Method, controller, valve arrangement, and portioning device for portioning a flowable, optionally pressurized mass

A valve device, fluidity technology, applied in the direction of valve device, mechanical equipment, diaphragm valve, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

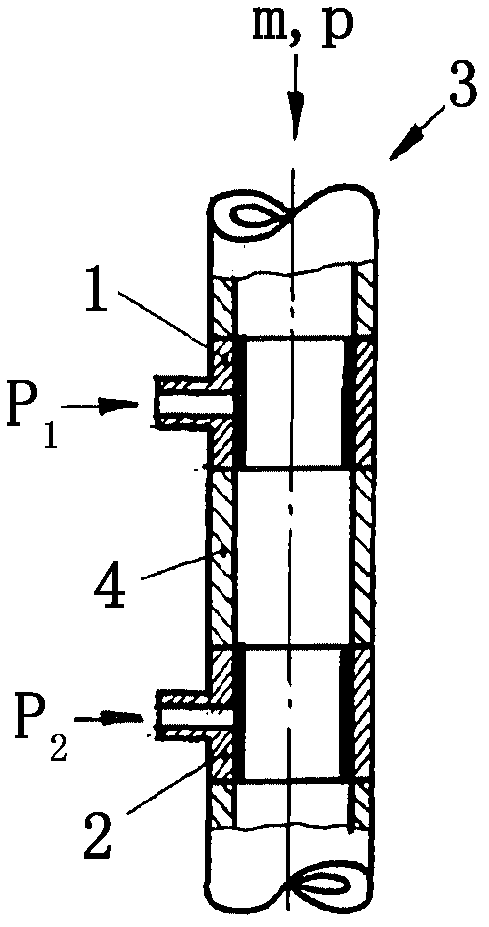

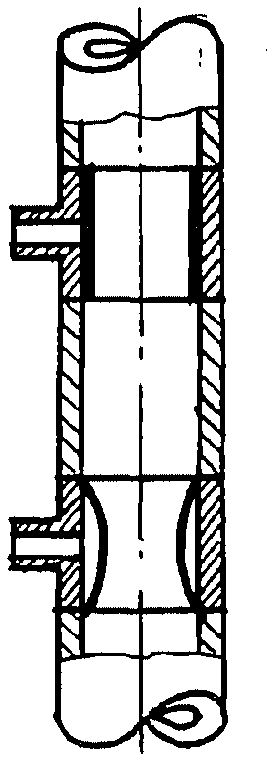

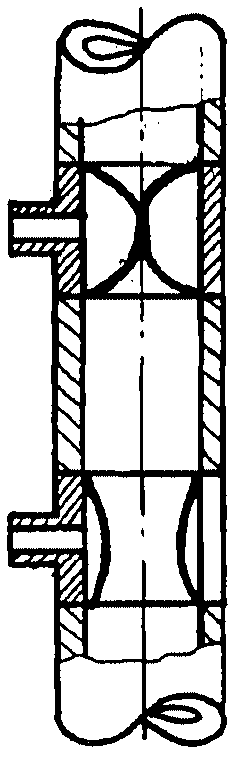

[0045] Figure 1a The first valve device 3 is schematically shown, which has a pipe 4 and a first squeeze valve 1 arranged along the pipe 4 and a second squeeze valve 2 arranged along the pipe 4. The fluid substance m flows through the pipe 4, and in this embodiment, the pressure of the substance loading is p. The main flow direction is indicated by arrows. The first squeeze valve includes a control interface with a first control pressure p 1 The control medium can flow through the control interface. Finally, the second squeeze valve has a control passage with a second control pressure p 2 The control medium can flow through the control interface.

[0046] Both squeeze valves have a structure known per se. In the example shown, they are controlled by pressurized gas. In principle, it is also possible to control the squeeze valves 1 and 2 with other control media. Using pressurized gas, a flexible tubular membrane (indicated by the thick line in the figure) can be deformed, nar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com