Tool for welding special-shaped workpiece

A special-shaped workpiece, welding station technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc. Uncontrollable effects of springs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

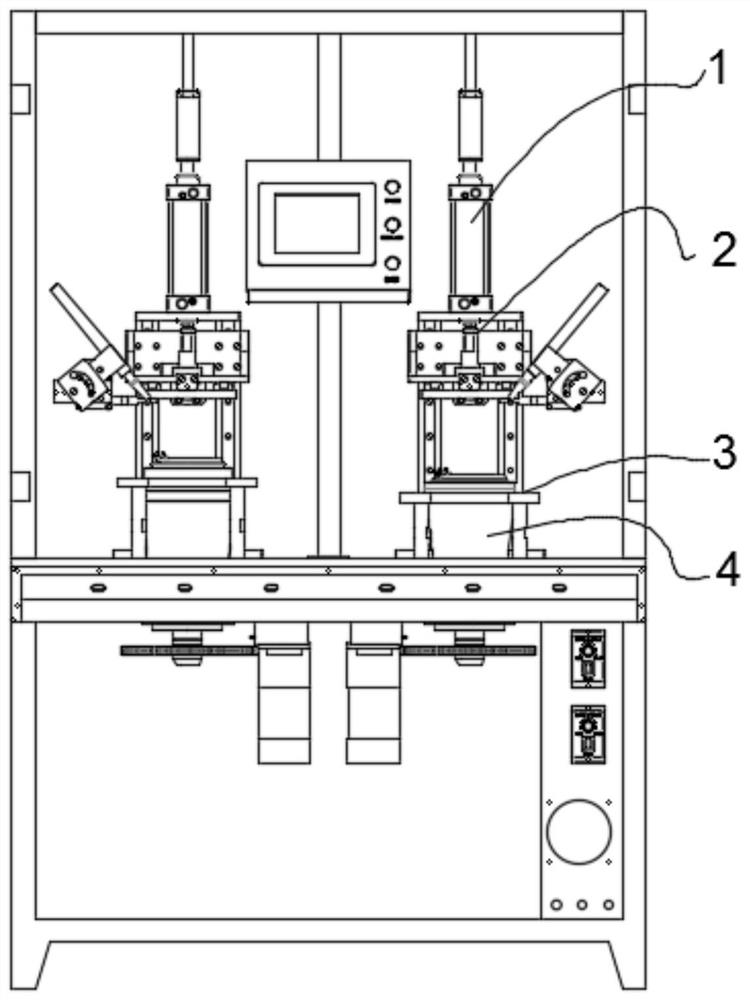

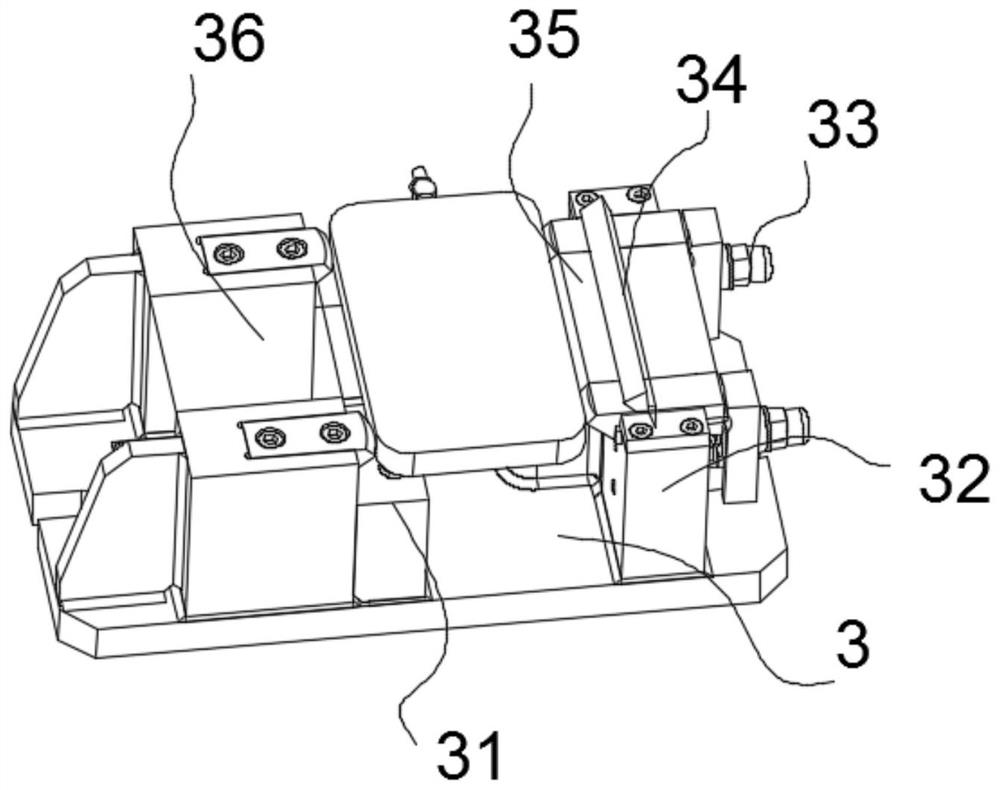

[0021] Example: refer to figure 1 As shown, the present embodiment takes the automatic electric welding machine on the market as an example, including a tooling platform 3 installed on the welding station of the welding machine, and the upper end surface of the tooling platform 3 is fixedly equipped with a first clamping platform 32 and a second clamping platform 32. Clamping