Patents

Literature

109 results about "Design framework" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A design framework is a simple visual structure that helps organize the information and ideas of a problem so you can work on it more effectively. A framework is often composed of a relevant list of categories. These categories are developed from initial research that should be a part of every new project.

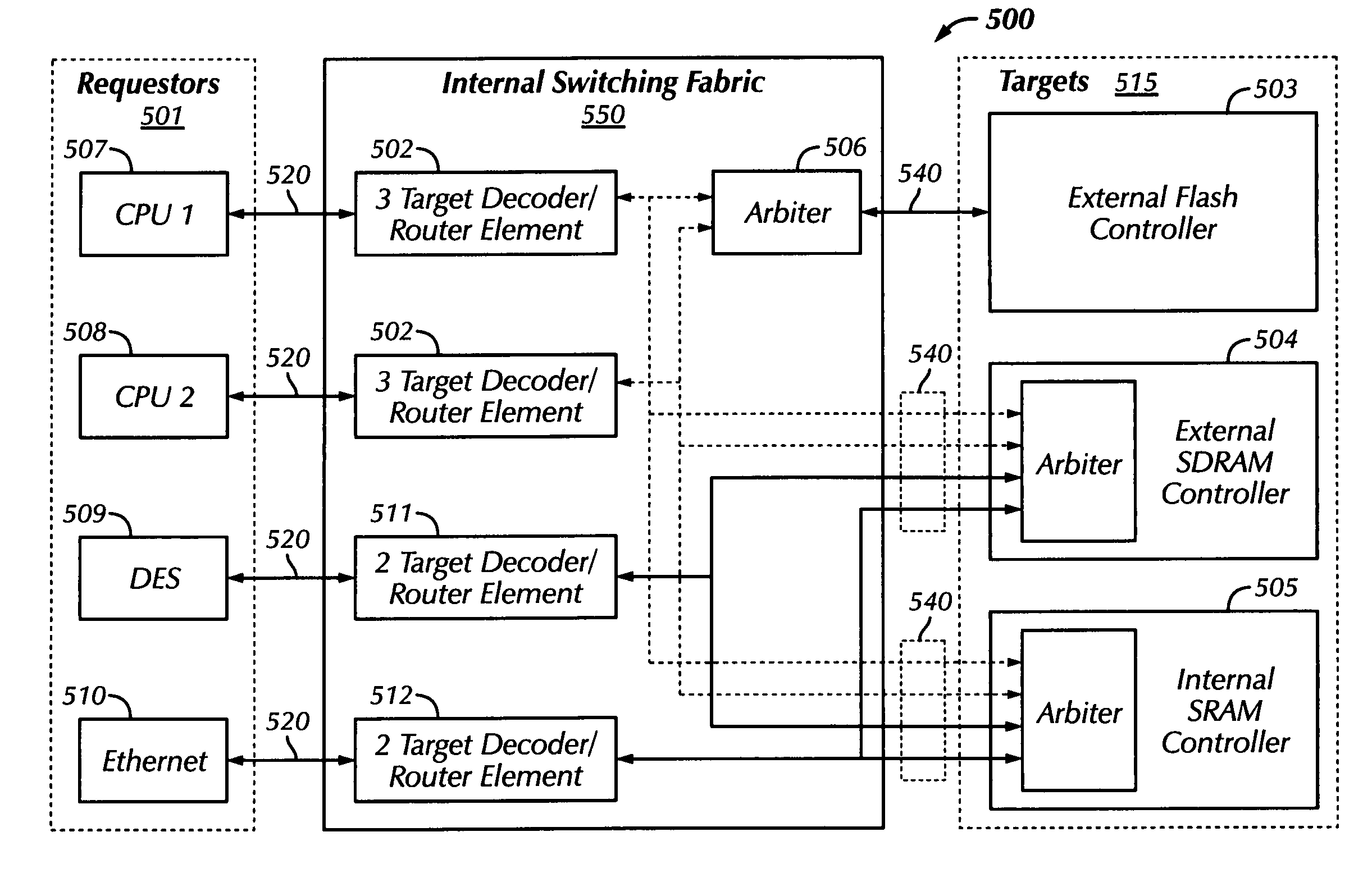

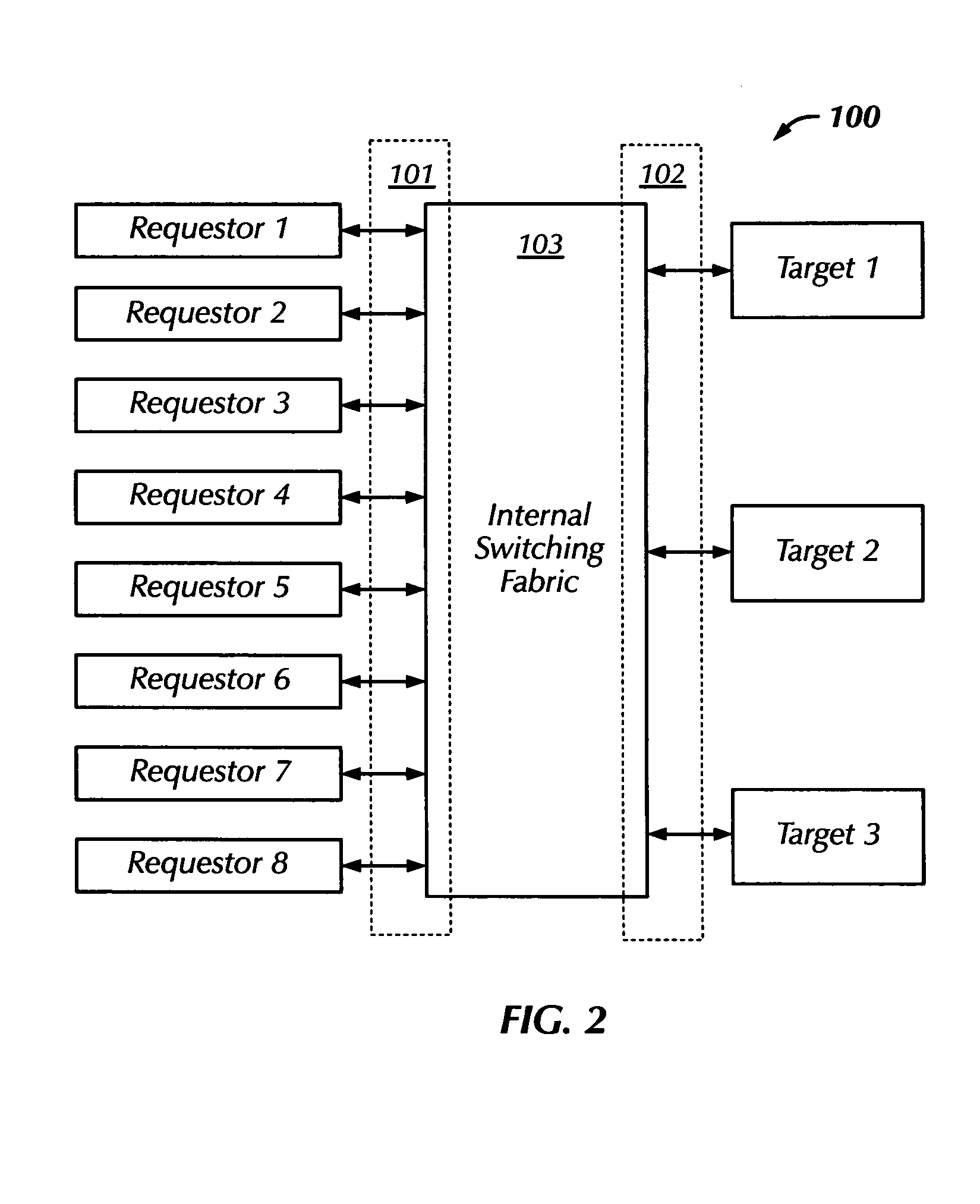

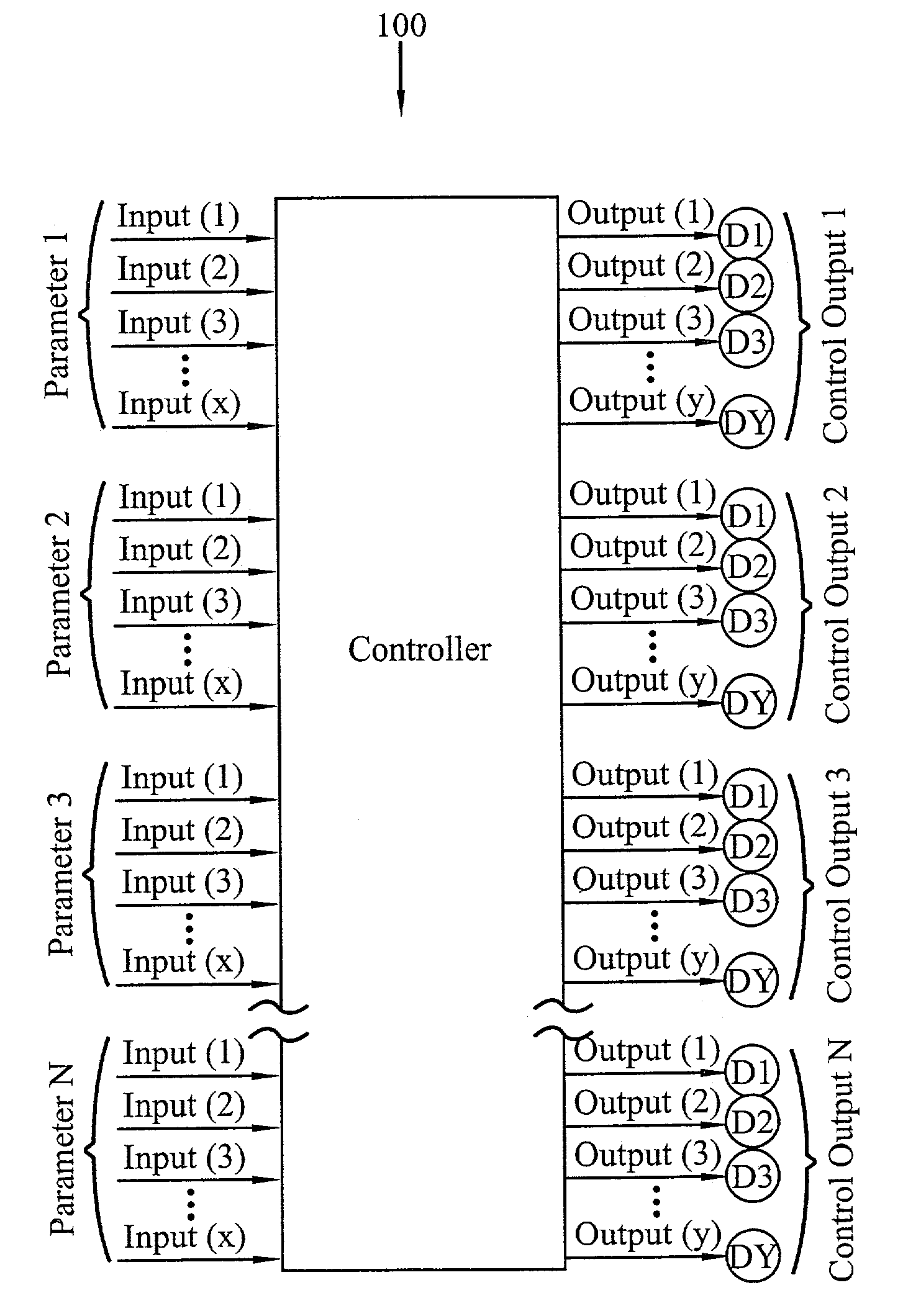

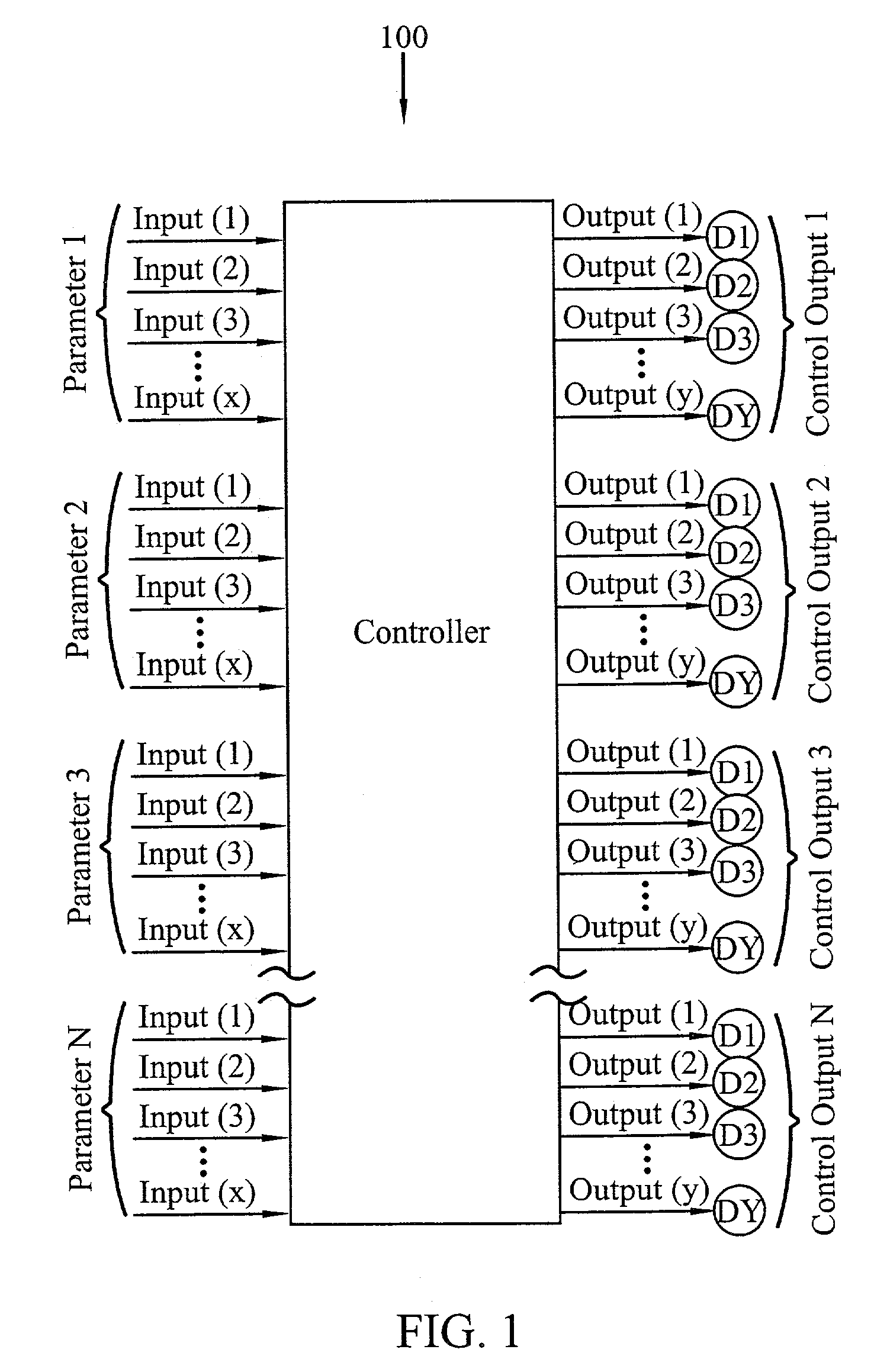

Flexible matrix fabric design framework for multiple requestors and targets in system-on-chip designs

The System-on-Chip (SOC) interconnection apparatus and system discloses an internal switching fabric that interconnects, via standard connection ports, one or more requestors and one or more addressable targets on a single semiconductor integrated circuit. Each target has a unique address space, may or may not have internal arbitration, and may be resident (i.e., on-chip) memory, a memory controller for resident or off-chip memory, an addressable bridge to a device, system, or subsystem, or any combination thereof. Targets and requesters are connected to the internal switching fabric using target and requestor connection ports. The internal switching fabric routes signals between requesters and targets using one or more decoder / router elements that determine which target is the designated target using an internal system memory map. Dedicated arbiters may be included for targets without internal arbitration.

Owner:PALMCHIP CORP

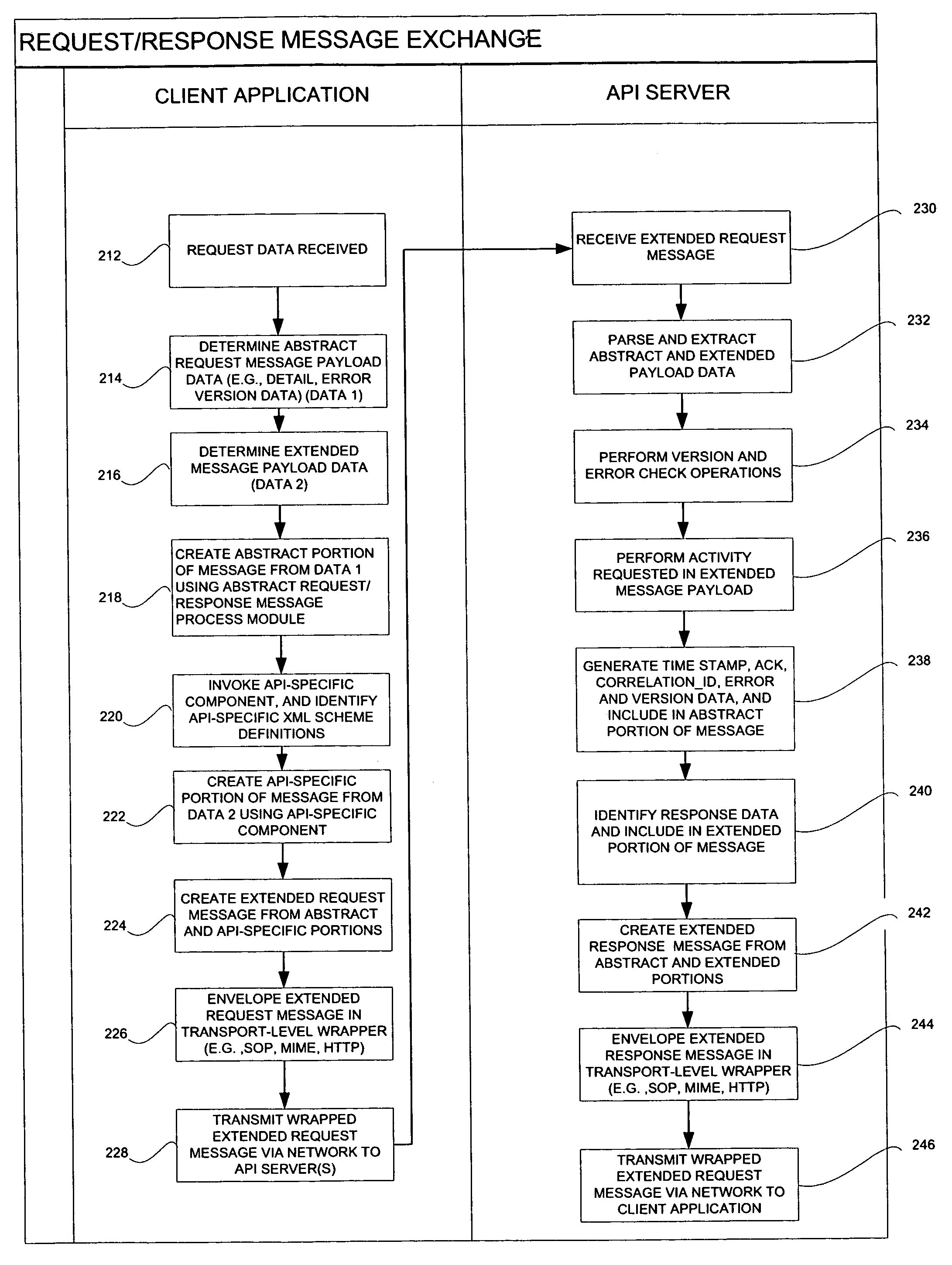

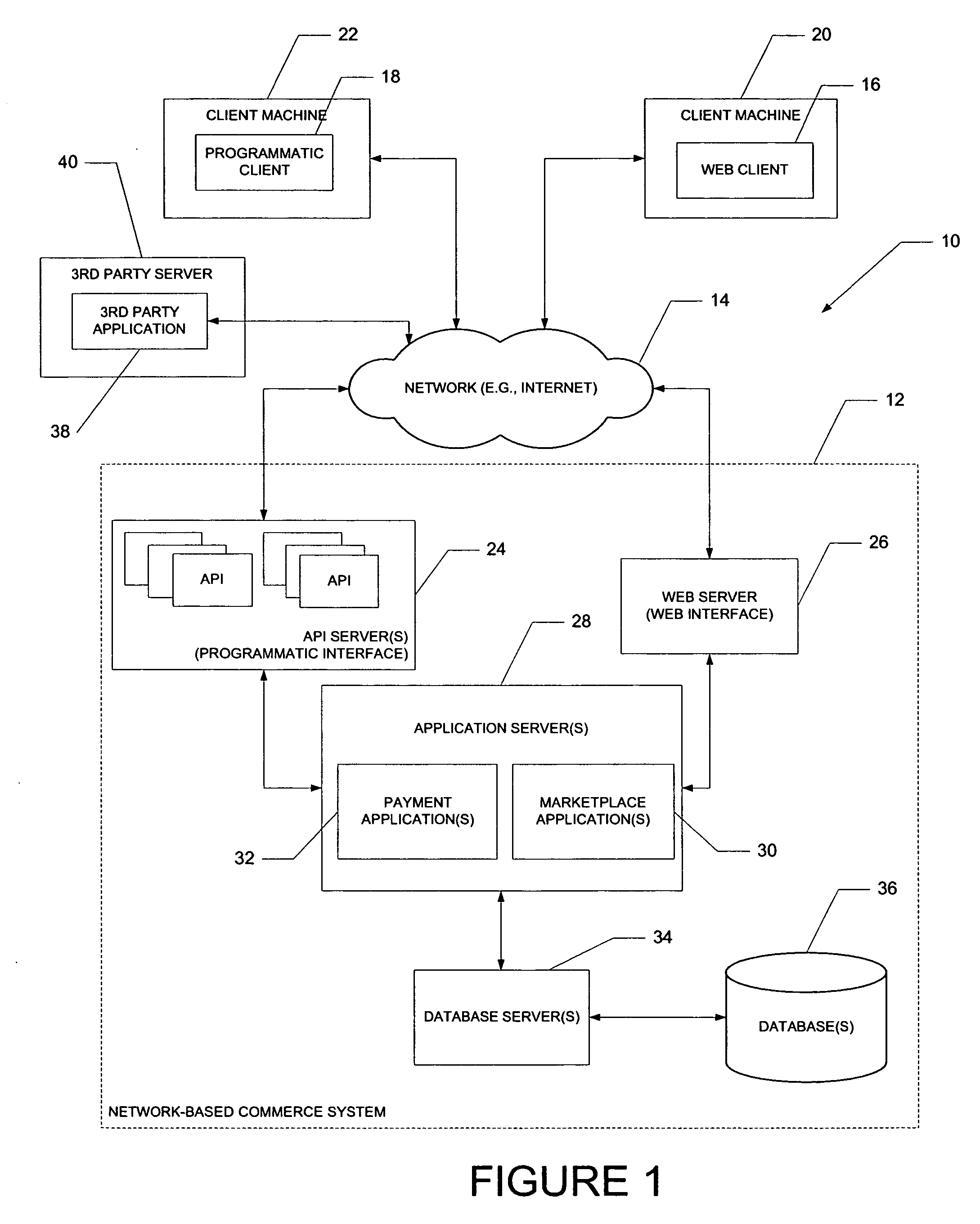

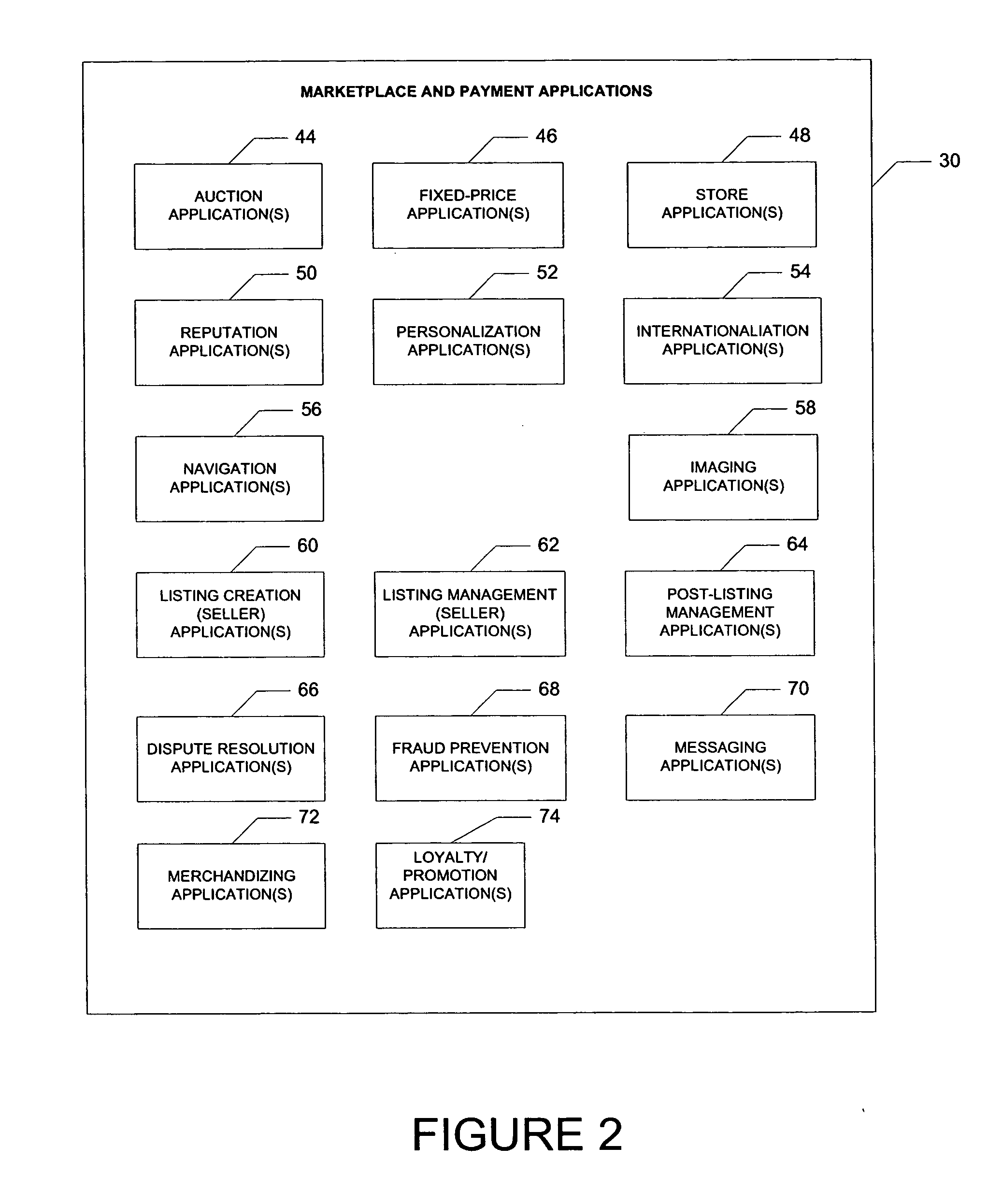

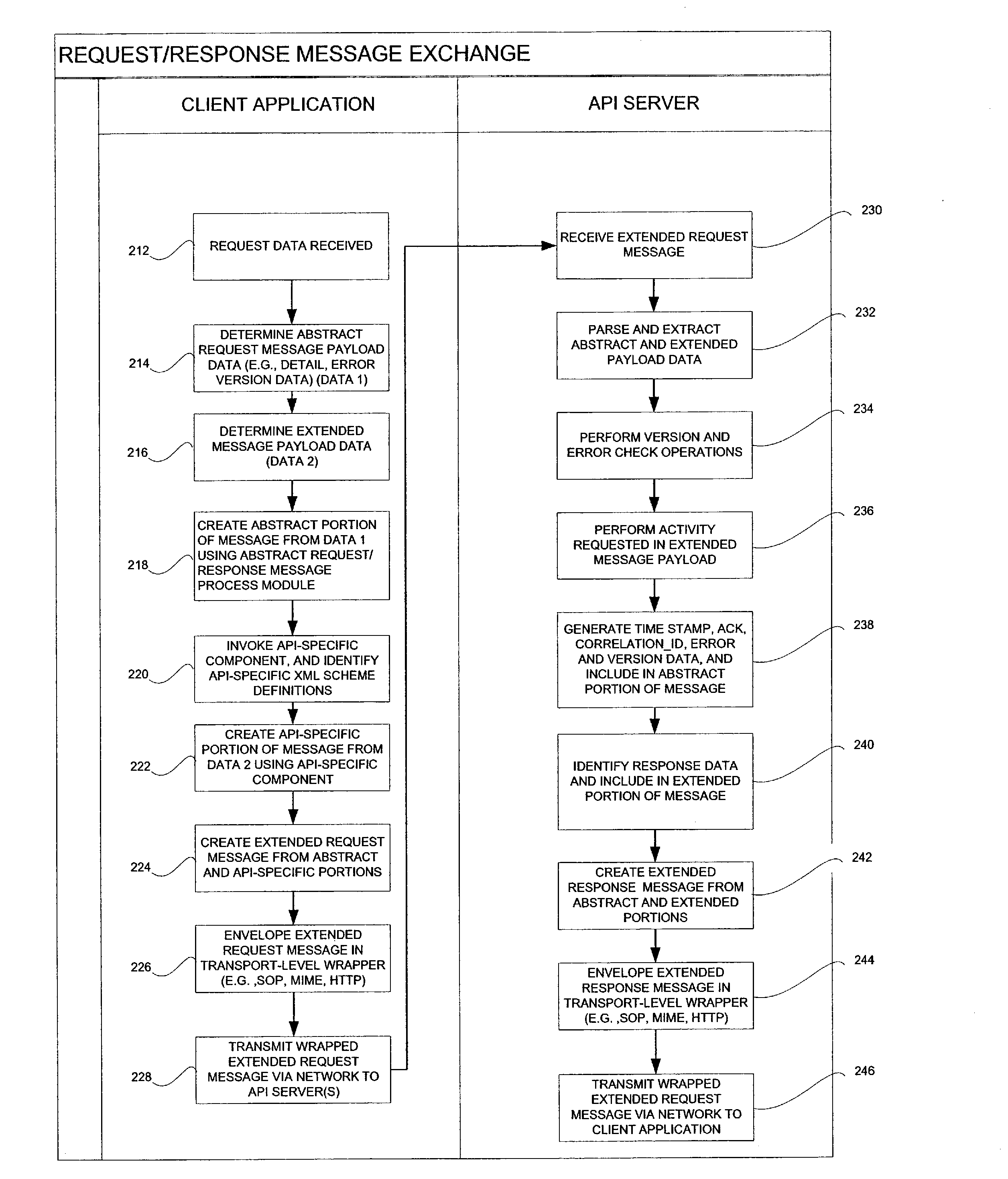

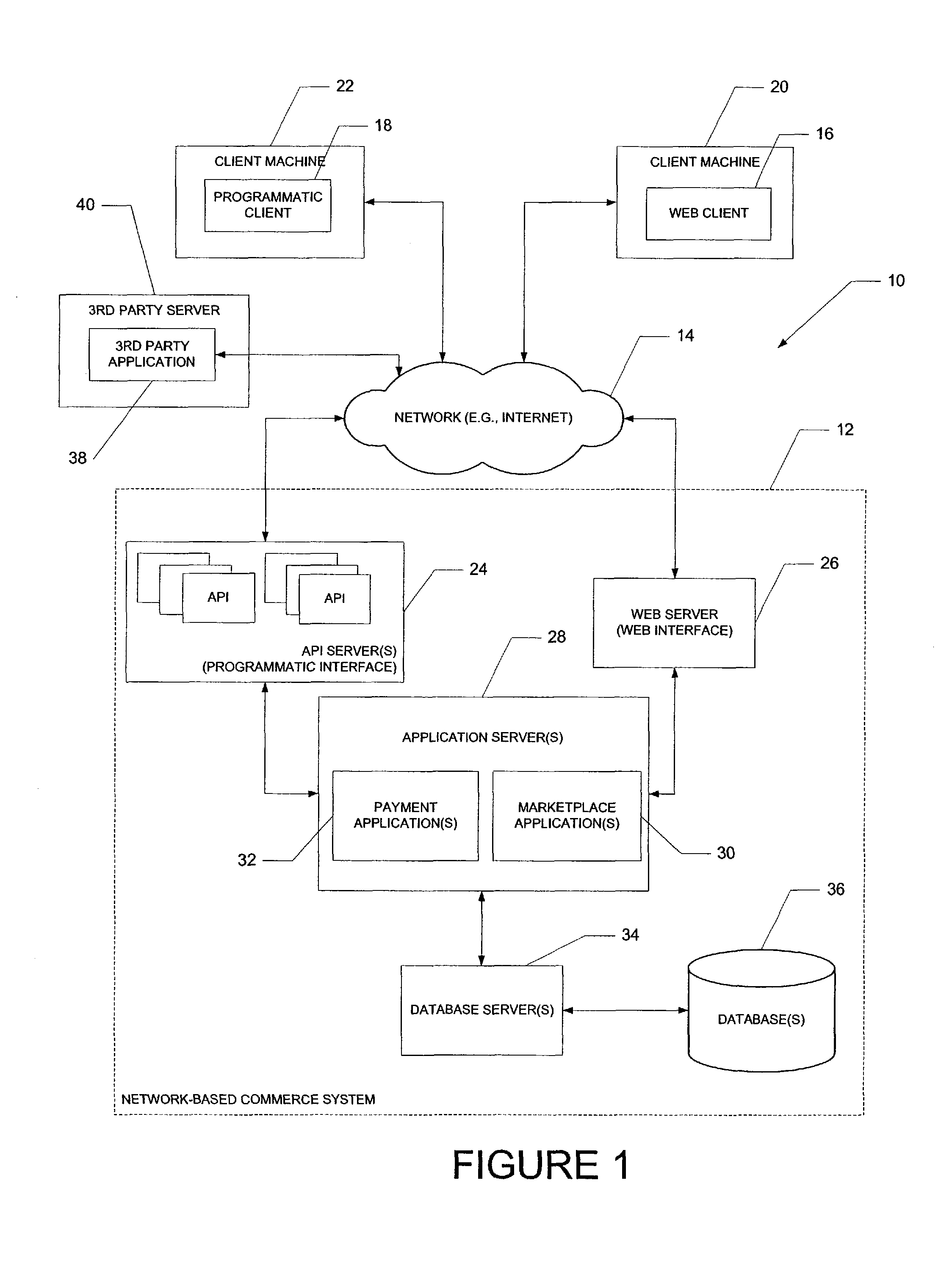

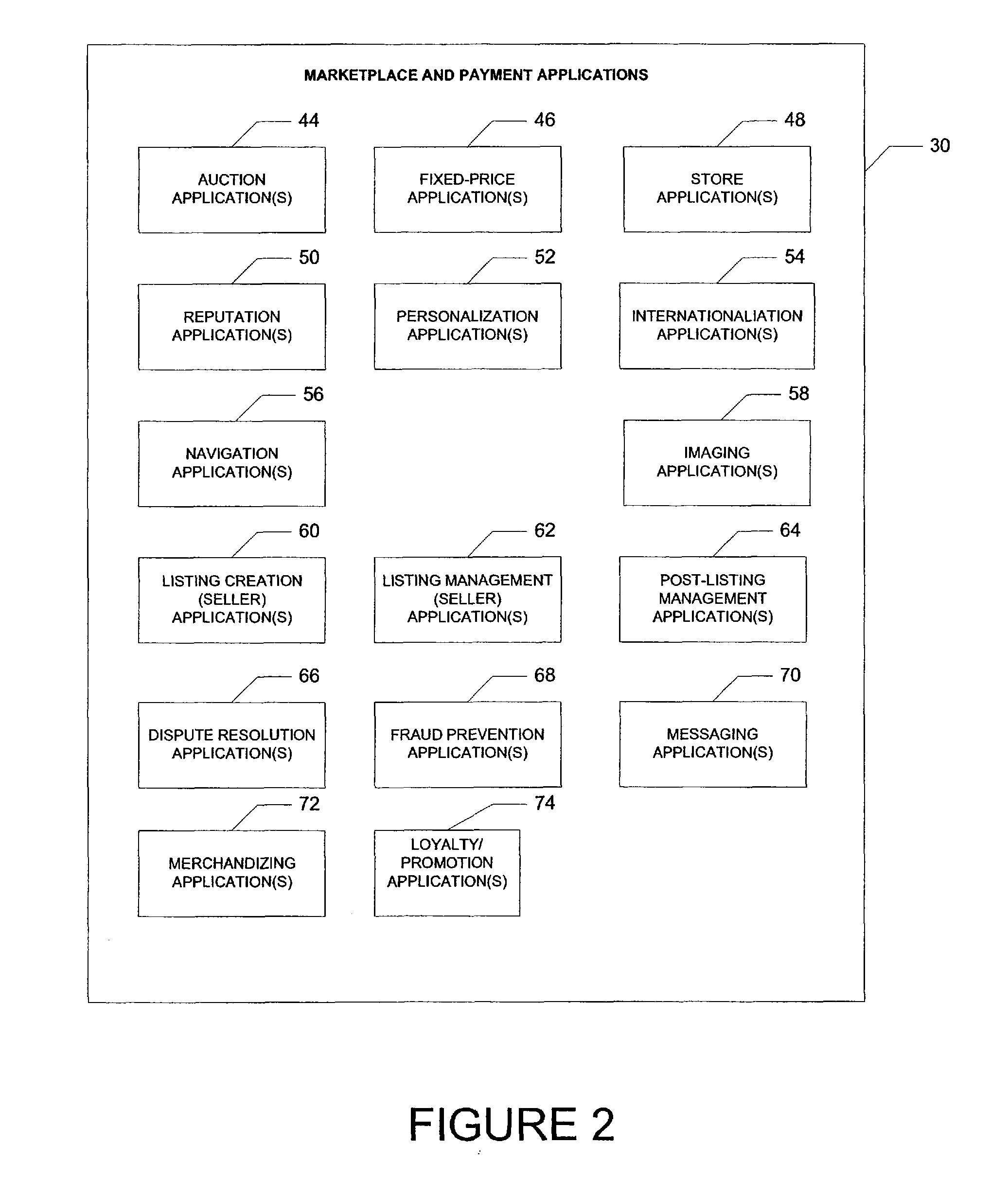

API and business language schema design framework for message exchanges

ActiveUS20050138648A1Facilitate communicationInterprogram communicationTransmissionApplication serverMessage switching

