Copper-deficiency automatic supplementing method with no need of repeatedly avoiding copper

An automatic and complementary technology, applied in the EDA field, can solve problems such as redundant workload, waste of manpower and material resources, and hinder the design speed of PCB boards, so as to avoid redundant workload and improve design speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

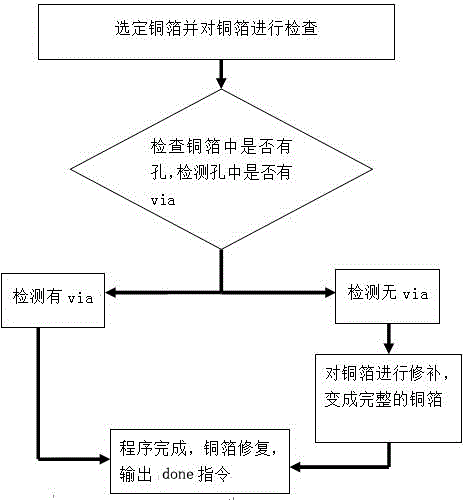

[0012] This embodiment describes a method for automatically filling copper deficiency without repeated copper avoidance. On the basis of cadence software, through the Skill program interface of Allegro software, the copper deficiency of copper foil (Shape) is automatically filled; mainly The steps include: 1) Set the attributes of the copper foil (Shape) hole, 2) Step by step detect each hole, determine whether there is a hole (via) in the hole, 3) Determine the shape of the copper foil to fill the hole And select it, and fill all the gaps without holes (via).

[0013] The copper deficiency described in this embodiment automatically fills up and does not need to repeat the method of avoiding copper. Through the Skill program interface of Allegro software, the written skill performs calculations, and each hole is detected step by step; if a hole is detected in the center of the hole ( If via) exists, the output is done; if no via is detected in the center of the hole, it means ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com