platform 36, the first clamping platform 32 and the second clamping platform 36 are surrounded to form a clamping station;

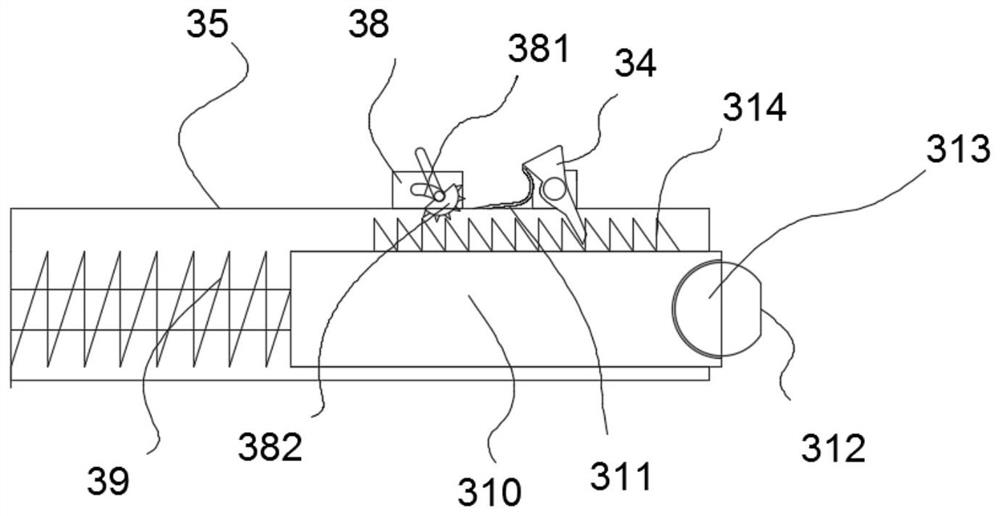

[0022] A clamping base 35 is slidably connected to the upper surface of the first clamping platform 32 , and a screw rod 33 is connected to the rear end of the clamping base 35 ; the clamping base 35 can also be installed on two clamping platforms at the same time.

[0023] The clamping seat 35 has a built-in slide cavity, and a push post 310 is slidably connected to the slide cavity, and a spring 39 is connected to the tail end of the push post 310, and a stressed end of the spring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com