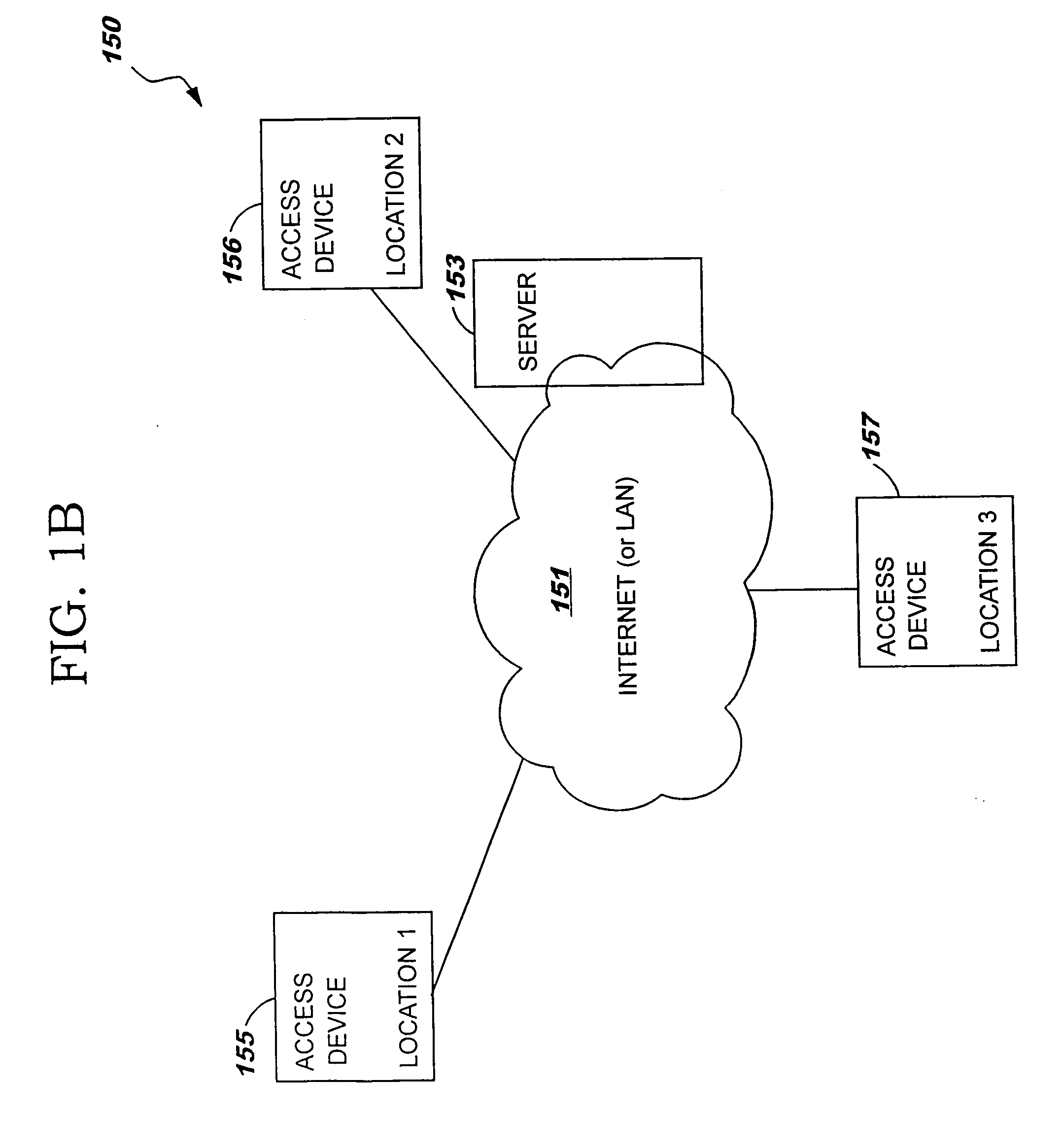

A server system facilitates an exchange of messages with a remote client application. The server system includes a plurality of application servers hosting a plurality of applications. A plurality of Application Program Interfaces (APIs) provides programmatic access to the plurality of applications, each of the APIs being configured to receive request messages compiled by the remote client application. First and second request messages, respectively addressed to first and second APIs of the plurality of APIs by a remote client application, each comprise at least one common data component. Further, the first request message includes a first payload specific to the first API, and the second request message includes a payload specific to the second API.

Owner:EBAY INC

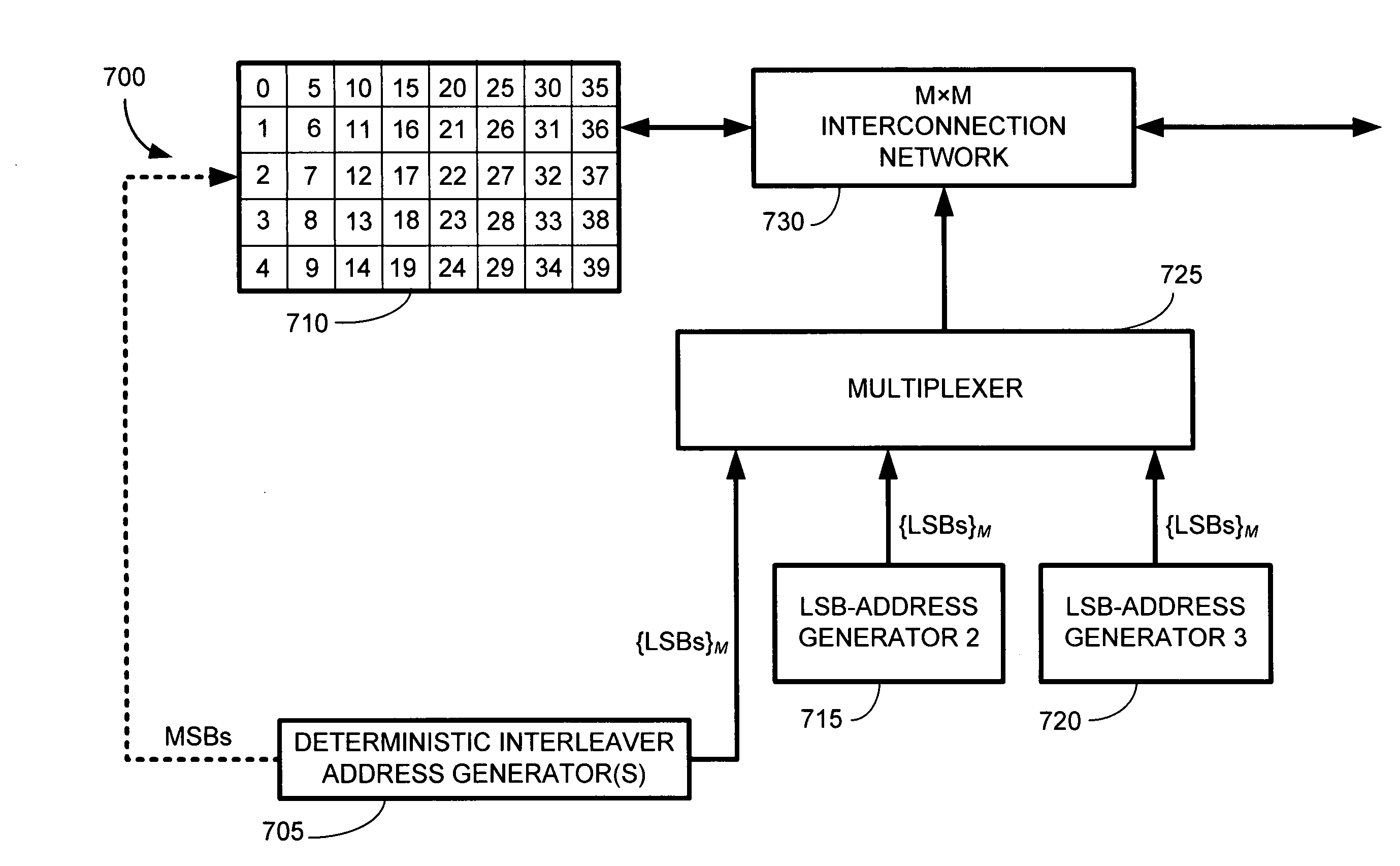

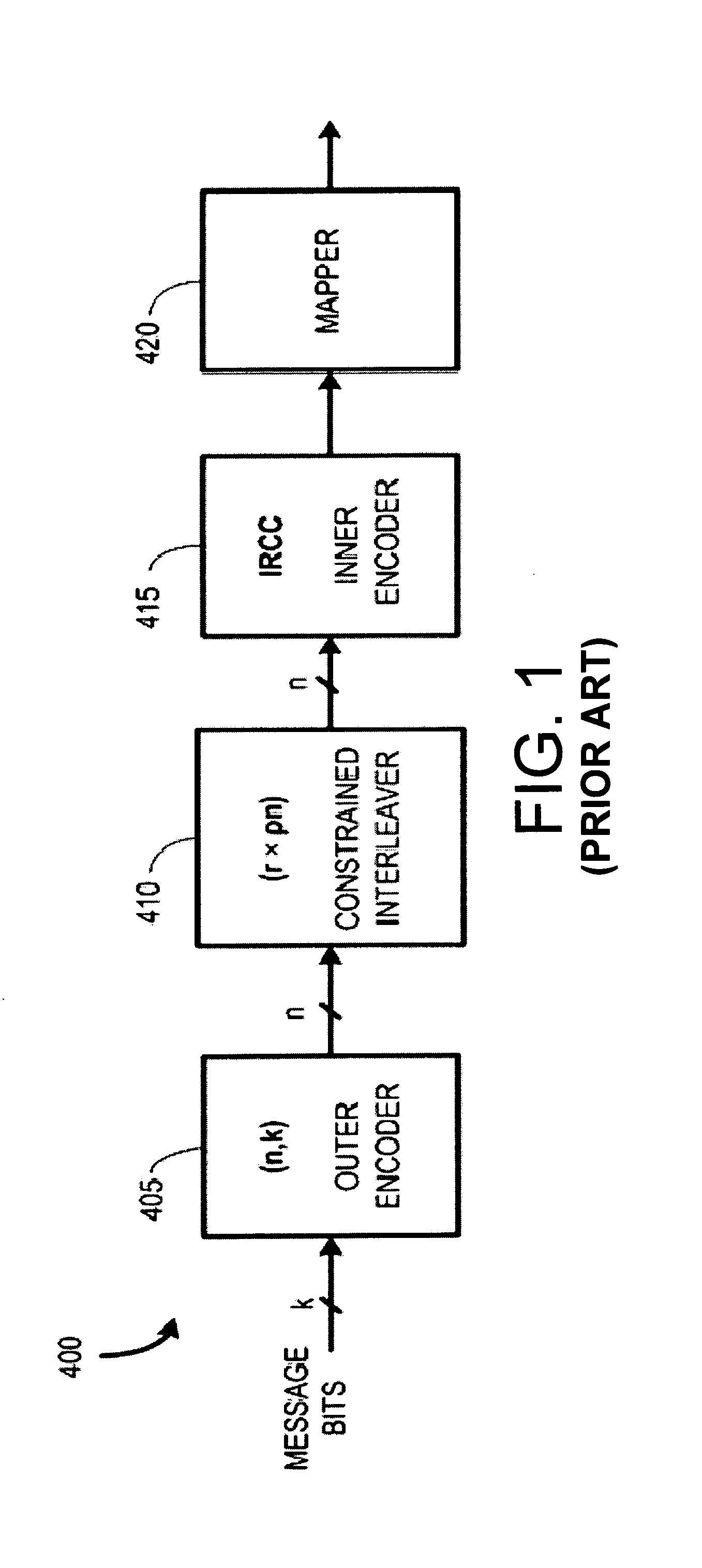

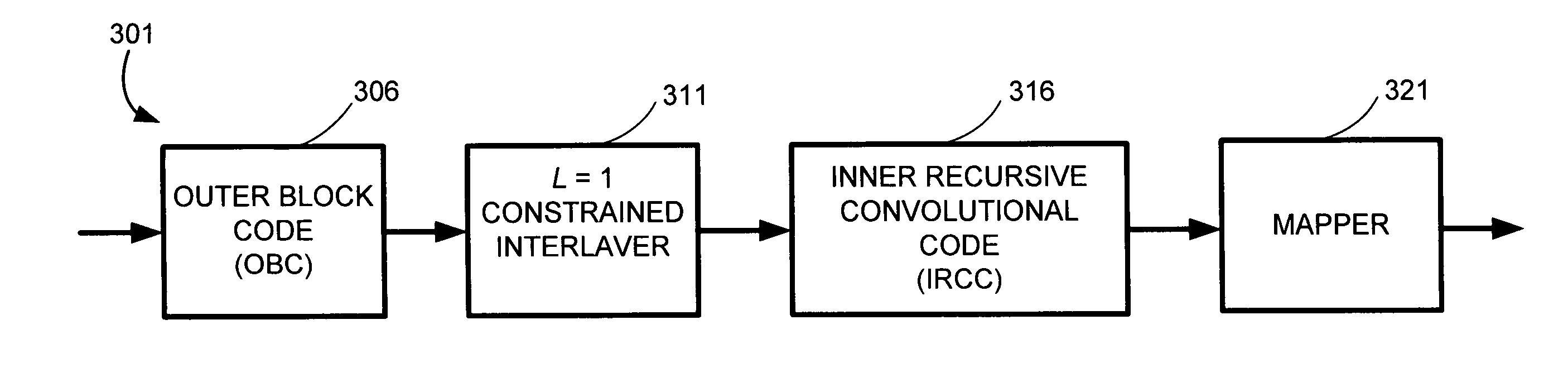

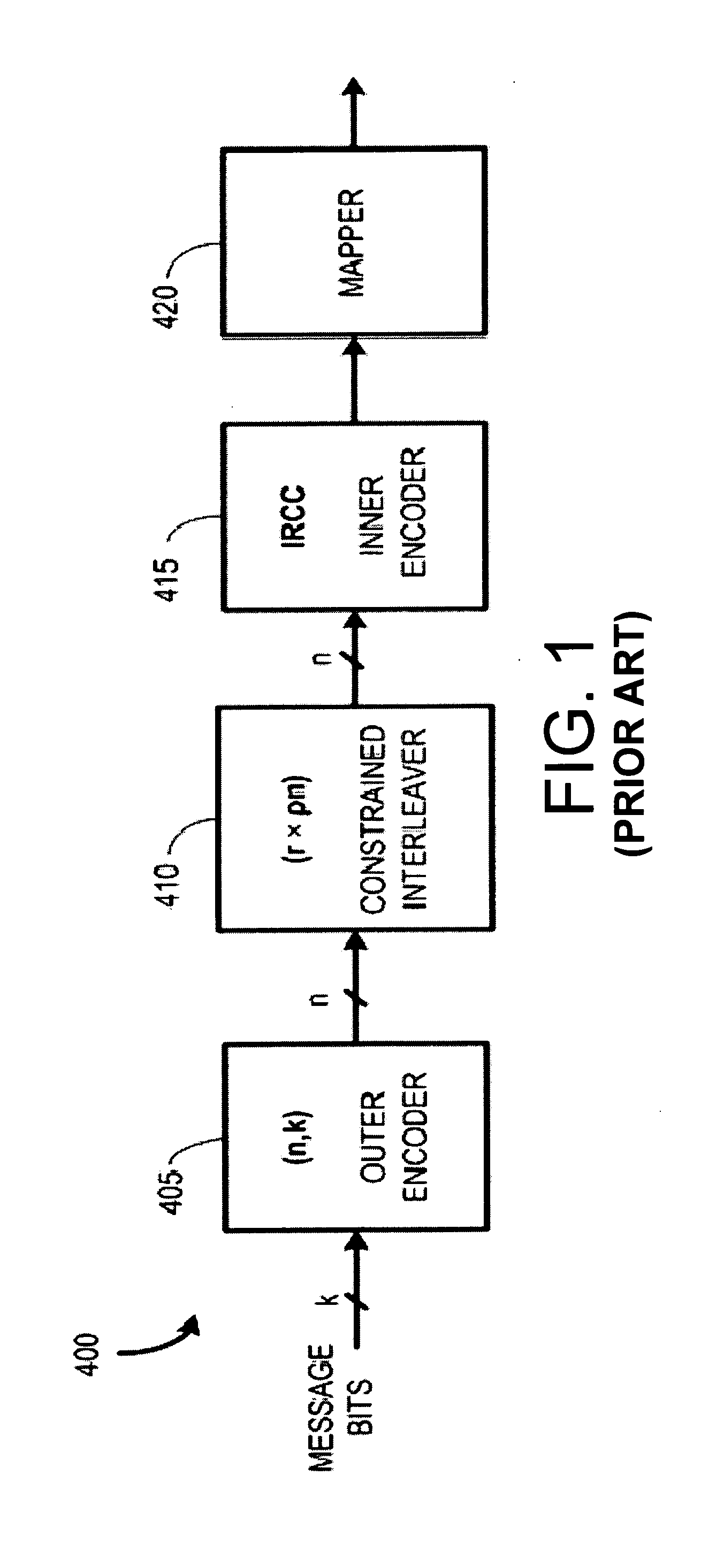

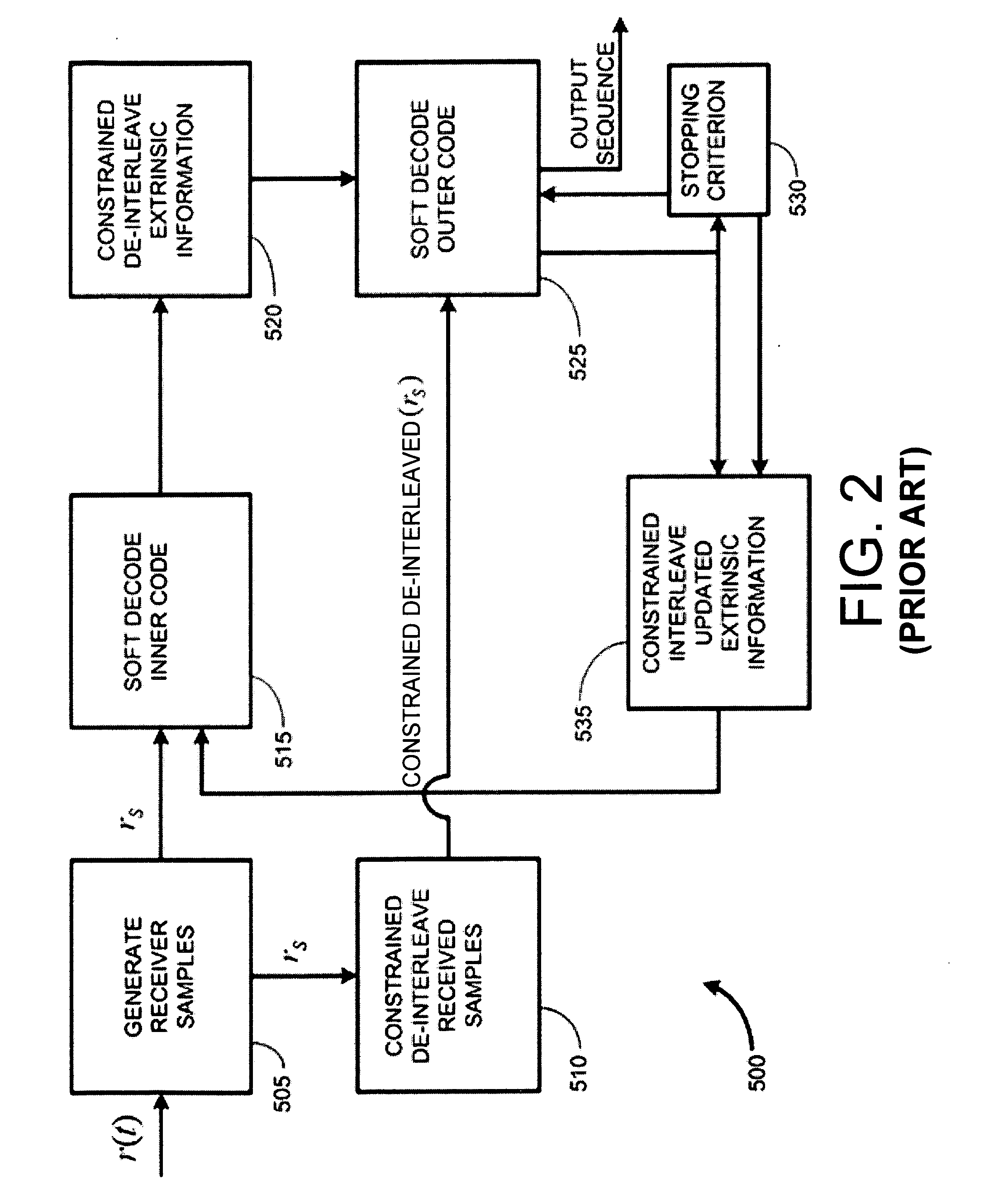

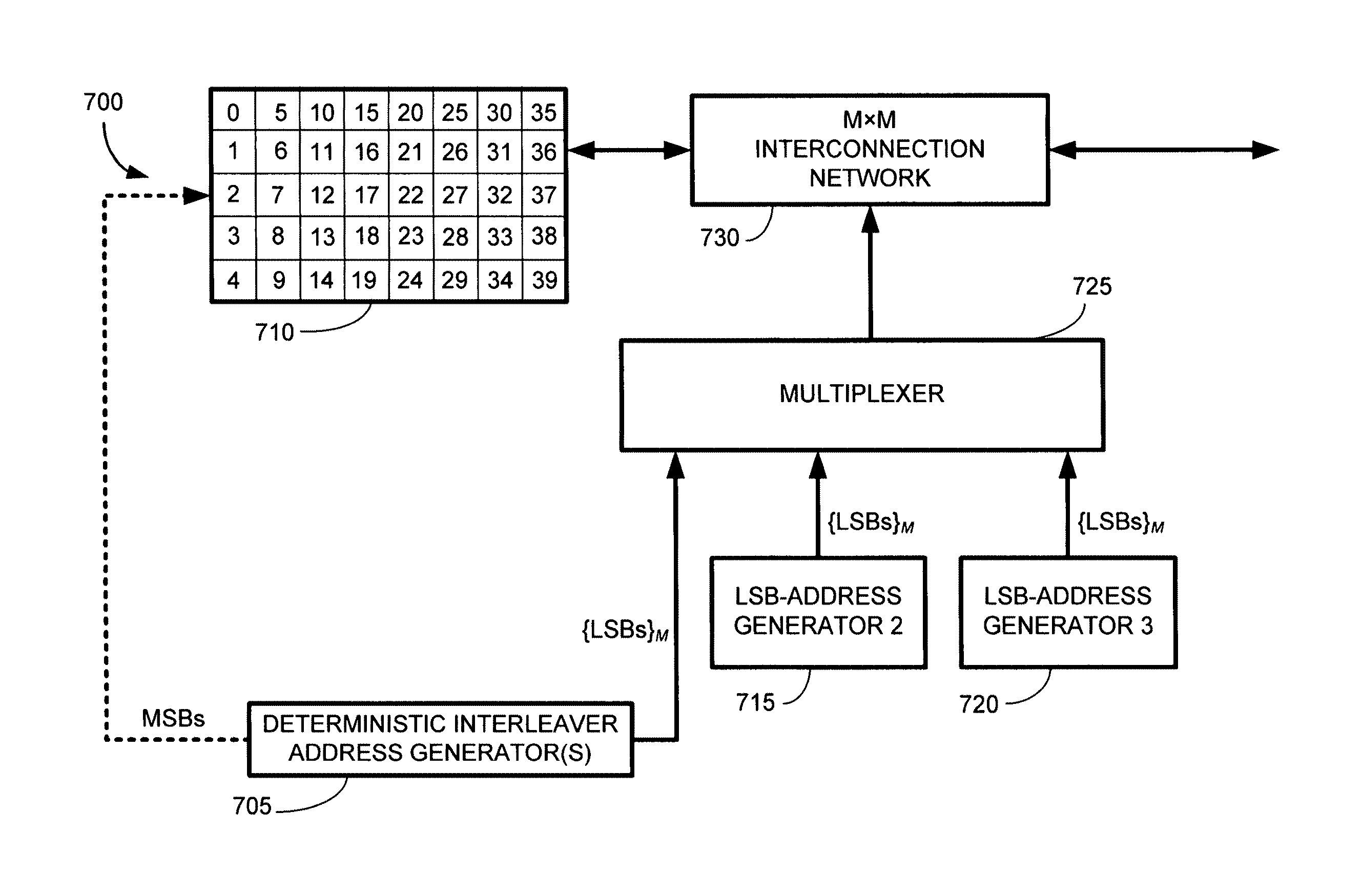

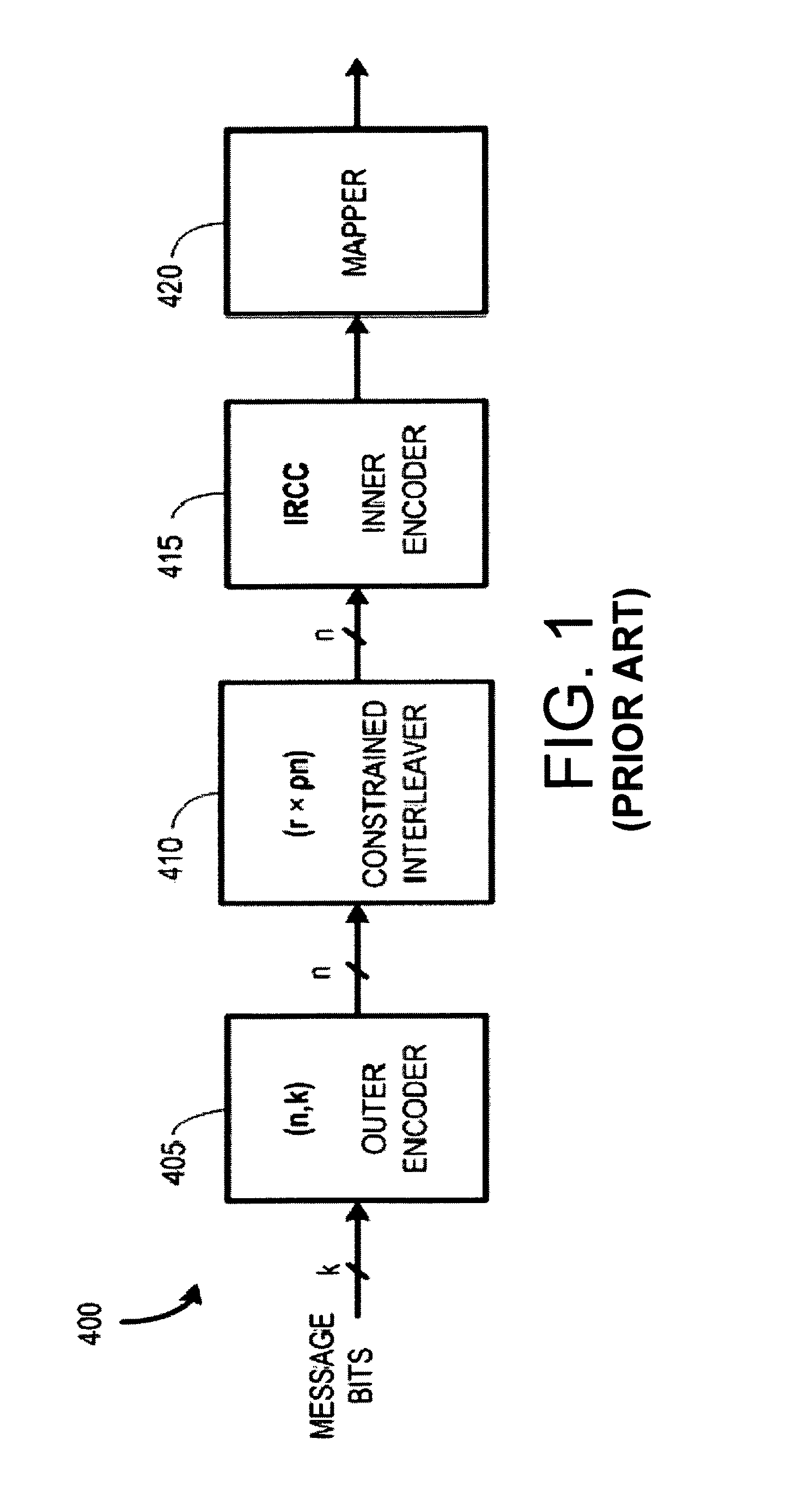

Constrained interleaving for 5G wireless and optical transport networks

InactiveUS20160352419A1Increase data rateIncrease performance rateSpatial transmit diversityPolarisation multiplex systemsCommunications systemAlgorithm

