Supercritical-CO2-assisted ozone desulfurization regeneration technique of waste rubber

A waste rubber, supercritical technology, applied in the production of bulk chemicals, plastic recycling, recycling technology, etc., can solve the problems of destroying the cross-linked network structure and failing to achieve continuous production, and achieve the effect of avoiding difficult control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

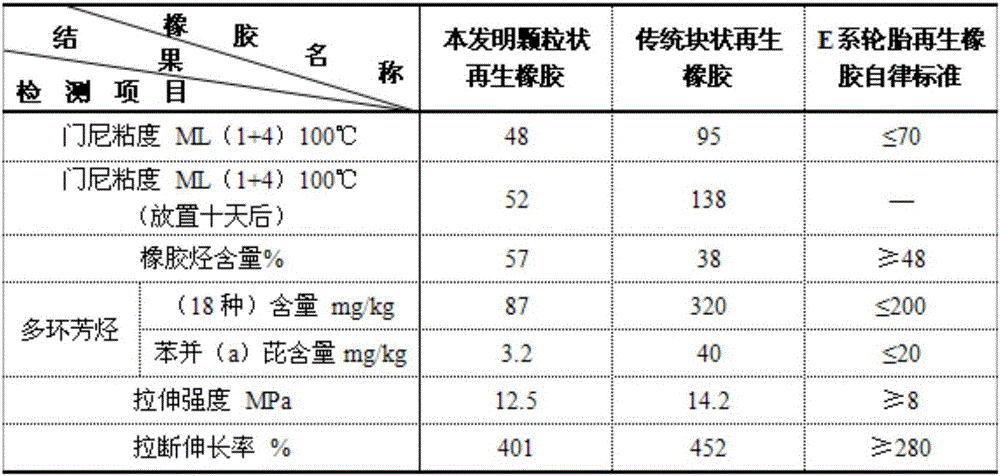

Image

Examples

Embodiment Construction

[0019] A supercritical CO 2 A new process for auxiliary waste rubber ozone desulfurization regeneration, including the following steps:

[0020] (1) The 20-50 mesh rubber powder obtained by crushing and separating the waste tires through the automatic linkage crushing line, and then the 20-50 mesh rubber powder is screwed into the co-rotating full-meshing twin-screw extruder through the feeding device for mixing Refining, plasticizing and preheating, and feeding supercritical CO into the second half of the twin-screw extruder 2 , making the preheated plastic powder subjected to supercritical CO 2 Strong penetration and swelling effect;

[0021] (2), the swollen plasticized rubber powder obtained in the screw conveying step (1), during the screw conveyed process, no chemical additives are needed and an ozone generating device is used to emit ozone to act on the swollen plasticized rubber powder, and the plasticized rubber powder of swelling The cross-linked network structure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com