Synthetic refrigerating machine oil and preparation method thereof

A technology of refrigerating machine oil and base oil, which is applied in the petroleum industry, lubricating compositions, base materials, etc., and can solve the problems of poor dispersion stability and viscosity, high pour point of refrigerating machine oil, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

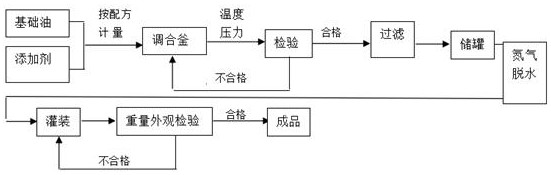

Method used

Image

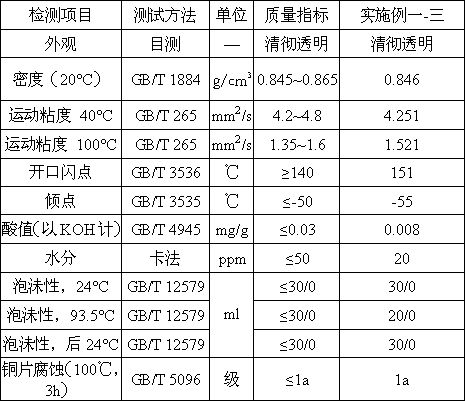

Examples

Embodiment 1

[0028] A kind of synthetic refrigerating machine oil proposed by the present invention comprises the following raw materials in weight percentage: 30% of naphthenic base oil, 68.248% of alkylbenzene oil, 1.75% of additive, and the balance is defoamer;

[0029] Among them, the naphthenic base oil is synthesized from benzene and dodecene;

[0030] Wherein, the alkylbenzene oil is compounded by 99% by weight of alkylbenzene base oil and 1% by weight of additives;

[0031] Among them, the alkylbenzene base oil is synthesized by the alkylation of high-purity alpha olefins and aromatic hydrocarbons;

[0032] Wherein, the auxiliary agent is a compound of nano-titanium dioxide and nano-graphene with a mass ratio of 1:3;

[0033] Wherein, the additive is tricresyl phosphate;

[0034] Among them, the defoamer is a mixture of silicon-containing polyacrylate and synthetic hydrocarbon.

[0035] A kind of preparation method of synthetic refrigerating machine oil that the present inventio...

Embodiment 2

[0042] A kind of synthetic refrigerating machine oil proposed by the present invention comprises the following raw materials in weight percentage: 50% of naphthenic base oil, 48.499% of alkylbenzene oil, 1.5% of additive, and the balance is defoamer;

[0043] Among them, the naphthenic base oil is synthesized from benzene and dodecene;

[0044] Wherein, the alkylbenzene oil is compounded by 99% by weight of alkylbenzene base oil and 1% by weight of additives;

[0045] Among them, the alkylbenzene base oil is synthesized by the alkylation of high-purity alpha olefins and aromatic hydrocarbons;

[0046] Wherein, the auxiliary agent is a compound of nano-titanium dioxide and nano-graphene with a mass ratio of 1:4;

[0047] Wherein, the additive is tricresyl phosphate;

[0048] Among them, the defoamer is a mixture of silicon-containing polyacrylate and synthetic hydrocarbon.

[0049] A kind of preparation method of synthetic refrigerating machine oil that the present invention...

Embodiment 3

[0056] A kind of synthetic refrigerating machine oil proposed by the present invention comprises the following raw materials in weight percentage: 10% of naphthenic base oil, 87.498% of alkylbenzene oil, 2.5% of additive, and the balance is defoamer;

[0057] Among them, the naphthenic base oil is synthesized from benzene and dodecene;

[0058] Wherein, the alkylbenzene oil is compounded by 99% by weight of alkylbenzene base oil and 1% by weight of additives;

[0059] Among them, the alkylbenzene base oil is synthesized by the alkylation of high-purity alpha olefins and aromatic hydrocarbons;

[0060] Wherein, the auxiliary agent is a compound of nano-titanium dioxide and nano-graphene with a mass ratio of 1:5;

[0061] Wherein, the additive is tricresyl phosphate;

[0062] Among them, the defoamer is a mixture of silicon-containing polyacrylate and synthetic hydrocarbon.

[0063] A kind of preparation method of synthetic refrigerating machine oil that the present invention p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com