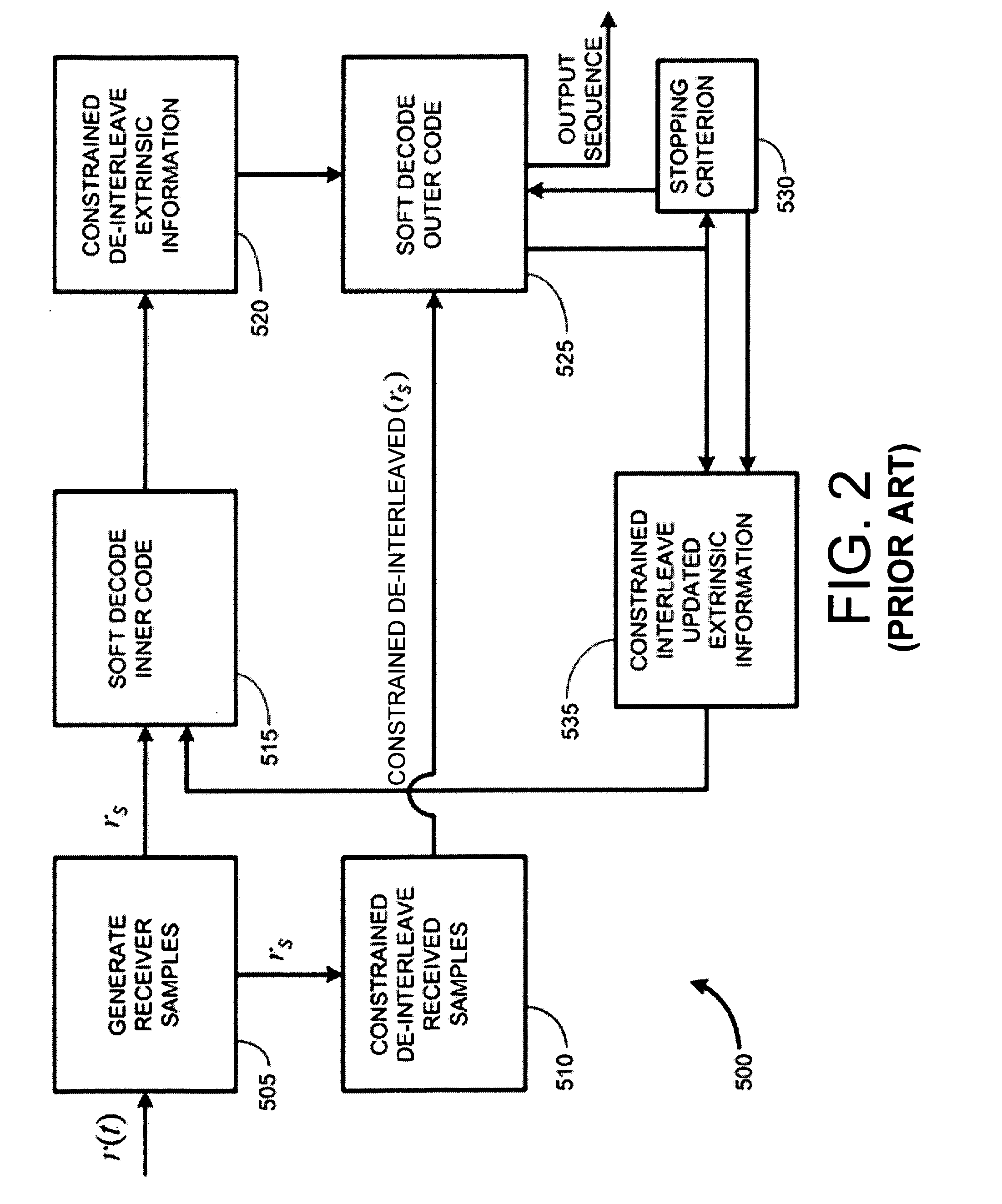

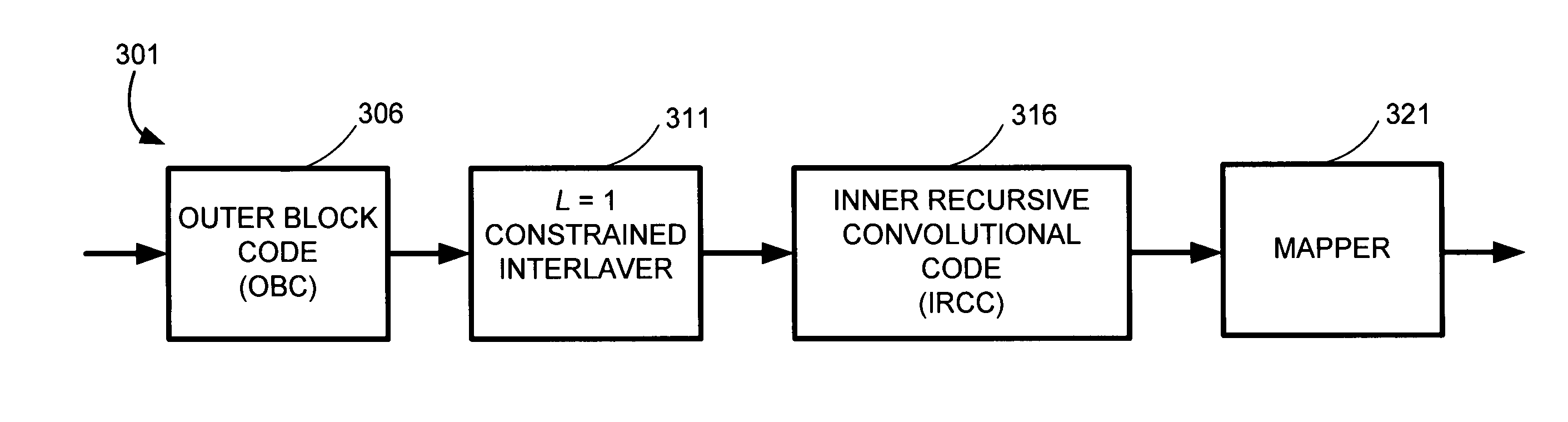

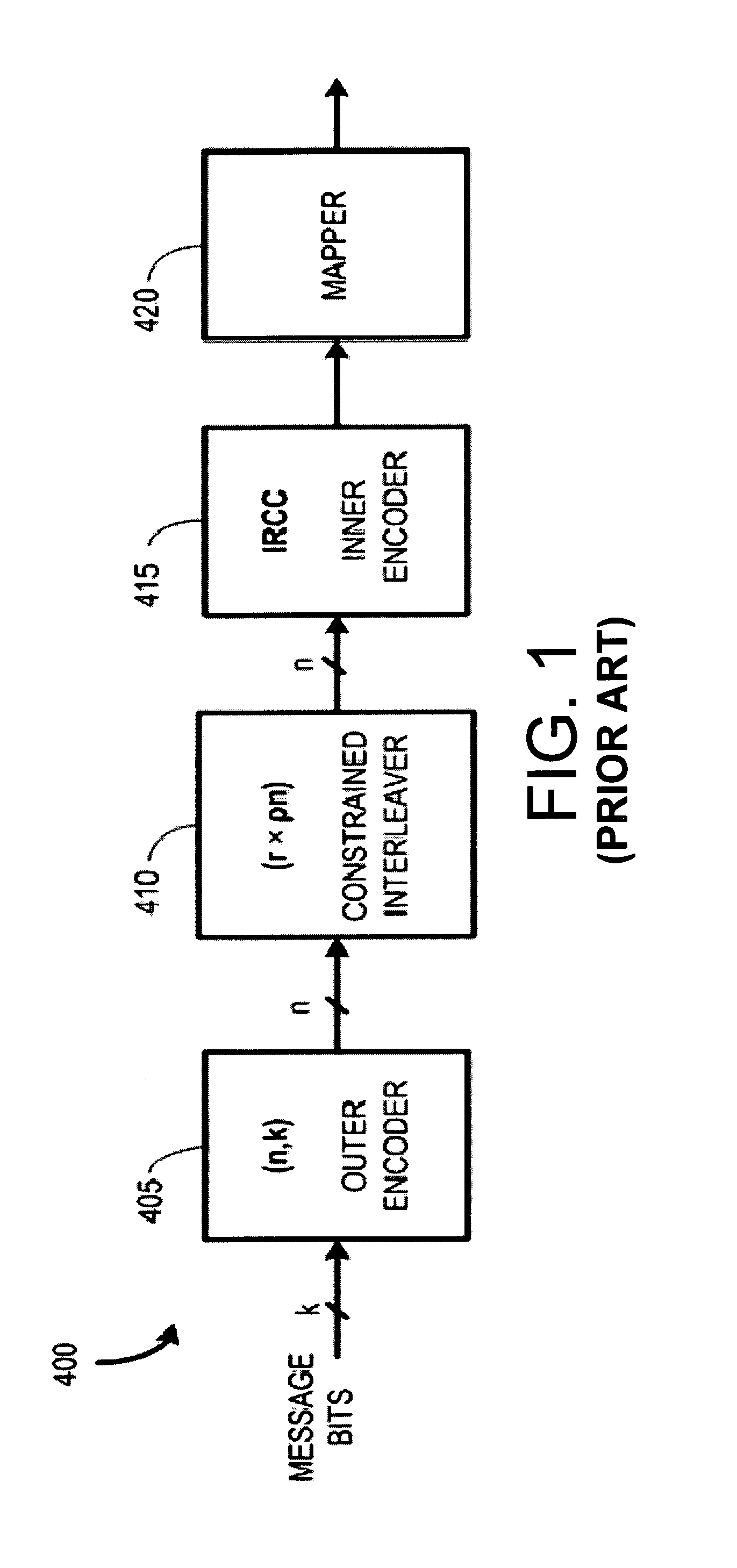

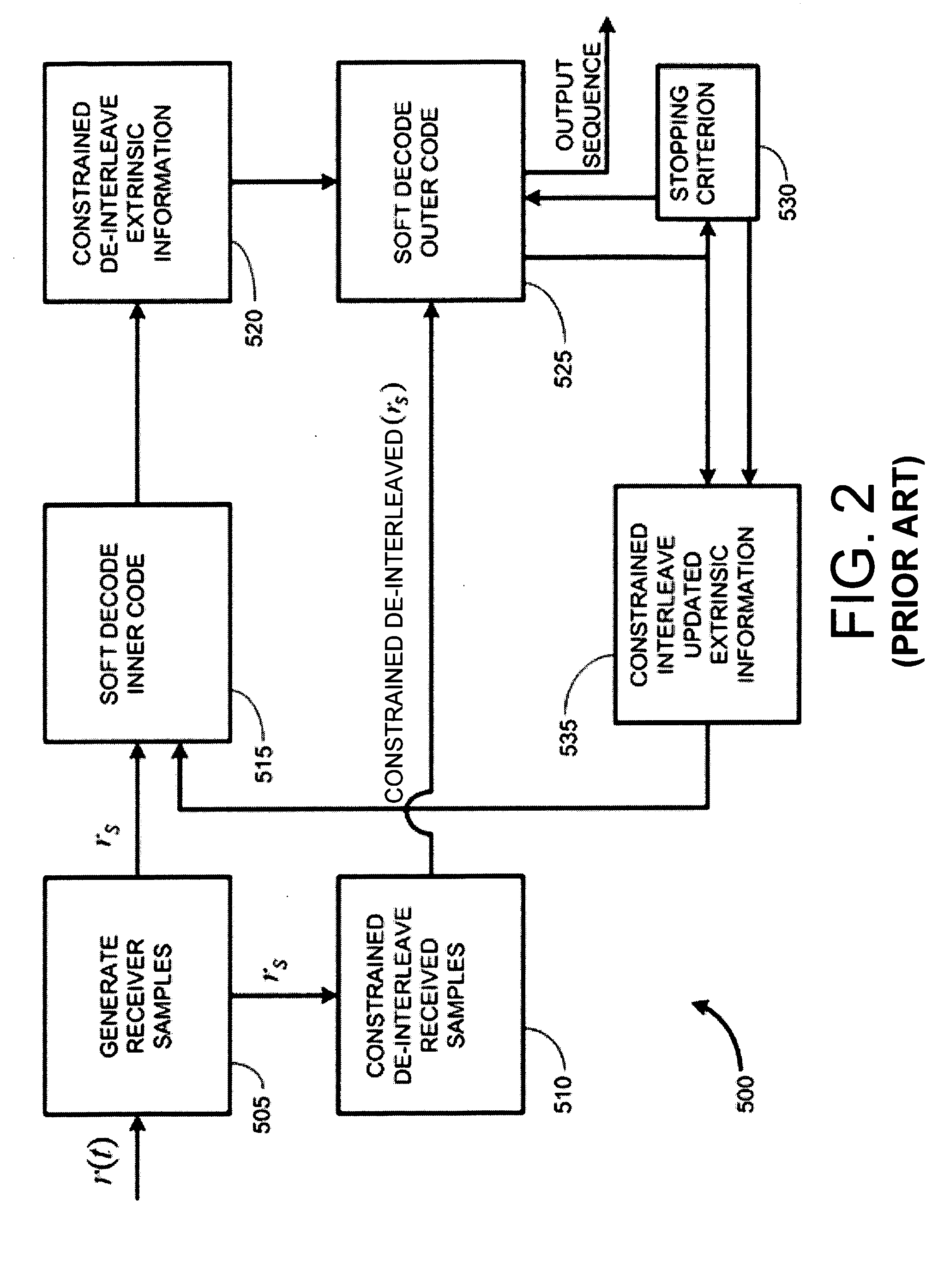

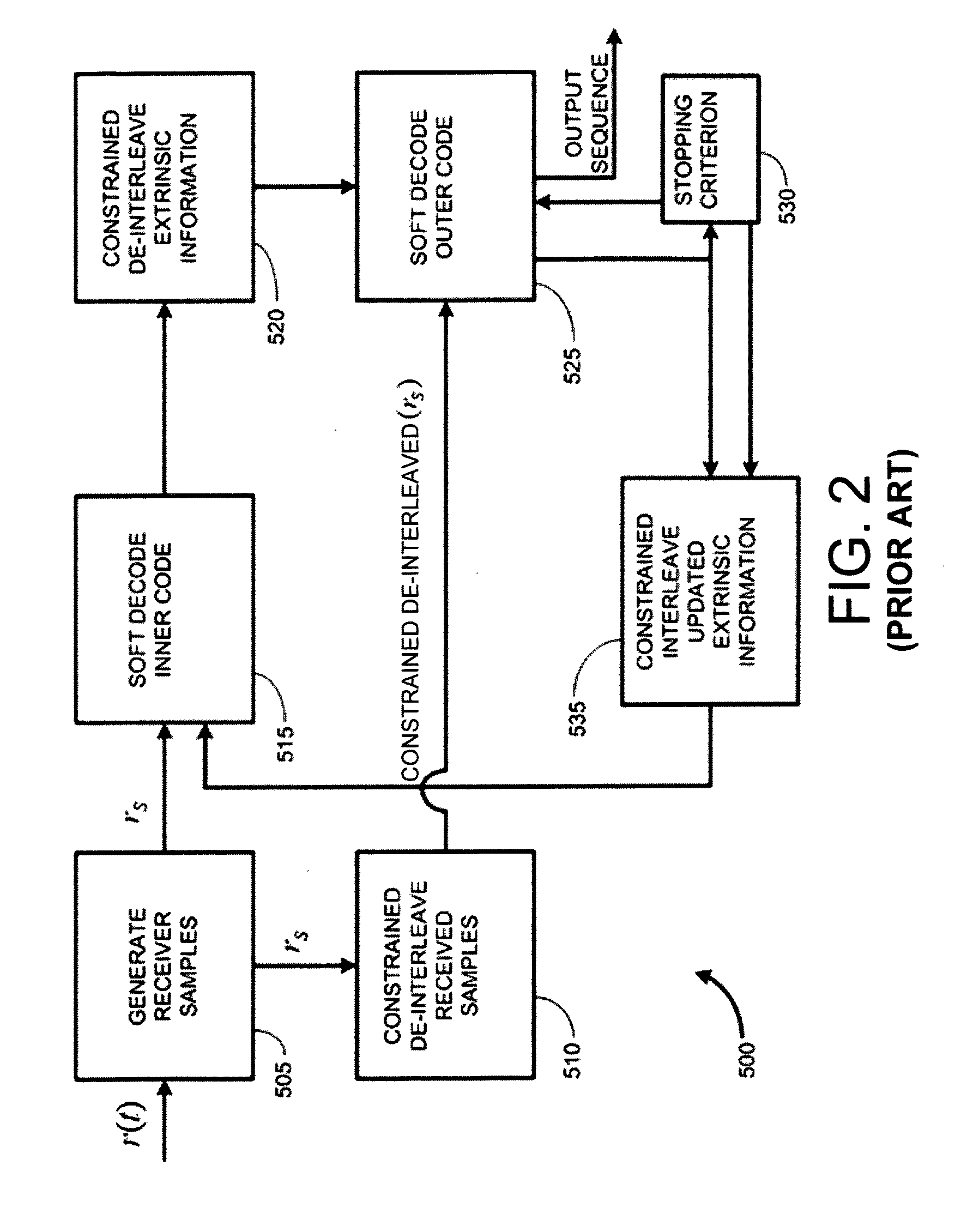

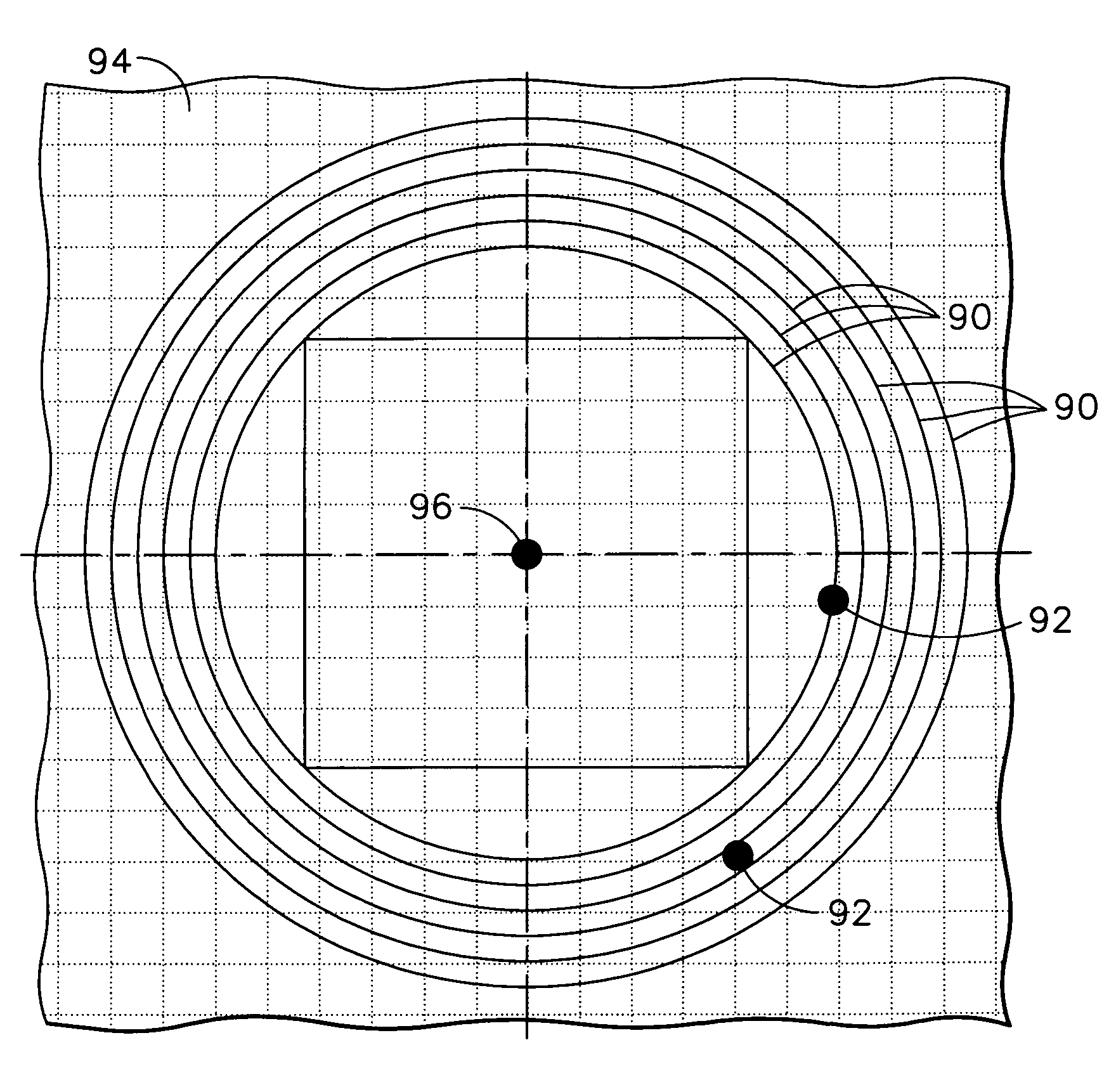

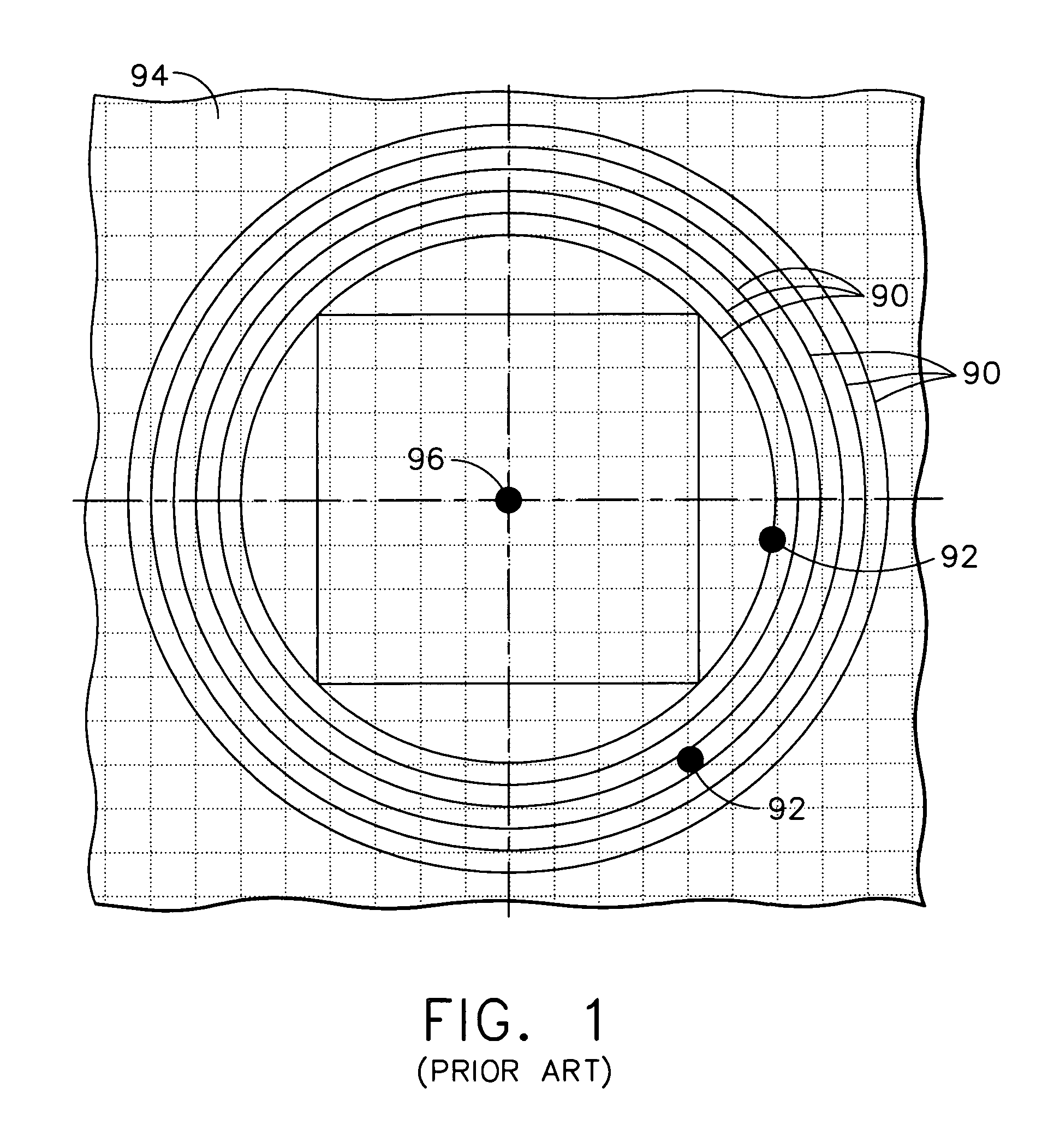

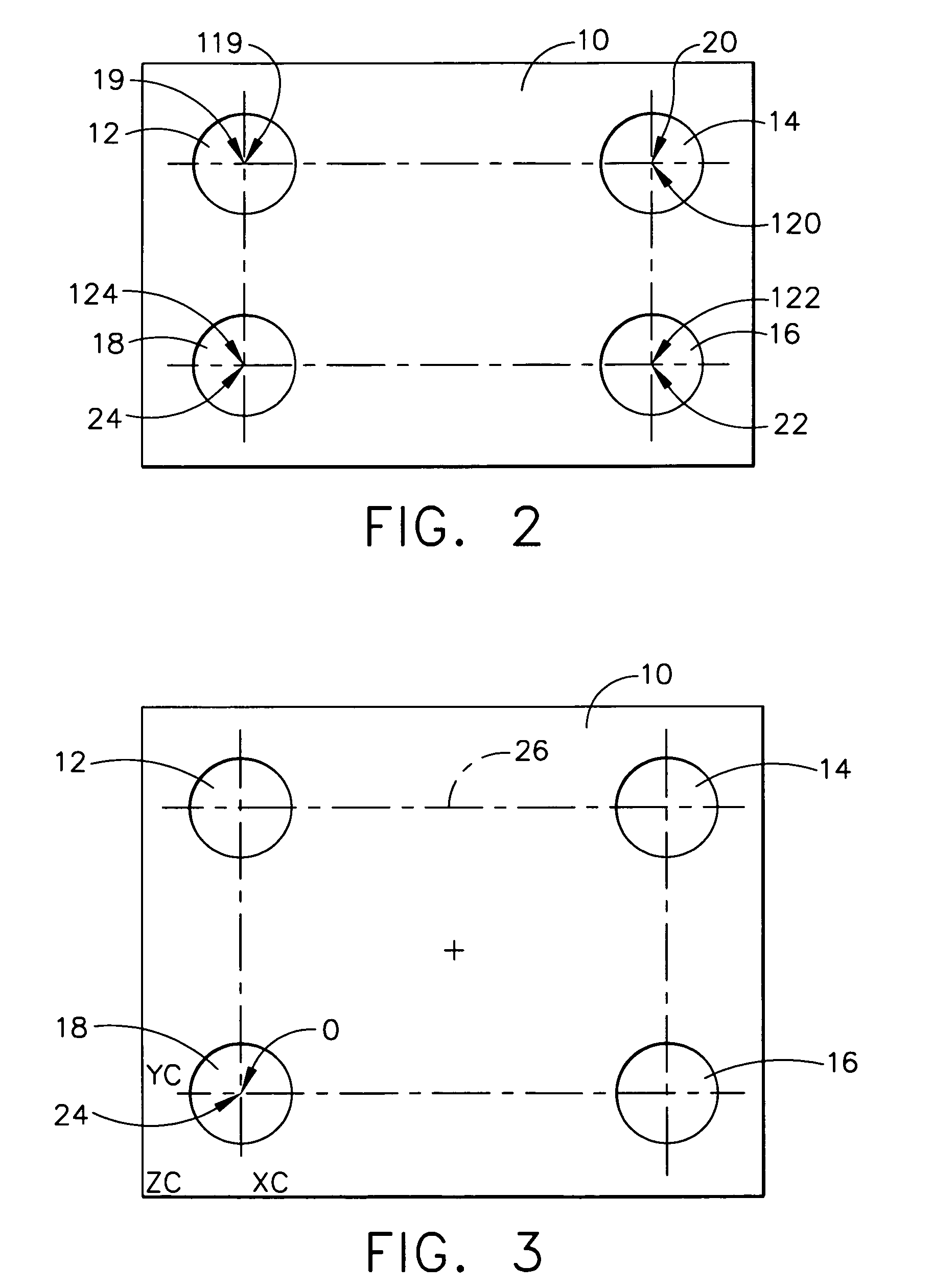

The present invention provides a design framework that is used to develop new types of constrained turbo block convolutional (CTBC) codes that have higher performance than was previously attainable. The design framework is applied to design both random and deterministic constrained interleavers. Vectorizable deterministic constrained interleavers are developed and used to design parallel architectures for real time SISO decoding of CTBC codes. A new signal mapping technique called constrained interleaved coded modulation (CICM) is also developed. CICM is then used to develop rate matching, spatial modulation, and MIMO modulation subsystems to be used with CTBC codes and other types of codes. By way of example, embodiments are primarily provided for improved 5G LTE and optical transport network (OTN) communication systems. Detailed descriptions of embodiments are also provided that combine aspects of MIMO and spatial modulation systems to improve bandwidth efficiency. Such embodiments are applicable to multi-antenna and single antenna MIMO systems as well as multichannel systems, OFDM systems, and TDM systems.

Owner:FONSEKA JOHN P +1

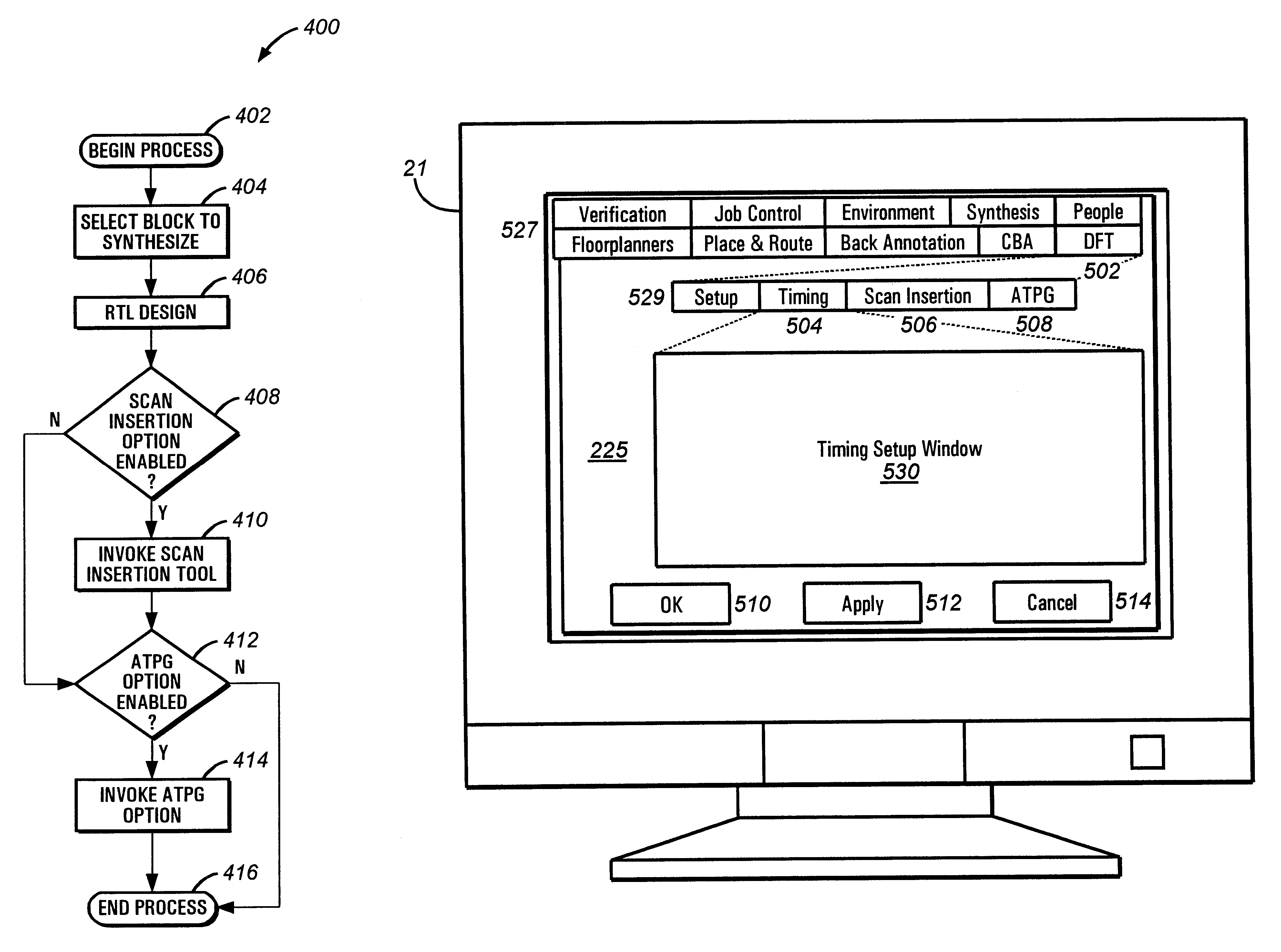

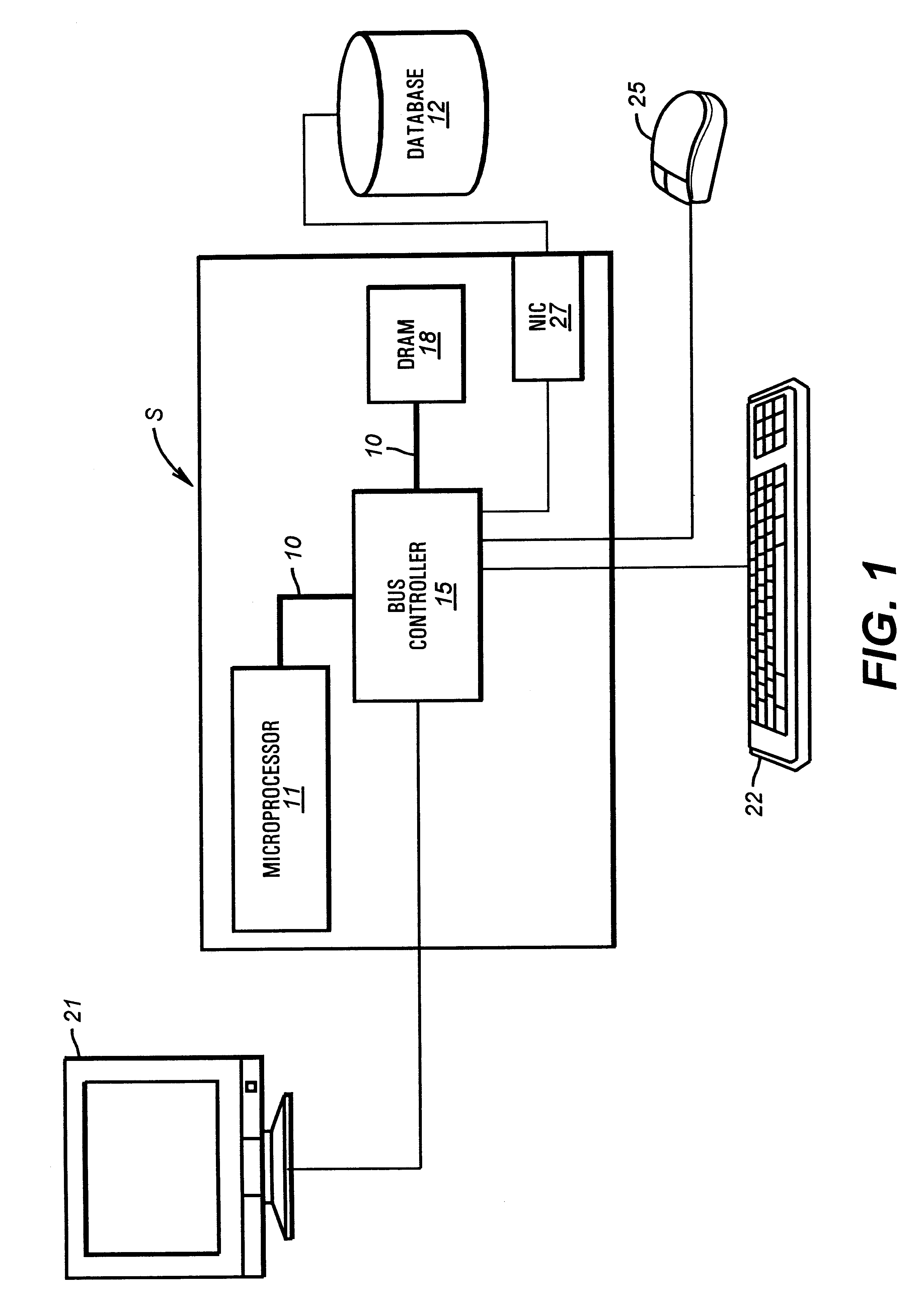

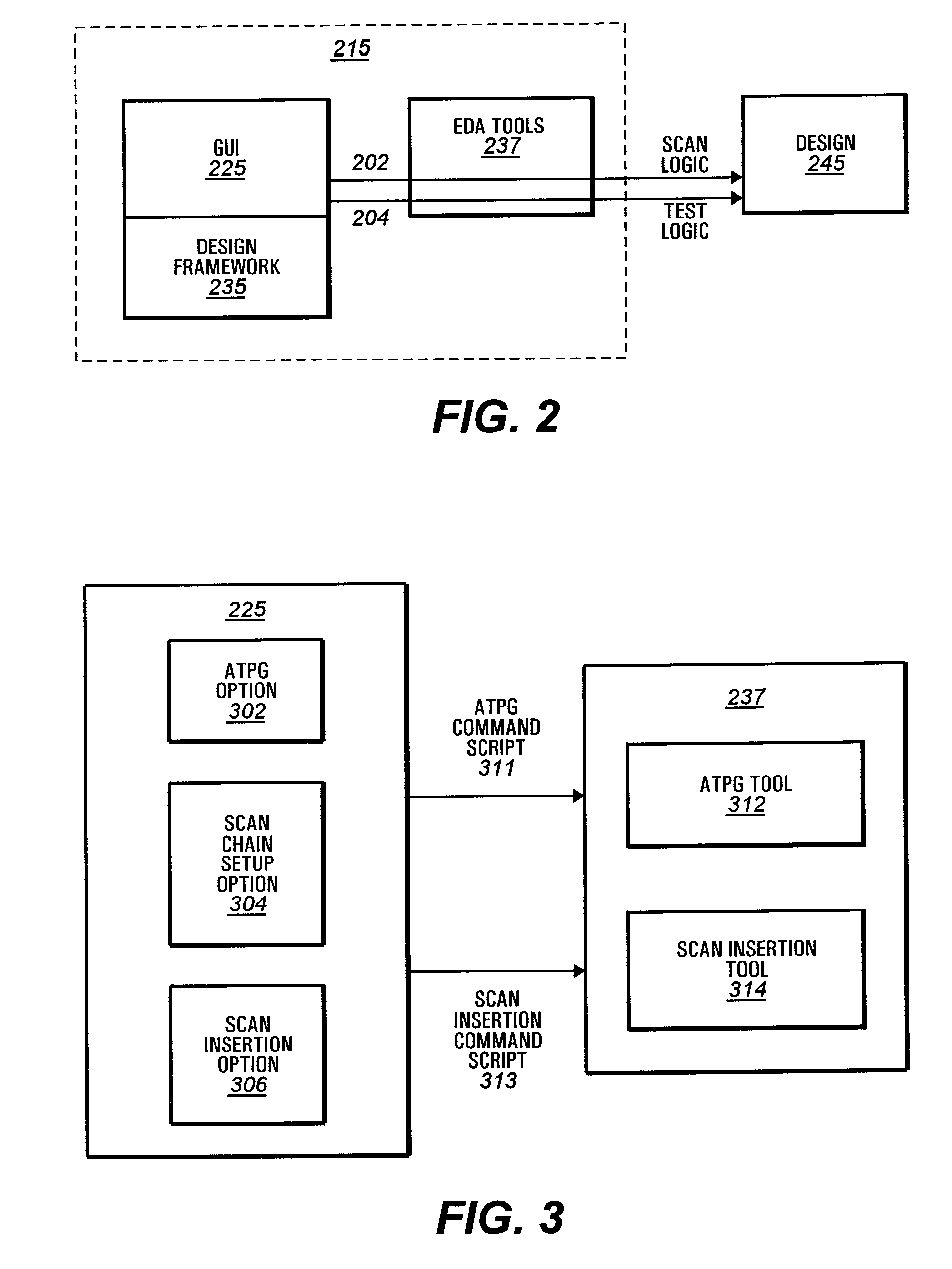

Graphical user interface for testability operation

InactiveUS6341361B1Accurate analysisQuickly and efficiently and accurately testabilityElectronic circuit testingFunctional testingFault coverageGraphics

A graphical user interface (GUI) provides a design engineer the capability of automatically inserting scan logic and test logic into a design. The graphical user interface includes a scan insertion option for a design engineer to invoke a scan insertion tool to check the design for testability. The graphical user interface also permits the design engineer to invoke a test generation tool such as an automatic test pattern generator (ATPG) tool to check the design for fault coverage. The graphical user interface, which can serve as a front end for a design framework, enables a design engineer to efficiently increase testability while still in a design phase.

