Fresh rice bran pretreatment process and matched device thereof

A pretreatment device and fresh rice bran technology, applied in the direction of fat production, fat oil/fat production, etc., can solve the problems of material permeability and feeding impact, affecting normal oil extraction, material adhesion, etc., to improve sterilization and inactivation efficiency and Effect, facilitate transportation and storage, and prolong the effect of storage period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] A kind of fresh rice bran pretreatment process, comprises the following steps:

[0018] 1) Fresh rice bran is separated from rice bran to obtain purified rice bran with rice bran content less than 1%; at the same time, the separated broken rice and rice bran are collected and further processed.

[0019] 2) Collect and purify rice bran, sterilize, inactivate and shape it.

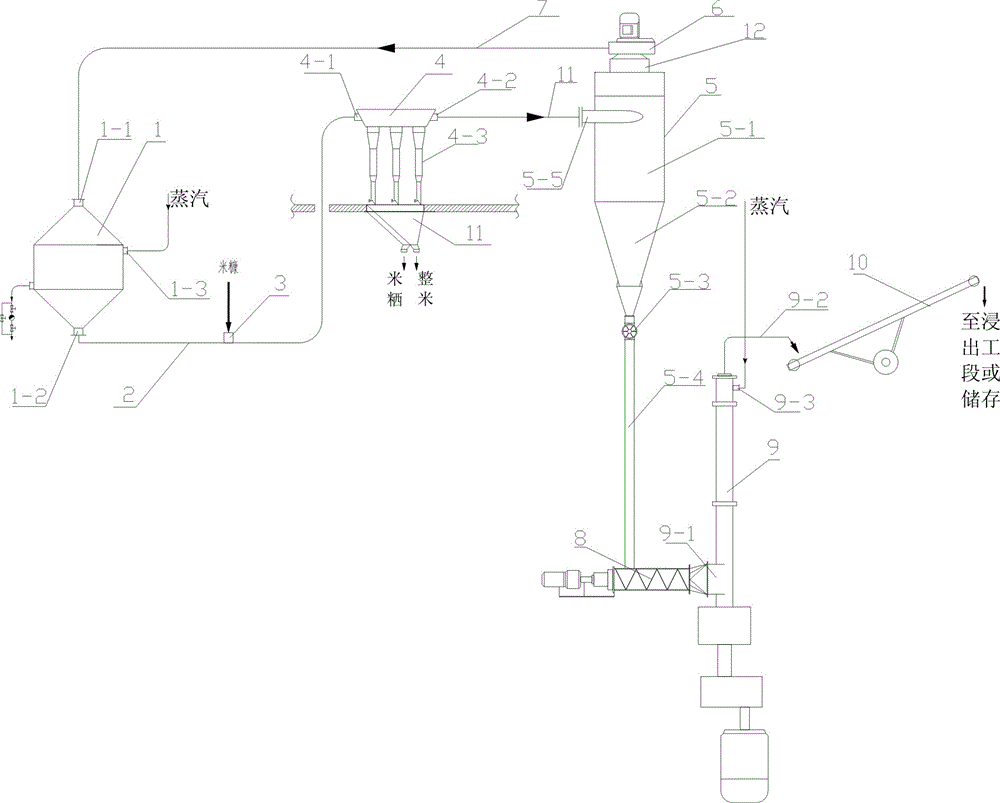

[0020] The device matched with the above-mentioned fresh rice bran pretreatment process, such as figure 1 As shown, it includes a bran and rice separator 4, a collection brake dragon 5 and a sterilizing molding machine 9; the bottom of the bran and rice separator 4 is provided with broken rice and rice rice outlet 4-3, and the broken rice and rice rice outlet are provided with broken rice below the outlet and the rice rice collection auger 11; the air inlet 4-1 of the bran separator 4 is communicated with the hot blast pipeline 2, and the other end of the hot blast pipeline 2 is connected with the ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com