Cleaning agent compound for magnetic drum type magnetic filter and preparation method of compound

A magnetic filter and cleaning agent technology, applied in detergent compositions, soap detergent compositions, organic cleaning compositions, etc., can solve the problems of insufficient cleaning ability of common cleaning agents, and achieve the effect of meeting the requirements of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

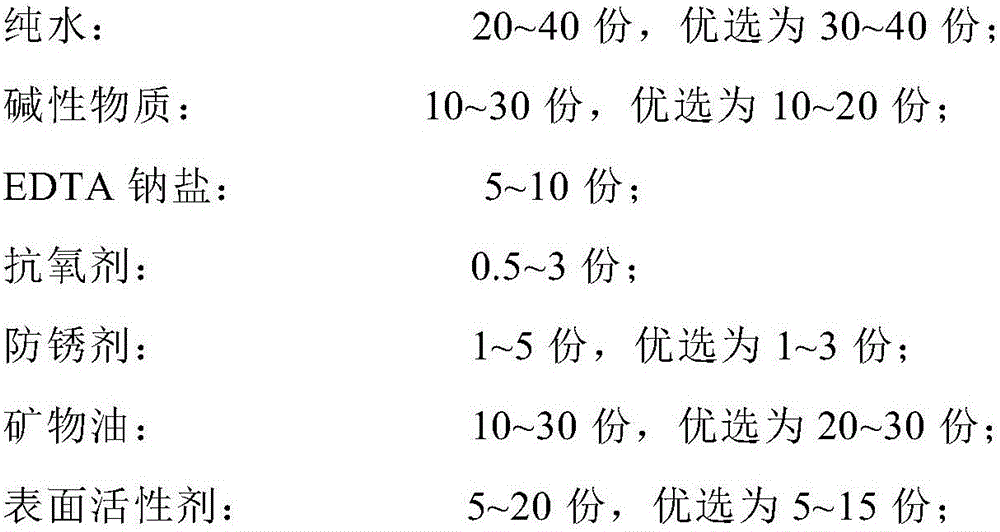

[0035] One, the formula that the present embodiment relates to is used for the cleaning composition of magnetic drum type magnetic filter:

[0036]

[0037] Two, the preparation method of the cleaning composition for magnetic drum type magnetic filter that the present embodiment relates to comprises the following steps:

[0038] At 50-60°C, add antioxidants, anti-rust agents, and surfactants to the mineral oil;

[0039] After stirring evenly, add pure water, alkaline substances, EDTA sodium salt and defoamer, stir at 60-70°C, and filter through a 300-mesh filter and a 5μm filter bag in sequence to obtain the magnetic drum-type magnetic Filter cleaning composition.

Embodiment 2

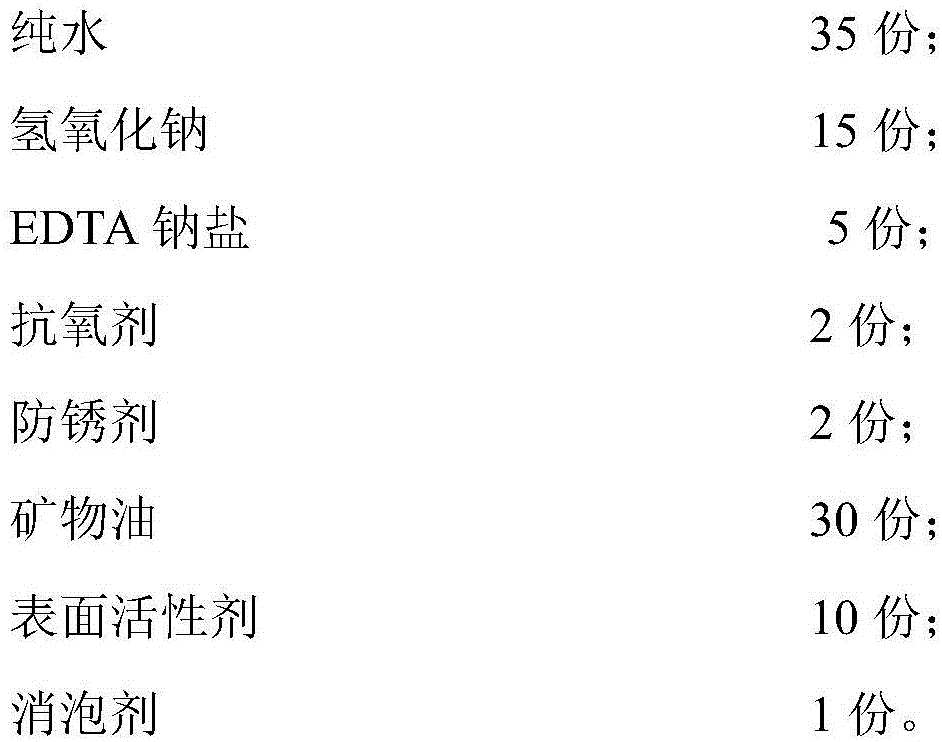

[0041] One, the formula that the present embodiment relates to is used for the cleaning composition of magnetic drum type magnetic filter:

[0042]

[0043] Two, the preparation method of the cleaning composition for magnetic drum type magnetic filter that the present embodiment relates to comprises the following steps:

[0044] At 50-60°C, add antioxidants, anti-rust agents, and surfactants to the mineral oil;

[0045] After stirring evenly, add pure water, alkaline substances, EDTA sodium salt and defoamer, stir at 60-70°C, and filter through a 300-mesh filter and a 5μm filter bag in sequence to obtain the magnetic drum-type magnetic Filter cleaning composition.

Embodiment 3

[0047] One, the formula that the present embodiment relates to is used for the cleaning composition of magnetic drum type magnetic filter:

[0048]

[0049] Two, the preparation method of the cleaning composition for magnetic drum type magnetic filter that the present embodiment relates to comprises the following steps:

[0050] At 50-60°C, add antioxidants, anti-rust agents, and surfactants to the mineral oil;

[0051] After stirring evenly, add pure water, alkaline substances, EDTA sodium salt and defoamer, stir at 60-70°C, and filter through a 300-mesh filter and a 5μm filter bag in sequence to obtain the magnetic drum-type magnetic Filter cleaning composition.

[0052] Table 1 shows the cleaning effects of the cleaning agent compositions used in drum type magnetic filters prepared in Examples 1-3.

[0053] Table 1

[0054] Example Example 1 Example 2 Example 3 cleaning rate 90% 95% 97%

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com