Preparation process of high-base value sulfurized alkyl salicylate

A technology for sulfurizing alkyl salicylate and alkyl salicylic acid, which is applied in the petroleum industry, additives, lubricating compositions, etc., to achieve the effects of easy operation, mild reaction conditions, good high-temperature detergency and hydrolysis stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

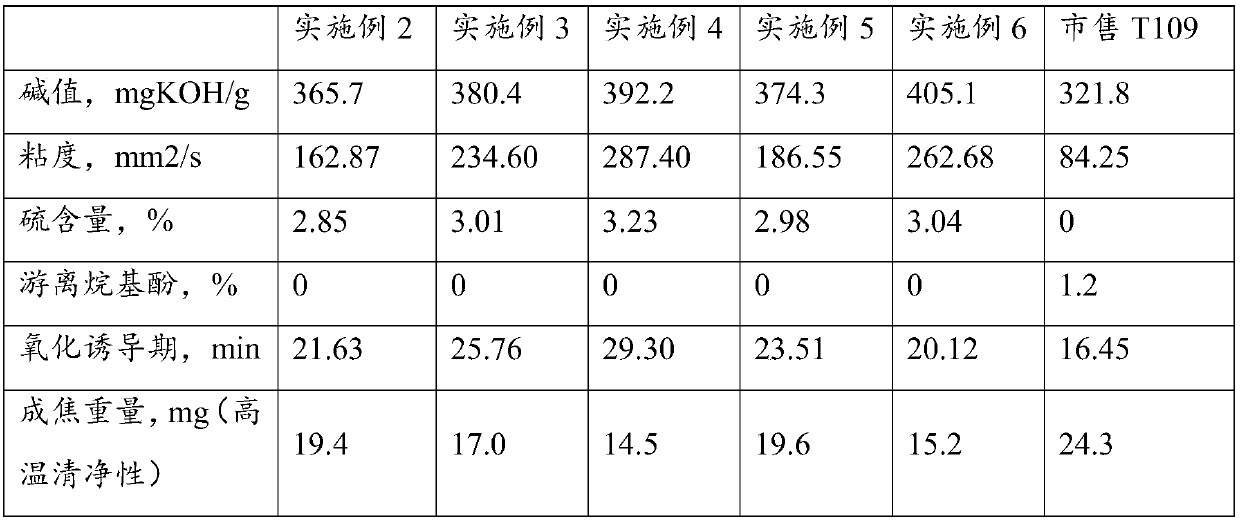

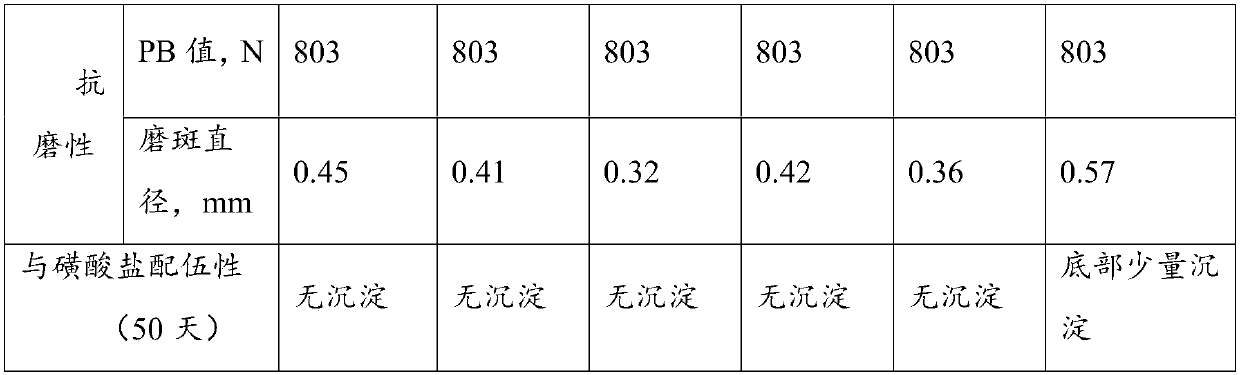

Examples

Embodiment 1

[0034] The present embodiment 1 provides a kind of preparation technology of alkyl salicylic acid solution, specifically:

[0035] Add 160g of salicylic acid, 400g of a mixture of n-hexadecene, n-octadecene and n-eicosene into the flask, and 80g of polar catalyst methanesulfonic acid, heat the system to 130°C, stir and keep it warm for 15h, after the reaction Add 500g of 200# solvent oil, leave standstill for 48h and then separate layers, centrifuge to remove the lower layer of methanesulfonic acid, and the upper layer is solvent-containing alkyl salicylic acid, get the upper layer sample and do gas chromatography, and record the content of the alkyl salicylic acid solution. The acid content is 50%.

Embodiment 2

[0037] Step 1: Preparation of alkyl salicylic acid products

[0038] Using the samples and data from Example 1, a solvent-containing alkyl salicylic acid product was prepared.

[0039] Step 2: Preparation of high alkali value sulfurized alkyl salicylate

[0040] Add 150g of alkyl salicylic acid products (acid content 50%), 10g of polyisobutylene succinimide, 50g of hydrogenated base oil, 10g of calcium oxide, and 9g of sulfur in the flask, start heating and slowly heat up, at 130°C Maintain 3h. Add 30g of ethylene glycol to the flask for vulcanization reaction, keep the system at 155°C for 6h, then put in 25g of calcium oxide (adding in 4 times) and introduce carbon dioxide to start the high alkalinization reaction, keep the carbon dioxide aeration time at 5h, and the aeration ends After cooling down to 100°C, add 100g of 200# solvent oil and use a filter aid to filter and remove the slag. The filtrate is distilled under reduced pressure to remove ethylene glycol and solvent...

Embodiment 3

[0042] The present embodiment 3 provides a kind of preparation technology of high alkali value sulfurized alkyl salicylate, specifically comprises the following several steps:

[0043] Step 1: Preparation of alkyl salicylic acid products

[0044] Using the samples and data from Example 1, a solvent-containing alkyl salicylic acid product was prepared.

[0045] Step 2: Preparation of high alkali value sulfurized alkyl salicylate

[0046] Add 150g of alkyl salicylic acid products (acid content 50%), 5g of polyisobutylene succinic anhydride, 50g of hydrogenated base oil, 10g of calcium oxide, and 9g of sulfur into the flask, start heating and slowly raise the temperature, and maintain it at 150°C for 2h . Add 30g of ethylene glycol to the flask for vulcanization reaction, keep the system at 160°C for 6h, then add 25g of calcium oxide (adding in 4 times) and carbon dioxide to start the high alkalinization reaction, the carbon dioxide aeration time is kept at 5h, and the aeration...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com