Base oil for metal working fluid and preparation method of base oil

A metalworking fluid and base oil technology, applied in additives, petroleum industry, organic chemistry, etc., can solve the problems of cumbersome preparation process steps, accelerated ester hydrolysis, and deterioration of lubricating oil hydrolysis stability, achieving good hydrolysis stability, The effect of mild reaction conditions and simple preparation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

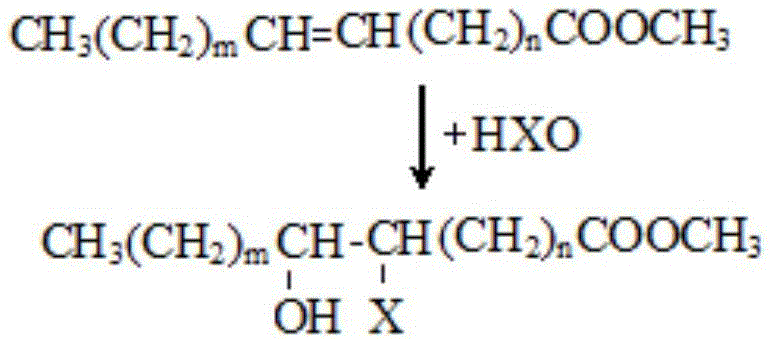

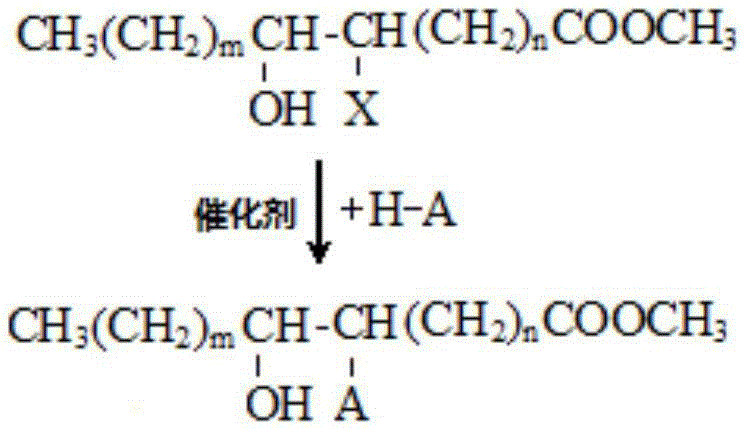

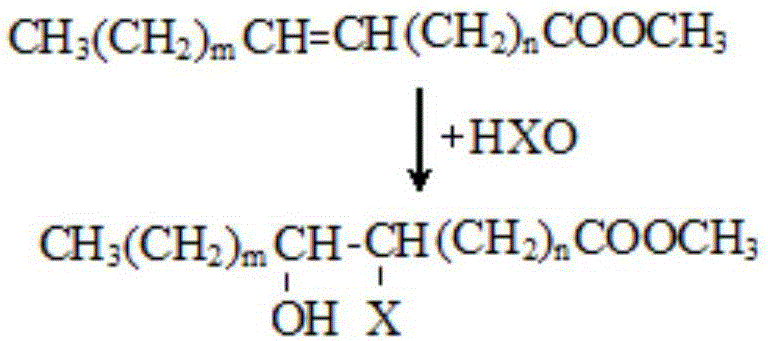

[0030] The first step: using soybean fatty acid methyl ester as a raw material, continuously stirring at room temperature, gradually adding a 2-fold molar ratio of hypobromous acid (HBrO) solution dropwise, and reacting for 3 hours.

[0031] The second step: take by weighing 2-mercaptothiazole of the same molar amount as the hypobromous acid in the first step and 0.5% sodium hydroxide whose quality is the fatty acid methyl ester quality, dissolve in the ethanol solution, under constant stirring, add the second The reaction liquid obtained in one step is reacted for 3 hours to obtain soybean oil fatty acid methyl ester mercaptothiazole, the obtained product is washed with ethanol, dried to remove ethanol, and can be used as base oil for metalworking fluid.

Embodiment 2

[0033] The first step: using palm oil fatty acid methyl ester as a raw material, continuously stirring at room temperature, gradually adding a 3-fold molar ratio hypochlorous acid (HClO) solution dropwise, and reacting for 2 hours.

[0034] The second step: take by weighing the 2-mercaptobenzothiazole of the same molar amount as HClO in the first step and the sodium hydroxide whose quality is 1.0% of the fatty acid methyl ester quality, dissolve in the ethanol solution, under constant stirring, add the second The reaction liquid obtained in one step is reacted for 2 hours to obtain palm oil fatty acid methyl ester mercaptobenzothiazole, and the obtained product is washed with ethanol, dried to remove ethanol, and can be used as base oil for metalworking fluid.

Embodiment 3

[0036] The first step: taking rapeseed oil fatty acid methyl ester as a raw material, continuously stirring at room temperature, gradually adding a 4-fold molar ratio of hypoiodous acid (HIO) solution dropwise, and reacting for 3 hours.

[0037] The second step: take by weighing the 2-mercaptobenzothiazole of the same molar amount as HIO in the first step and the sodium hydroxide whose quality is 2.0% of the fatty acid methyl ester quality, be dissolved in the ethanol solution, under constant stirring, add the second The reaction liquid obtained in one step is reacted for 4 hours to obtain the rapeseed oil fatty acid methyl ester mercaptothiazole, and the obtained product is washed with ethanol, dried to remove the ethanol, and can be used as a metalworking fluid base oil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com