Rapid design method of tyre mould

A design method and mold design technology, applied in forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems affecting the mold production preparation cycle, low design efficiency of tire molds, low mold standardization, etc., to shorten production preparation. The effect of cycle, rapid design and drawing, saving manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

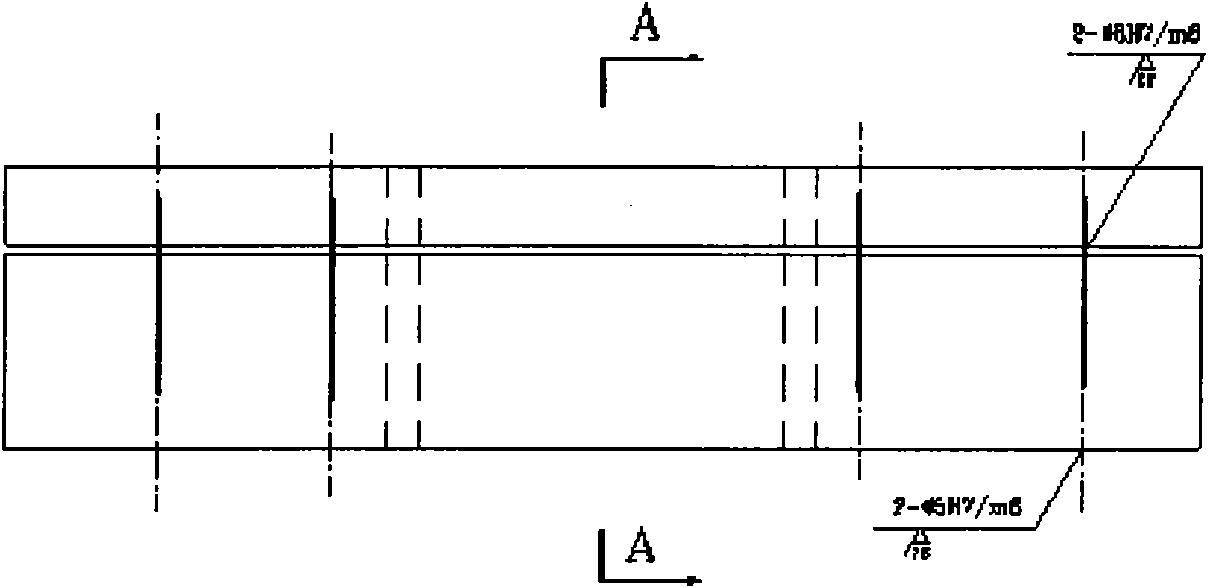

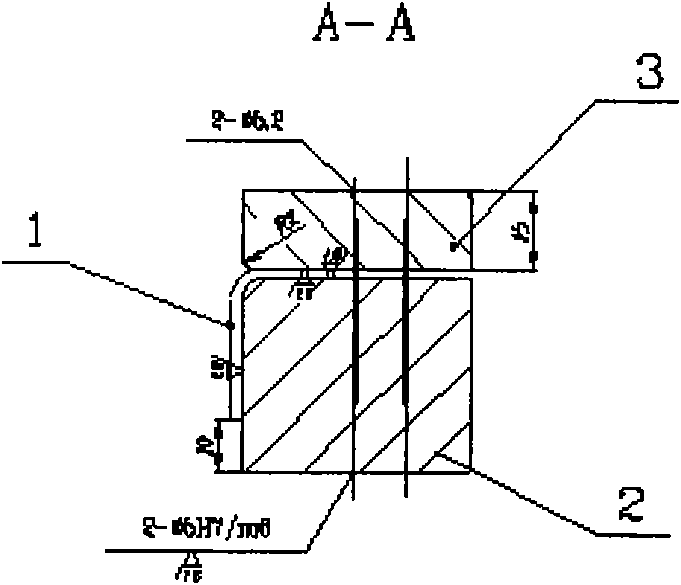

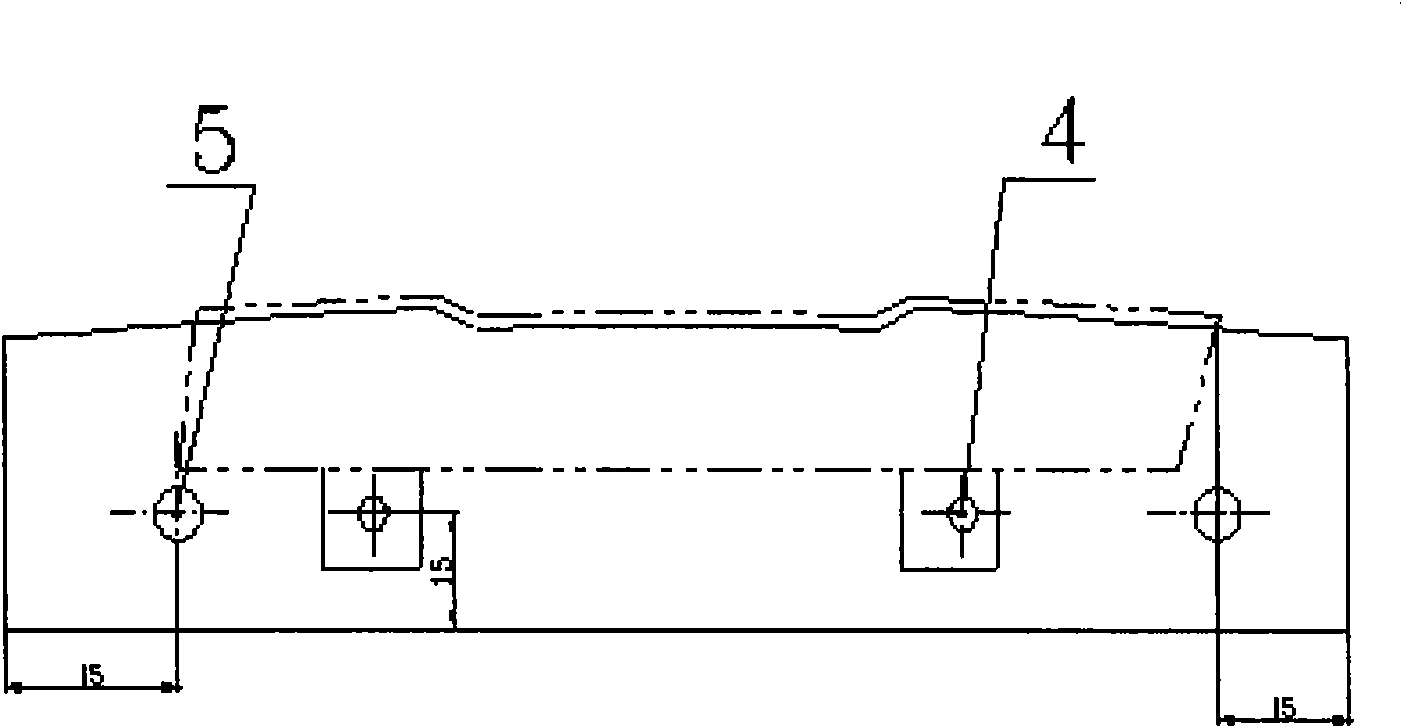

[0015] refer to Figure 1-Figure 3 . According to the present invention, on the basis of absorbing the experience of existing tire mold design, the typical and reasonable tire structure is summarized, the shape expression related to the mold tire and the product is simplified, and the quantity, direction, positioning form, etc. Features to classify, draw and build CAD libraries of typical structures of various types of tires. for example figure 2 The typical structural form of the molded tire with single-flange open angle and hole positioning shown. The profile of the upper and lower mold tires, the profile is flat or curved surface with small curvature, single curved edge, all are right angles or open angles, and no non-working sharp edges are rounded R, the size is determined according to the template, mold body 2, cover The corresponding profile of the plate 3, belt depression, curved surface features, detailed expression features such as the graphics, position, and tol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com