Owner:ADVANCED MICRO DEVICES INC

Constrained interleaving for 5G wireless and optical transport networks

InactiveUS20160352362A1Reduce weightInterleaver gain can be improvedError correction/detection using convolutional codesError correction/detection using multiple parity bitsCommunications systemAlgorithm

The present invention provides a design framework that is used to develop new types of constrained turbo block convolutional (CTBC) codes that have higher performance than was previously attainable. The design framework is applied to design both random and deterministic constrained interleavers. Vectorizable deterministic constrained interleavers are developed and used to design parallel architectures for real time SISO decoding of CTBC codes. A new signal mapping technique called constrained interleaved coded modulation (CICM) is also developed. CICM is then used to develop rate matching, spatial modulation, and MIMO modulation subsystems to be used with CTBC codes and other types of codes. By way of example, embodiments are primarily provided for improved 5G LTE and optical transport network (OTN) communication systems.

Owner:FONSEKA JOHN P +1

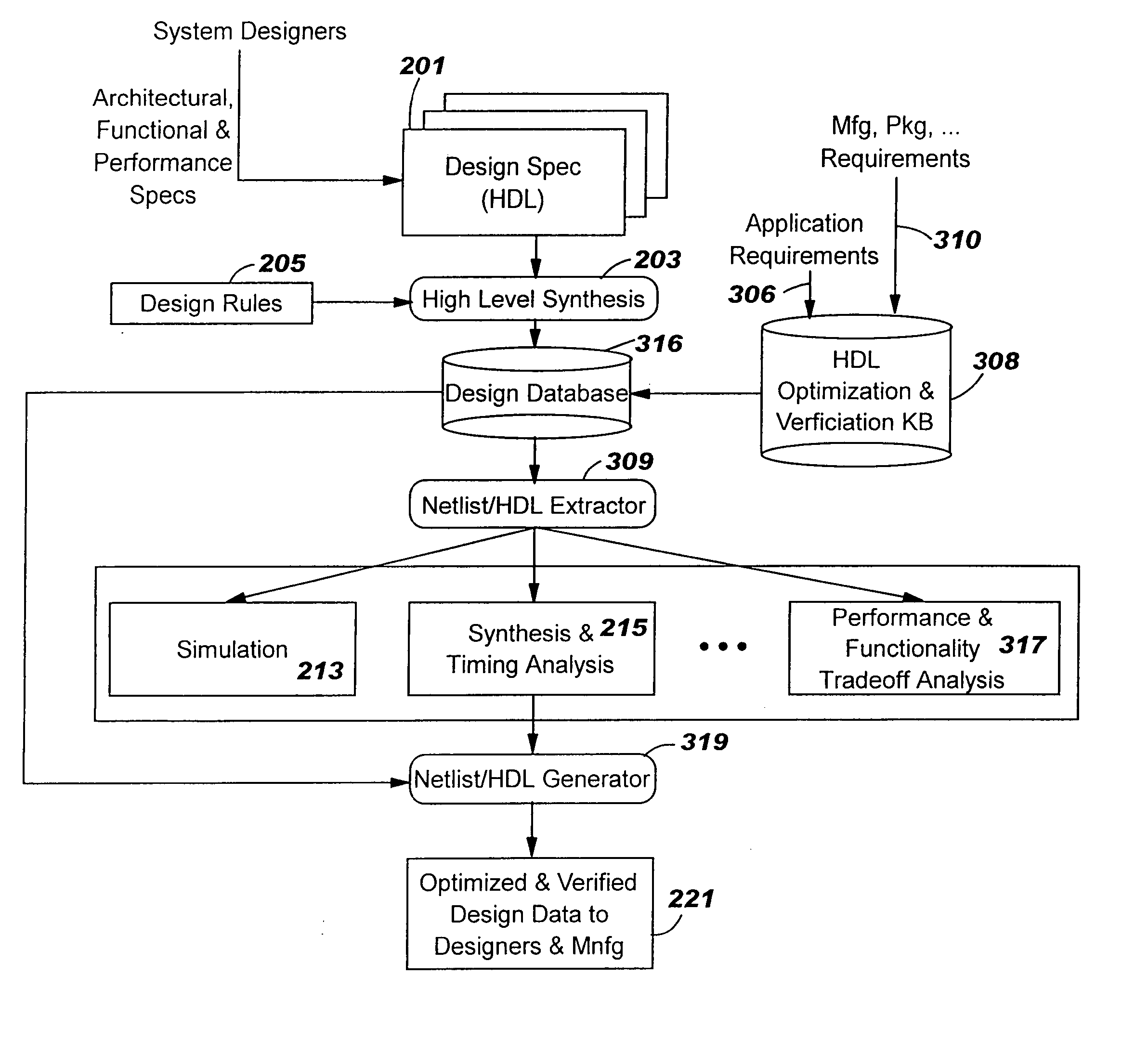

XML-based system and method for collaborative web-based design and verification of system-on-a-chip

InactiveUS20060041582A1Data processing applicationsDigital data processing detailsDatabase interfaceRelational database

A computer-based design framework for collaborative design of a product by distributed design team members. The design framework comprises: a virtual database management system, which receives data from a plurality of distinct sources and creates a single relational database interface to each of the distinct sources; software code associated with the virtual database management system for mapping various informational structures utilized by the distinct sources to a common XML syntax; and additional logic associated with the virtual database management system that provides publishing rules for extracting information on demand and publishing the extracted information in a format recognized by a requestor of the information. When the product is a system on a chip (SOC) a special set of functions are generated that enable platform-independent application and services exchange utilizing XML wrapped data, service, and applications.

Owner:INT BUSINESS MASCH CORP

Constrained interleaving for 5G wireless and optical transport networks

InactiveUS20160352361A1Increase data rateIncrease performance rateError correction/detection using convolutional codesCode conversionCommunications systemAlgorithm

The present invention provides a design framework that is used to develop new types of constrained turbo block convolutional (CTBC) codes that have higher performance than was previously attainable. The design framework is applied to design both random and deterministic constrained interleavers. Vectorizable deterministic constrained interleavers are developed and used to design parallel architectures for real time SISO decoding of CTBC codes. A new signal mapping technique called constrained interleaved coded modulation (CICM) is also developed. CICM is then used to develop rate matching, spatial modulation, and MIMO modulation subsystems to be used with CTBC codes and other types of codes. By way of example, embodiments are primarily provided for improved 5G LTE and optical transport network (OTN) communication systems.

Owner:FONSEKA JOHN P +1

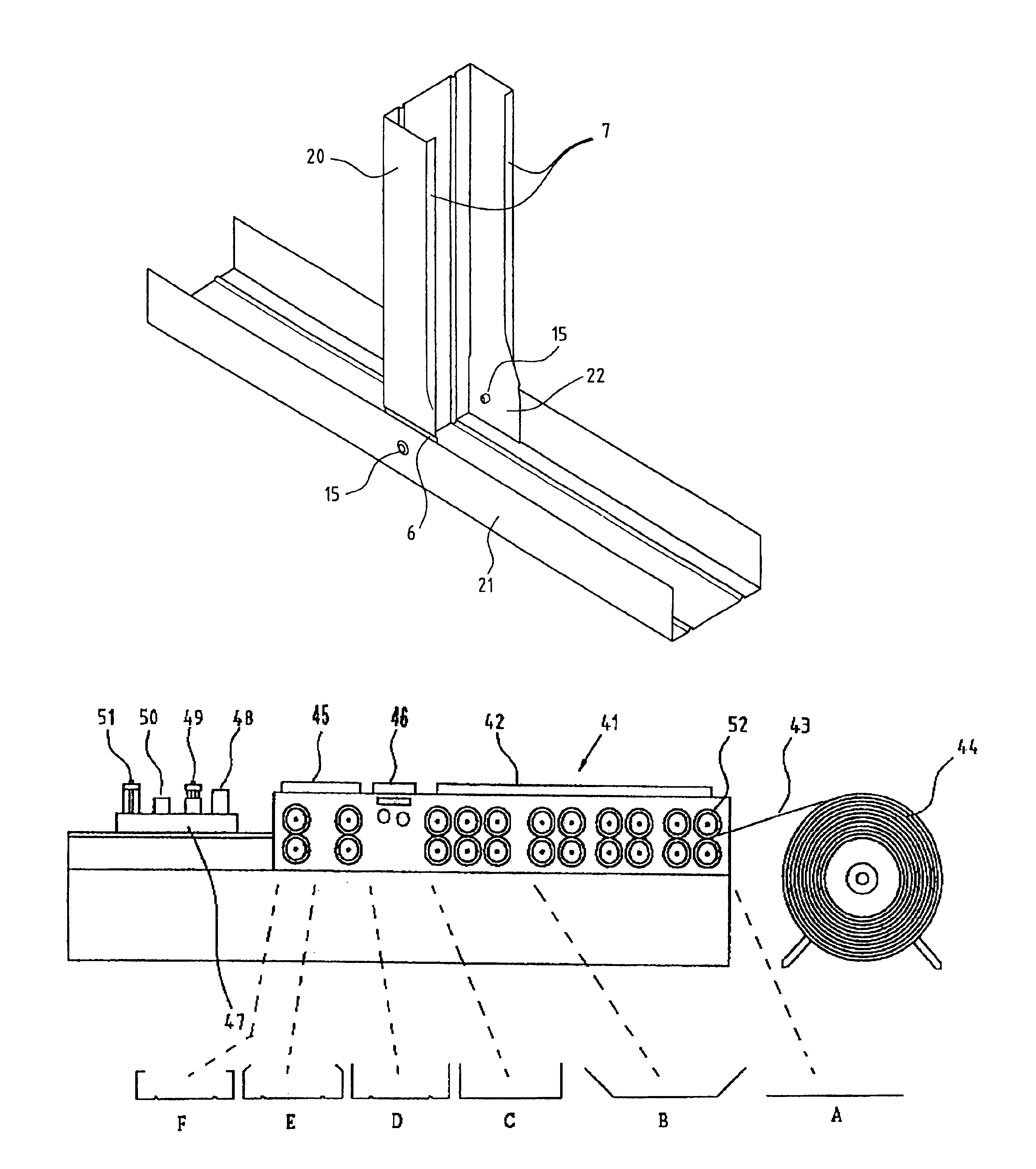

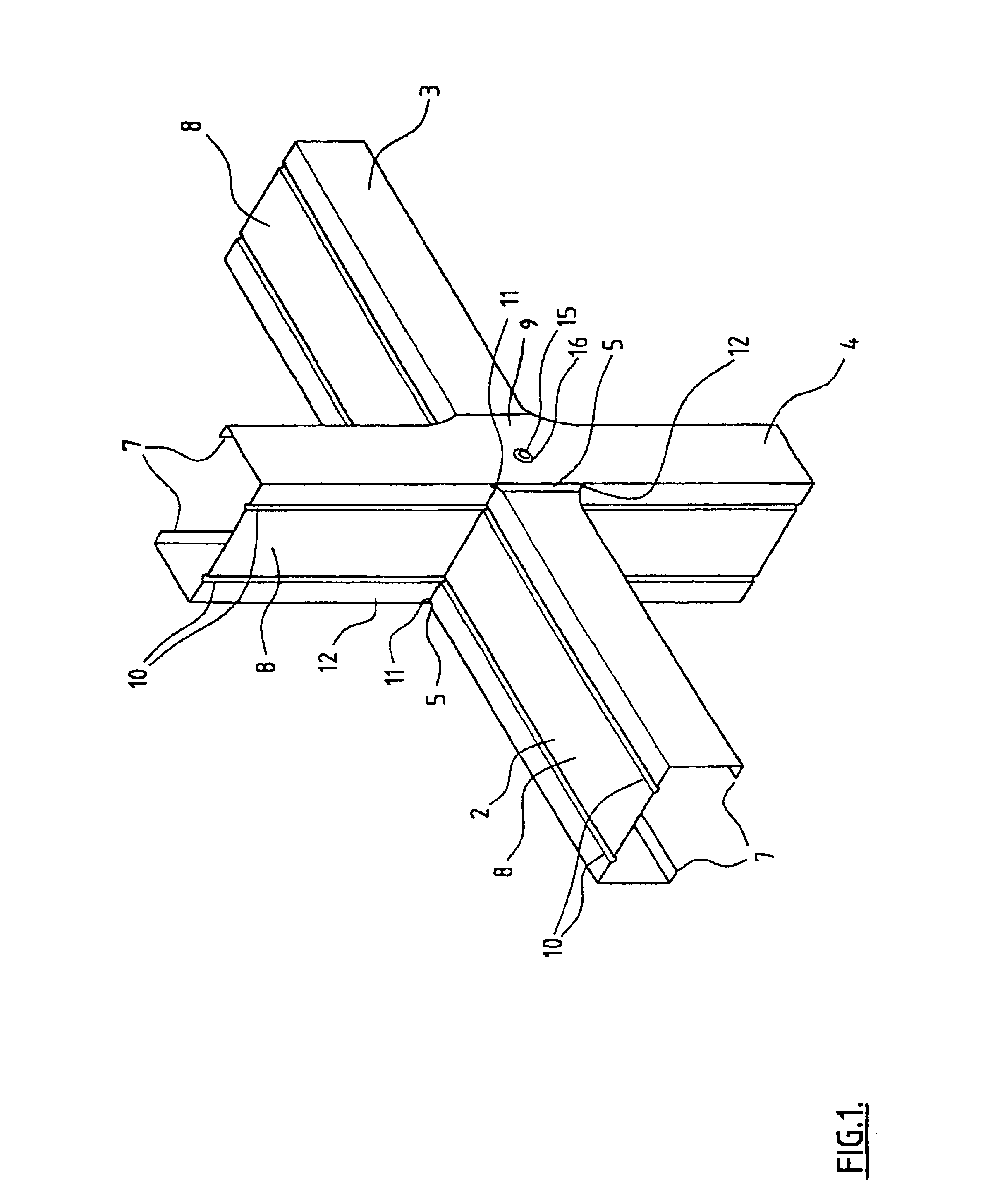

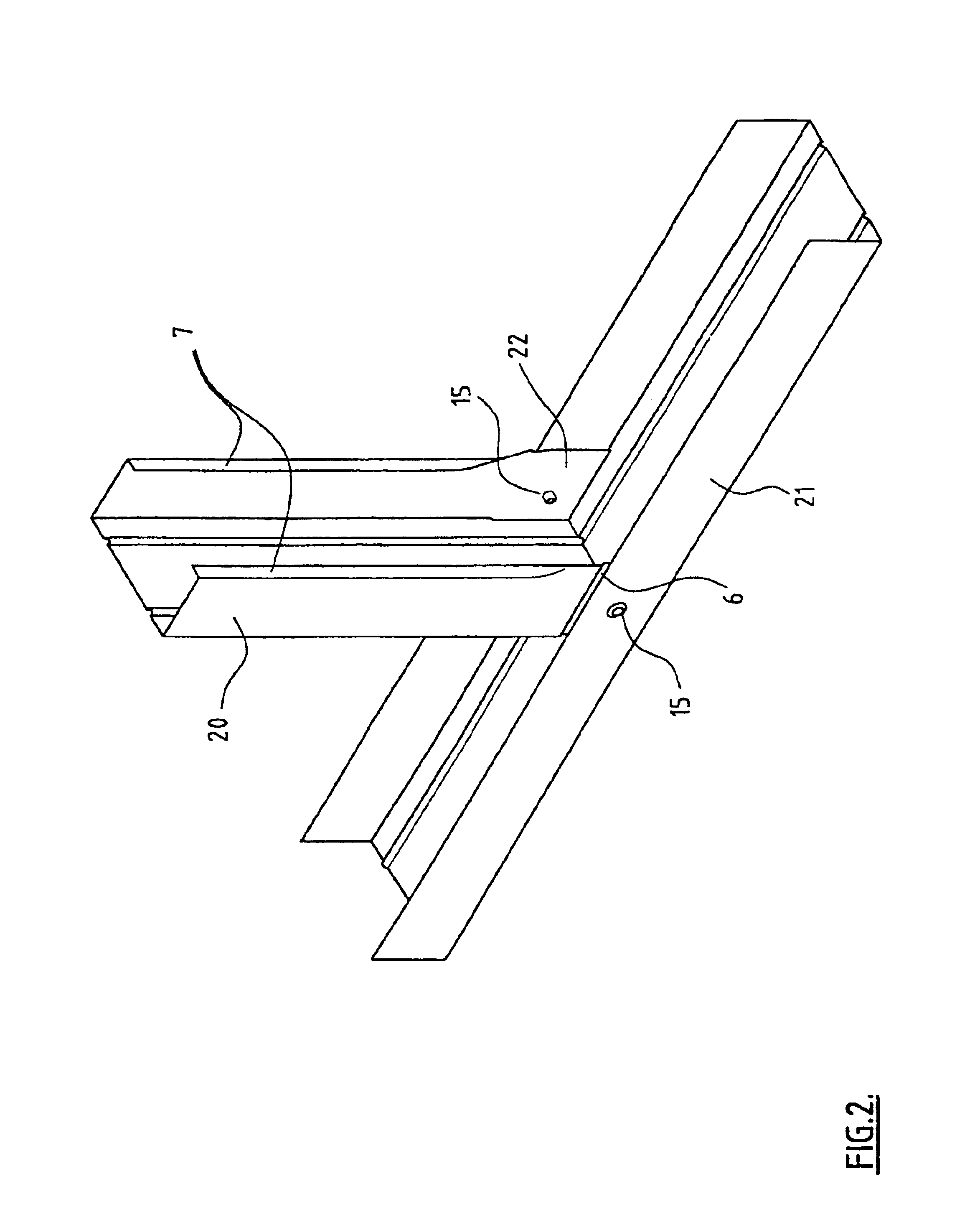

Method of making a frame member into U-section and C-section panel profiles

This invention relates to metal framing (2, 3, 4), in particular steel framing for building construction. The invention also relates to a method of constructing a metal frame assembly (2, 3, 4) and roll forming apparatus (41) for producing metal framing for building construction. The individual components of the metal frame (2, 3, 4), and assembly made from these components is adapted to provide for a substantially even planar surface without deformations, to which a cladding may be attached with a preferred even finish. The invention also includes roll forming apparatus (41) adapted for producing metal framing (2, 3, 4) of this type, and particularly adapted to produce metal frame members (2, 3, 4) having a predominantly C-section profile (7), with one or more portions of a U-section profile (9, 6), the U-section (9, 6) and C-section (7) profiles formed simultaneously on the same sheet metal strip (43). The apparatus (41) is also adapted to form narrowing or swaging of the channel at same or all U-section portions (6). The overall method of constructing a building frame assembly of the invention includes recording data defining a unit area in which a frame assembly is to fit, processing the data to design a frame assembly to fit that unit area, and controlling operation of roll forming apparatus (41) by a computing means using the processed data, to produce frame members (2, 3, 4) cut and formed ready for assembly to produce the required design of frame assembly.

Owner:FRAMEMAX INC

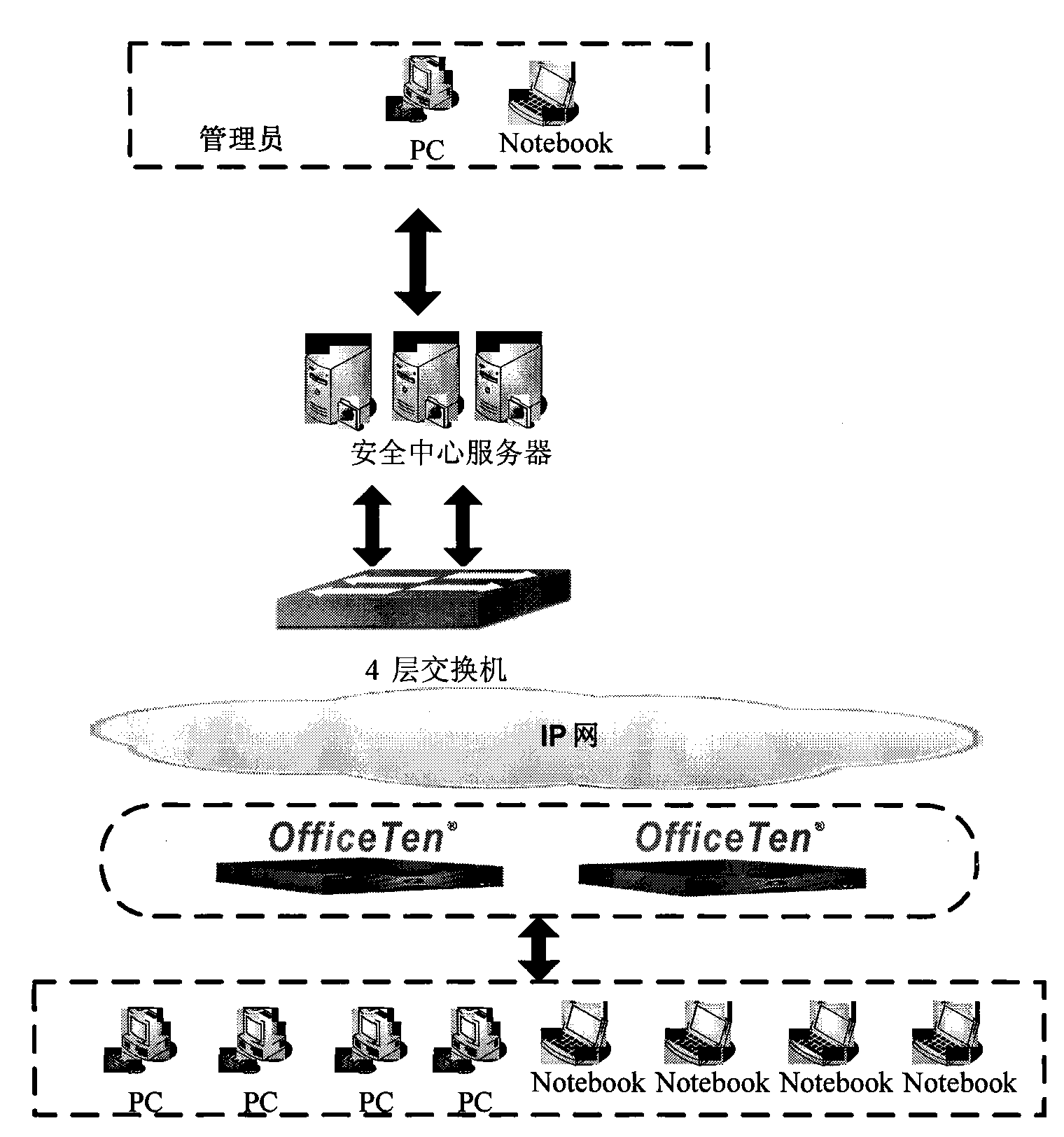

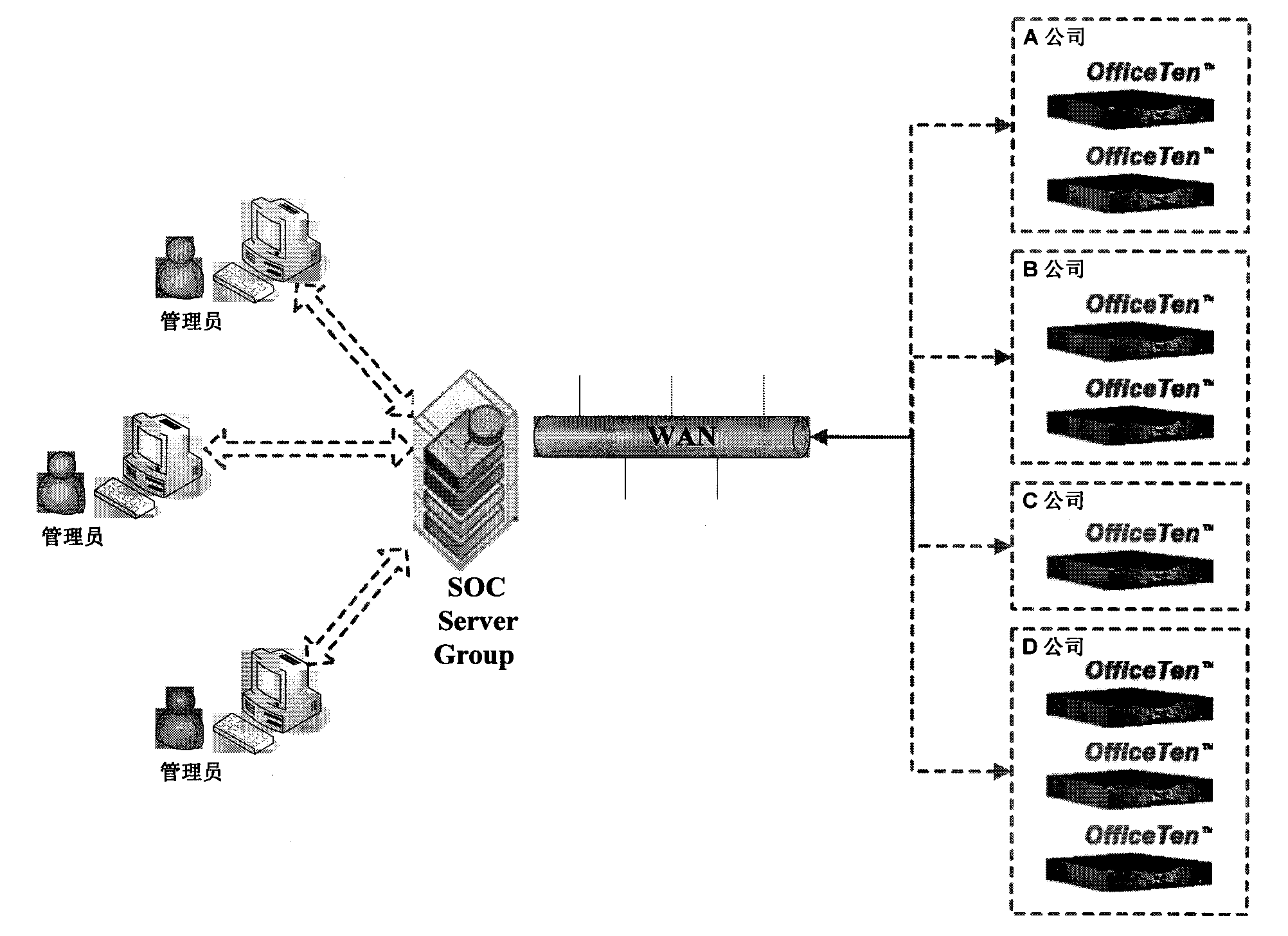

Remote network behavior real time monitoring method based on multilayer data interception

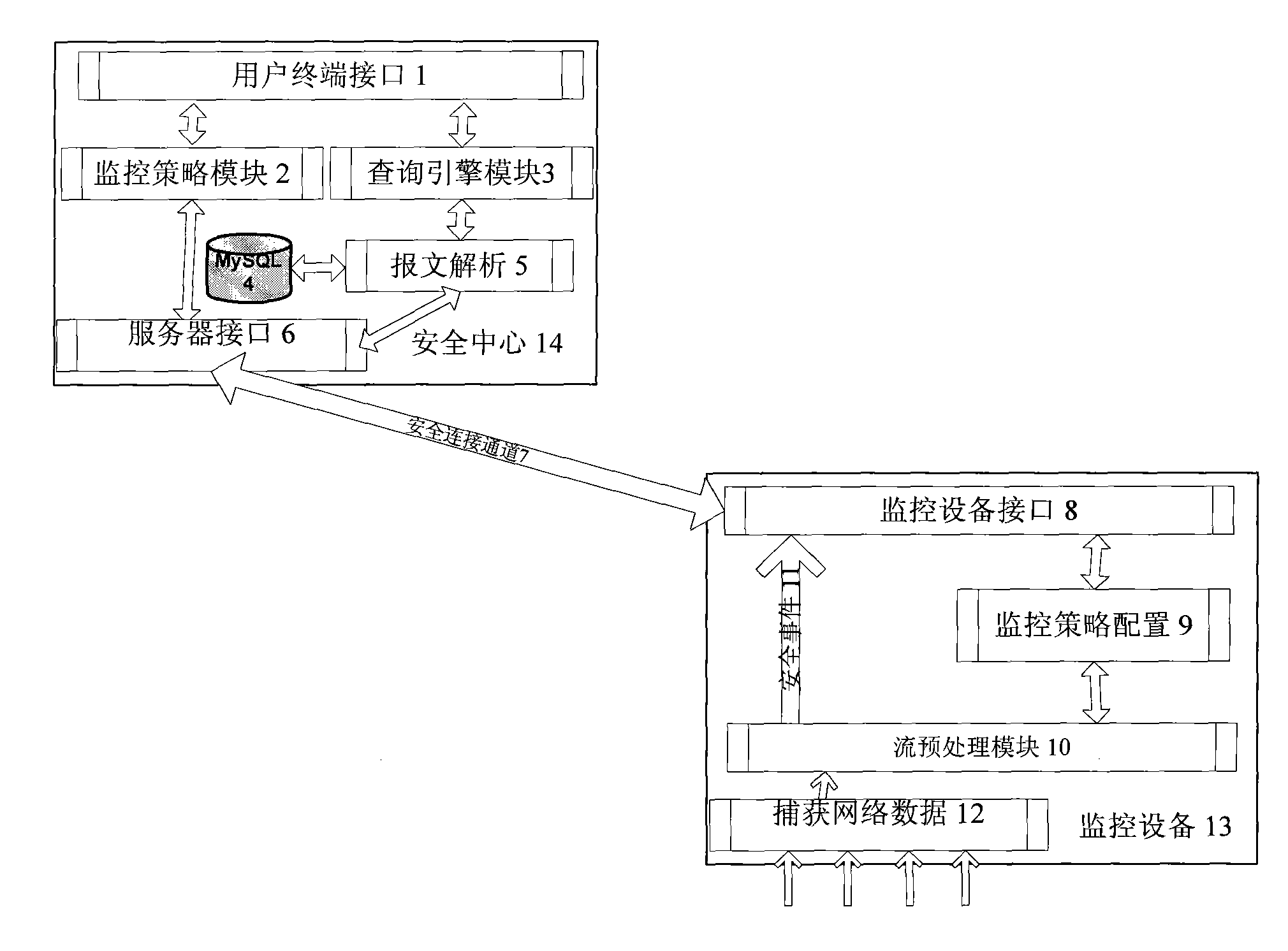

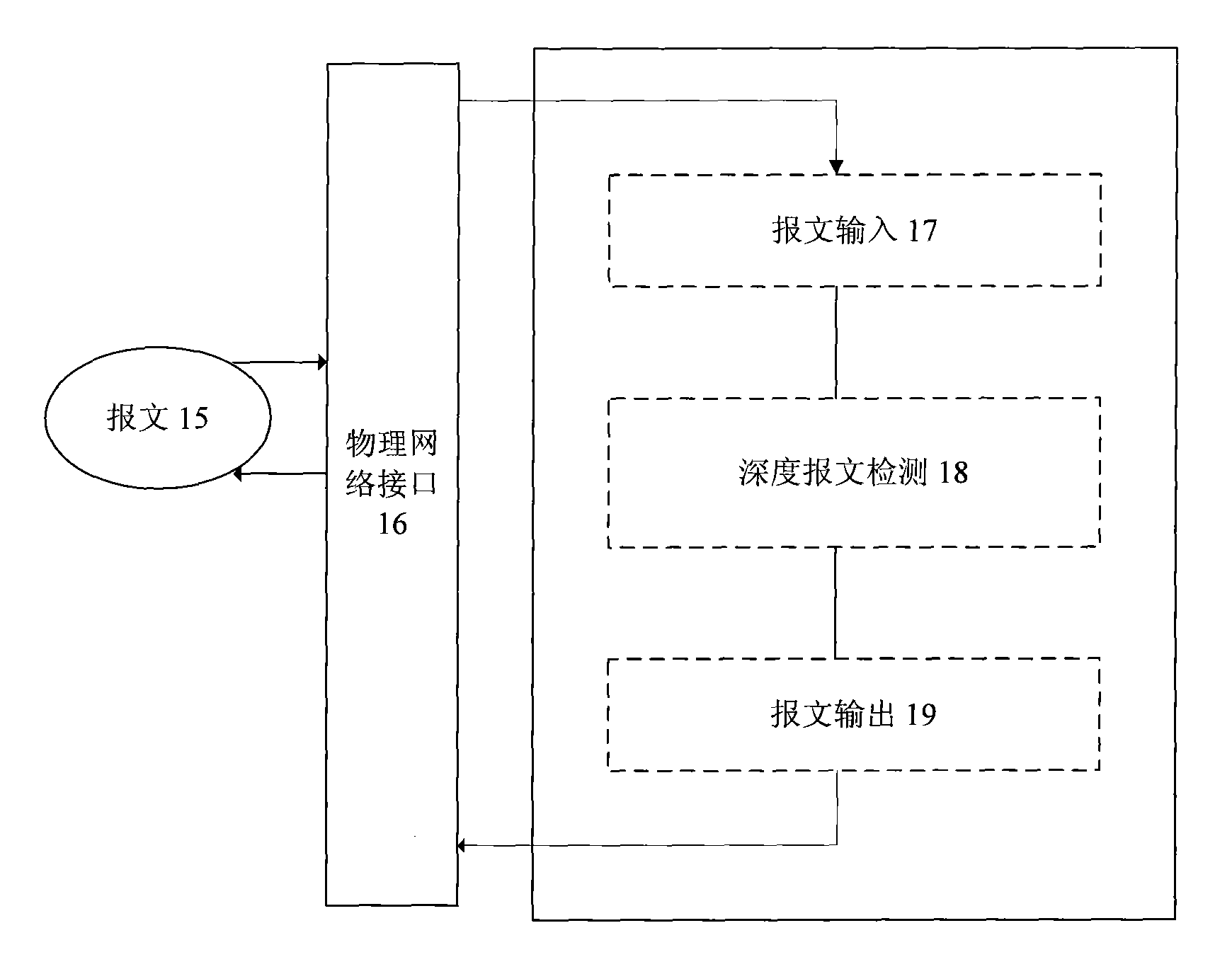

ActiveCN101605066AImprove information securityMeet the requirements of real-time monitoringData switching networksNetwork behaviorMonitoring system

The invention provides a remote network behavior real time monitoring method based on multilayer data interception. A plurality of monitor devices are connected with a security center, the design framework of the monitoring system is implemented based on B / S model distributed network behavior, and the network behavior real time monitoring is divided into two parts: the monitor devices analyze the messages in real time, and the messages in conformity with the monitoring strategy are reported to the security center; the security center issues the monitoring strategy to the monitor devices, the messages are analyzed and a search engine is provided, a user is connected with the security center by a terminal, and the user configures the monitoring strategy and queries the network behaviour to realize monitoring the remote network behavior in real time. The application of remote network behavior real time monitoring technology based on multilayer data interception can effectively manage the information security of the remote network, thus realizing information security uniform management and secondary mining and analyzing of data and improving the information security of the whole network.

