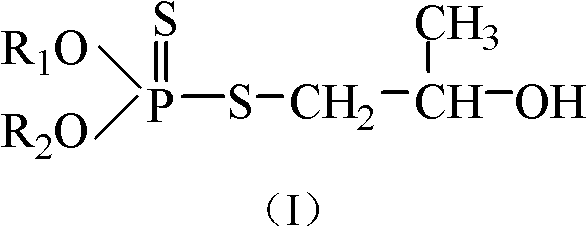

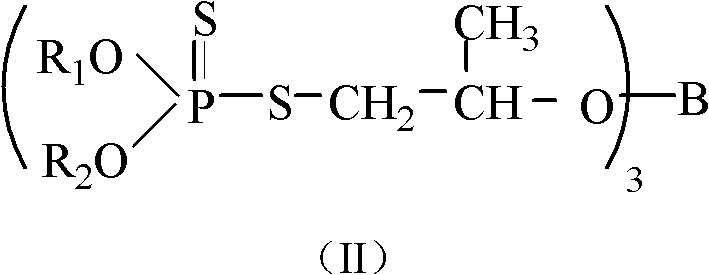

Preparation and application of dialkyl dithiophosphate hydroxyl derivative and boric acid ester thereof

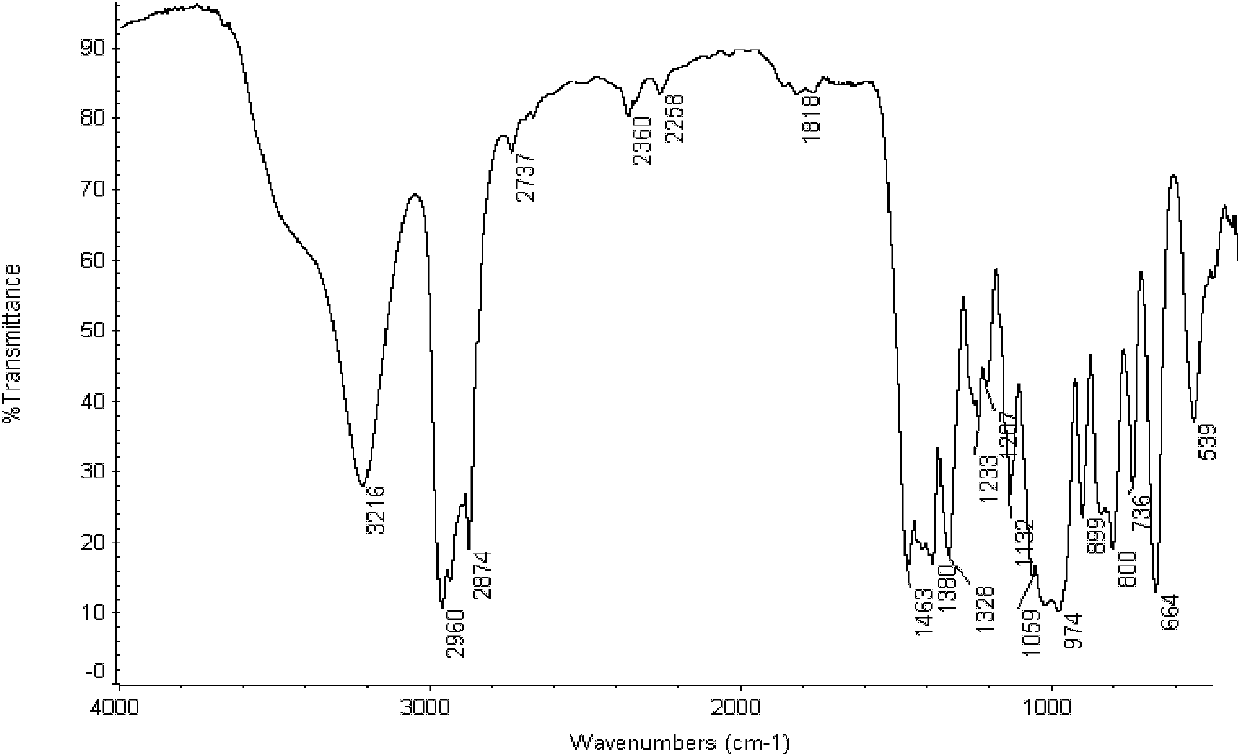

A technology of dialkyl dithiophosphoric acid and hydroxyl derivatives, which is applied in lubricating compositions, compounds of Group 5/15 elements of the periodic table, and the petroleum industry. Conditions and other issues, to achieve the effect of high thermal stability, good oil solubility, and low hydrolytic stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Add the appropriate amount of C 4 h 9 OH was added to the three-necked flask, and P was added in batches under vigorous stirring. 2 S 5 (the molar ratio of the two is 4:1), continue to stir at room temperature for 0.5h, then heat up to 90°C and continue to react for 3h. After the reaction solution is thoroughly clarified, an intermediate is obtained; take an appropriate amount of the above intermediate product in a three-necked flask, Add an equimolar amount of propylene oxide dropwise at room temperature, keep it warm for 0.5h, then gradually raise the temperature to 50°C, and continue the reaction for 2h to obtain di-n-butyl dithiophosphoric acid hydroxy derivative (a);

[0023] Add boric acid and the above product in a molar ratio of 1:3 into a reaction bottle equipped with a water separator, and add an appropriate amount of acidic resin as a catalyst and an appropriate amount of benzene as a water-carrying agent, and react at 70-80°C for 4-6 hours. After the wate...

Embodiment 2

[0026] Add an appropriate amount of dodecylphenol into a three-necked bottle, add an appropriate amount of toluene as a solvent, and add P in batches under vigorous stirring. 2 S 5 (the molar ratio of the two is 4:1), continue to stir at room temperature for 0.5h, and then heat up to 110°C to continue the reaction for 5h. After the reaction solution is thoroughly clarified, the toluene is evaporated to obtain an intermediate; take an appropriate amount of the above intermediate product in In a three-neck flask, add an equimolar amount of propylene oxide dropwise at room temperature, keep it warm for 0.5h, then gradually raise the temperature to 50°C, and continue the reaction for 3h to obtain a behenylphenol dithiophosphoric acid hydroxyl derivative;

[0027] Add boric acid and the above product in a molar ratio of 1:3 to a reaction bottle equipped with a water separator, and add an appropriate amount of acid resin as a catalyst and an appropriate amount of toluene as a water-...

Embodiment 3

[0029] This example is a tribological performance test.

[0030] Get example 1 and obtain the borate of di-n-butyl dithiophosphoric acid hydroxy derivative and di-n-butyl dithiophosphoric hydroxy derivative, take Mobil diester A51 as base oil on four-ball friction and wear testing machine to evaluate all The anti-wear and anti-friction performance of synthetic additives, the test conditions are: according to the GB / T 3142-82 standard method, the maximum non-seizing load P of the sample is measured B and sintering load P D To evaluate the extreme pressure performance; under the load of 392N, measure the wear spot diameter (WSD) of the sample according to the SH / T 0189-92 standard method to evaluate the anti-wear performance; under the load of 392N, according to the ASTM D5183-95 (1999) standard Methods The coefficient of friction (μ) of the samples under different loads was measured to evaluate the anti-friction performance. The test results are listed in Table 1 and Table 2....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com