Lubrication oil composition, preparation method of lubrication oil composition and trace quantity lubrication oil prepared by adopting lubrication oil composition

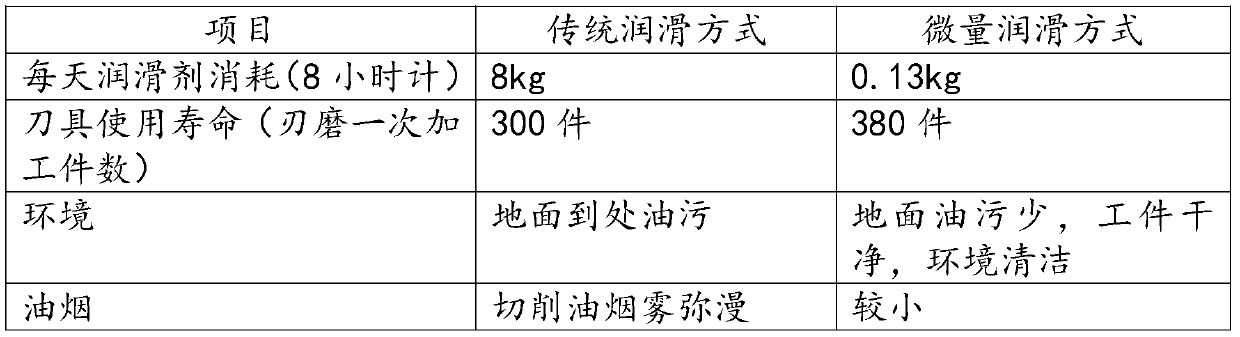

A lubricating oil composition and lubricating oil technology, applied in the field of lubrication, can solve the problems of large amount of lubricant used, affecting the health of operators, unfriendly sulfur-containing and chlorine-containing additives, etc., and achieve good lubricity and extreme pressure resistance. Grinding, environmental protection effect is remarkable, good degradability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Weigh 465.95g (2.5mol) of lauryl alcohol and 192.14g (1mol) of citric acid into the reaction kettle together, stir and heat to 200°C, fully react for 8 hours, drain 3 times in the middle of the reaction, and drain the water after the reaction, which is a kind of lubricating oil composition.

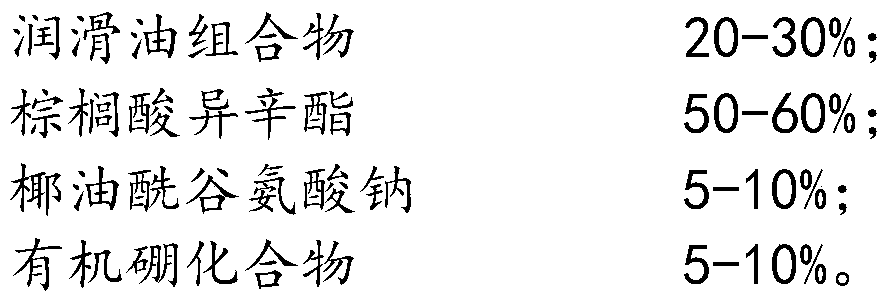

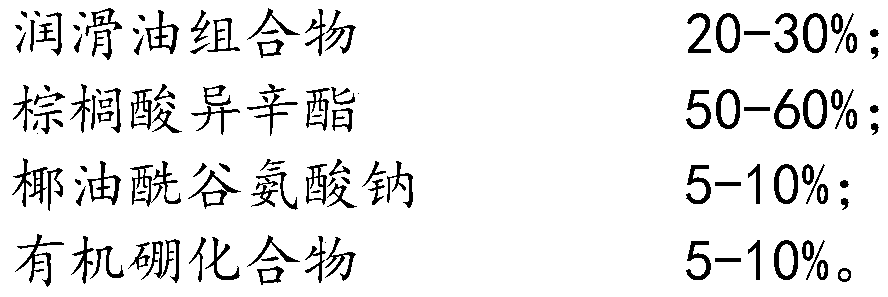

[0026] Weigh 300 g of lubricating oil composition prepared above, 500 g of isooctyl palmitate, 100 g of sodium cocoyl glutamate, and 100 g of organoboron compound, mix and stir at 40° C. until transparent, then it becomes a kind of micro lubricating oil.

[0027] Weigh 100g of oleamide, 20g of boric acid, and 20g of hydroxyethylethanolamine and mix them at 80°C for 2 hours, then raise the temperature to 120°C and stir under reduced pressure (keep the pressure in the container not greater than 100mmHg) for 2 hours to obtain an organoboron compound.

Embodiment 2

[0029] Weigh 447.82g (1.5mol) of isomeric eicosanol and 192.14g (1mol) of citric acid into the reaction kettle together, add 1g of germanium dioxide, stir and heat to 220°C, fully react for 6 hours, drain water twice during the reaction, After the reaction, water is discharged, which is a lubricating oil composition.

[0030] Weigh 240g of lubricating oil composition prepared above, 600g of isooctyl palmitate, 60g of sodium cocoyl glutamate, and 100g of organoboron compound, and mix and stir at 60°C until it becomes transparent.

[0031] Weigh 100g of oleamide, 25g of boric acid, and 15g of hydroxyethylethanolamine, mix them at 100°C and stir for 1 hour, then raise the temperature to 110°C and stir under reduced pressure (keep the pressure in the container not greater than 100mmHg) for 3 hours to obtain an organoboron compound.

Embodiment 3

[0033] Weigh 428.78g (2mol) of myristyl alcohol and 192.14g (1mol) of citric acid into the reaction kettle together, add 3g of germanium dioxide, stir and heat to 210°C, fully react for 7 hours, drain 3 times during the reaction, and then Drain the water, which is a lubricating oil composition.

[0034] Weigh 290 g of lubricating oil composition prepared above, 580 g of isooctyl palmitate, 50 g of sodium cocoyl glutamate, and 80 g of organoboron compound, mix and stir at 50° C. until transparent, then it becomes a micro lubricating oil.

[0035] Weigh 100g of oleamide, 22g of boric acid, and 18g of hydroxyethylethanolamine, mix them at 90°C and stir for 1.5 hours, then raise the temperature to 113°C for 2.5 hours under reduced pressure (keep the pressure in the container not greater than 100mmHg) and stir for 2.5 hours to obtain an organoboron compound.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com