Antioxidant nickel-based high-temperature alloy powder and preparation method thereof

A high-temperature alloy and nickel oxide-based technology, which is applied in the preparation of oxidation-resistant nickel-based superalloy powder and the field of anti-oxidation nickel-based superalloy powder, can solve the problem of high carbon oxide content in nickel-based alloy powder, and achieve the elimination of component segregation, Avoid high melting point carbides and oxides and meet the needs of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The preparation method of an anti-oxidation nickel-based superalloy powder of the present invention is specifically carried out according to the following steps:

[0043] Step 1, get the alloy of 64% Ni, 19% Cr, 13% W, 0.5% Mo, and 3.5% Nb for subsequent use;

[0044] Step 2, putting the alloy in step 1 into a vacuum induction furnace for melting, and then remelting in a vacuum consumable furnace to obtain a master alloy ingot with a diameter of 80 mm.

[0045] Step 3: Put the master alloy ingot into a high-temperature box-type resistance furnace, heat treat it at 1210°C for 12 hours to make its composition homogeneous, and then cool it to room temperature with the furnace, and machine the cooled master alloy ingot Electrode rod, the diameter of the electrode rod is 75mm, and the length is 650mm;

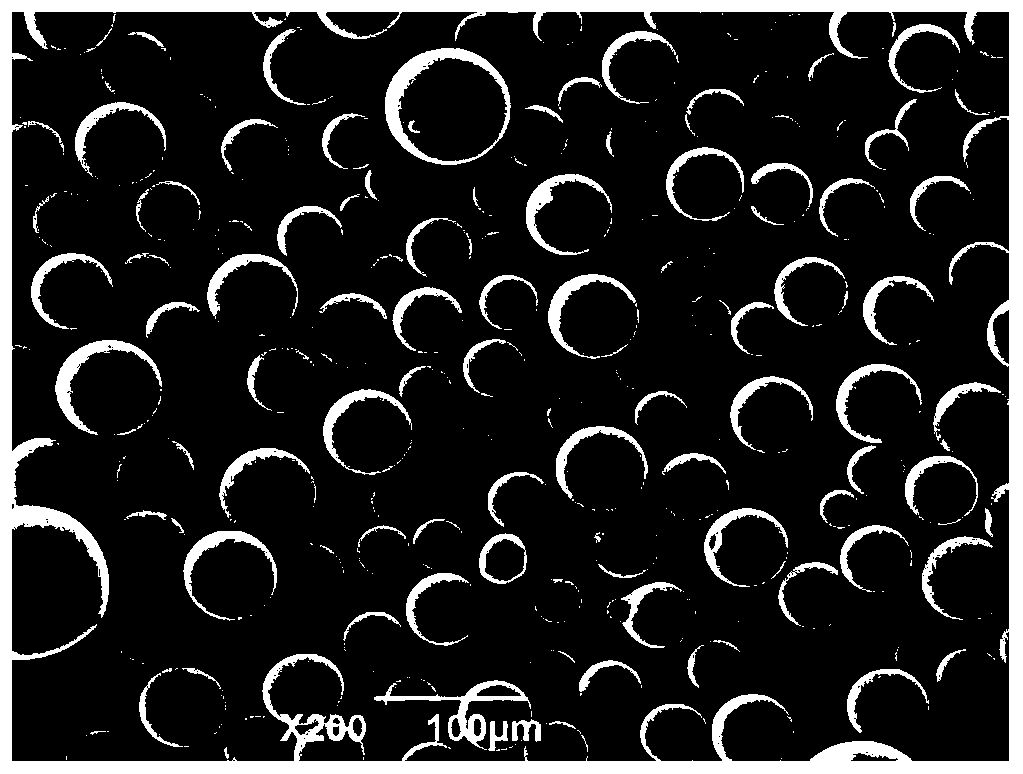

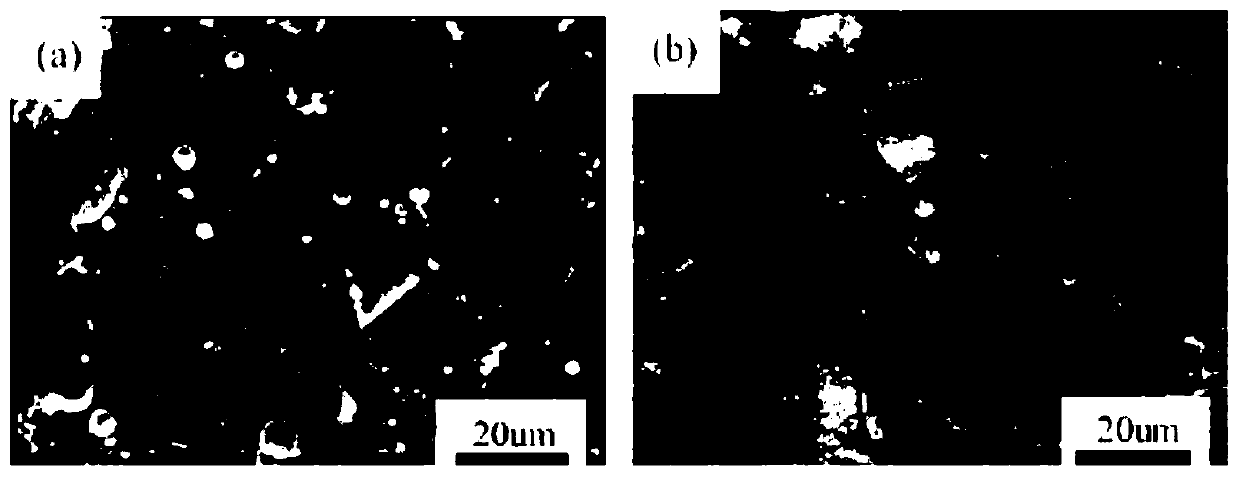

[0046] Step 4, put the electrode rod into the plasma rotary electrode powder making machine, vacuumize and fill it with argon gas, adjust the power of the plasma gun to 30KW...

Embodiment 2

[0050] The preparation method of an anti-oxidation nickel-based superalloy powder of the present invention is specifically carried out according to the following steps:

