Ash-free hydraulic oil composition

An ashless hydraulic oil and composition technology, applied in the field of lubricating oil composition and ashless hydraulic oil composition, can solve the problems of poor comprehensive performance of hydraulic oil, poor oxidation stability, poor solubility and susceptibility, etc., and achieve excellent Filterability, excellent hydrolysis stability, excellent effect of abrasion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

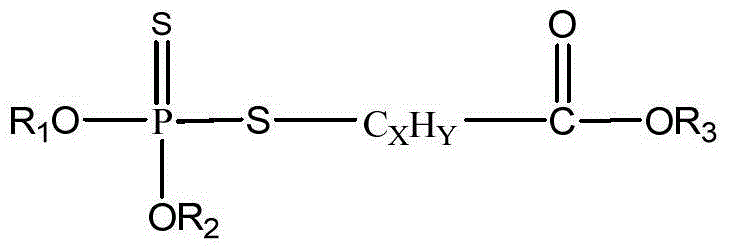

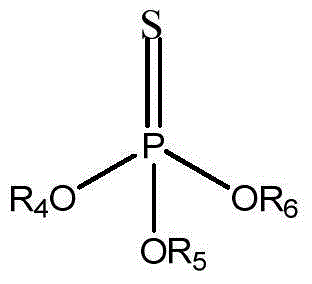

[0093] The antiwear agent of the ashless hydraulic oil composition is a compound of tri-tert-butylphenyl thiophosphate and 3-(O,O-diisopropyl dithiophosphoryl)-propionic acid, and the mass percentages are respectively 28.6 % and 7.1%, the rust inhibitor is a compound of n-oleyl sarcosine and amino acid derivative A, the mass percentages are 4.3% and 7.1%, and the antioxidant is 2,6-di-tert-butyl p-cresol , the mass percentage is 42.9%, the metal deactivator is N,N-di-n-butylaminomethylene methyl benzotriazole, the mass percentage is 7.1%, the polysuccinimide derivative dispersant is succinyl Imine T154A, the mass percentage is 2.9%. Wherein the amino acid derivative A structural formula is:

[0094]

Embodiment 2

[0096] The antiwear agent of the ashless hydraulic oil composition is tri-tert-butylphenyl thiophosphate and 3-(O, O-diisopropyldithiophosphoryl)-2-methyl-propionic acid methyl ester, The mass percentages are 27.4% and 13.7%, the antirust agent is a compound of n-oleyl sarcosine and amino acid derivative A, the mass percentages are 2.7% and 6.8%, respectively, and the antioxidant is 2,6-di-tert-butyl P-cresol, the mass percentage is 41.1%, the metal deactivator is N,N-di-n-butylaminomethylene methyl benzotriazole, the mass percentage is 4.2%, polysuccinimide derivative dispersant Succinimide T154A, the mass percentage is 4.1%.

Embodiment 3

[0098] The antiwear agent of the ashless hydraulic oil composition is tri-tert-butylphenyl phosphorothioate and 3-(O,O-diisopropyldithiophosphoryl)-2-methyl-propionic acid, mass percent 37.5% and 2.5%, the antirust agent is n-oleyl sarcosine and amino acid derivative A compound, the mass percentages are 6.3% and 6.3%, and the antioxidant is 2,6-di-tert-butyl p-methyl 25% and 12.5% by mass respectively, the metal deactivator is N,N-di-n-butylaminomethylene methyl benzotriazole, the mass percentage is 6.3%, poly The succinimide derivative dispersant succinimide T154A is 3.6% by mass.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com