Zinc-free high pressure anti-wear hydraulic oil and preparation method thereof

A technology of anti-wear hydraulic oil and extreme pressure anti-wear agent, which is applied in the petroleum industry, additives, lubricating compositions, etc., can solve problems such as difficult to meet the performance of oil products, achieve the goal of weakening catalytic oxidation and improving thermal stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

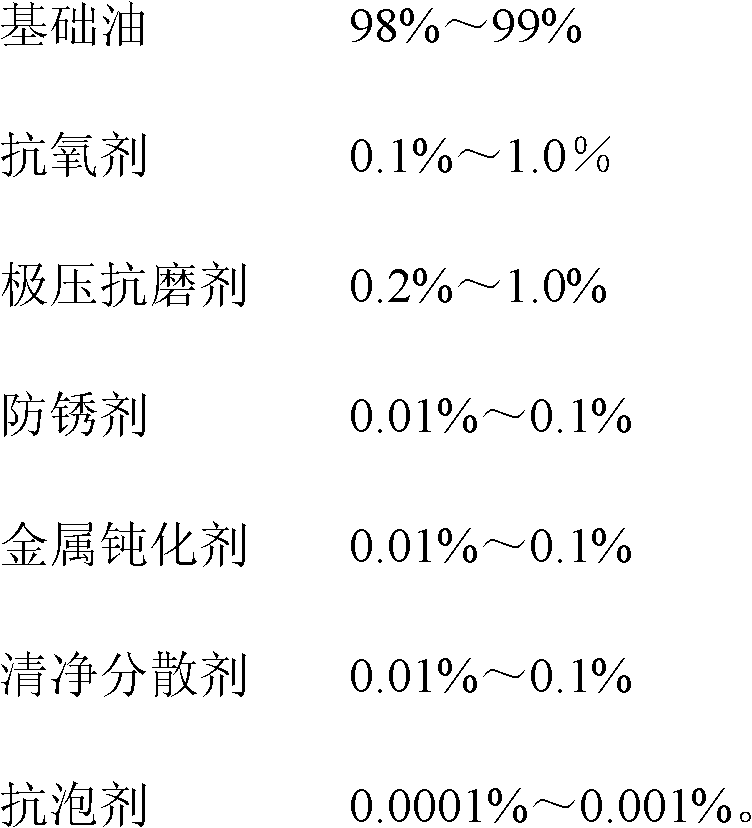

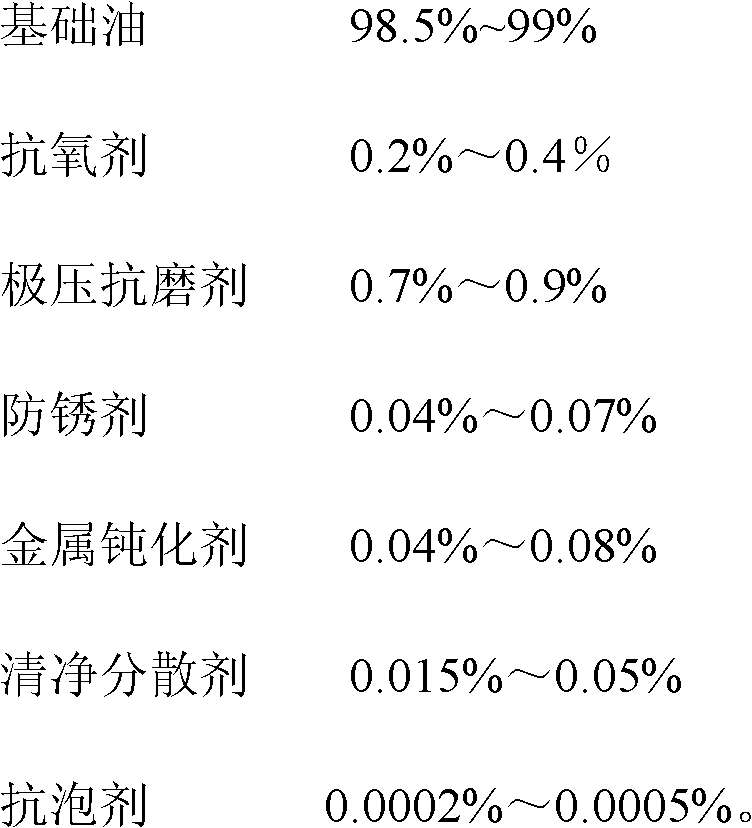

Method used

Image

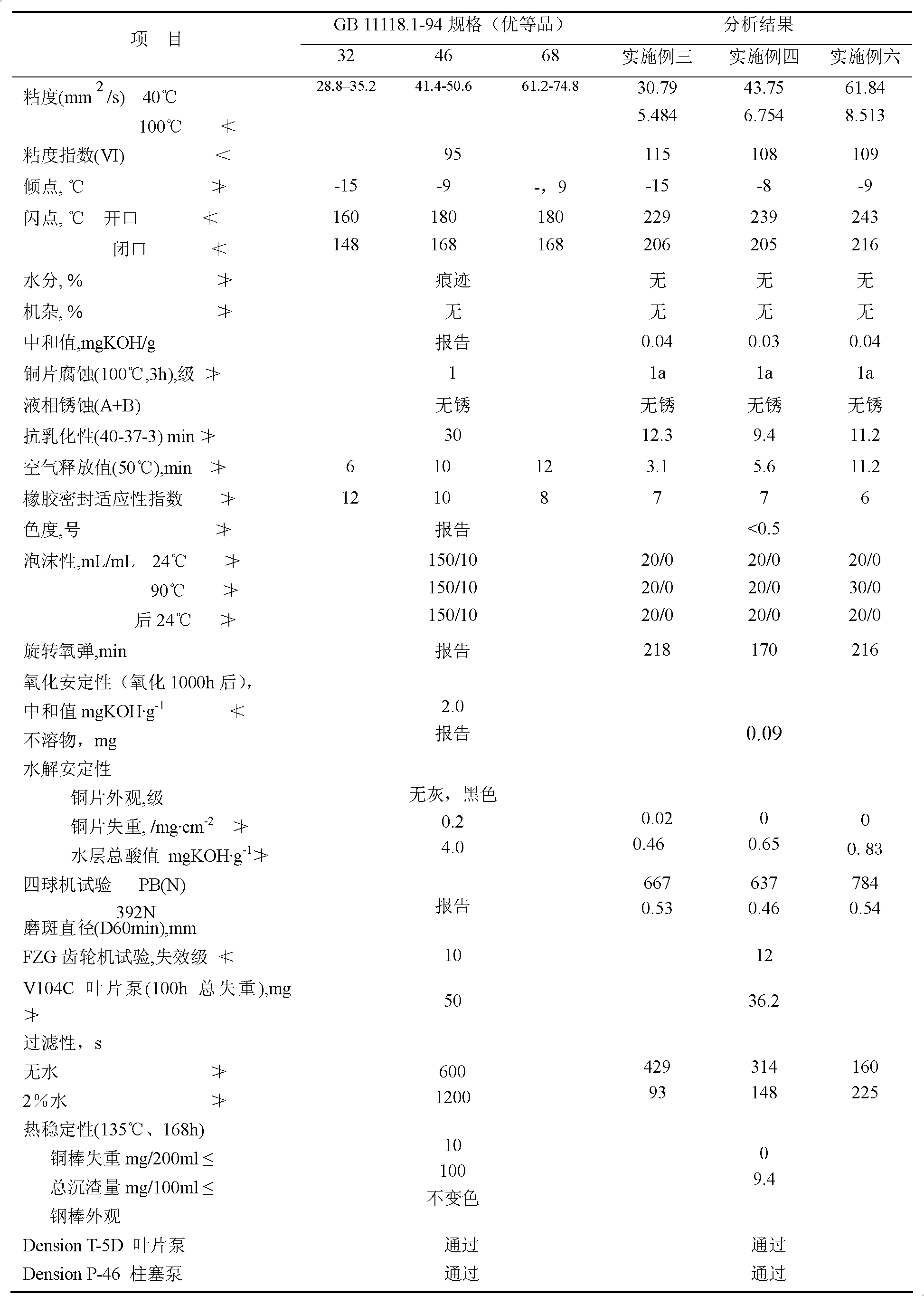

Examples

Embodiment 1

[0027] (1) Put 985 kg of hydroisomerization 150SN in the reaction kettle, and heat up to 50°C to 60°C;

[0028] (2) Add 5 kg of T309, 2 kg of T501, 3 kg of T306, 0.5 kg of AD-12, 0.6 kg of T705, 0.3 kg of P52 (the base value is 300 mgKOH / g), 0.003 kg of T901, stir and mix for 20 minutes to 30 minutes to obtain a mixture Materials, that is, zinc-free high-pressure anti-wear hydraulic oil.

Embodiment 2

[0030] (1) First put 985 kg of hydroisomerization 500SN in the reaction kettle, and heat up to 50°C to 60°C;

[0031] (2) Add 5 kg of T309, 2 kg of T501, 3.5 kg of T306, 0.5 kg of T551, 0.6 kg of T705A, 0.5 kg of P52 (base value is 300 mgKOH / g), 0.003 kg of T901, stir and mix for 20 minutes to 30 minutes to obtain a mixed material, That is, zinc-free high-pressure anti-wear hydraulic oil is obtained.

Embodiment 3

[0033] (1) First put 985 kg of hydroisomerization 500SN in the reaction kettle, and heat up to 50°C to 60°C;

[0034] (2) Add 6 kg of T309, 3 kg of T501, 2 kg of T306, 0.6 kg of T561, 0.5 kg of T705A, 0.3 kg of P52 (base value is 300 mgKOH / g), 0.002 kg of T901, stir and mix for 20 min to 30 min to obtain a mixed material, That is, zinc-free high-pressure anti-wear hydraulic oil is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com