A matching flux-cored welding wire for fusion welding of seamless copper tubes for medical gas and vacuum

A flux-cored welding wire and vacuum technology, applied in welding equipment, welding medium, welding/cutting medium/material, etc., can solve the problem that the tensile strength and elongation of deposited metal cannot meet the requirements of use, and the chemical composition of deposited metal Inhomogeneity, poor airtightness of deposited metal, etc., to achieve the effect of fine structure, good airtightness, and improved airtightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

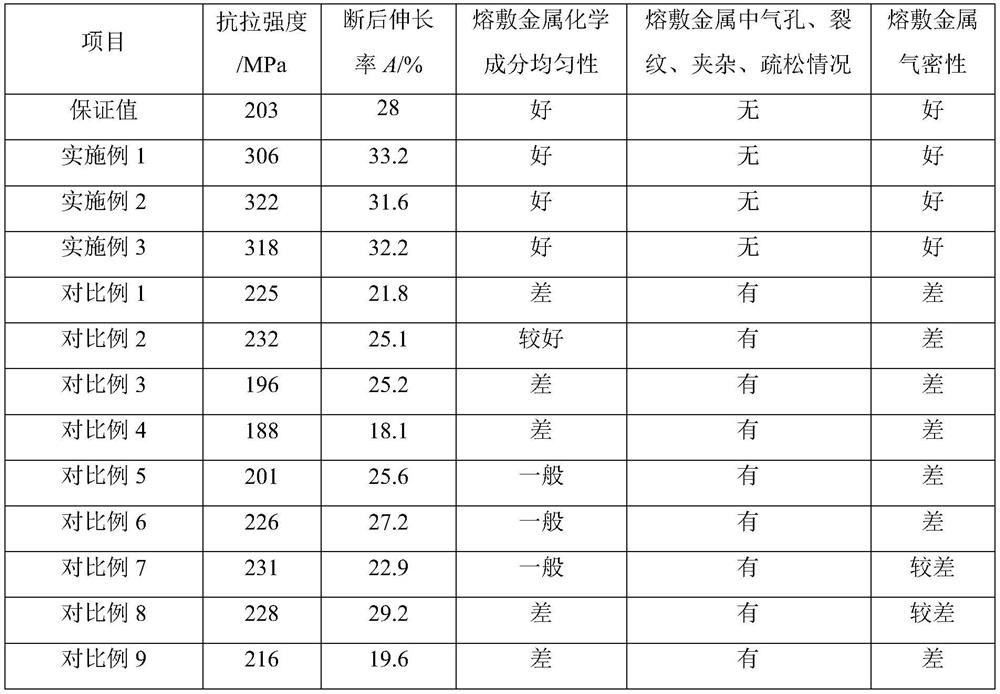

Examples

Embodiment 1

[0035] A matching flux-cored wire for fusion welding of seamless copper tubes for medical gas and vacuum, including a flux core and a sheath, the chemical composition and dosage of the flux core are calculated by mass percentage: 2.1% of CuSi16 powder, 2.2% of CuMn30 powder, and CuP12 powder 1.5%, AlSr40 powder 3.0%, nano F 3 Ti powder 2.8%, nanometer NdF 3 Powder 3.2%, the balance is FTD1 electrolytic copper powder; the outer skin is made of TU1 copper alloy strip.

[0036] The 100 mesh pass rate of CuSi16 powder, CuMn30 powder, CuP12 powder and AlSr40 powder is 100%.

[0037] Nano F 3The particle size range of Ti powder is 30nm-80nm.

[0038] Nano-NdF 3 The particle size range of the powder is 30nm-80nm.

[0039] The 200 mesh pass rate of FTD1 electrolytic copper powder is 100%, and the 300 mesh pass rate is 95%.

[0040] The thickness of the TU1 copper alloy strip is 0.5mm.

[0041] The state of TU1 copper alloy strip is semi-hard.

[0042] The filling rate of the d...

Embodiment 2

[0050] A matching flux-cored wire for fusion welding of seamless copper tubes for medical gas and vacuum, including a flux core and a sheath, the chemical composition and dosage of the flux core are calculated by mass percentage: CuSi16 powder 3.2%, CuMn30 powder 3.0%, CuP12 powder 2.2%, AlSr40 powder 3.8%, nano F 3 Ti powder 3.6%, nanometer NdF 3 Powder 4.5%, the balance is FTD1 electrolytic copper powder, and the outer skin is made of TU1 copper alloy strip.

[0051] The 100 mesh pass rate of CuSi16 powder, CuMn30 powder, CuP12 powder and AlSr40 powder is 100%.

[0052] Nano F 3 The particle size range of Ti powder is 30nm-80nm.

[0053] Nano-NdF 3 The particle size range of the powder is 30nm-80nm.

[0054] The 200 mesh pass rate of FTD1 electrolytic copper powder is 100%, and the 300 mesh pass rate is 95%.

[0055] The thickness of the TU1 copper alloy strip is 1.5mm.

[0056] The state of TU1 copper alloy strip is semi-hard.

[0057] The filling rate of the drug c...

Embodiment 3

[0060] A matching flux-cored wire for fusion welding of seamless copper tubes for medical gas and vacuum, including a flux core and a sheath, the chemical composition and dosage of the flux core are calculated by mass percentage: 2.6% of CuSi16 powder, 2.6% of CuMn30 powder, and CuP12 powder 1.8%, AlSr40 powder 3.4%, nano F 3 Ti powder 3.2%, nanometer NdF 3 Powder 3.8%, the balance is FTD1 electrolytic copper powder; the outer skin is made of TU1 copper alloy strip.

[0061] The 100 mesh pass rate of CuSi16 powder, CuMn30 powder, CuP12 powder and AlSr40 powder is 100%.

[0062] Nano F 3 The particle size range of Ti powder is 30nm-80nm.

[0063] Nano-NdF 3 The particle size range of the powder is 30nm-80nm.

[0064] The 200 mesh pass rate of FTD1 electrolytic copper powder is 100%, and the 300 mesh pass rate is 95%.

[0065] The thickness of the TU1 copper alloy strip is 1.0mm.

[0066] The state of TU1 copper alloy strip is semi-hard.

[0067] The filling rate of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com