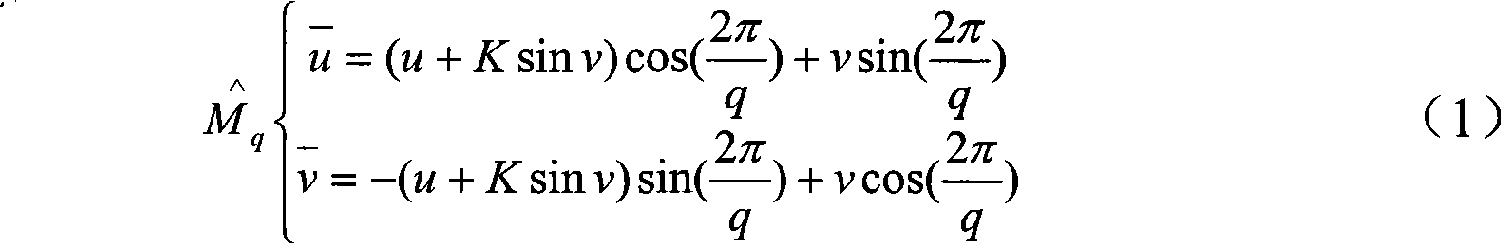

Kinematic and dynamic mixed dimensionality reduction solving method for 10-bar underactuated mechanism

InactiveCN105975733ASolve kinematic problemsImprove stabilitySpecial data processing applicationsC bandingKinematics

The invention provides a kinematic and dynamic mixed dimensionality reduction solving method for a 10 bar underactuated mechanism. The method comprises the following steps: step 1, a 10 bar mechanism mathematical model is established according to a Radarsat 2 battery panel deployment mechanism, wherein Radarsat 2 is a high resolution commercial radar satellite carrying a C band sensor; step 2, corresponding geometric equation is created according to the 10 bar mechanism mathematical model; step 3, the geometric equation is solved, and a dynamic model is established through combination with the Euler Lagrange equation; step 4, dynamic parameters of a 10 bar mechanism are solved according to the dynamic model. With adoption of the method, the dynamic parameters of the 10 bar mechanism can be solved, sizes of rod members of the Radarsat 2 battery panel deployment mechanism are optimized, and the battery panel deployment process stability and reliability in actual application satellite deployment process are improved.

Owner:SHANGHAI JIAO TONG UNIV

Simulation system for industrial design

InactiveCN105022657AAvoid design riskReduce productionEducational modelsSoftware simulation/interpretation/emulationDesign planSoftware system

The invention relates to a simulation system for industrial design. The simulation system comprises a hardware device and a software system, wherein the software system comprises a virtual reality editor and VRP-IE for converting a three-dimensional file to a file capable of being browsed in an IE (internet explorer); and the hardware device comprises a processing system, a three-dimensional display system and an interactive apparatus. The contributions of the simulation system are that product design and release as well as design assessment and check can be realized. A designer is helped to conveniently modify a design plan in time, so that the research and development costs are reduced and the research and development speed is increased. The interaction between a virtual scene and a user is realized, so that the internal structure of a product can be carefully observed; and meanwhile, the functions of virtual assembly, internet release and the like of the product also can be realized, so that the resource waste of enterprises in the industrial design process is reduced to the maximum extent, and the research and development cycle of the enterprises in the industrial design process is shortened to the maximum extent.

Owner:FOSHAN SIXVECTOR DESIGN & CONSULTANT CO LTD

Method for preparing 3D ornament based on poor-chaos graph

InactiveCN101533530AFast designJewelry with high precision3D-image rendering3D modellingMoulding deviceVisual field loss

The invention discloses a method for preparing the 3D ornament based on the poor-chaos graph, including the steps: (1) generating the poor-chaos graph; (2) treating poor-chaos graph; (3) generating 3D point cloud; (4) performing the grid reconstruction for the 3D point cloud to form the grid curved surface; (5) closing the grid curved surface to form the 3D closed curved surface; (6) converting the 3D closed curved surface into a file capable of be identified by a rapid moulding device, inputting the file to the rapid moulding device for forming and completing the preparation of the3D ornament. The invention has outstanding characteristics: the 2D poor-chaos graph adopts the curved surface forming way to perform the 3D closed curved surface, the data is transmitted to the rapid moulding device for forming, the designed speed is rapid, the ornament has high precision and changeful graph, thus effectively expanding the design visual field and forming rich and novel ornament.