Owner:网经科技(苏州)有限公司

Constrained interleaving for 5G wireless and optical transport networks

InactiveUS9564927B2Reduce weightInterleaver gain can be improvedError correction/detection using convolutional codesCode conversionCommunications systemAlgorithm

The present invention provides a design framework that is used to develop new types of constrained turbo block convolutional (CTBC) codes that have higher performance than was previously attainable. The design framework is applied to design both random and deterministic constrained interleavers. Vectorizable deterministic constrained interleavers are developed and used to design parallel architectures for real time SISO decoding of CTBC codes. A new signal mapping technique called constrained interleaved coded modulation (CICM) is also developed. CICM is then used to develop rate matching, spatial modulation, and MIMO modulation subsystems to be used with CTBC codes and other types of codes. By way of example, embodiments are primarily provided for improved 5G LTE and optical transport network (OTN) communication systems.

Owner:FONSEKA JOHN P +1

Combined feature dimensional parameter analysis

A computerized method is disclosed for determining the size and location effects of simulated or manufactured features on an object, determining the transformation of a pattern of features, determining usable feature size within a pattern of features, and determining the remaining feature tolerances. The simulated or manufactured position of a pattern of features is used to determine how to translate a tolerance zone framework. Positional errors and remaining feature tolerances are determined relative to the translated design framework.

Owner:THE BOEING CO

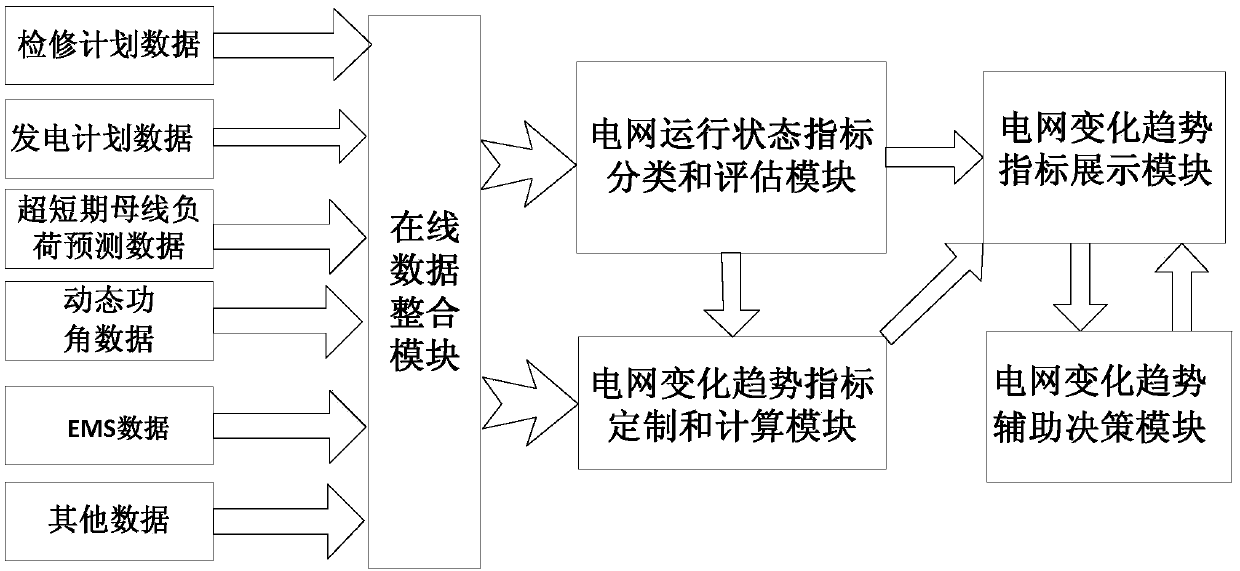

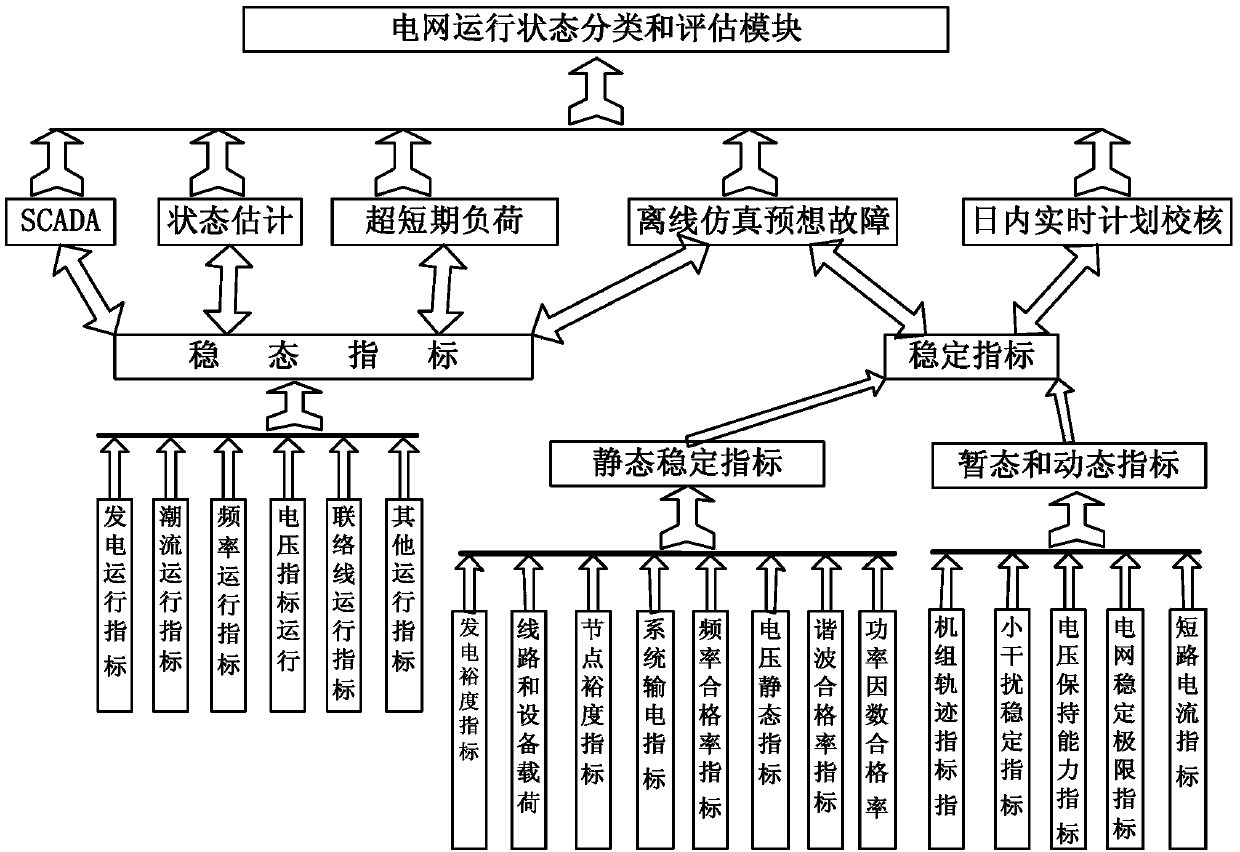

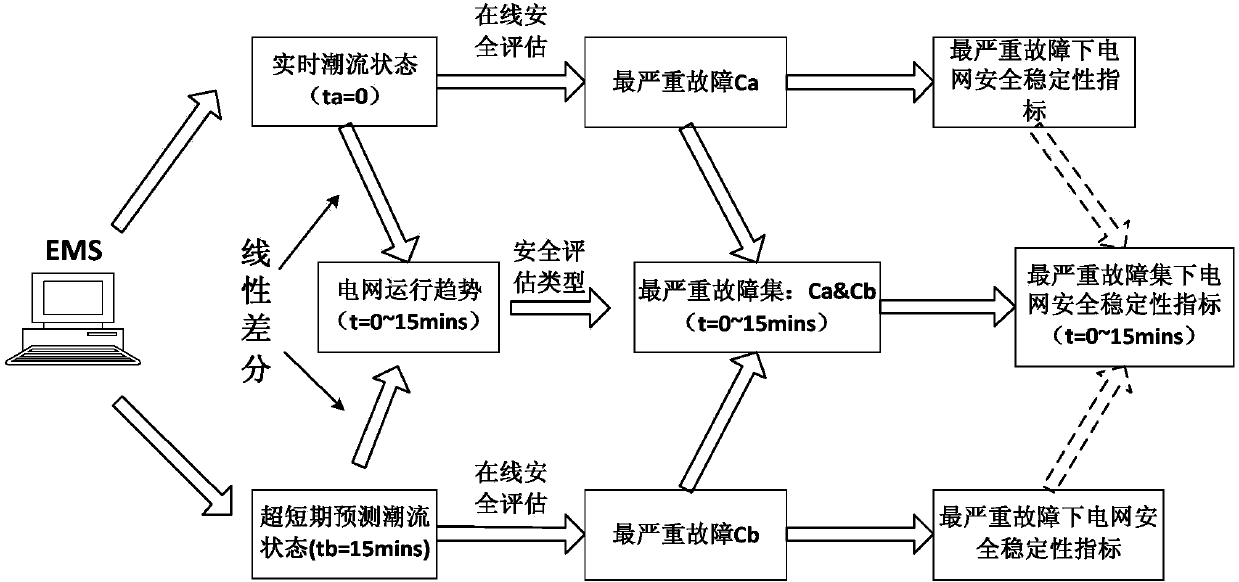

Online stability evaluation index system of electric power system

ActiveCN104008512AClear display of future operating statusData processing applicationsInformation technology support systemElectric power systemClassification methods

The invention provides an online stability evaluation index system of an electric power system. The online stability evaluation index system comprises an online data integration module, a power grid operating state index classification and evaluation module, a power grid variation trend index customization and calculation module, a power grid variation trend index display module and a power grid variation trend decision-making aid module. On the basis of an online integration method of basic data, index classification and calculation are carried out accompanied by index display, and thus a reliable and reasonable basis is provided for aiding decision making of future trend variation of the power grid. Algorithm development, induction, summarization and classification are carried out on indexes reflecting the future operating state of the power grid in all aspects, and the future operating state of the power grid is clearly displayed. What needs to be protected mainly includes the design framework and the function content of an index system, an index classification method and a method adopted for a platform index customization tool and a formula parser.

Owner:STATE GRID CORP OF CHINA +4

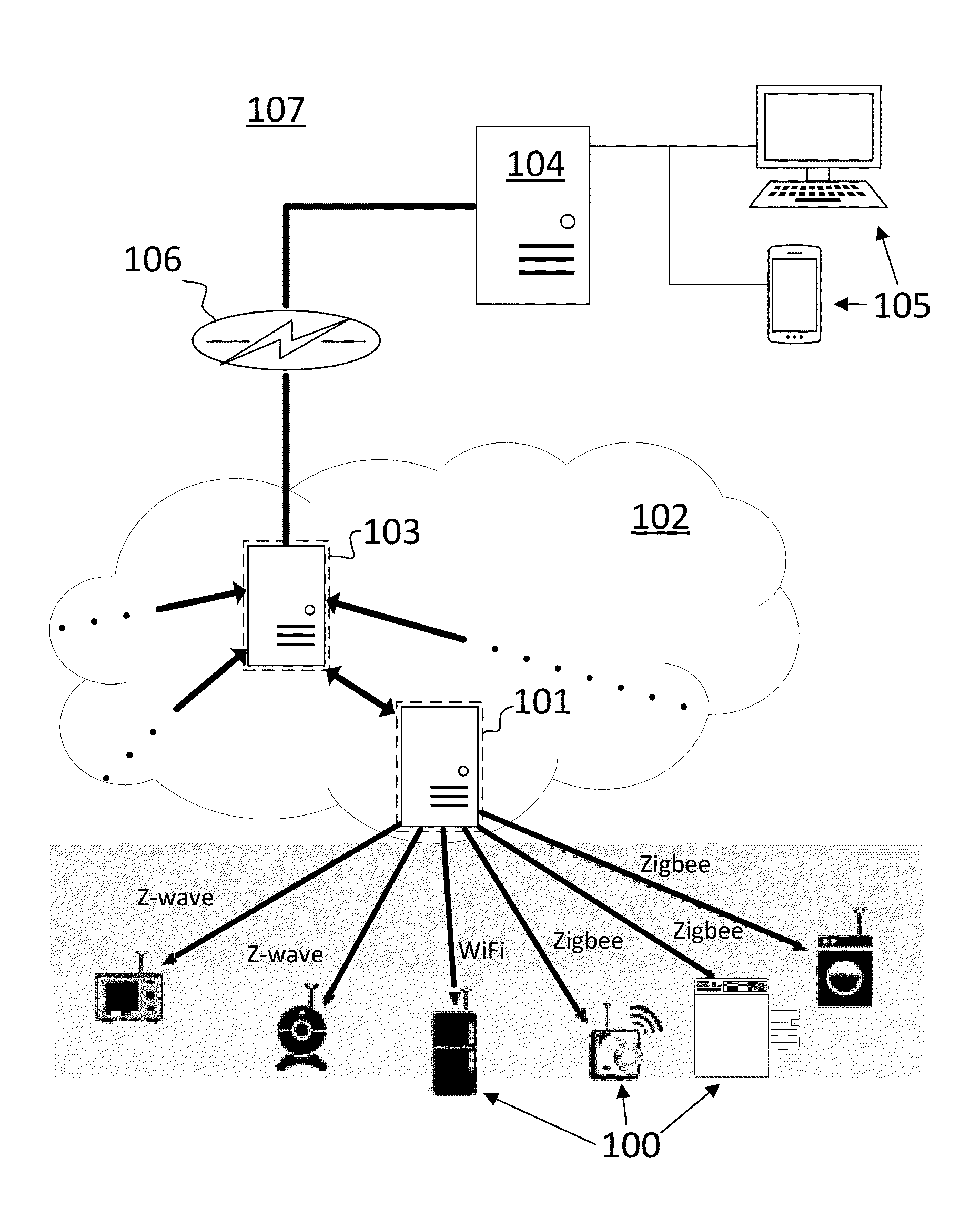

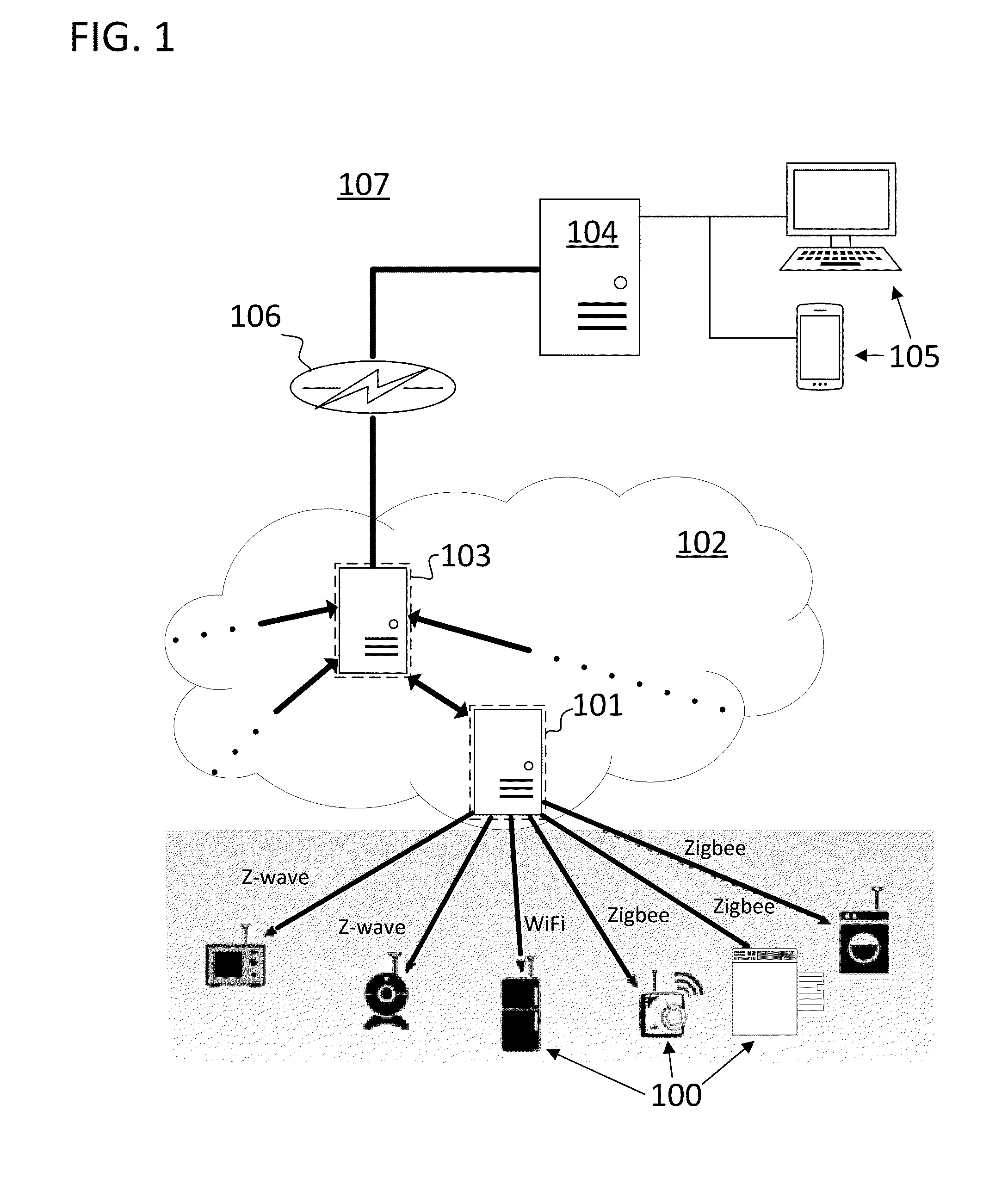

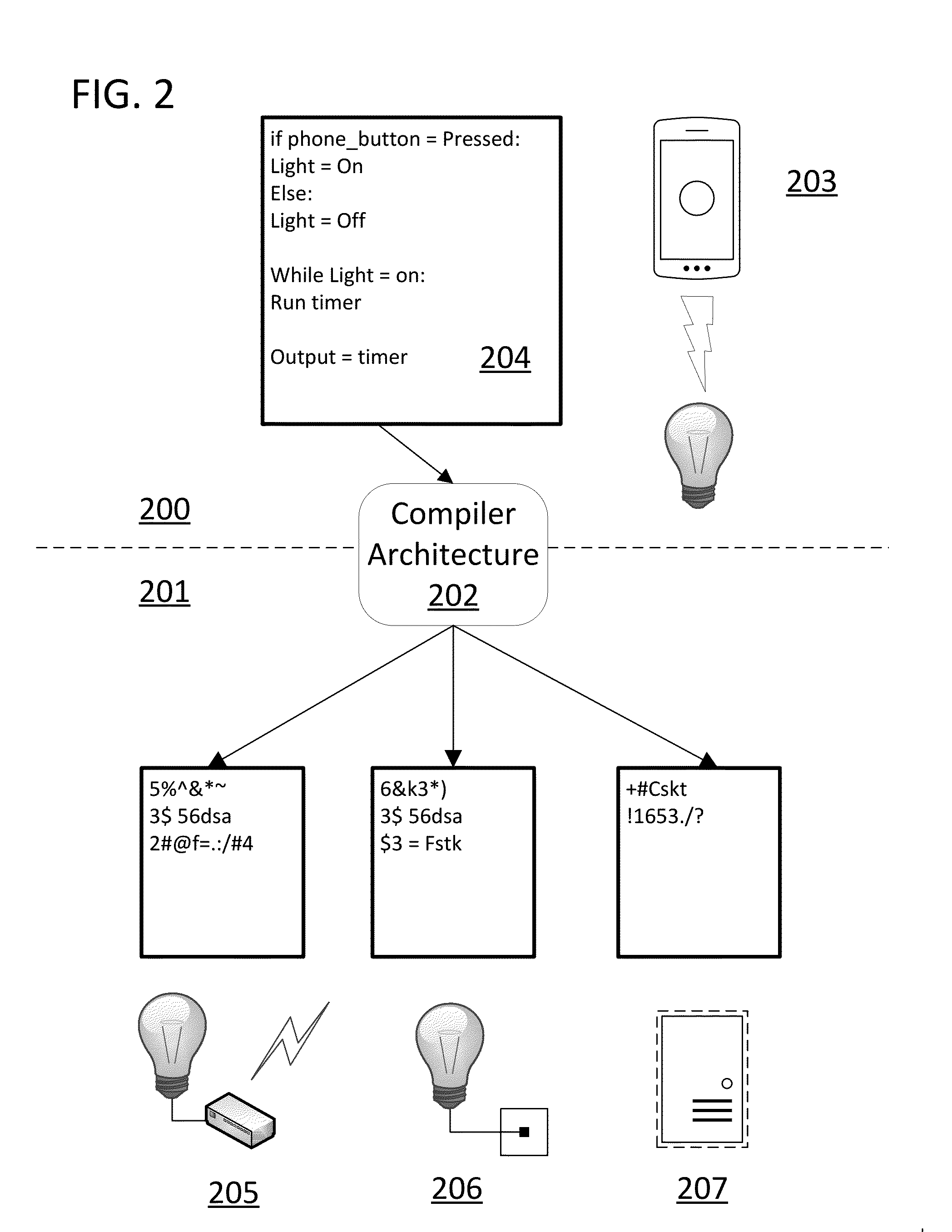

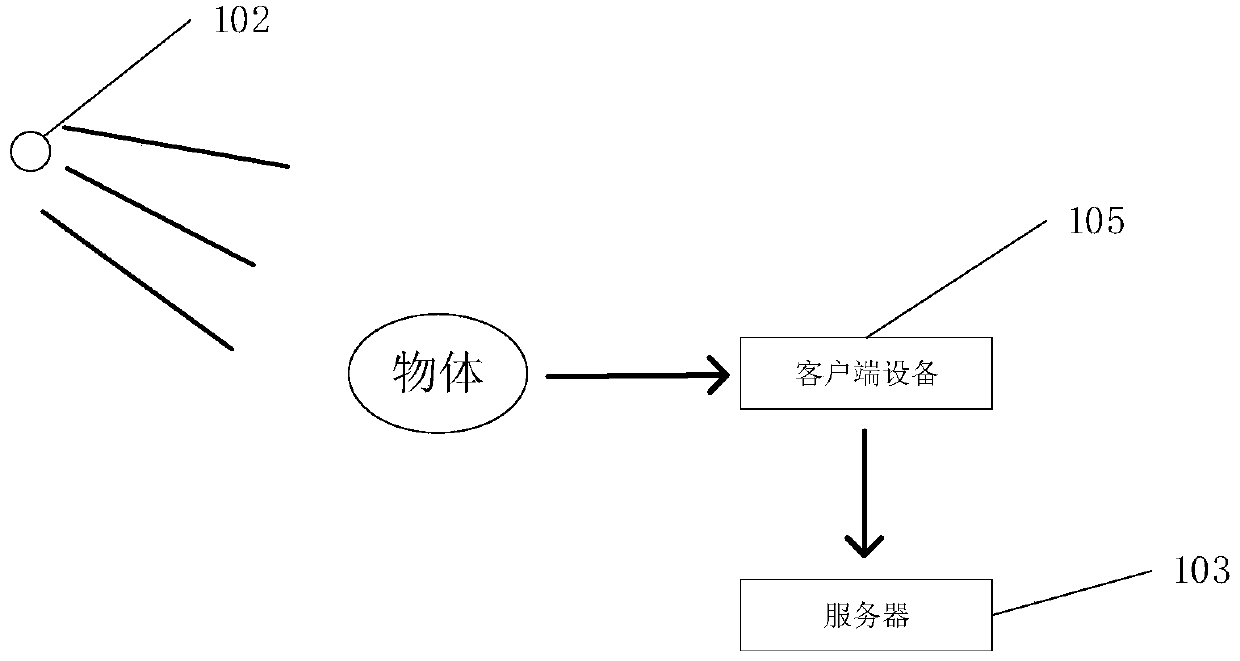

Design framework for an IoT system

InactiveUS20160274870A1Programming languages/paradigmsModel driven codeCompiled languageEmbedded system

A design framework for an Internet-of-Things (IoT) system uses a programming-language-neutral file that describes an embedded device that is a specific-purpose end node in the IoT system. A programming-language-specific file is generated from the programming-language-neutral file for a node in the IoT system. The programming-language-specific file is in a programming-language-dependent code and specifies a compilable-language program for a control application to be installed in a computer in the IoT system for communicating with and controlling the embedded device. In some embodiments, at least one of the programming-language-specific file is created for at least one of several types of nodes in the IoT system.

Owner:ARRAYENT

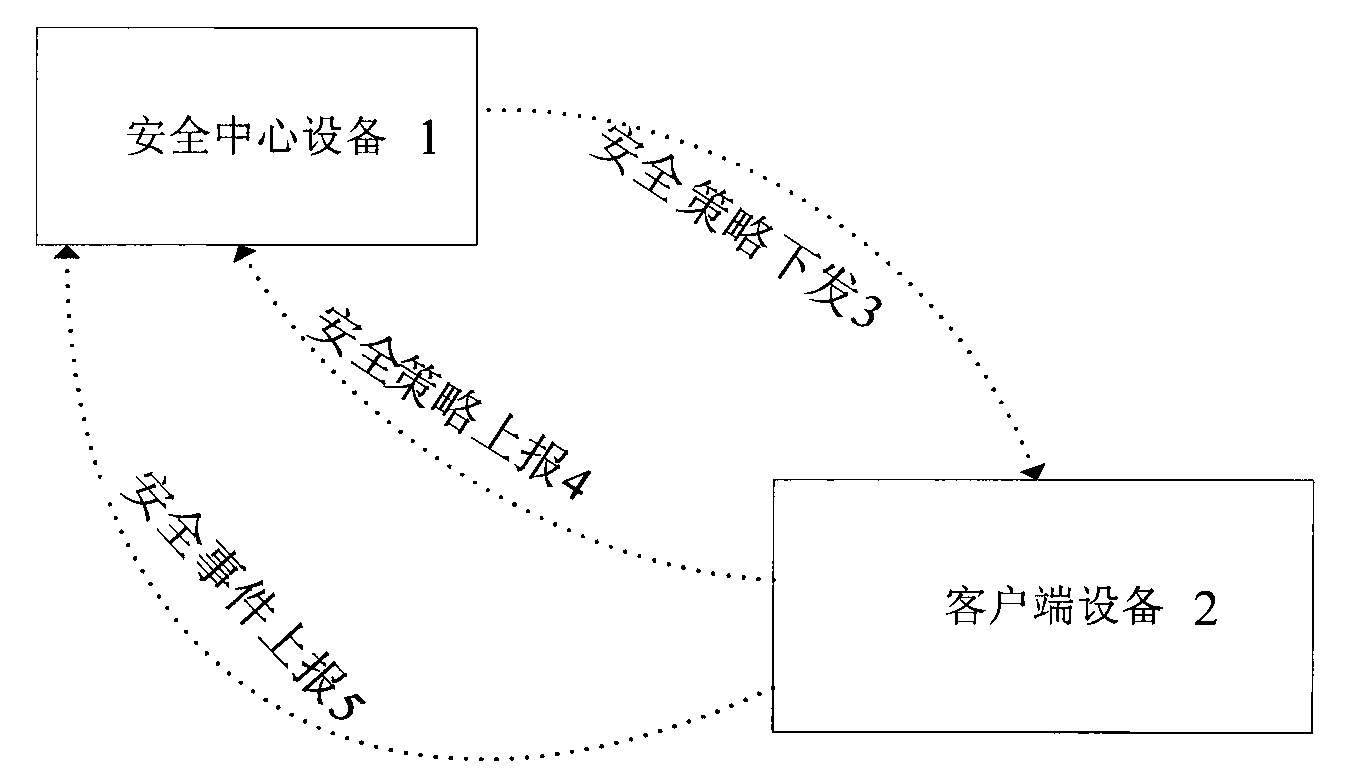

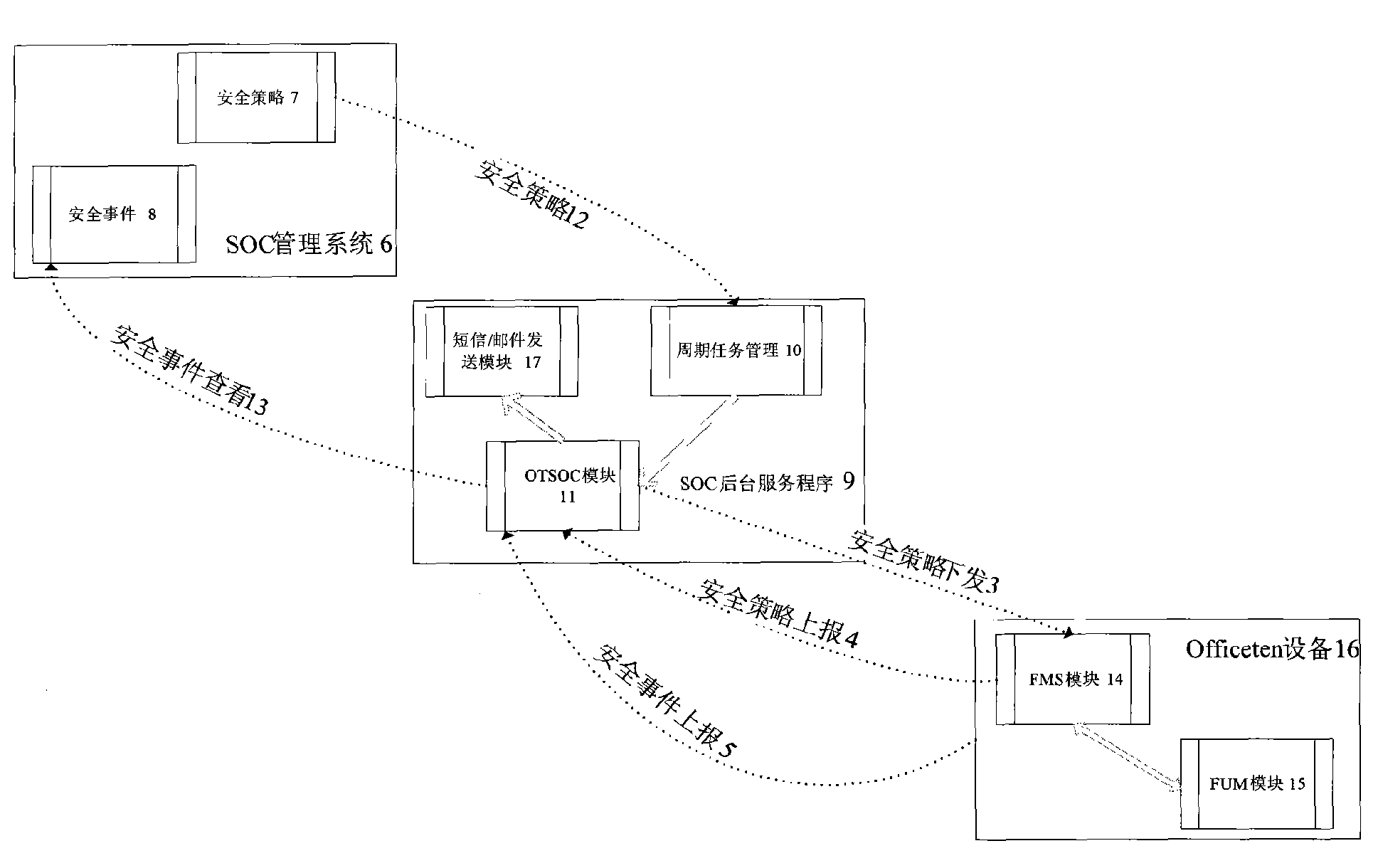

Implementation method of security event monitoring in security center system

InactiveCN101605065ARealize monitoringStrong noveltyMessaging/mailboxes/announcementsData switching networksNetwork behaviorMonitoring system

The invention provides a design framework of a distributed network behavior real time monitoring system based on a B / S model in which a plurality of monitoring devices are connected with a security center, the security event monitoring is divided into two parts, and the security center is configured with security strategy which is issued to the monitoring devices and self-defines an alarm manner; the monitoring devices monitor the network behavior of a user in real time, and security event and local security strategy are submitted to the security center in real time; the security center analyzes the security event and informs a manager in a mail / short message way so as to realize the real time monitoring of the network behavior of the user. The invention adopts a remote communication way to realize the management of the security center on the monitoring devices, and collectedly manage the security event of the monitoring devices, thus realizing the security event monitoring of the security center on the plural monitoring devices.