[0051] Step 1, get the alloy of 61% Ni, 20% Cr, 14% W, 1% Mo, and 4% Nb for subsequent use;

[0052] Step 2, putting the alloy in step 1 into a vacuum induction furnace for melting, and then remelting in a vacuum consumable furnace to obtain a master alloy ingot with a diameter of 80 mm.

[0053] Step 3: Put the master alloy ingot into a high-temperature box-type resistance furnace, heat-treat it at 1230°C for 16 hours to make its composition homogeneous, then cool to room temperature with the furnace, and machine the cooled master alloy ingot into Electrode rod, the diameter of the electrode rod is 78mm, and the length is 665mm;

[0054] Step 4, put the electrode rod into the plasma rotary electrode powder making machine, vacuumize and fill it with argon gas, adjust the power of the plasma gun to 33KW, use ...

Embodiment 3

[0058] The preparation method of an anti-oxidation nickel-based superalloy powder of the present invention is specifically carried out according to the following steps:

[0059] Step 1, get the alloy of 58% Ni, 21% Cr, 15% W, 1.5% Mo, and 4.5% Nb for subsequent use;

[0060] Step 2, putting the alloy in step 1 into a vacuum induction furnace for melting, and then remelting in a vacuum consumable furnace to obtain a master alloy ingot with a diameter of 80 mm.

[0061] Step 3: Put the master alloy ingot into a high-temperature box-type resistance furnace, heat-treat it at 1250°C for 20 hours to homogenize its composition, and then cool to room temperature with the furnace, and machine the cooled master alloy ingot into Electrode rod, the diameter of the electrode rod is 80mm, and the length is 680mm;

[0062] Step 4, put the electrode rod into the plasma rotary electrode powder making machine, vacuumize and fill it with argon gas, adjust the power of the plasma gun to 35KW, us...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com