Owner:ZHEJIANG SCI-TECH UNIV

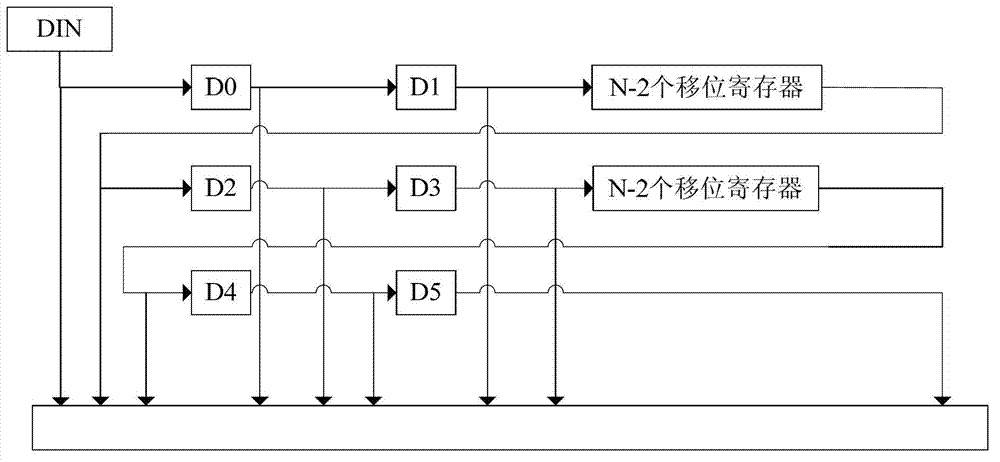

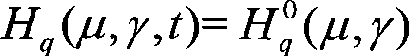

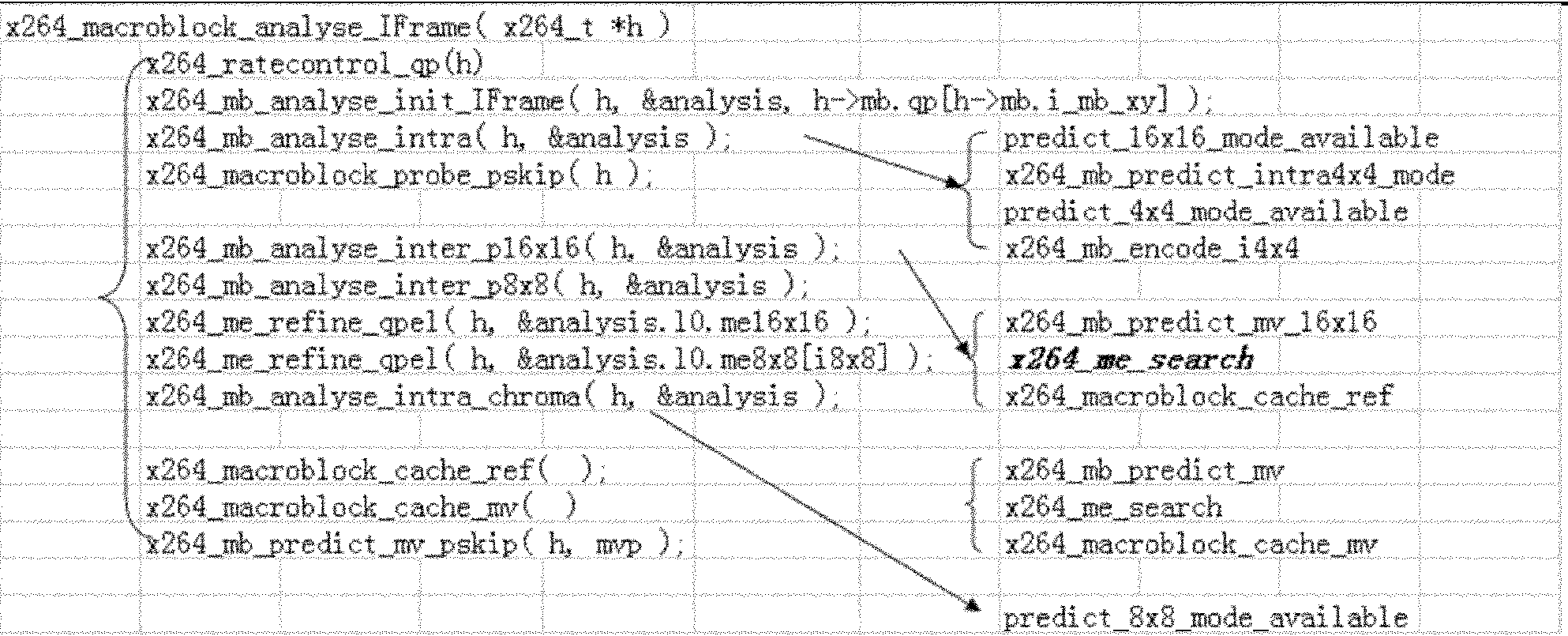

Inter-frame predictor circuit for video encoder and method for implementing same

InactiveCN102075762ADesign fasterTelevision systemsDigital video signal modificationComputer architectureVideo encoding