Owner:网经科技(苏州)有限公司

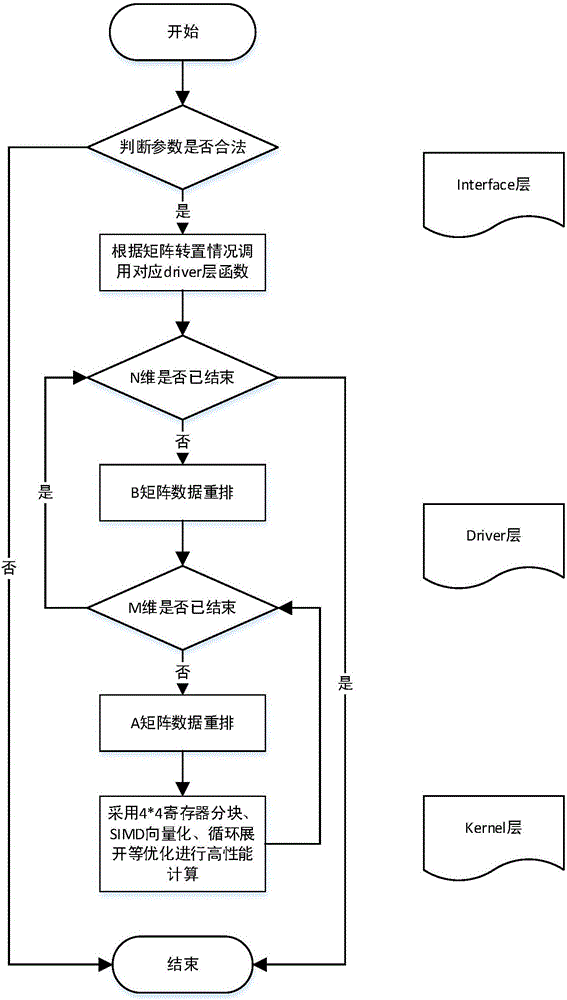

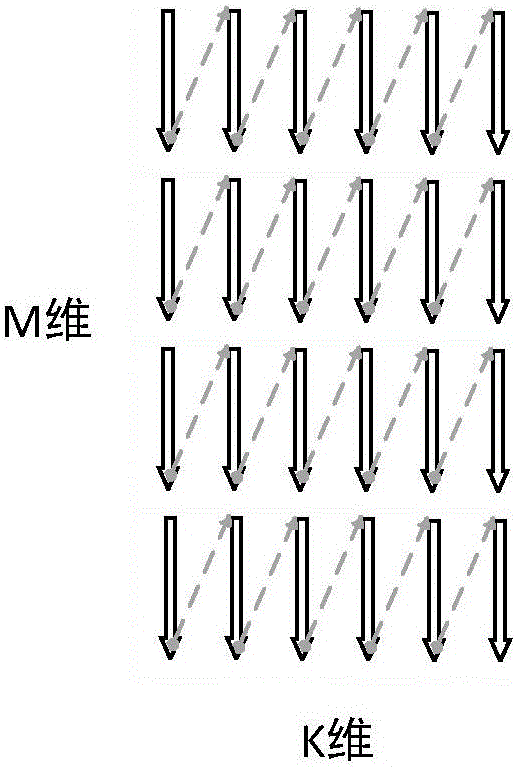

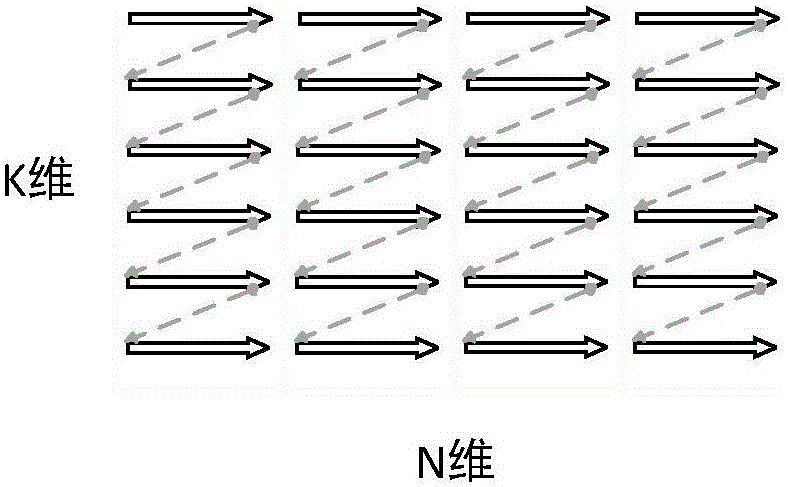

High-performance realization method of BLAS (Basic Linear Algebra Subprograms) three-level function GEMM on the basis of SW platform

ActiveCN105808309AImprove performanceReduce consumptionProgram controlMemory systemsThree levelOpen source

The invention puts forward a high-performance realization method of a BLAS (Basic Linear Algebra Subprograms) three-level function GEMM on the basis of an SW platform. An ''interface-driver-kernel assembly core code'' three-layer code design framework is adopted by aiming at a domestic SW1600 platform, technical means, including a multiply-add instruction, loop unrolling, software pipeline instruction rearrangement, SIMD (Single Instruction Multiple Data) vector operation, register blocking technology and the like which are associated with platform architecture, are adopted to realize assembly level manual optimization, the problem that a compiler can not sufficiently optimize a compute-intensive function GEMM is solved, and function performance is greatly improved. Compared with an open source BLAS math library GotoBLAS, the high-performance realization method is characterized in that an average speed-up ratio is 4.72 and a highest speed-up ratio is 5.61.

Owner:INST OF SOFTWARE - CHINESE ACAD OF SCI

Api and business language schema design framework for message exchanges

A server system facilitates an exchange of messages with a remote client application. The server system includes a plurality of application servers hosting a plurality of applications. A plurality of Application Program Interfaces (APIs) provides programmatic access to the plurality of applications, each of the APIs being configured to receive request messages compiled by the remote client application. First and second request messages, respectively addressed to first and second APIs of the plurality of APIs by a remote client application, each comprise at least one common data component. Further, the first request message includes a first payload specific to the first API, and the second request message includes a payload specific to the second API.

Owner:EBAY INC

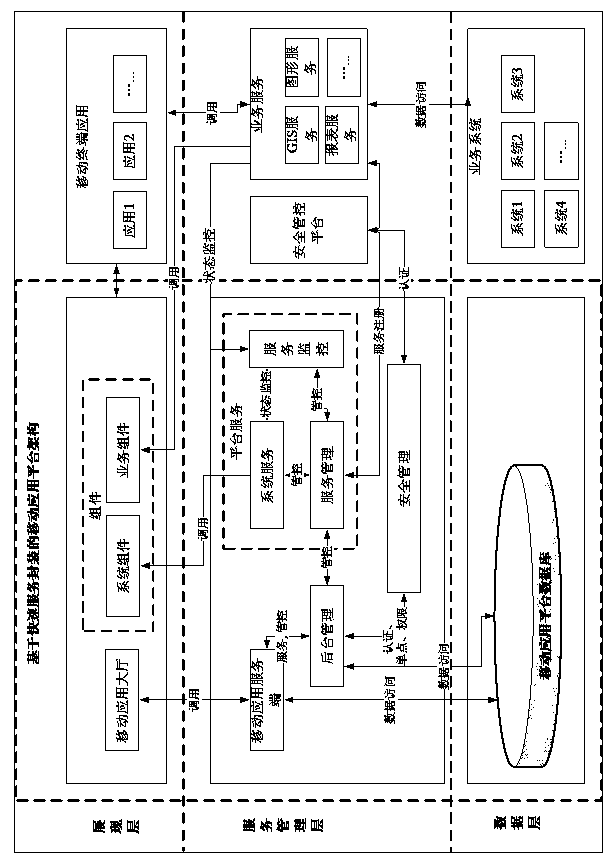

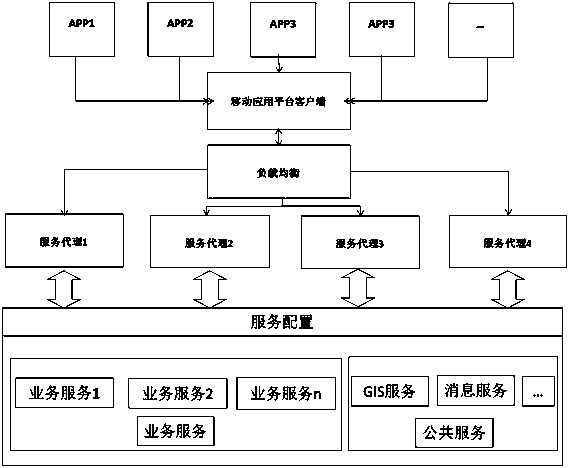

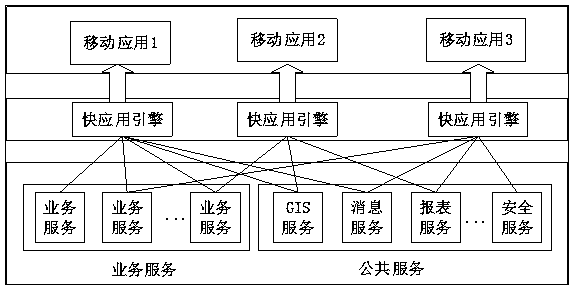

Mobile application platform based on quick service encapsulation

InactiveCN104301401ARealize unified publishingRealize unified management and controlTransmissionWireless communicationIT service managementPoint of entry

The invention discloses a mobile application platform based on quick service encapsulation, and relates to the field of the mobile internet. A layered design framework is adopted in the platform and comprises a data layer, a service management layer and a display layer. The platform framework supports unified entrance, unified publishing and unified management and control of an application, and design of a system public assembly and a general industry assembly is provided. A quick service encapsulation framework is provided for unified encapsulation of public services and system services. The services are provided for service callers through a service agent and service providers obtain the services. A quick application framework is supported, and applications can be quickly generated in a configuration mode. Compared with the prior art, the mobile application platform based on quick service encapsulation can greatly reduce development requirements, improves development efficiency, and has good application and popularization value.

Owner:INSPUR TIANYUAN COMM INFORMATION SYST CO LTD

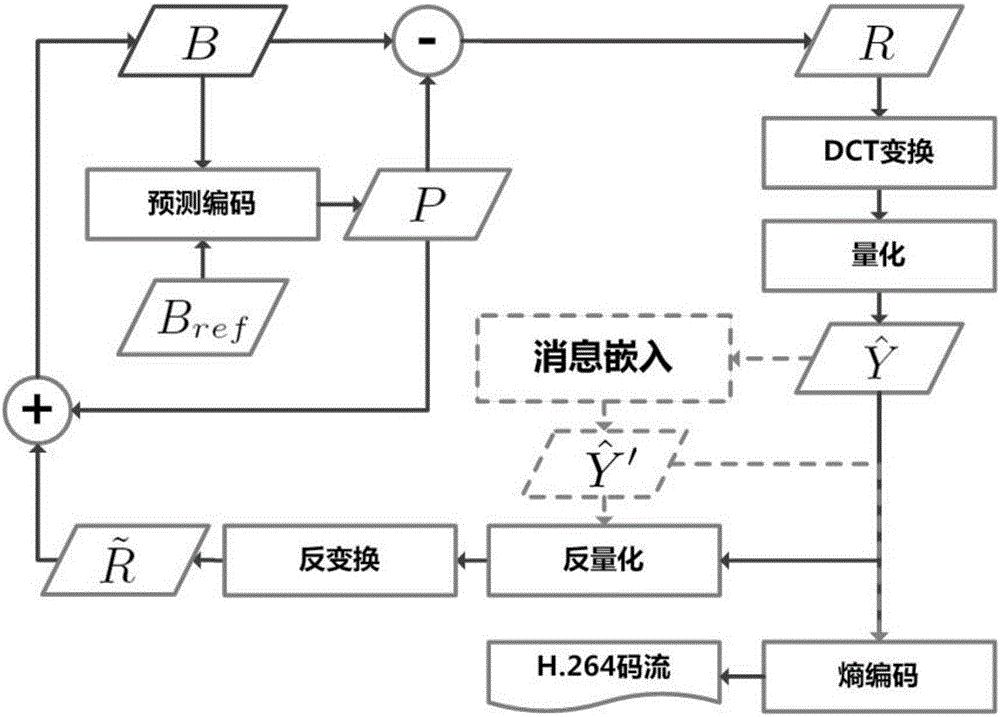

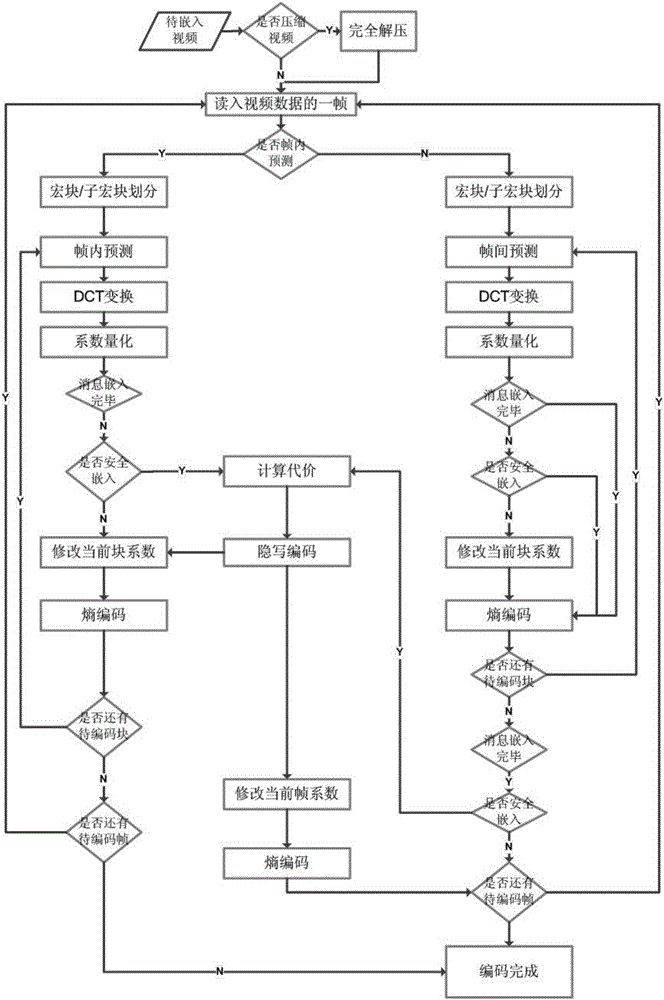

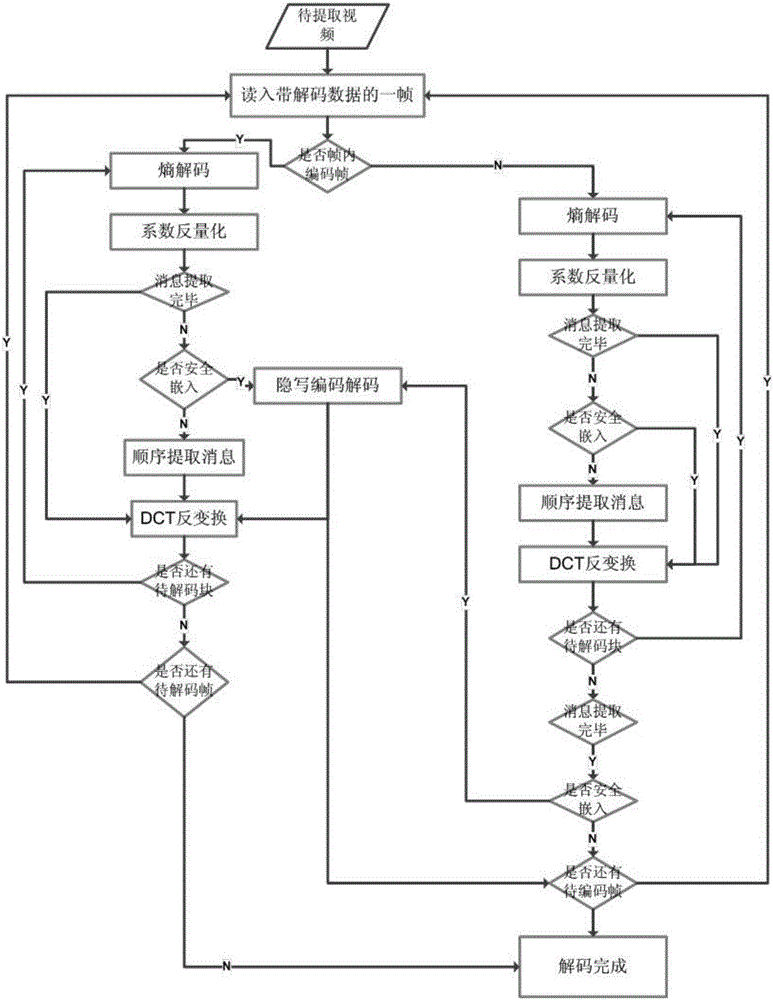

H.264 video information hiding method tightly coupled to compression coding process

InactiveCN106101714AMinimal impact on compression qualityGood reconstruction visual qualityTelevision systemsDigital video signal modificationComputer architectureInformation hiding

The invention relates to a H.264 video information hiding method tightly coupled to a compression coding process. The core concept of the H.264 video information hiding method is as follows: on the basis of complete coding, high-security or high-capacity information hiding without distortion drift phenomenon is realized in a manner of tightly coupling to compression coding. The method is designed based on complete compressing and coding, so that the distortion drift phenomenon can be completely avoided; simultaneously, the concept of an independent coding unit is introduced; therefore, users can perform different configuration of a design framework according to different requirements, so that demand preferences on the security or the embedding capacity can be satisfied; the method is different from the past any H.264 video steganography method; and thus, the method disclosed by the invention is particularly suitable for a hiding communication scene having low real-time requests and relatively high algorithm performance (the security or the embedding capacity) requests.

Owner:INST OF INFORMATION ENG CHINESE ACAD OF SCI

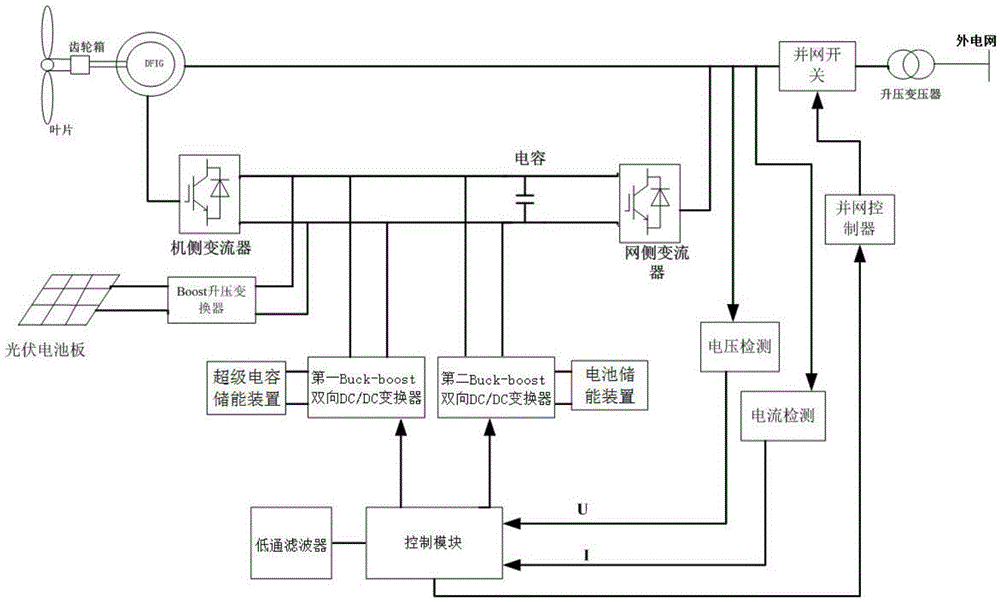

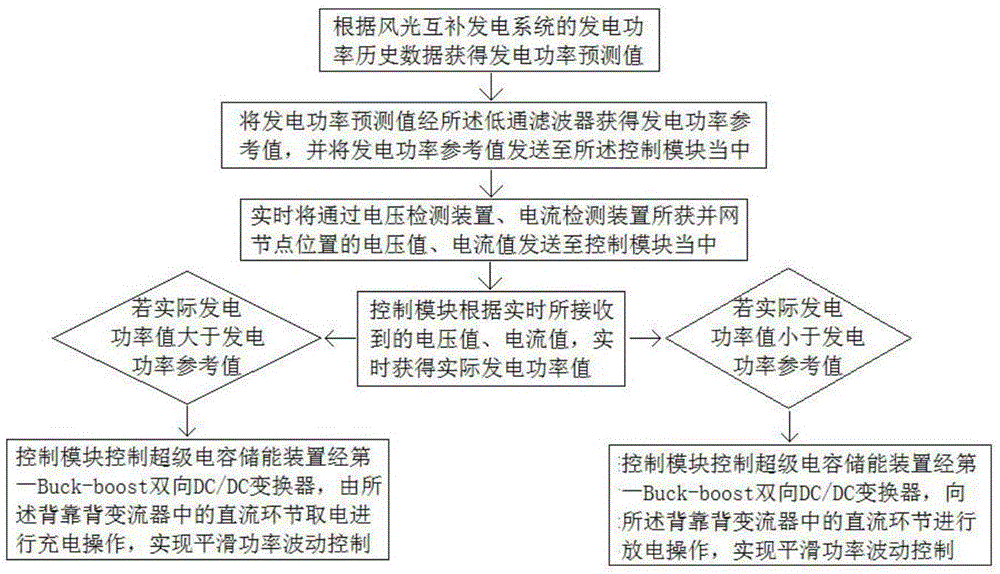

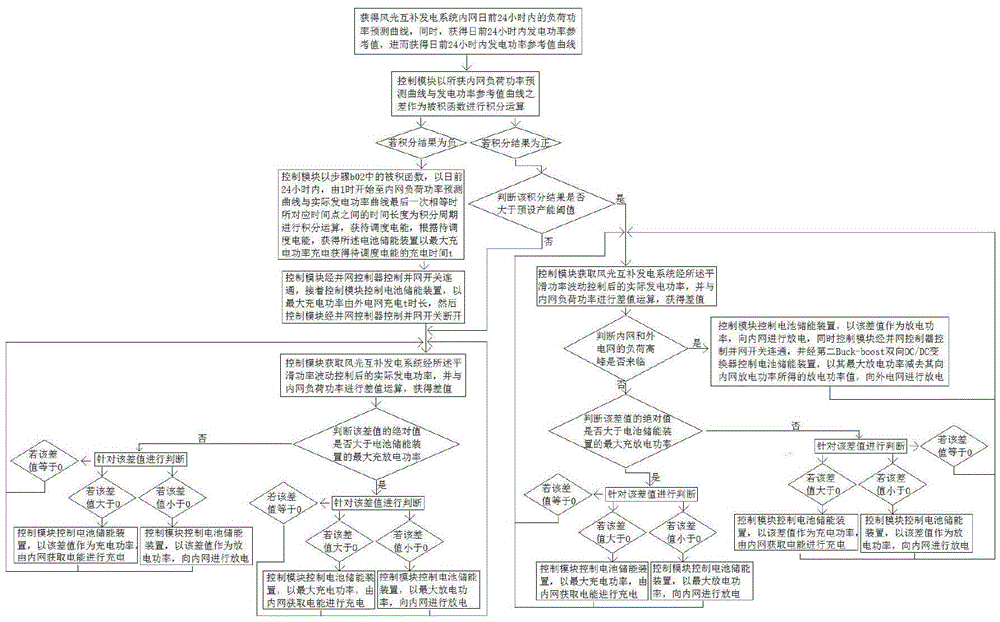

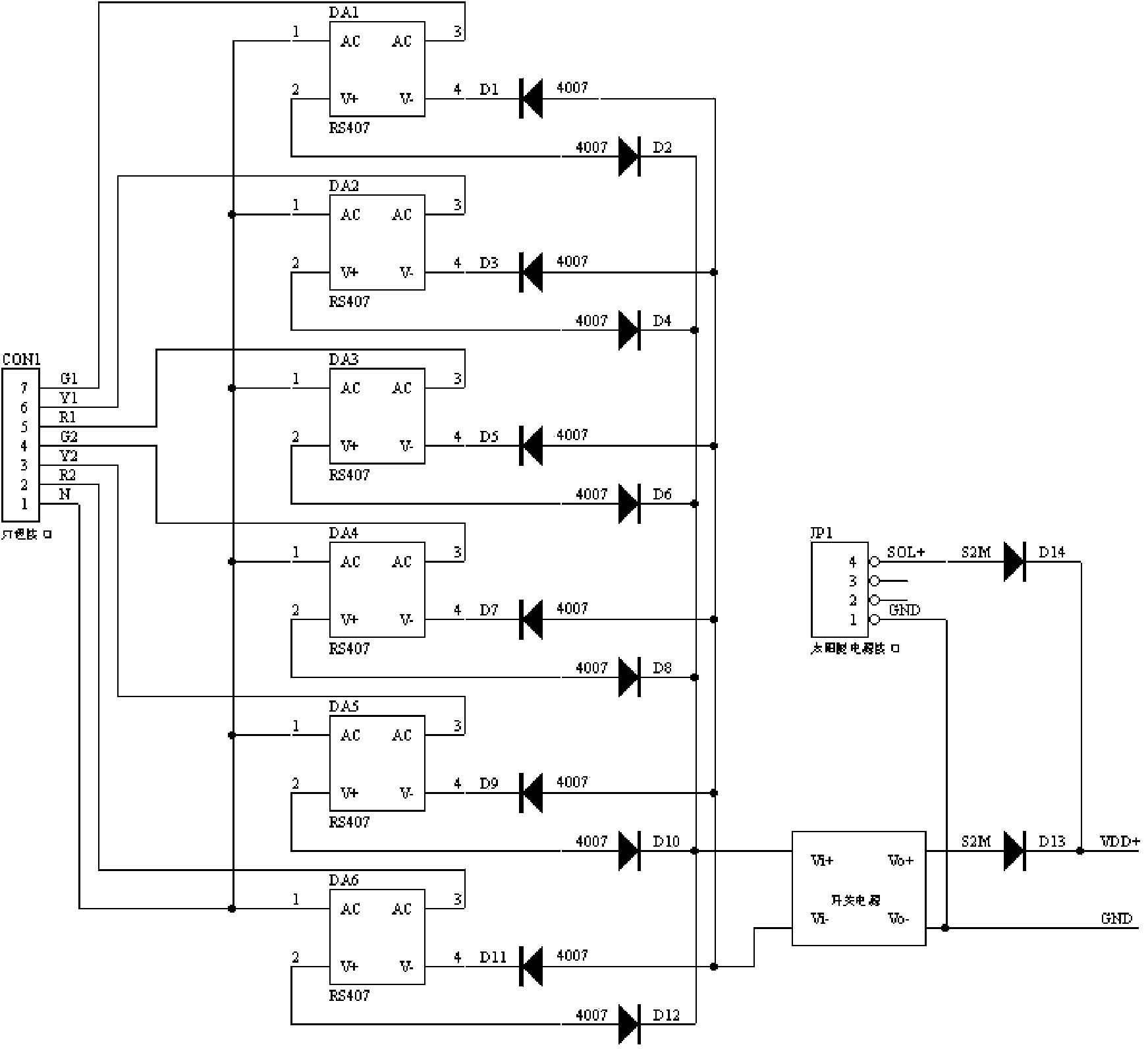

Wind-solar complementary generation system and control method

ActiveCN105680771AImprove work efficiencyRegulating loadPV power plantsEnergy storageMicrogridLow-pass filter

The invention relates to a wind-solar complementary generation system. By a bran-new design framework, a photovoltaic power generation link is embedded into a wind power generation link, so that system output power fluctuation can be stabilized; a load in a microgrid can be adjusted; and the work efficiency of the generation system is effectively improved. The invention further relates to a control method for the wind-solar complementary generation system. The method comprises a combined control method for stabilizing power fluctuation and adjusting the load in the microgrid. By combination of a power prediction technology and a low-pass filter principle, the system generation power in the next 24 hours is predicted in advance by the perspectiveness of the prediction technology. Due to the uncertainty and the volatility of wind and solar radiation, a lot of high-frequency components exist in the actual generation power of the wind-solar complementary generation system. A predicted value is very close to an actual value, the high-frequency component in the predicted value is filtered out through a low-pass filter; and the processed predicted value is taken as a reference value of the system output power, so that the system generation power fluctuation can be effectively stabilized.

Owner:NANTONG UNIVERSITY

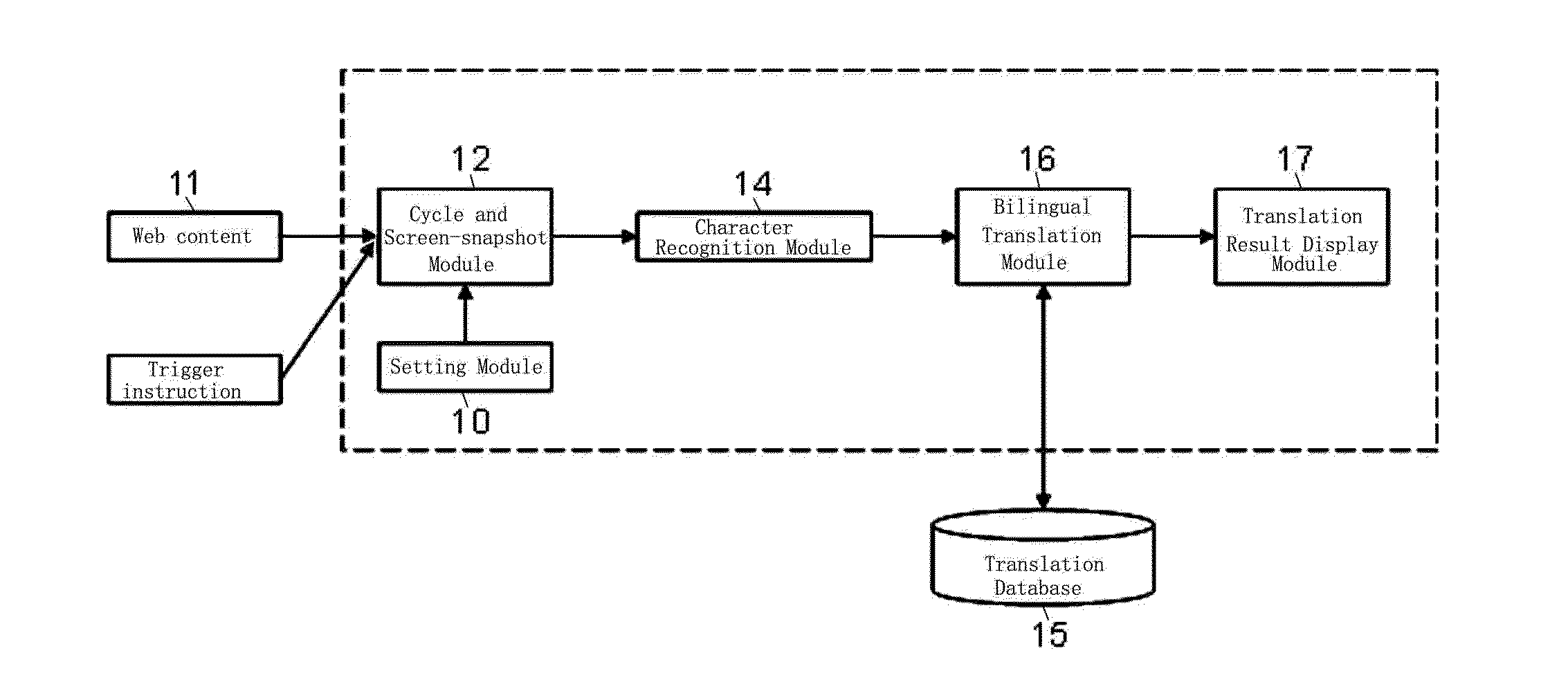

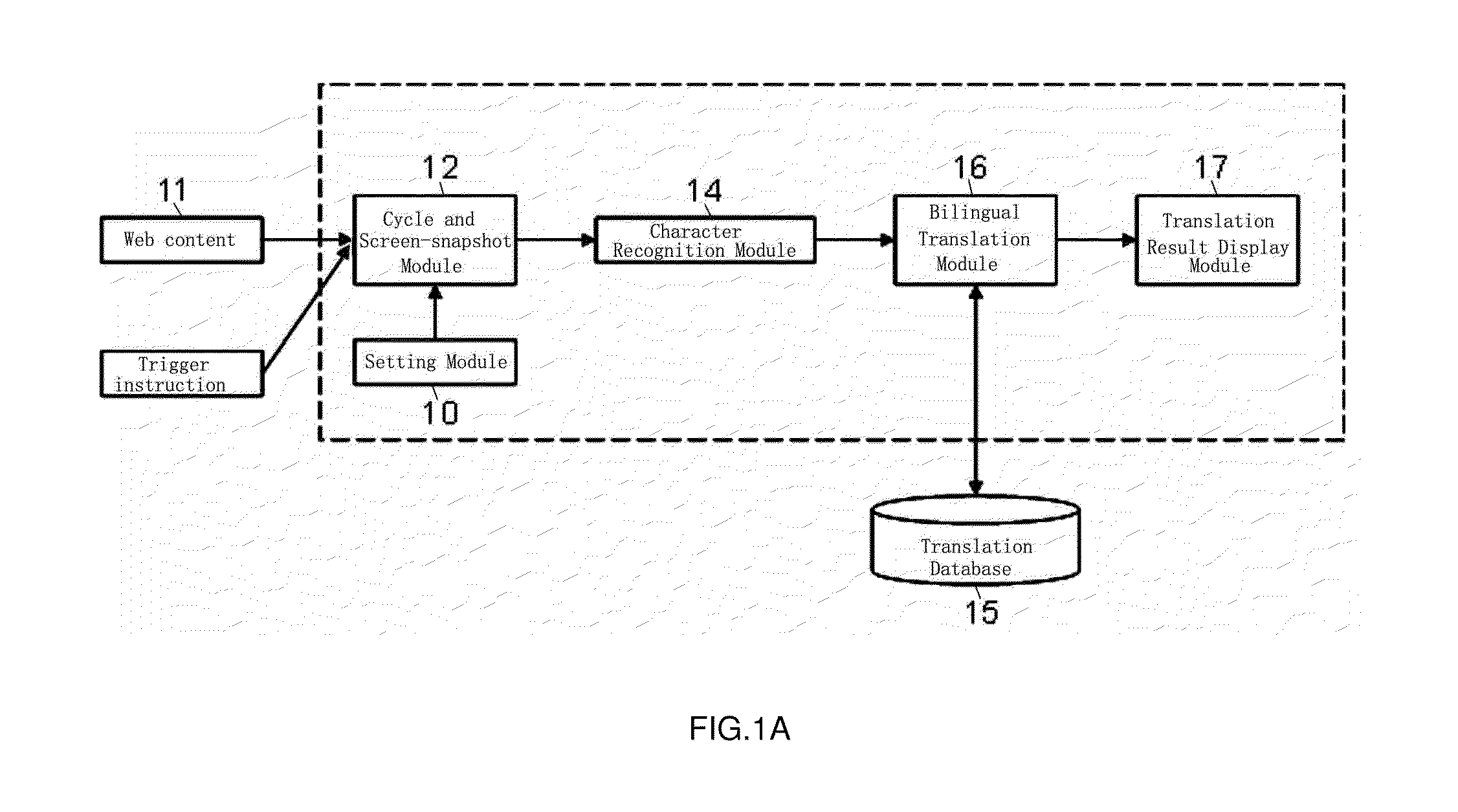

System and method of online user-cycled web page vision instant machine translation

InactiveUS20100324887A1Natural language translationSpecial data processing applicationsCellular telephoneVisual perception

This invention refers to a novel online user-cycled web page vision instant translation (OUWVIT) system and method, which is provided to capture, process and translate the online user-cycled paragraph of web page instantly. The system comprises Setting Module, Cycle and Screen-snapshot Module, Character Recognition Module, Bilingual Translation Module, Translation Result Display Module and Translation Database, wherein the said Setting Module is used to set specific shortcut key; the said Cycle and Screen-snapshot Module is used to capture the user-cycled paragraph of web page after user cycles the paragraph on web page; the said Character Recognition Module is used to recognize and process the text in the captured paragraph and eliminate the non-text information; the said Bilingual Translation Module translates the recognized and processed text to target language instantly; the said Translation Result Display Module displays the translation result in a pop-up independent window. It is noteworthy that the linkages and communications between modules are implemented automatically. The system and method can be applied to various types of wired or wireless Internet accessing equipments including personal computers, embedded or portable systems, system chips, cell phones and other mobile electronic devices. The core values of the present invention are that it is neither restricted by inner design framework format and programming language of web page, nor restricted by outer displaying style, animation and colors. It thoroughly overcomes the fatal shortcomings of existing online translation systems, which are significantly restricted by inner framework layout of web page. Consequently, it translates the user-cycled any paragraph of web page from source language to target language for reading instantly and freely.

