Multiple laser composite scanning process

A composite scanning, multi-laser technology, applied in the improvement of process efficiency, additive processing, additive manufacturing, etc., can solve problems such as large temperature difference, reduce fatigue life of workpiece, affect workpiece quality, etc., to achieve small temperature difference and reduce cracks. Frequency, the effect of sintered surface densification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

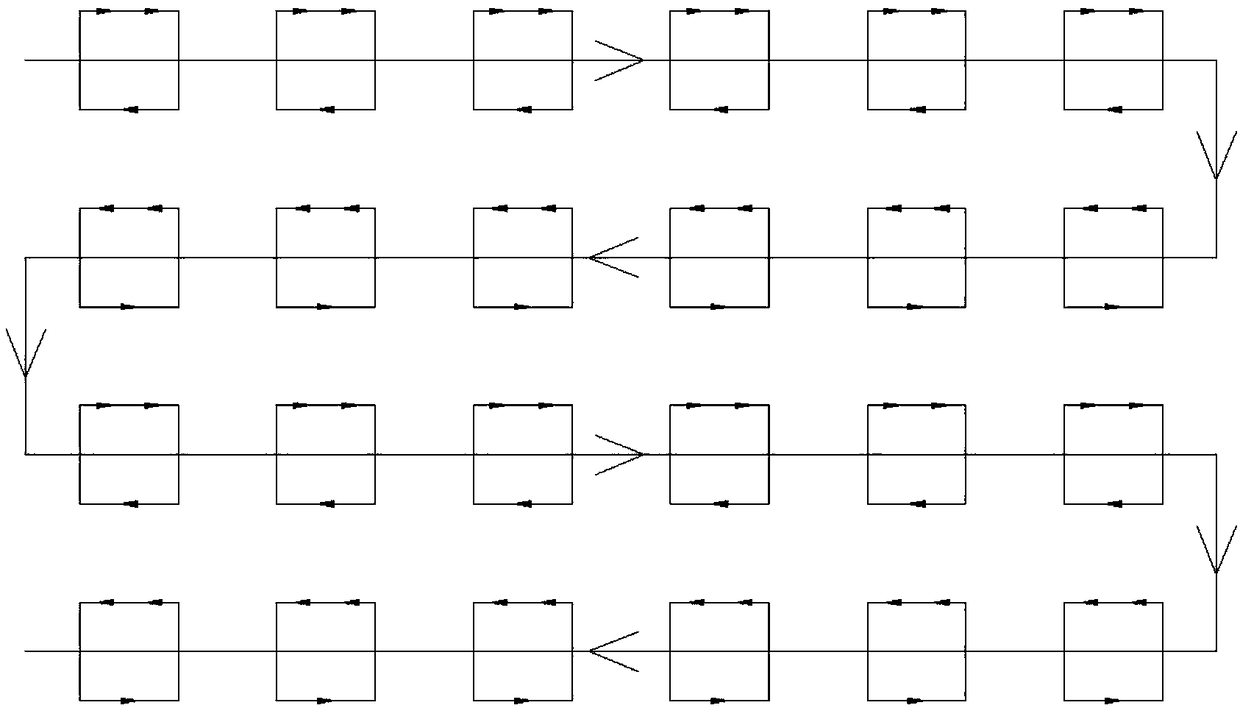

[0013] figure 1 A specific embodiment of the present invention is shown: a multi-laser composite scanning process. The multi-laser composite scanning process uses two laser generators, laser one and laser two, to carry out laser melting on metal powder. When melting, laser one uses power first. A pair of metal powder areas are scanned and preheated, and then laser 2 uses power 2 to scan and melt the metal powder area, and finally laser 1 or laser 2 uses power 3 to scan and modify the metal powder area, and power 1 is less than power 3, power Three is less than power two.

[0014] In this embodiment, the scanning paths of laser 1 and laser 2 are bent paths, and the bent paths are composed of a plurality of square frames. The square frames are parallel to each other and cover the entire metal powder area. The scanning direction of the square ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com