The invention discloses a method for implementing an inter-frame predictor for a video encoder. The method comprises the following steps of: mapping each functional block of the inter-frame predictor of the video encoder which is described by a high-level program language algorithm into hardware logic description consisting of arithmetic operator units; and generating a hardware integrated circuit of the inter-frame predictor by the hardware logic description consisting of the arithmetic operator units. By the method, the speed for implementing the integrated circuit of the inter-frame predictor can be increased. The invention also discloses the inter-frame predictor acquired by the method.

Owner:PEKING UNIV SHENZHEN GRADUATE SCHOOL

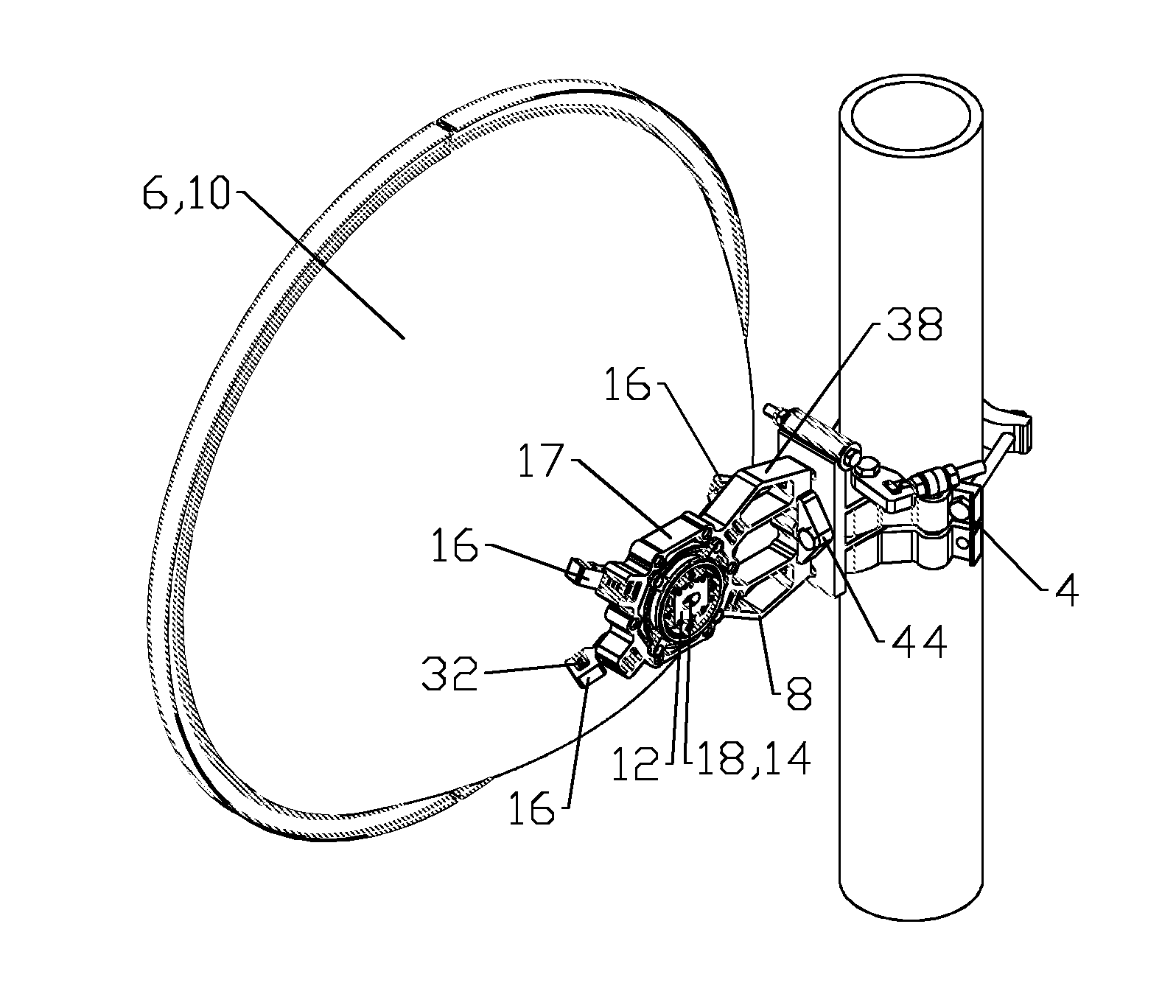

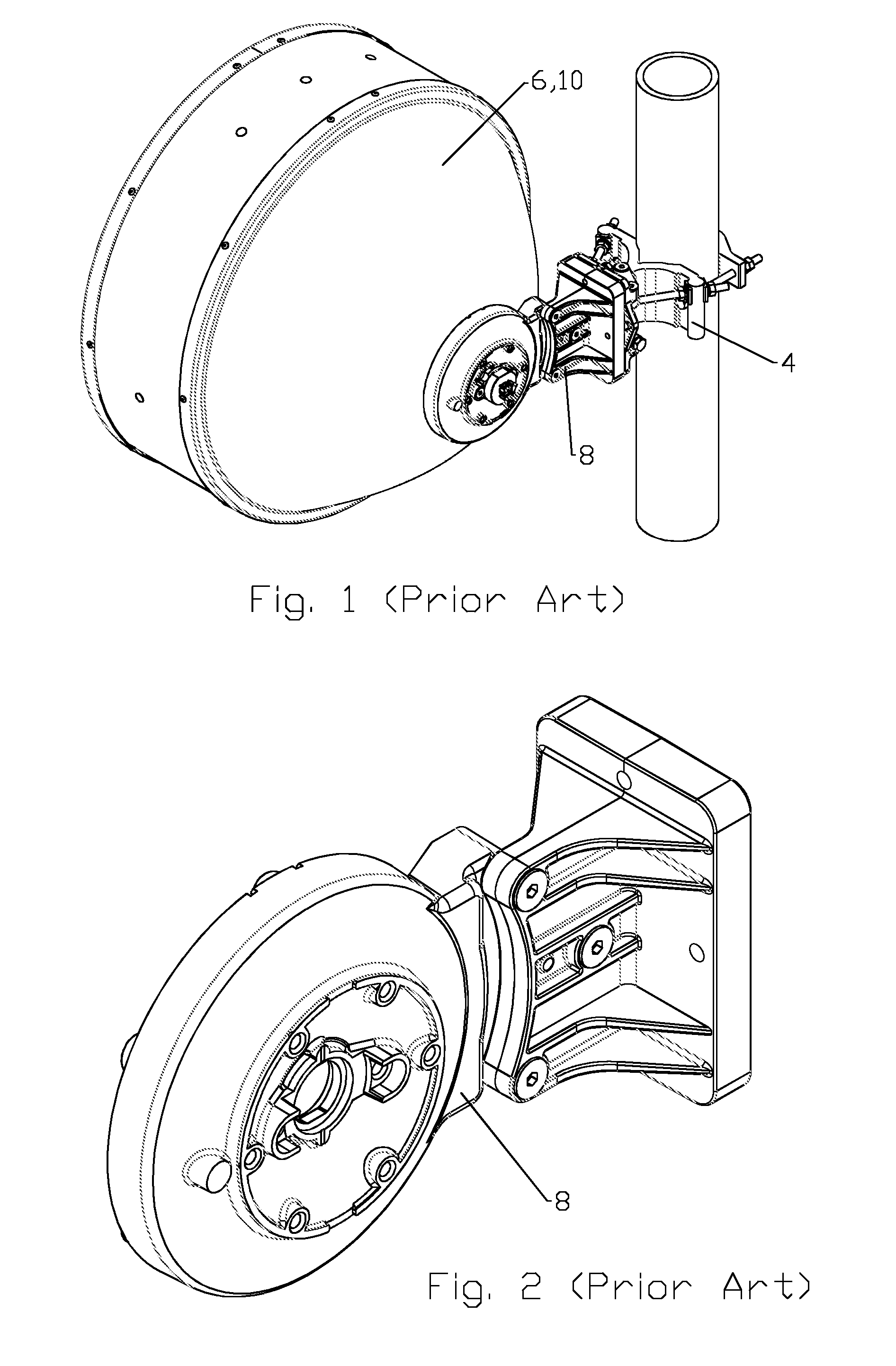

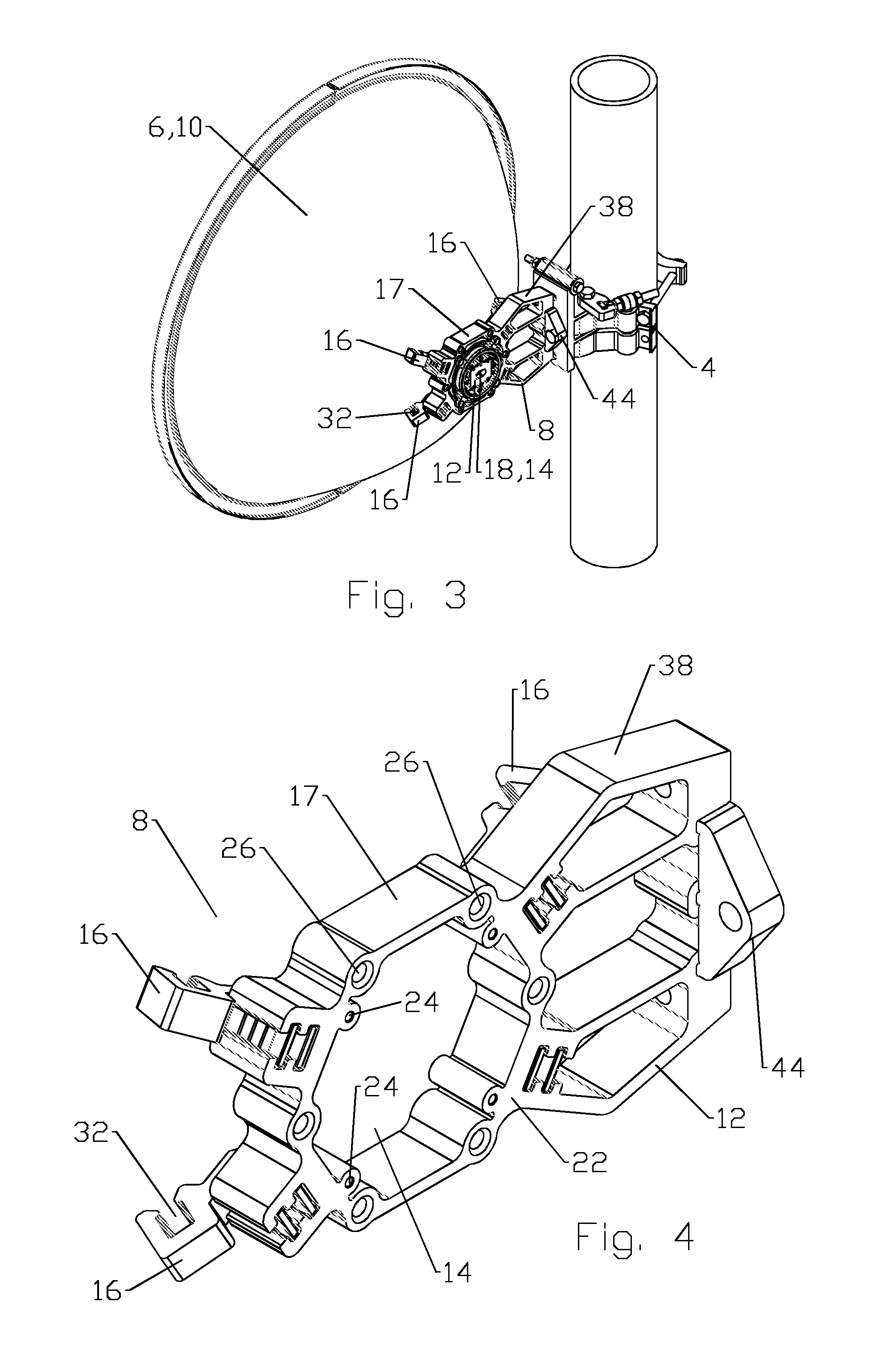

Mounting hub for antenna

ActiveUS20140347246A1Low costLower manufacturing requirementsMetal rolling stand detailsAntenna supports/mountingsElectrical and Electronics engineeringFastener

An antenna hub for a reflector dish has a frame with a feed aperture. A plurality of feet are coupled to the frame; each of the feet provided with a dish fastener coupling axis normal to a dish surface contacting each of the feet when the reflector dish is seated upon the feet, the feed bore of the reflector dish aligned coaxial with the feed aperture. The frame and feet may be formed via extrusion.

Owner:COMMSCOPE TECH LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com