Owner:DONG MINGCHUI +1

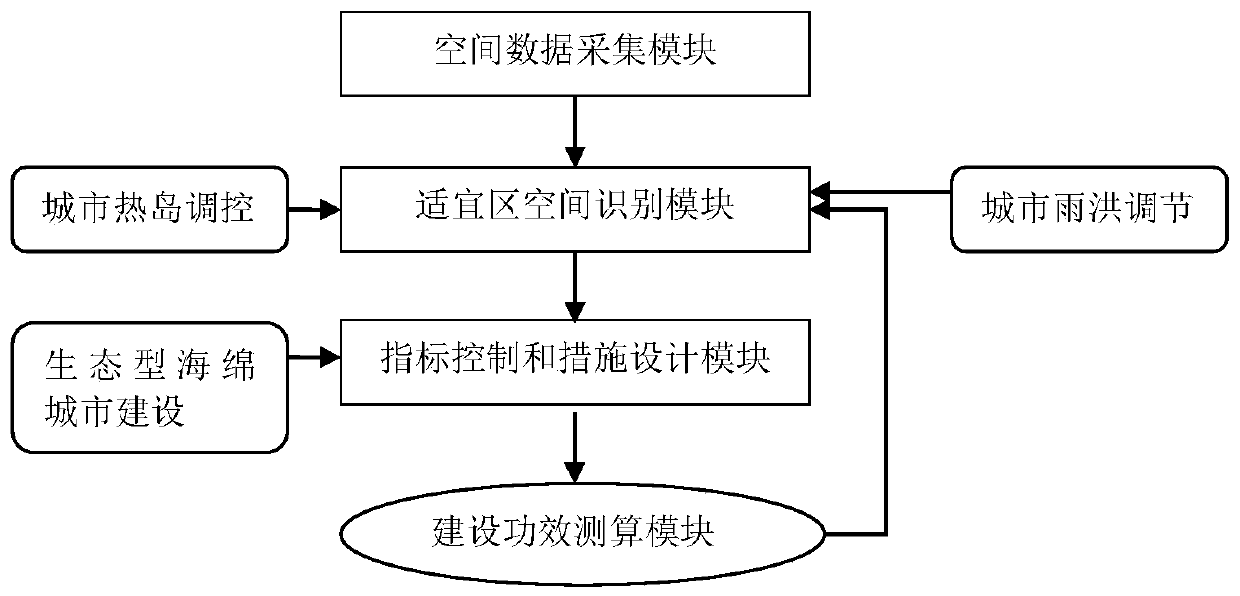

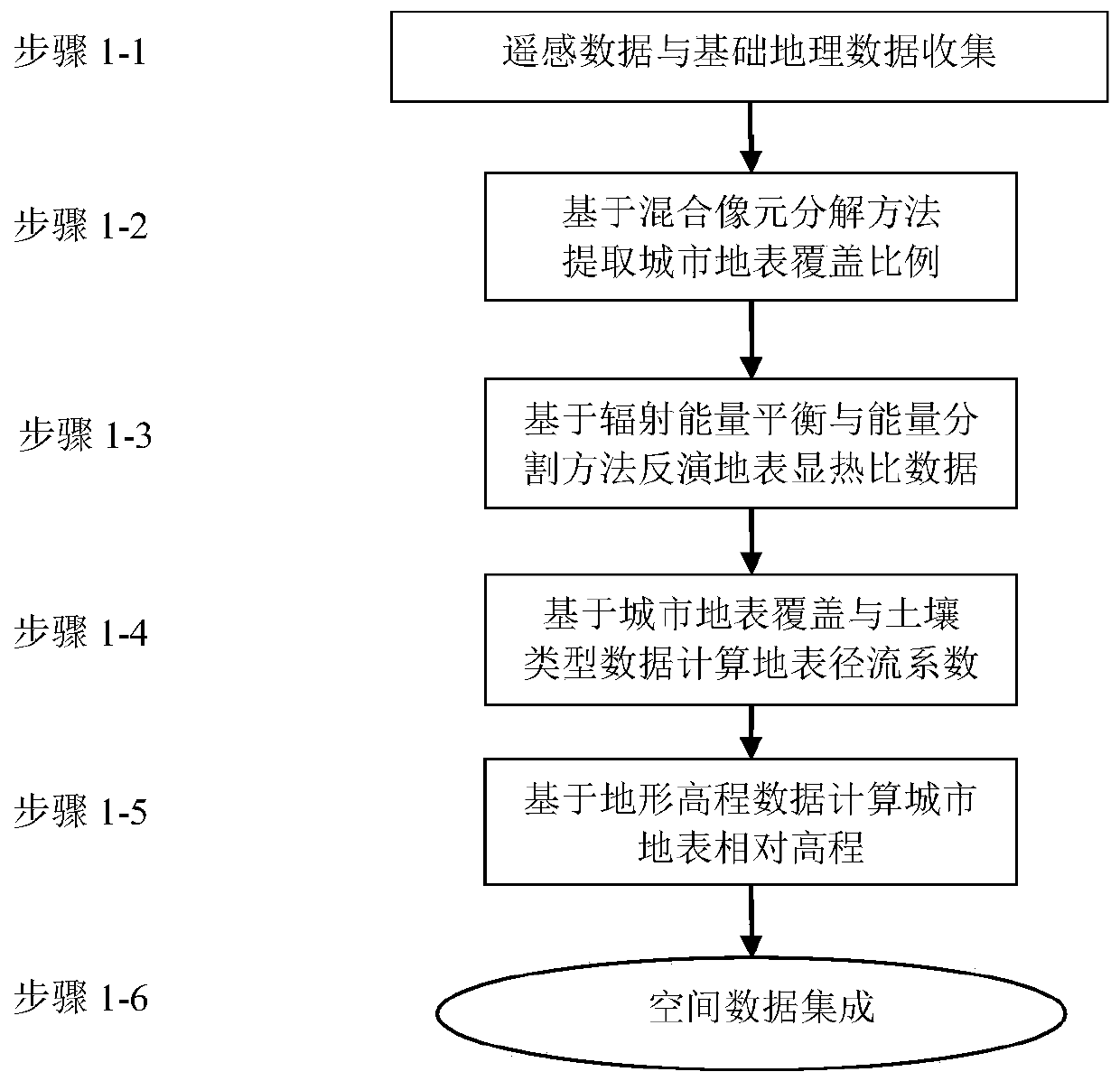

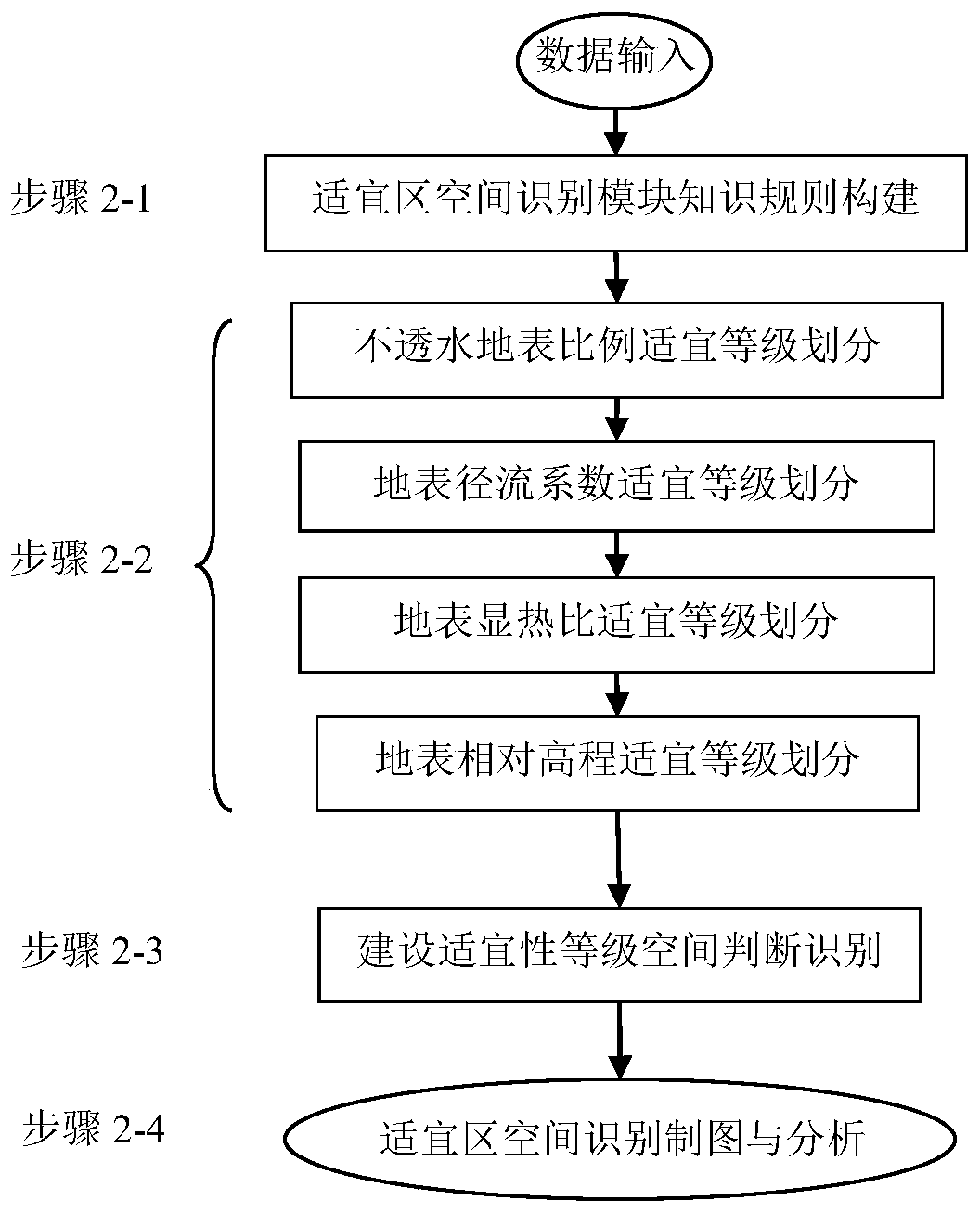

A system and a method for accurately identifying a target and measuring and calculating an effect in an ecological sponge-type city construction suitable area

ActiveCN109740562AIrreversibleEasy to operateForecastingCharacter and pattern recognitionClimate eventsLandscaping

The invention discloses a system and a method for precisely identifying a target and calculating an effect in an ecological sponge type urban construction suitable area. The system comprises a spatialdata acquisition module, a suitable area spatial identification module, an index control and measure design module and a construction effect calculation module. The method is used for sponge city construction from city construction planning to engineering design whole process. Accurate identification of construction and reconstruction target suitable areas and suitable grade targets in urban heatisland control and urban landscaping processes can be realized, and the effects of flood disasters and high-temperature extreme climate events under different urban construction and reconstruction scenarios can be measured and calculated. The system comprises a novel sponge city and heat island control dual-target city planning and design framework, achieves refined remote sensing classificationand artificial intelligence detection algorithm aiming at precise identification of the ecological sponge city space suitability, and can effectively simulate the effects of city construction and reconstruction on rain flood and extreme high temperature events.

Owner:INST OF GEOGRAPHICAL SCI & NATURAL RESOURCE RES CAS

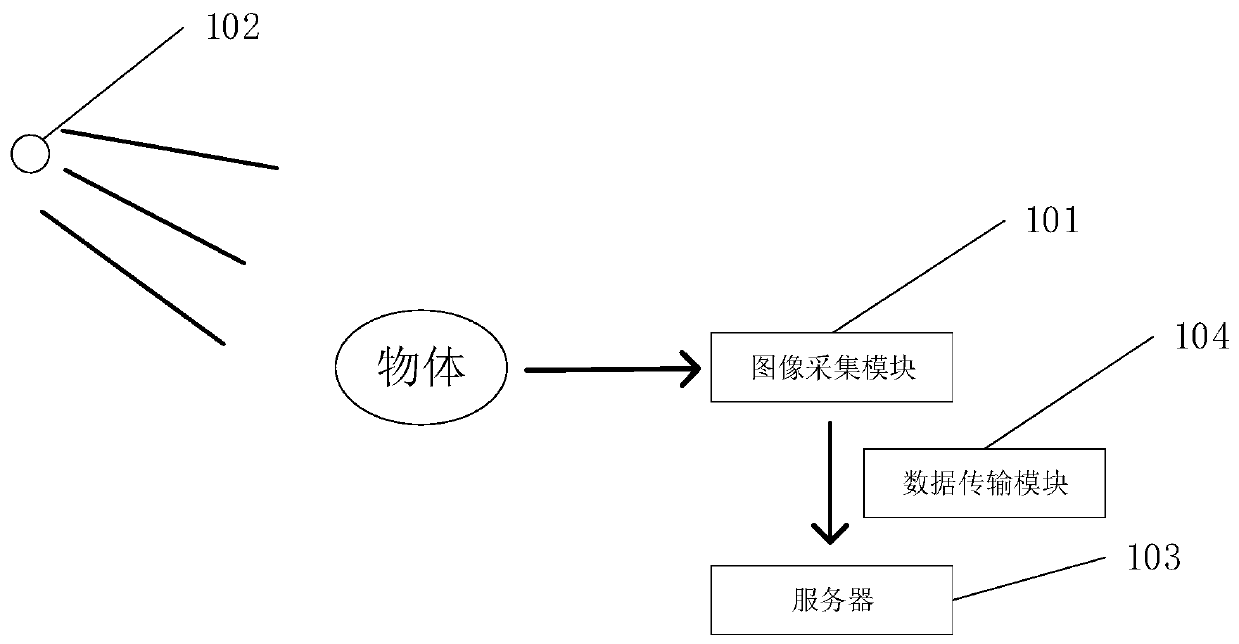

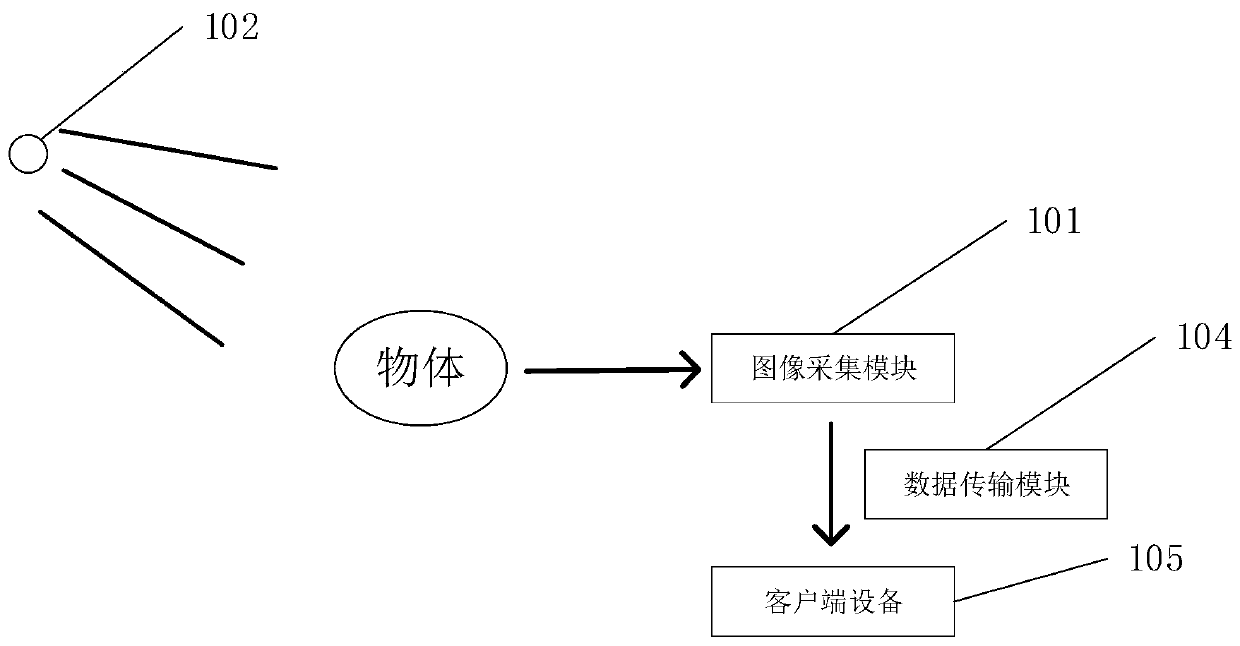

Parallax image generation method and system based on binocular stereo vision matching

ActiveCN110009691AEliminate post-processing stepsSubpixel enhancementImage enhancementImage analysisParallaxStereo matching

The invention provides a parallax image generation method and system based on binocular stereo vision matching. The parallax image generation method comprises the steps of obtaining a pair of speckleimages, wherein the pair of speckle images are images of speckles captured by an object through a pair of binocularly calibrated cameras under the irradiation of a set light beam; inputting the pair of speckle images into a preset deep learning neural network to generate corresponding parallax images, wherein the deep learning neural network is obtained by training a plurality of pairs of speckleimages. According to the method and the system, a pair of speckle images is used as input, a parallax image is directly output through binocular vision stereo matching network (deep learning neural network) processing, end-to-end calculation of the parallax image and an end-to-end network design framework are realized, post-processing steps of stereo matching, such as sub-pixel enhancement, filtering and noise reduction, refinement and the like, are eliminated, and the operation overhead is greatly reduced.

Owner:BEIJING TSINGMICRO INTELLIGENT TECH CO LTD

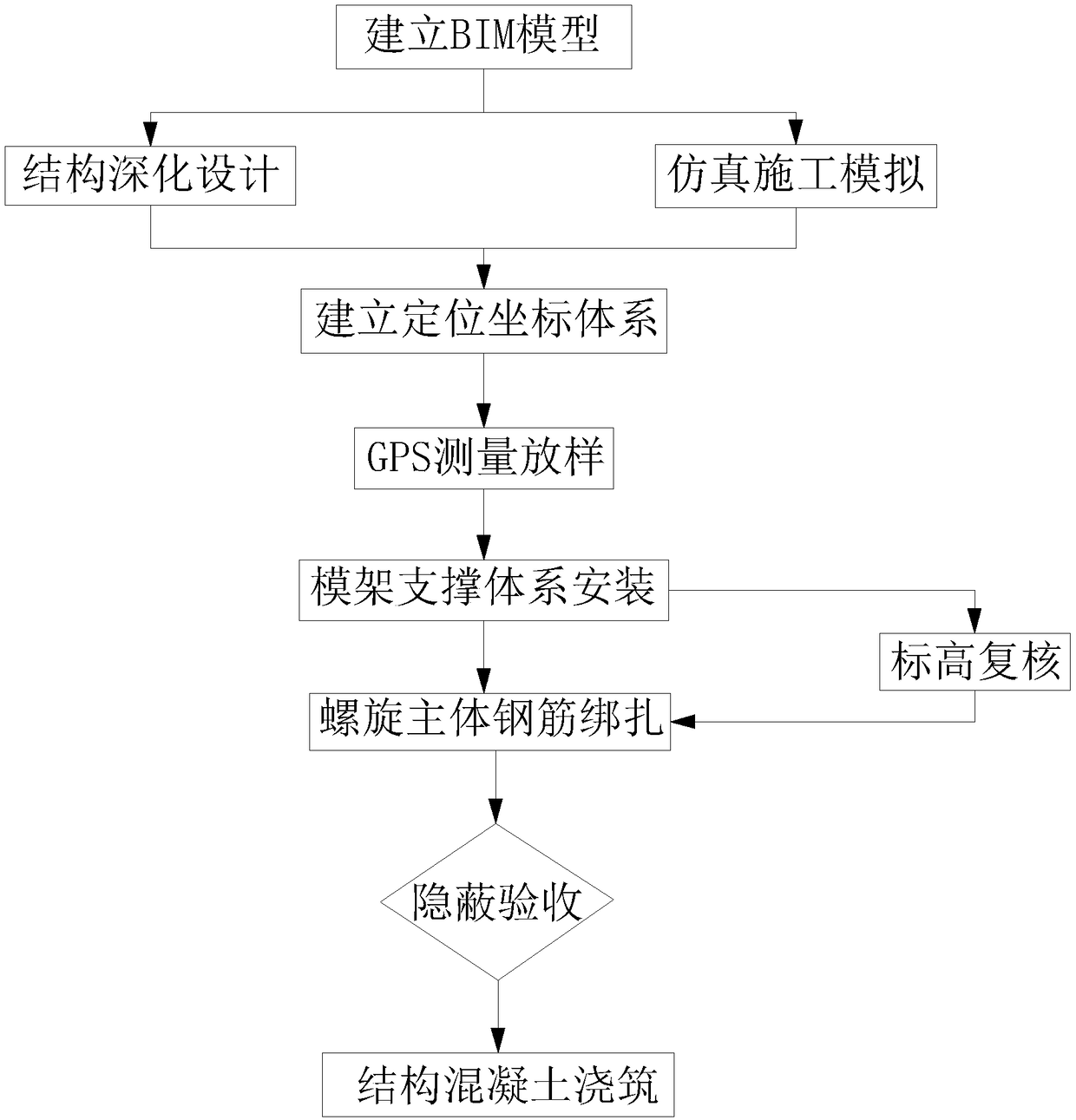

Construction method of spiral-rising-type reinforced concrete structure based on BIM

InactiveCN108416162ADesign fasterHigh precisionGeometric CADBuilding material handlingSupporting systemReinforced concrete

The invention discloses a construction method of a spiral-rising-type reinforced concrete structure based on BIM. A formwork and a supporting system can be automatically generated, the formwork splicing design can be automatically completed, three-dimensional construction simulation can be conducted, intelligent materials are optimized, and the use amount of various materials can be counted and precisely calculated. A BIM software technology is used for conducting three-dimensional modeling on a spiral-rising-type building structure, the splicing size, the supporting system and a safety calculation book of the building structure are determined, and construction workers conduct construction by directly in combination with a three-dimensional model according to a formwork scheme; by using the BIM technology, the speed of designing the formwork is high, the precision of designing the formwork is high, the loss of a supporting rack is reduced, the use efficiency of steel pipes is improved,and the situation is avoided that in the process of calculating the use amount of the materials of the framework and a scaffold, a common artificial design framework is changed, and the materials arewasted due to an unreasonable formwork splicing mode; the energy is saved, the environment is protected, and the engineering construction cost and the construction difficulty are reduced.

Owner:CHINA MCC17 GRP

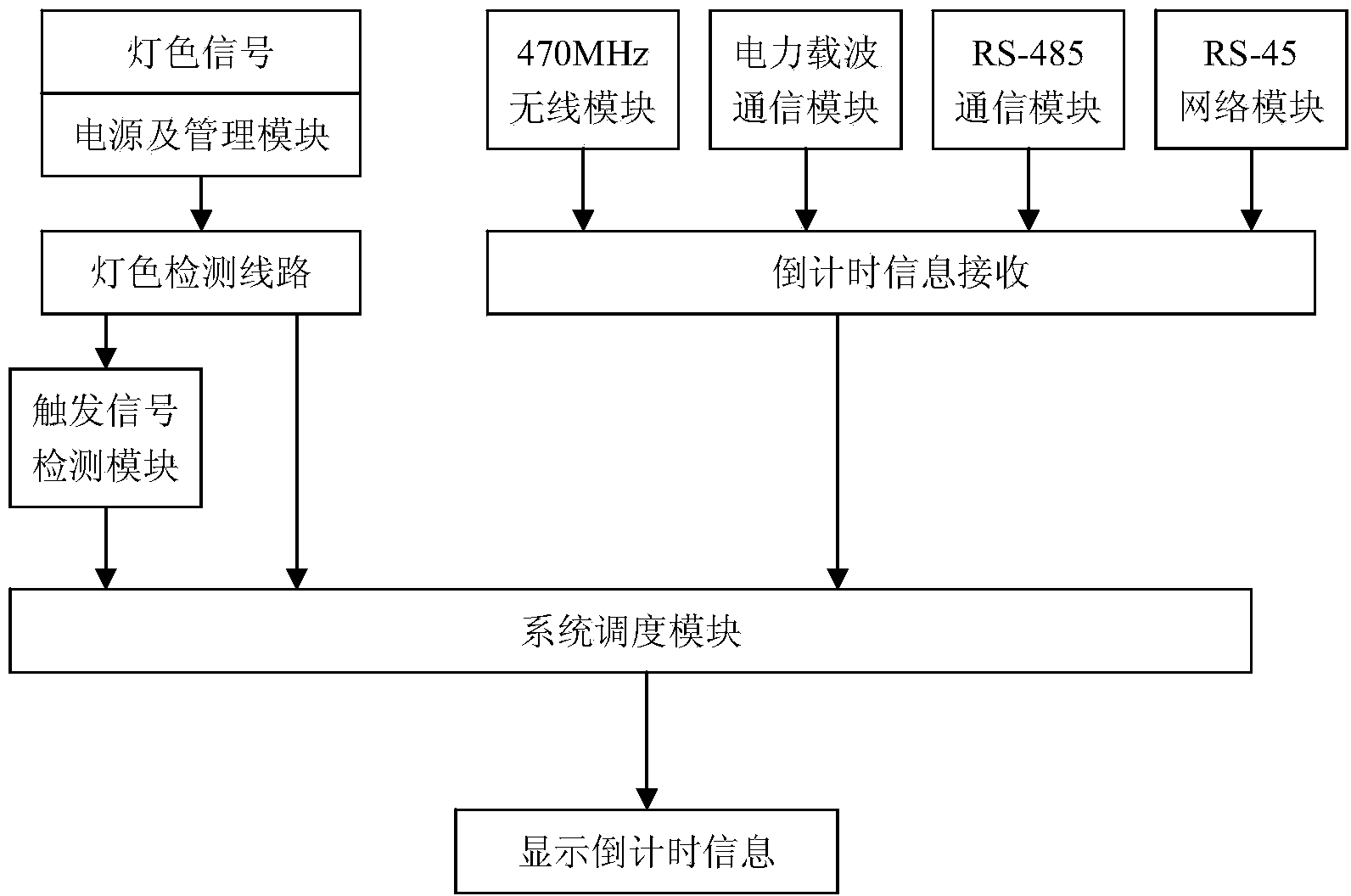

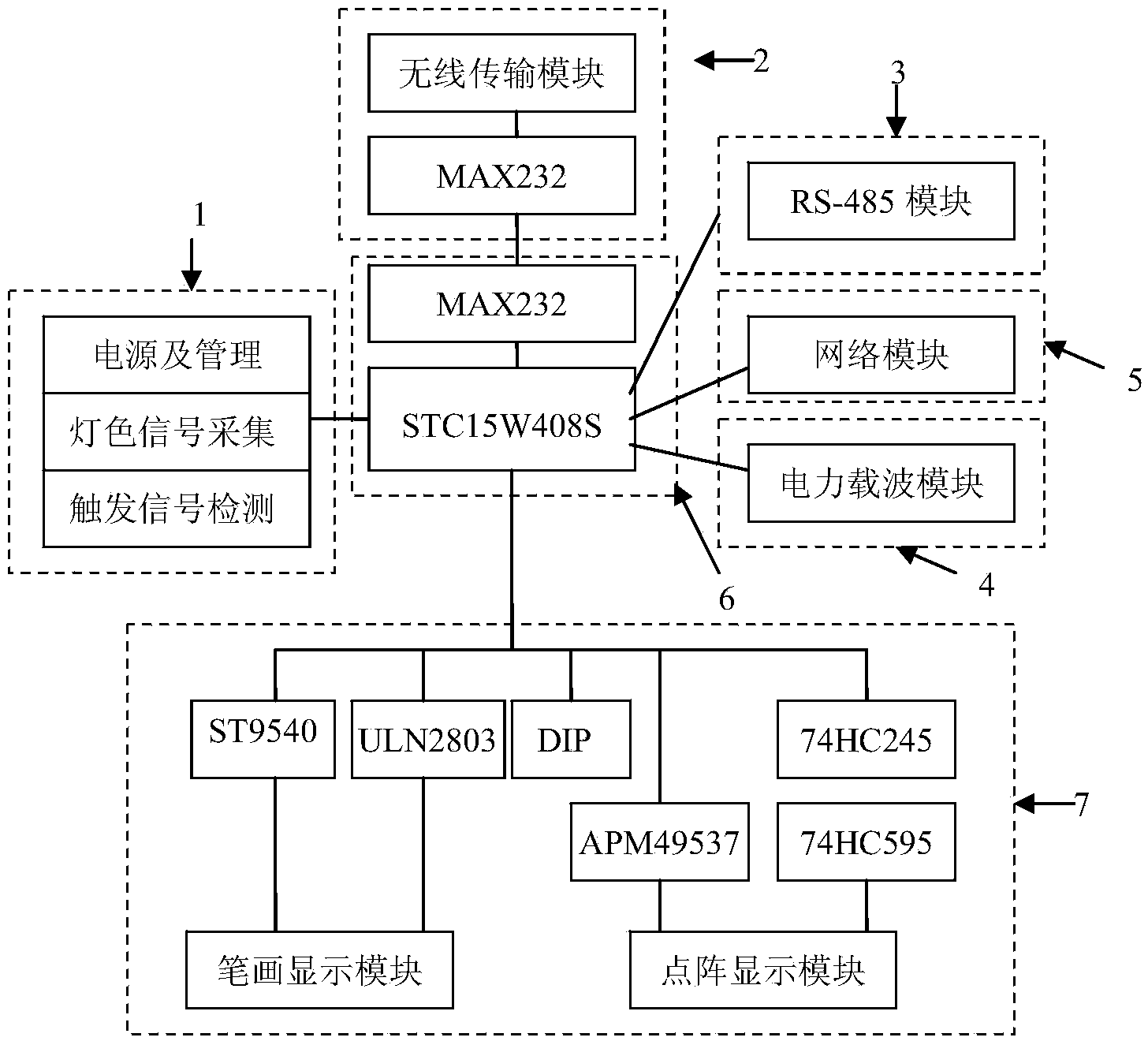

Self-adaptive traffic signal countdown display device and control method thereof

ActiveCN104167104AMeet display needsImprove performanceRoad vehicles traffic controlTraffic signalLow voltage

The invention provides a self-adaptive traffic signal countdown display device and a control method of the self-adaptive traffic signal countdown display device. The self-adaptive traffic signal countdown display device comprises a system scheduling module which is connected with a power source management module, a light color detection module and a trigger signal detection module respectively, a countdown information receiving module and a countdown information display module. The countdown information receiving module is connected with a wireless module, a network module, a power carrier communication module and an RS-485 communication module respectively. According to the self-adaptive traffic signal countdown display device and the control method of the device, a design framework that a high-voltage module is isolated from a low-voltage module is adopted, and the high-voltage part and the lower-voltage part are isolated through an optocoupler, so that system stability is enhanced, and convenience is brought to maintenance. The self-adaptive traffic signal countdown display device aims to be simplified in circuit and stable in performance and conduct display smooth transition when work modes are switched, and the traffic signal countdown device which is high in price performance ratio and complete in function is provided for the intelligent traffic control and management field.

