Graphite reaction kettle for hydrogen chloride production

A hydrogen chloride, reactor technology, applied in chemical/physical/physical-chemical stationary reactors, detailed information of chemical/physical/physical-chemical reactors, chemical instruments and methods, etc., can solve the problem of hydrogen chloride gas mixing, mixing uniformity It can reduce the heat loss, improve the mixing quality and save energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

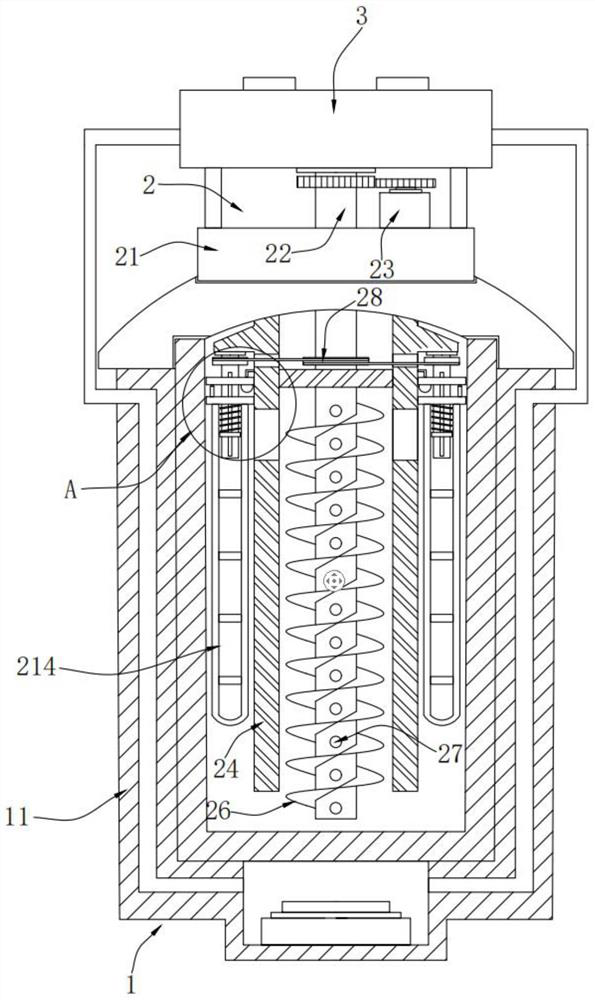

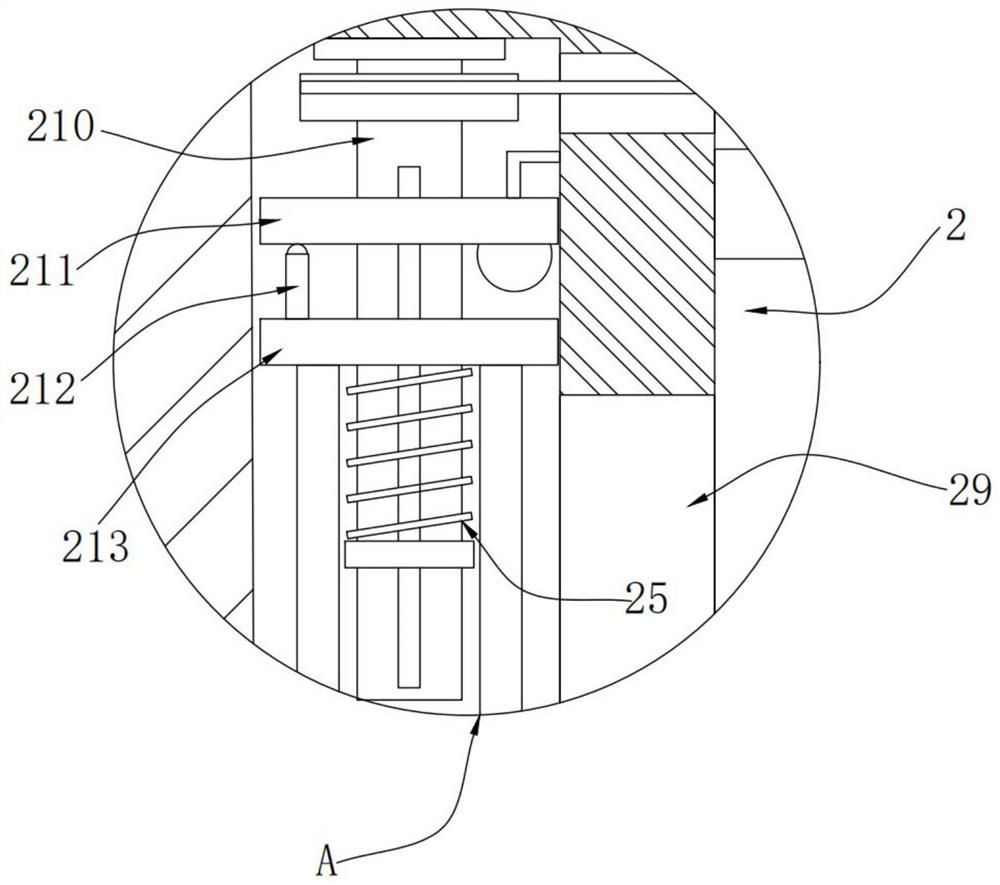

[0017] Please refer to Figure 1-3 , a graphite reactor for hydrogen chloride production, comprising,

[0018] Basic component 1, basic component 1 comprises heat-transfer graphite reactor cylinder 11 and exhaust port, heat-transfer graphite reactor cylinder 11 belongs to the prior art, and the "high-efficiency heat transfer structure of graphite reactor" proposed in the publication number "CN211659989U" "Disclosure, it is composed of steel cylinder, supporting feet, graphite cylinder, combustion box, combustion chamber, air hole, exhaust pipe, heating chamber, burner, hot water tank, circulating water pump and other structures, and will not be described in detail here. As mentioned above, the outer wall of the heat transfer graphite reaction cylinder 11 is