Three-stage-cooperated environment-friendly devulcanizing regeneration technology for waste/used rubber

A waste rubber and sulfur cutting technology, which is applied in recycling technology, plastic recycling, etc., can solve problems such as discontinuity in the production process, and achieve the effect of avoiding uncontrollable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

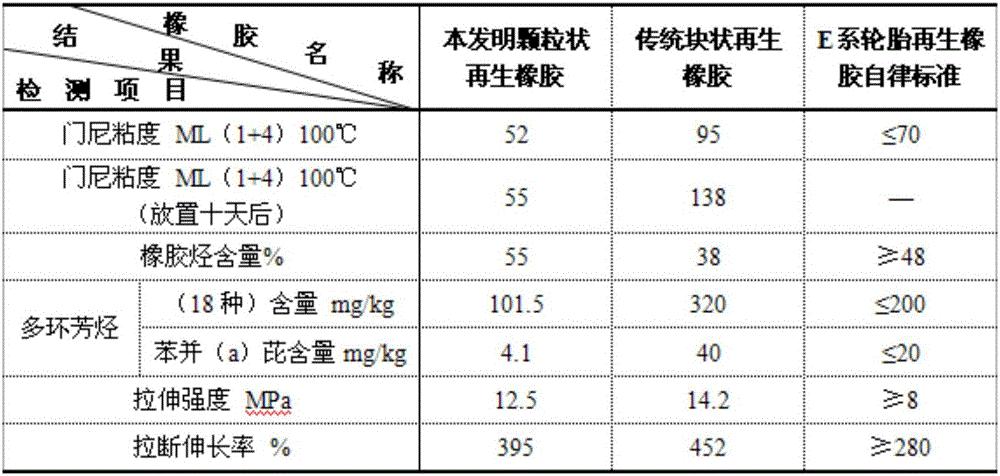

Examples

Embodiment Construction

[0018] A three-stage synergistic green sulfur breaking regeneration process for waste rubber, comprising the following steps:

[0019] (1) The 3-8mm rubber particles obtained by crushing and separating the waste tires through the automatic linkage crushing line, and then the 3-8mm rubber particles are screwed into the double-rotor continuous mixer through the feeding device; in the double-rotor continuous mixing In the machine, the rubber molecules of the rubber particles are subjected to the high shear and strong tension of the double-rotor mixing flow field, which promotes their mixing and plasticization and the initial sulfur removal and regeneration of part of the rubber to obtain a rubber mixture;

[0020] (2) The rubber mixture obtained in the screw conveying step (1). During the spiral conveying process, an ultrasonic power generator is used to emit ultrasonic waves to act on the rubber mixture. The acoustic cavitation of the ultrasonic waves concentrates the energy on t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com