Charging design method of solid rocket engine

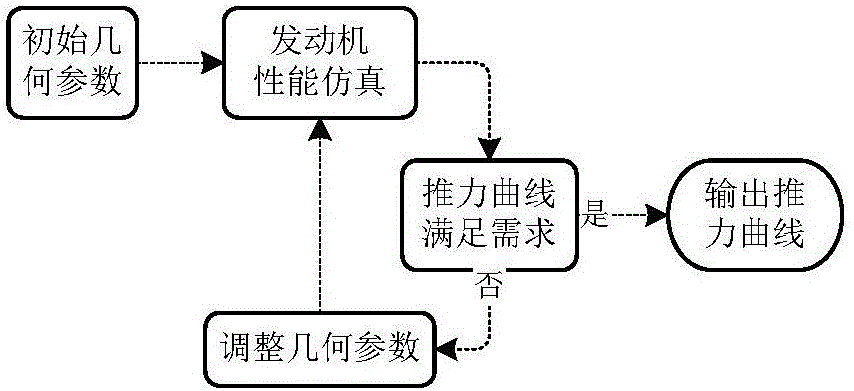

A design method, solid rocket technology, applied in design optimization/simulation, calculation, special data processing applications, etc., can solve the problems of relying on experience, low efficiency of the solid rocket motor charge design process, etc. The effect of reducing the number of simulations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

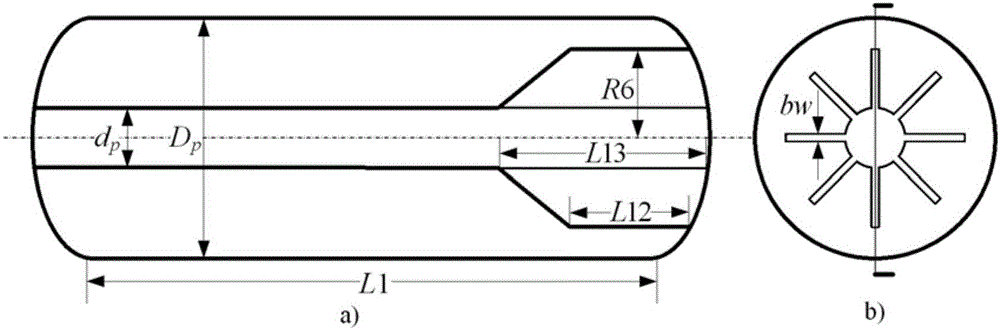

[0048] The accompanying drawings constituting a part of this application are used to provide further understanding of the present invention, and the schematic embodiments and descriptions of the present invention are used to explain the present invention, and do not constitute an improper limitation of the present invention.

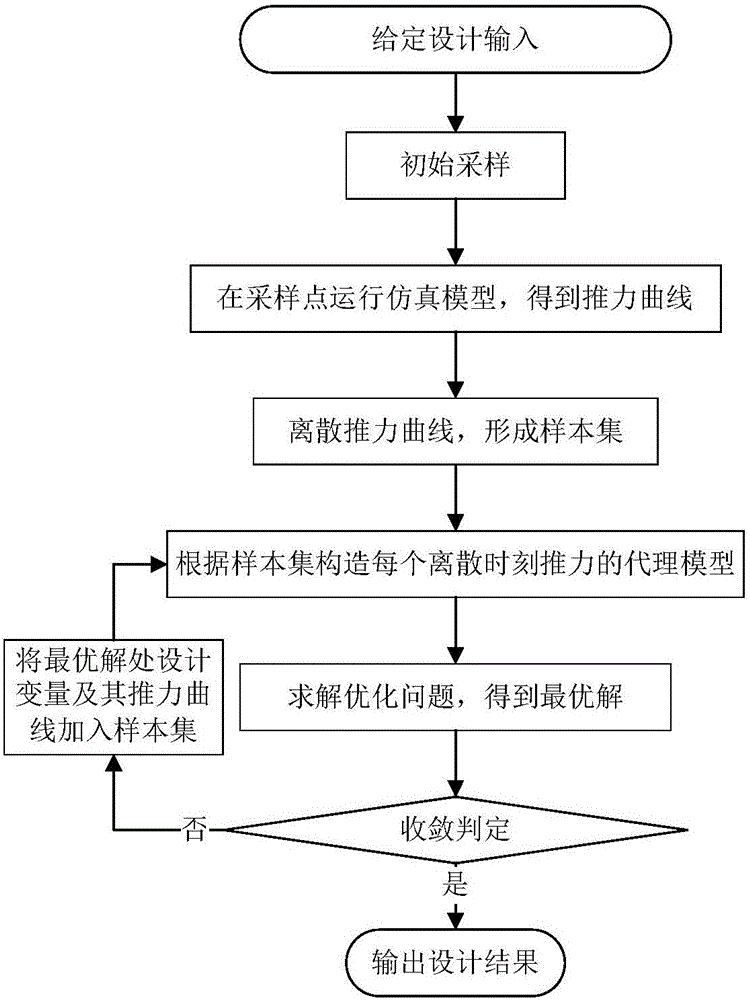

[0049] For ease of understanding, the brief description of the method provided by the present invention is as follows: the design method provided by the present invention first discretizes each thrust curve corresponding to the overall requirement into several points, constructs a proxy model through each discrete point, and depicts the thrust curve that varies with time. process. In the process of searching for the optimal solution, the approximation degree of each discrete point to the design index is considered, and the proxy model is updated by reducing the deviation between each discrete point and the design index. This reduces the number of iterati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com