also provided with a discharge port and a feed inlet, both of which are not shown in the figure, and the left and right sides of the heat transfer type graphite reaction cylinder 11 are provided with exhaust ports for disch...

Embodiment 2

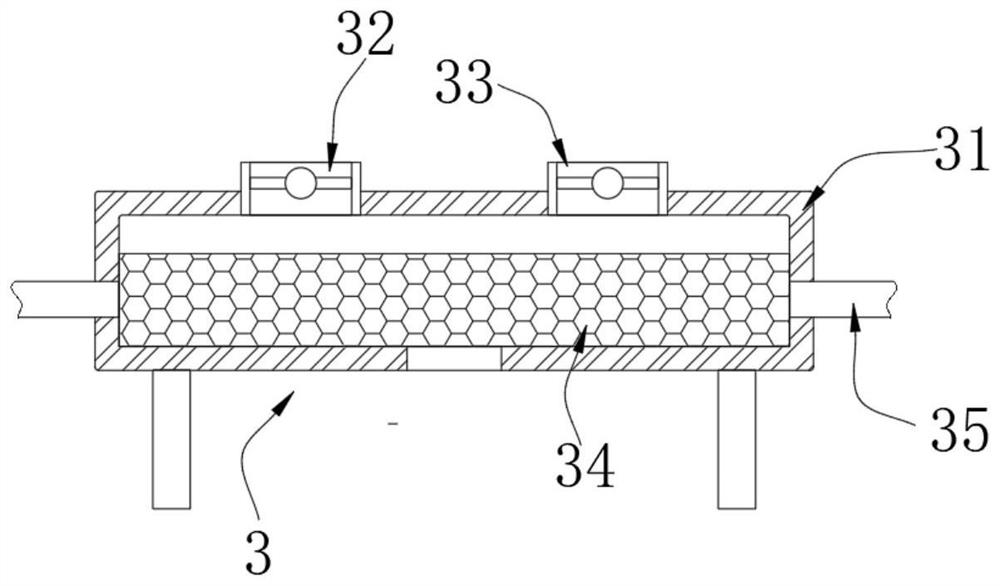

[0026] Please refer to image 3 As shown, the air intake assembly 3 includes an air intake shell 31 that is arranged on the top of the support base 21 through a bracket, and the left and right sides of the top of the air intake shell 31 are respectively provided with an air intake pipe 32 and an exhaust pipe 33 that communicate with each other, and the exhaust pipe 33 It is used to exhaust the hot gas and flue gas produced by combustion. The intake pipe 32 allows the hydrogen chloride gas to enter, and the intake pipe 32 and the exhaust pipe 33 are equipped with solenoid valves to facilitate the control of the opening and closing of the intake and outlet. Two sets of exhaust ports The other ends are connected with a connecting air pipe 35, and the other end of the connecting air pipe 35 communicates with the bottom of the side wall of the air intake shell 31. The connecting air pipe 35 allows the hot gas and smoke generated by combustion to enter the air intake shell 31, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com