Owner:杭州普乐科技有限公司

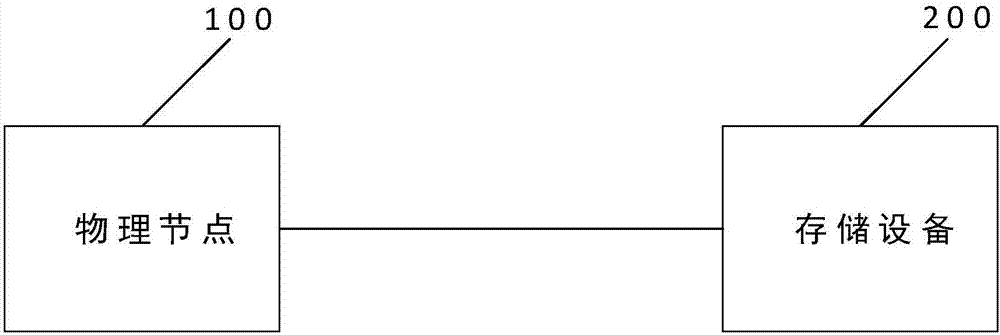

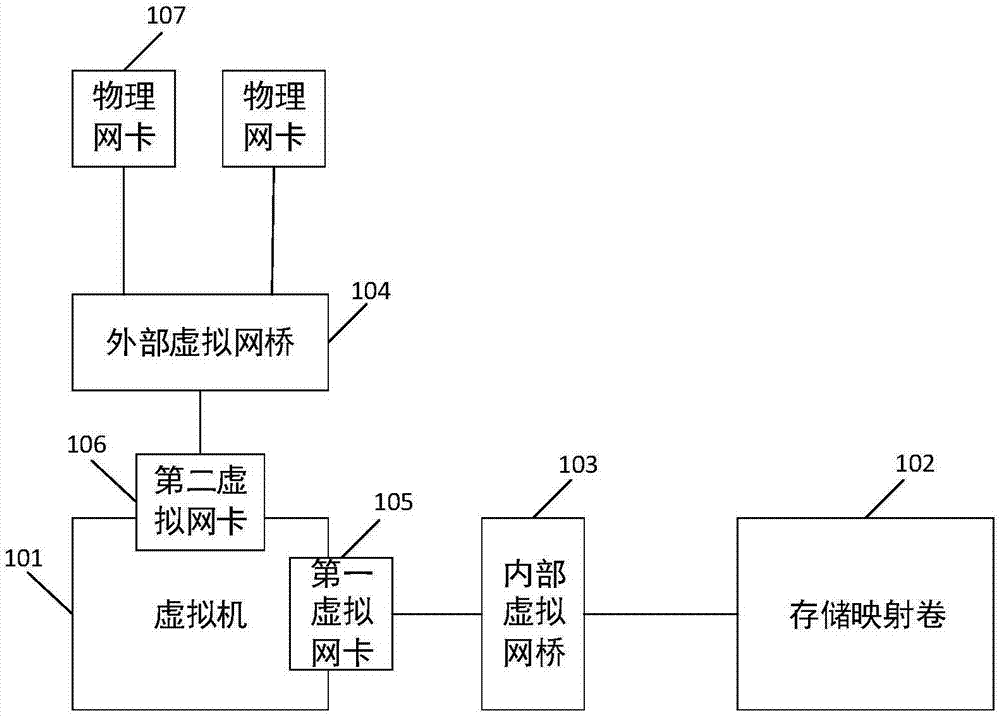

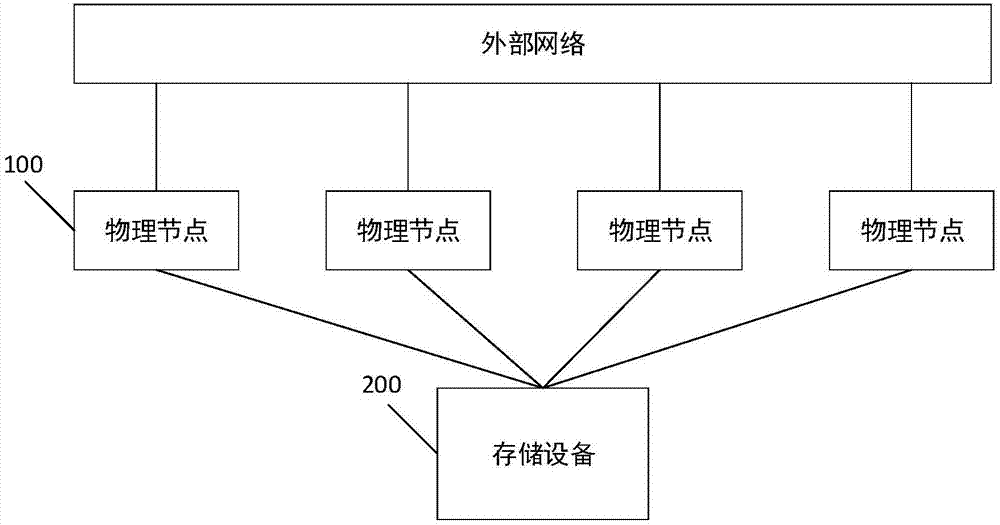

NAS storage system

ActiveCN107463339AAvoid incompatibilitiesReduce development difficultyInput/output to record carriersSpecial data processing applicationsFile systemComputer science

The invention discloses an NAS storage system. A storage device is connected with an external network through a virtual machine built in a physical node, namely, the virtual machine isolates a file system of the NAS storage device from the external network; the external network generally adopts an SAN storage network technology; an io stack of a design framework of the network is generally designed in a user state; a file system of an SAN storage network also can run in the user state; the file system in NAS needs to run in a kernel state; and the two file systems are incompatible. The storage device providing an NAS service is isolated from the external network through the virtual machine; and the virtual machine runs the file system of the NAS storage system, so that the problem that the two file systems are incompatible can be effectively avoided, the development difficulty can be lowered, and the development cycle can be shortened.

Owner:SUZHOU LANGCHAO INTELLIGENT TECH CO LTD

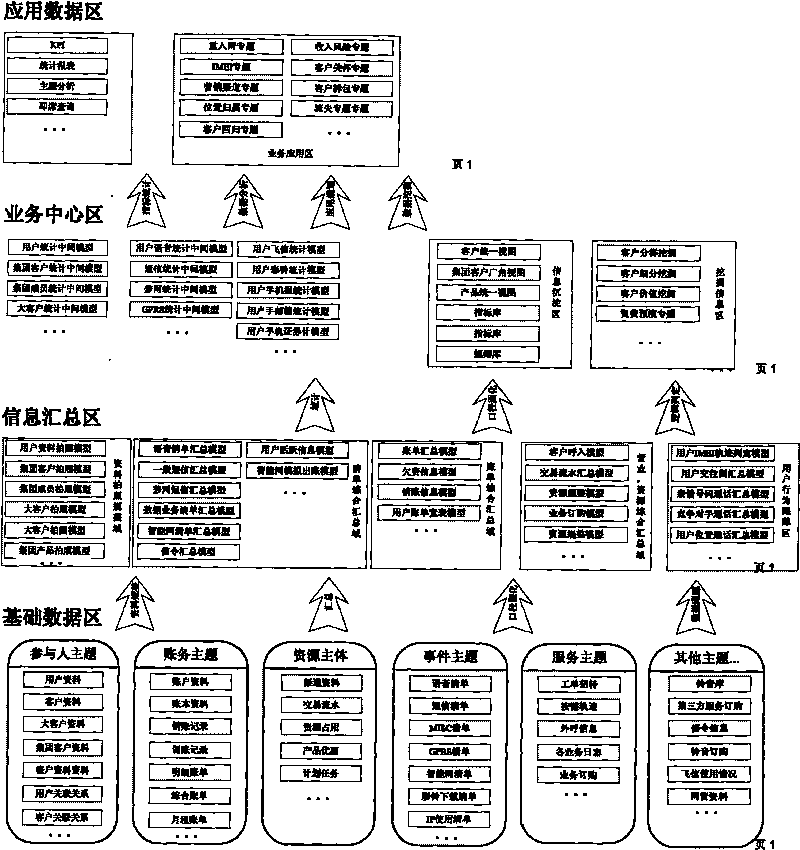

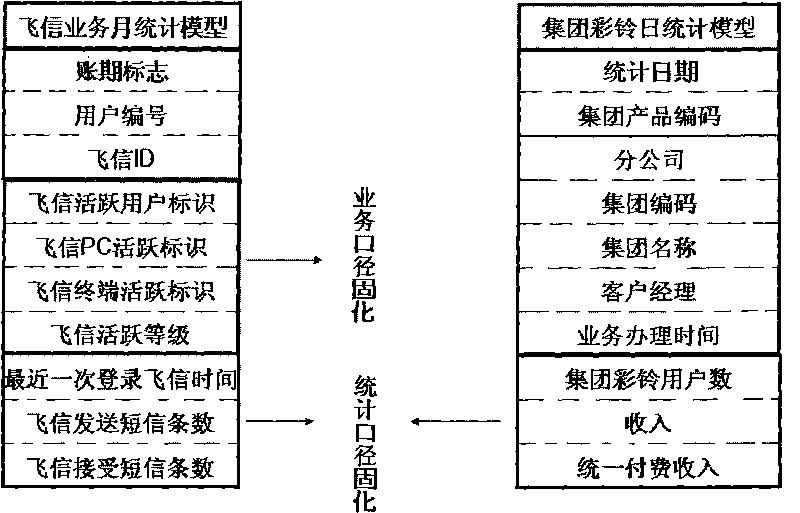

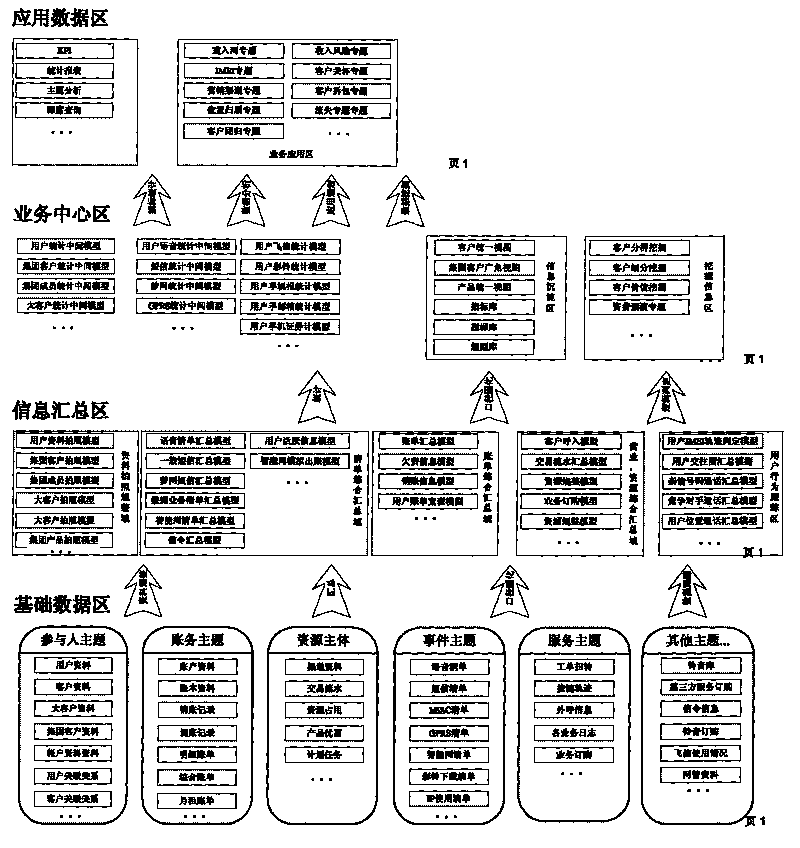

Design method of multi-service drive share frame model

InactiveCN101702798AQuick buildReduce investmentAccounting/billing servicesSupervisory/monitoring/testing arrangementsClose couplingData warehouse

The invention relates to a design method of a multi-service drive share frame model. In the method, the design idea of service close coupling and data loose coupling is adopted, a data warehouse system of an operator is redesigned and the traditional three-layer design framework consisting of a data storage layer, an intermediate layer and a result layer is deconstructed. The design method aims to establish a four-layer framework consisting of a result layer, a service intermediate layer, a basic intermediate layer and a data storage layer. The design method has the advantages of supporting similar applications of source data by the same operator from different provinces, quickly establishing the data warehouse and applying, uniformly developing to reduce the input of labor cost, solidifying the caliber to reduce the error probability of developers and updating a source system on a large scale to weaken the influence on the data warehouse in the deployment process of a warehouse system of a communication operator.

Owner:LINKAGE SYST INTEGRATION

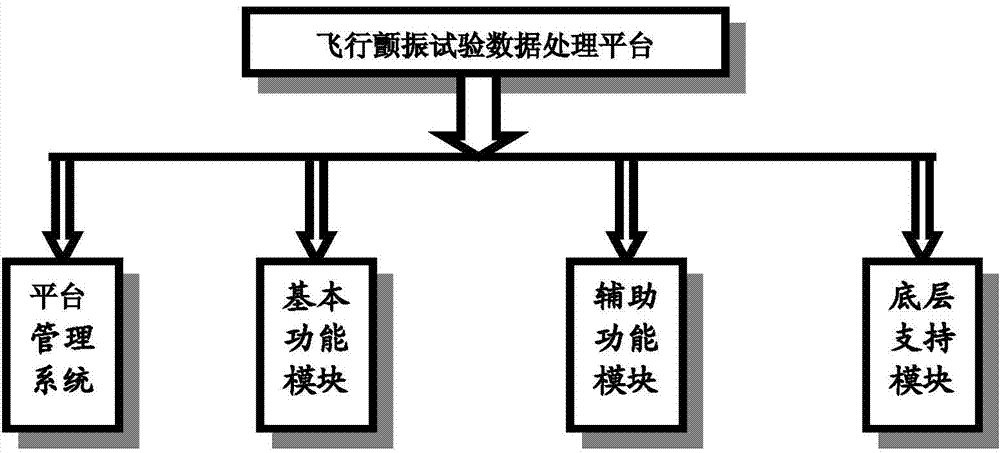

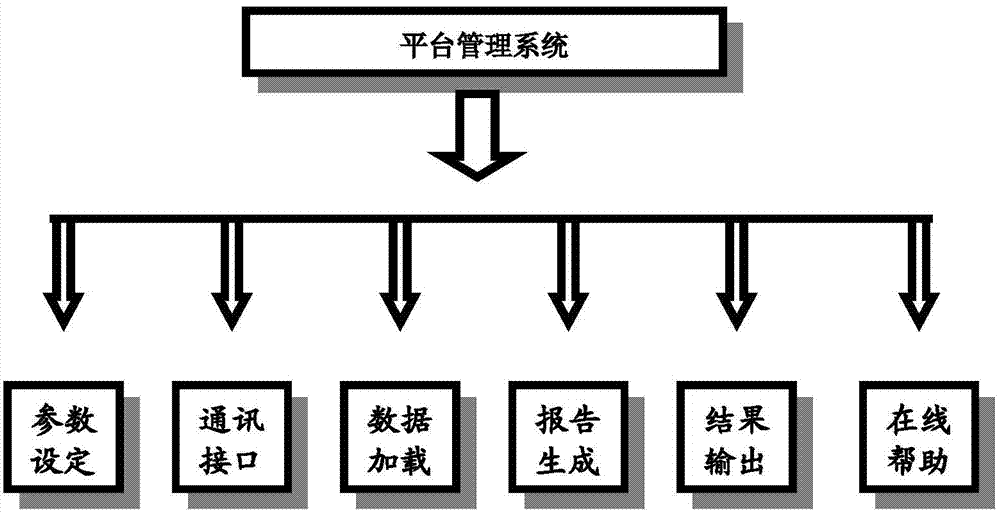

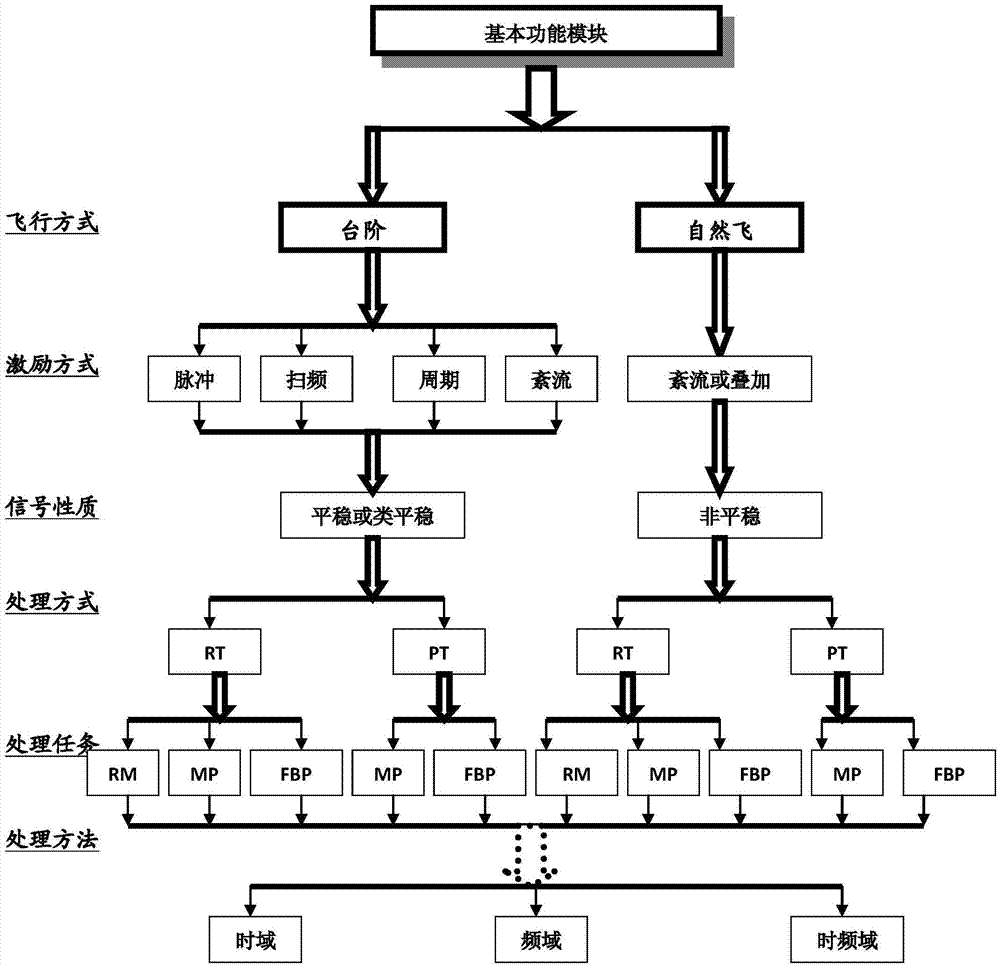

Flutter data processing framework based on flight test

InactiveCN103617323AProfessionalStrong advancedSpecial data processing applicationsAviationComputer module

The invention belongs to the technical field of aviation test flight, and particularly relates to a flutter data processing framework based on a flight test. The flutter data processing framework based on the flight test comprises a platform management system, a basic function module, an auxiliary function module and a bottom layer supporting module; the platform management system is used for resource dispatch and operational process management of a platform, the basic function module is used for processing data of a general flutter flight test, the auxiliary function module is used for analyzing flutter test flight data which are specific or are not provided with a currently established clear data processing technology system, the bottom layer supporting module is used for providing a basic environment supporting normal operation of the platform and basic software shared by each function module of the platform. The flutter flight test data processing platform concept and a top layer design framework are primarily raised, a plurality of layers such as a flight test mode, an incentive mode, the observation signal property, a processing mode, a processing task, a processing method and the like are projected in one unified framework, and therefore tradition, modernization, existence and development are coordinated in a higher level.

Owner:CHINESE FLIGHT TEST ESTAB

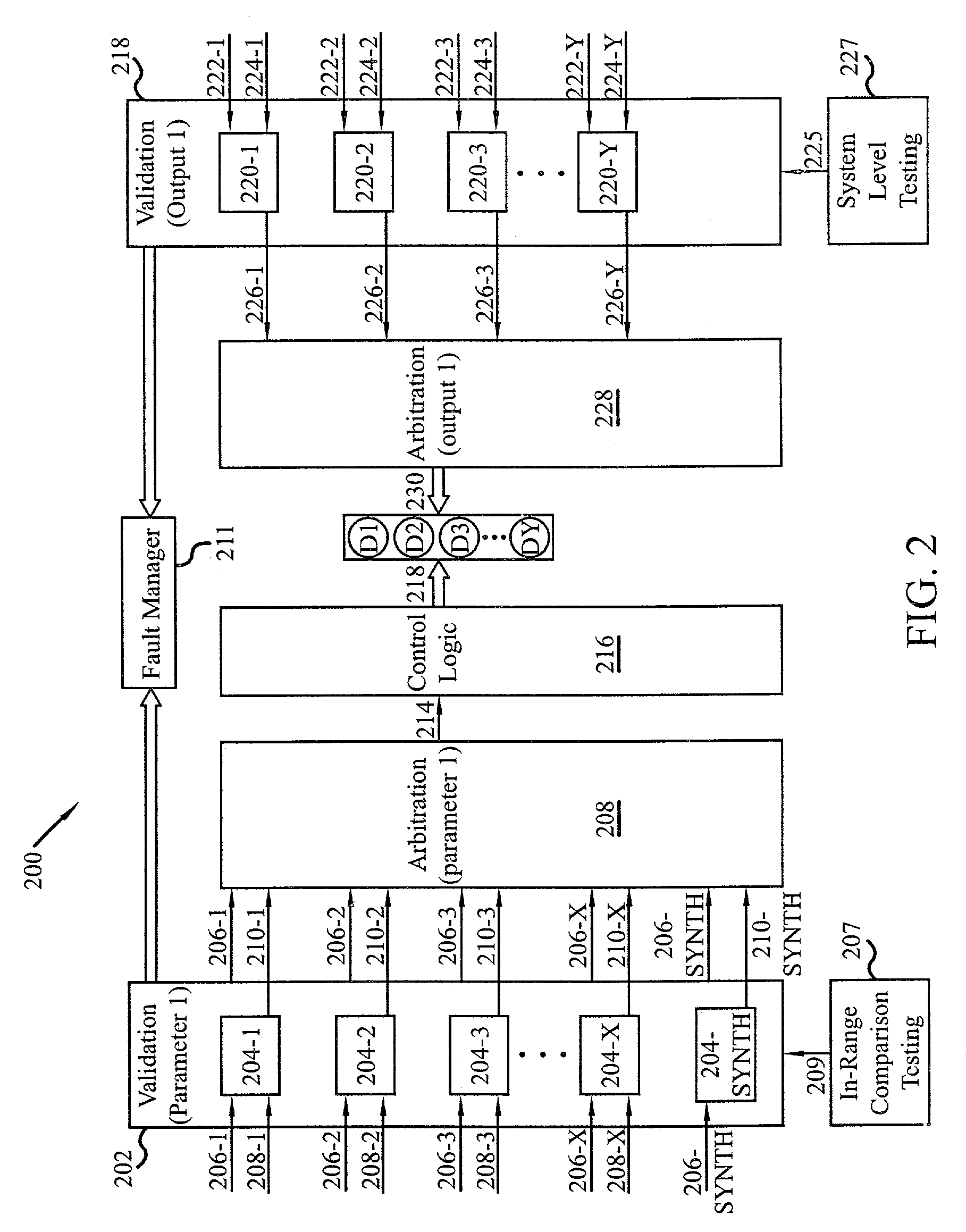

Signal validation and arbitration system and method

ActiveUS7093168B2Correct operation testingError detection/correctionFault severityReliability engineering

A common design framework for input and output signal validation, arbitration, and fault reporting for real-time controllers includes a method of validating redundant input and output signals and arbitrating between the redundant input and output signals by determining a fault severity level for each of the redundant input and output signals, and determining a signal to transmit for further processing based at least in part on the determined fault severity levels.

Owner:HONEYWELL INT INC

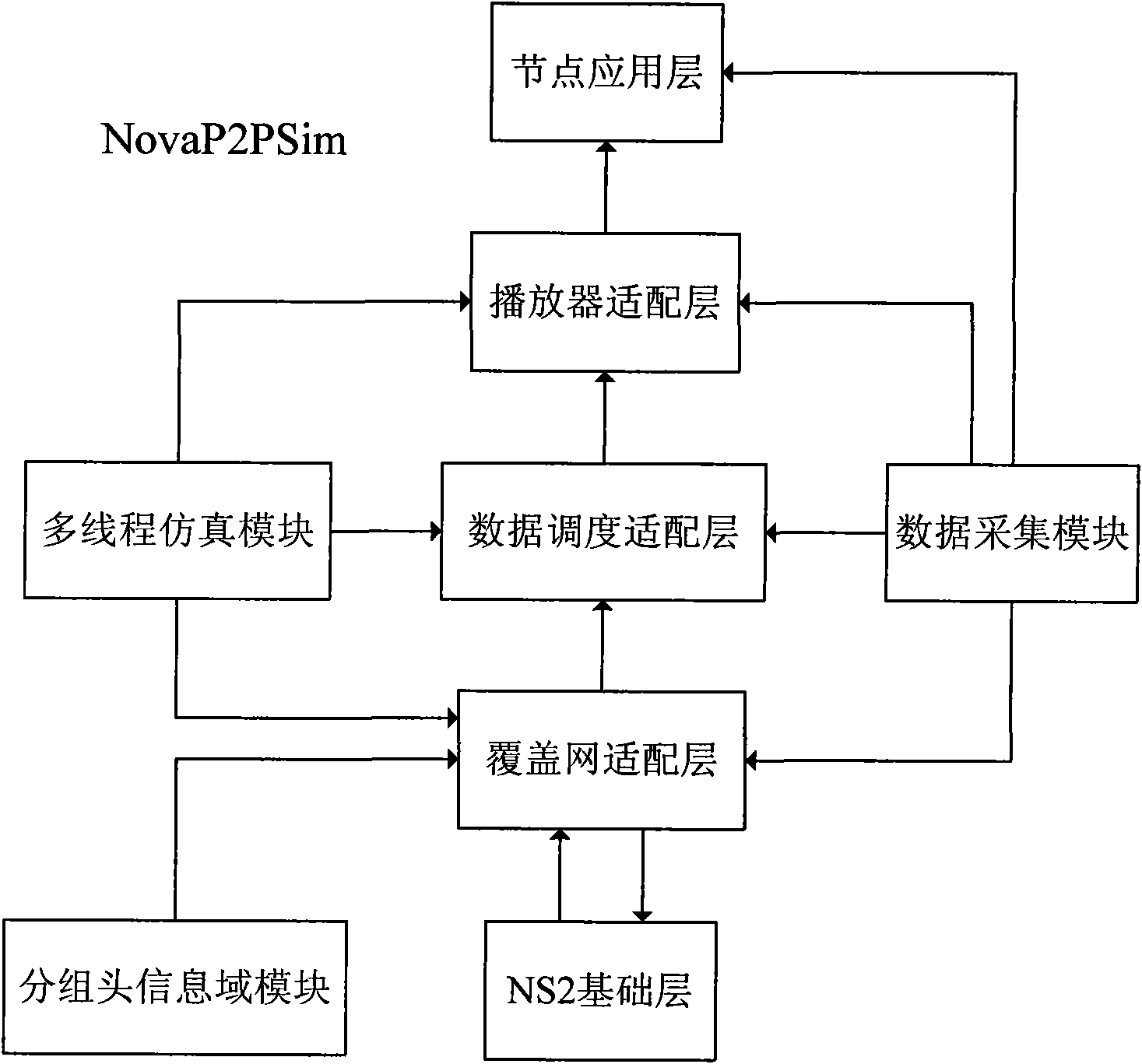

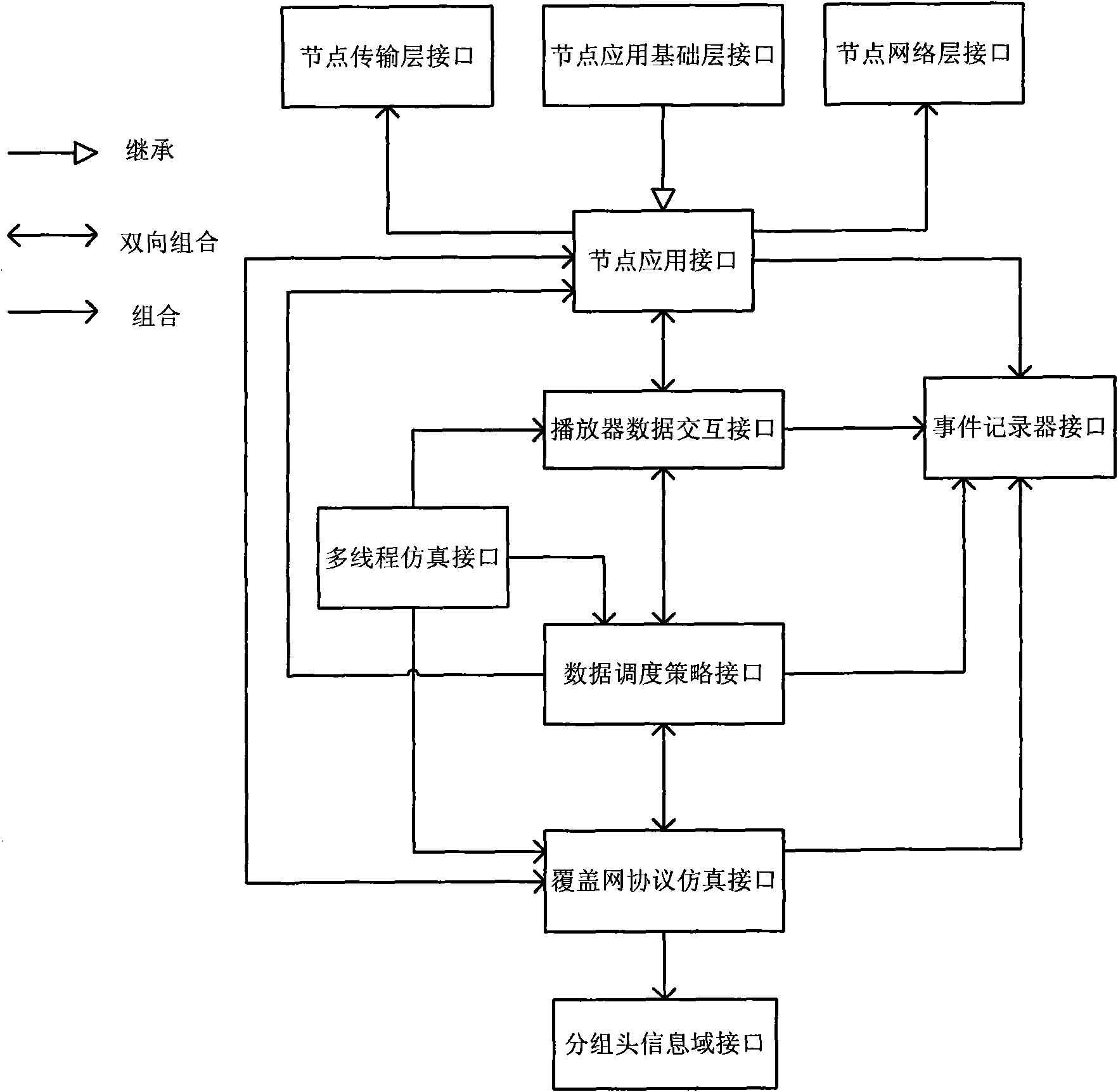

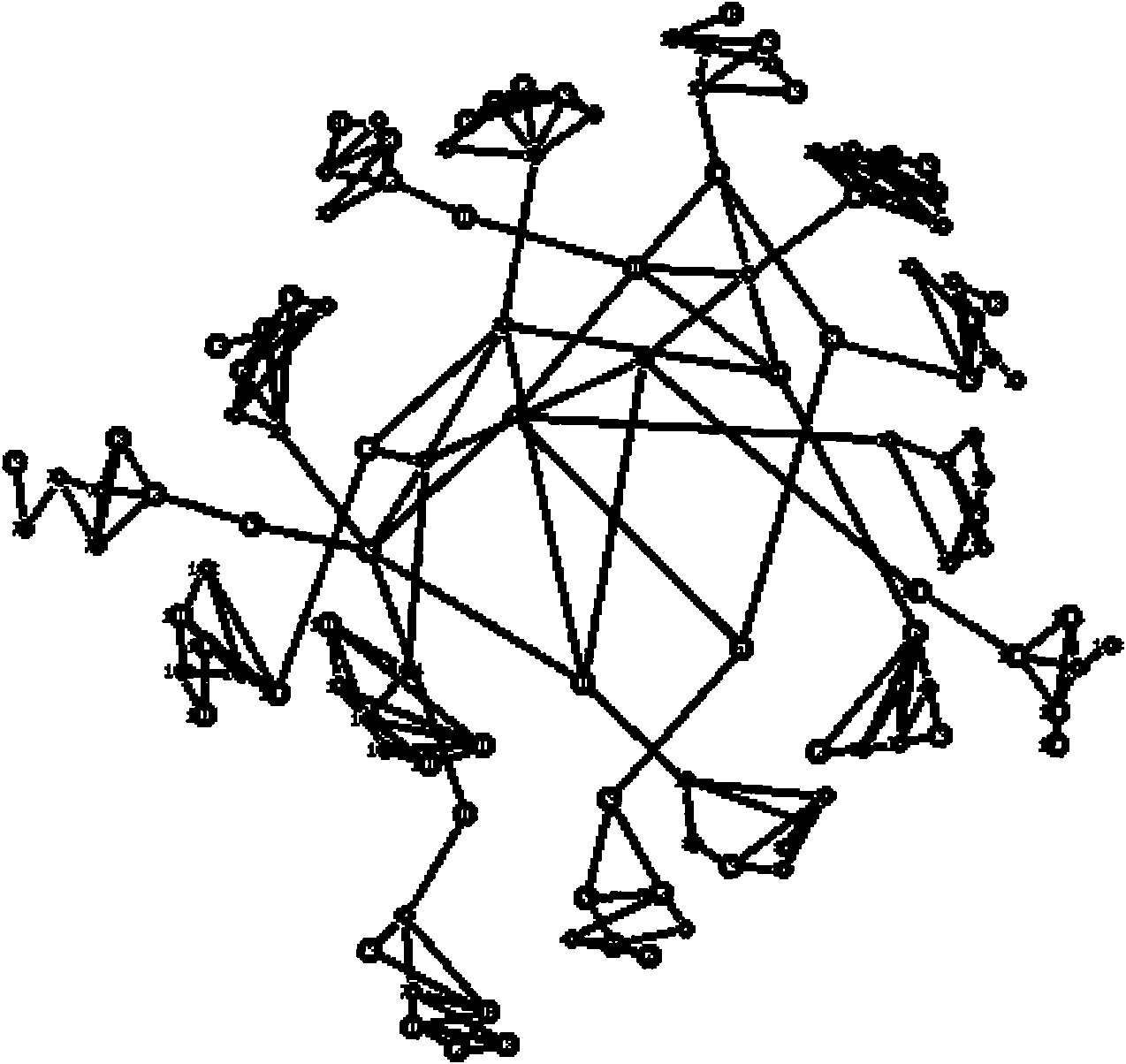

P2P streaming media system simulation platform based on NS2

The invention provides a P2P streaming media system simulation platform based on a general network simulator (NS2). The main framework of the simulation platform sequentially comprises an NS2 basal layer, an overlay network adaptation layer, a data-scheduling adaptation layer, a player adaptation layer and a node application layer from bottom to top, wherein the interface of the NS2 basal layer comprises a node network layer interface Node, a node transmission layer interface Agent and a node application basal layer interface Application. In addition, the simulation platform also comprises a packet header information domain interface NovaPacket, a multithread simulation interface Timer, an event recorder Log, an overlay network protocol simulation interface OverlayAdapter, a data-scheduling strategy interface DataScheduler, a player data interaction interface PlayAdapter, a peer application interface PeerApp, and the like. Accordingly, the P2P streaming media system simulation platformproposes a five-layered design framework aiming at the functional characteristics of a streaming media system, and each layer corresponds to a functional module of the system; and an interface specification is proposed aiming at each module, so that a user can simulate on the simulation platform after achieving all the interfaces, and the simulation efficiency is improved.

Owner:INST OF ACOUSTICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com