Process for preparing biodiesel

A biodiesel and process technology, used in biofuels, petroleum industry, liquid carbonaceous fuels, etc., can solve the problems of poor hydrolysis and oxidation stability of biodiesel, unusable biodiesel, low temperature crystallization, etc., and achieve excellent oxidation and hydrolysis stability. The effect of the reaction process is simple and easy to implement, and the acid reduction speed is fast.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

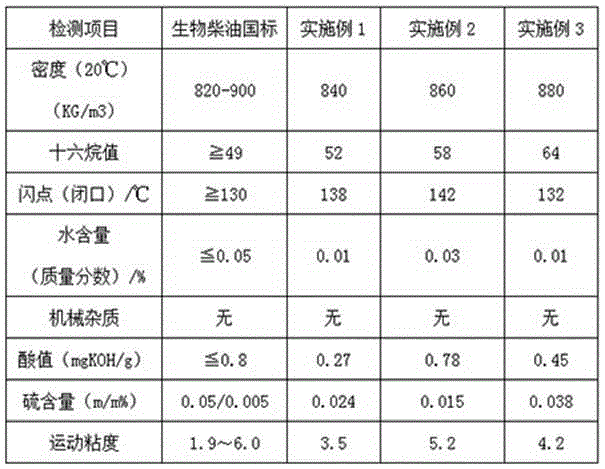

Examples

Embodiment 1

[0017] A process for preparing biodiesel, using fatty acid methyl ester biodiesel as raw material and methane on an acid-loaded catalyst to obtain isomerized fatty acid methyl ester biodiesel through an alkylation process, is characterized in that it comprises the following steps:

[0018] (1) Pass fatty acid methyl ester, methane and acid-loaded catalyst into the reactor, the mass ratio of fatty acid methyl ester to methane is 1:4, the amount of acid-loaded catalyst is 2wt% of fatty acid methyl ester, the pressure control range is 6MPa, the temperature 90°C, reaction time 2h;

[0019] (2) At a temperature of 90°C, continuously feed methanol liquid into the reactor with a methanol flow rate of 0.8mL / min. The condensing device recovers the water generated by esterification and excess methanol, and measures the acid value. When the acid value is lower than 1.0 The reaction stops when mgKOH / g.

[0020] The methanol liquid in step (2) is continuously passed to the bottom of the o...

Embodiment 2

[0023] A process for preparing biodiesel, using fatty acid methyl ester biodiesel as raw material and methane on an acid-loaded catalyst to obtain isomerized fatty acid methyl ester biodiesel through an alkylation process, is characterized in that it comprises the following steps:

[0024] (1) Pass fatty acid methyl ester, methane and acid-loaded catalyst into the reactor, the mass ratio of fatty acid methyl ester to methane is 1:4, the amount of acid-loaded catalyst is 5wt% of fatty acid methyl ester, the pressure control range is 8MPa, the temperature 120°C, reaction time 3h;

[0025] (2) At a temperature of 110°C, continuously feed methanol liquid into the reactor, the flow rate of methanol is 1.2mL / min, the condensing device recovers the water generated by esterification and excess methanol, and measures the acid value. When the acid value is lower than 1.0 The reaction stops when mgKOH / g.

[0026] The methanol liquid in step (2) is continuously passed to the bottom of th...

Embodiment 3

[0029] A process for preparing biodiesel, using fatty acid methyl ester biodiesel as raw material and methane on an acid-loaded catalyst to obtain isomerized fatty acid methyl ester biodiesel through an alkylation process, is characterized in that it comprises the following steps:

[0030] (1) Pass fatty acid methyl ester, methane and acid-loaded catalyst into the reactor, the mass ratio of fatty acid methyl ester to methane is 1:4, the amount of acid-loaded catalyst is 4wt% of fatty acid methyl ester, the pressure control range is 7MPa, the temperature The temperature is 105°C, and the reaction time is 2.5h;

[0031] (2) At a temperature of 100°C, continuously feed methanol liquid into the reactor, the flow rate of methanol is 1mL / min, the condensing device recovers the water and excess methanol generated by esterification, and measures the acid value. When the acid value is lower than 1.0mgKOH / g to stop the reaction.

[0032] The methanol liquid in step (2) is continuously...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com