GCL vertical laying structural member and construction process thereof

A technology of construction technology and structural parts, which is applied in the field of GCL vertical laying structural parts and its construction technology, can solve problems such as the inability to guarantee the quality of product laying, and achieve the effects of efficient vertical laying, high construction efficiency, and guaranteed construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

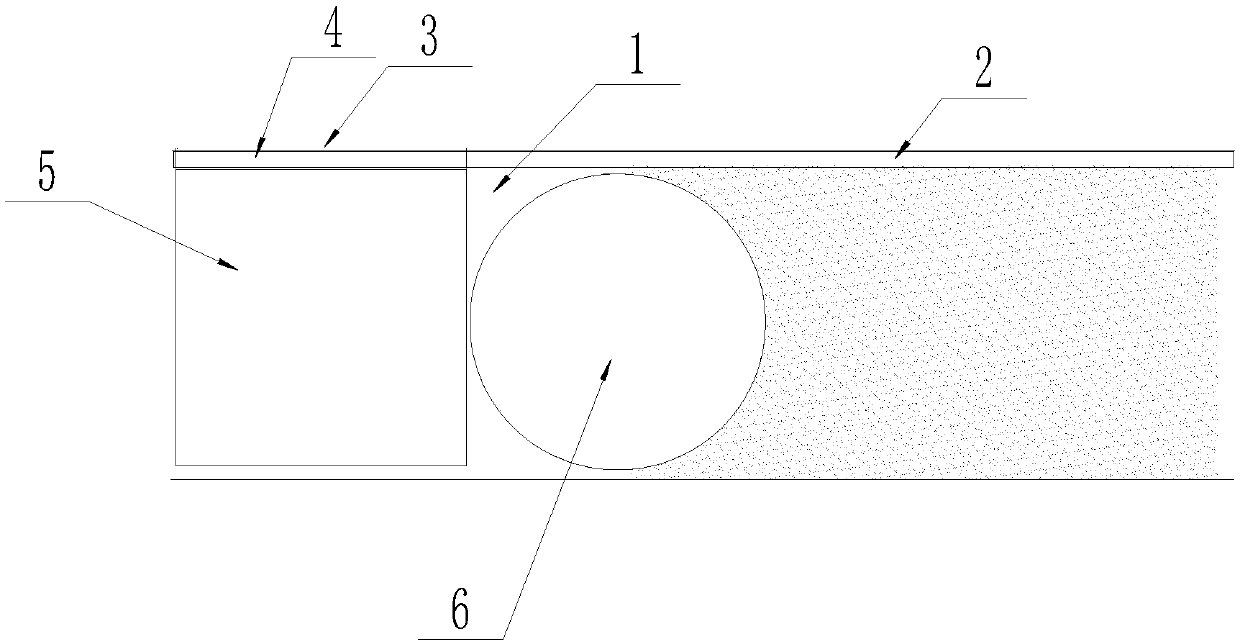

[0031] First excavate the trench for laying the special GCL composite component layer for vertical anti-seepage, and put the GCL composite component layer special for vertical anti-seepage into the trench with a spreader or a vertical laying device for GCL composite component;

[0032] The special GCL composite component layer for vertical anti-seepage is specially designed and developed according to the construction characteristics of vertical anti-seepage walls. Compared with the sodium-based bentonite waterproof blanket, it is composed of lap lines, support plates, counterweight grooves, O-rings, etc. As a whole, it can be laid vertically, flatly, safely and mechanized;

[0033] The vertical laying device of GCL composite components is developed according to the characteristics of flexible anti-seepage membranes such as GCL and the characteristics of vertical laying construction. The equipment has a high degree of mechanization, simple and safe operation, and mobility, which...

Embodiment 2

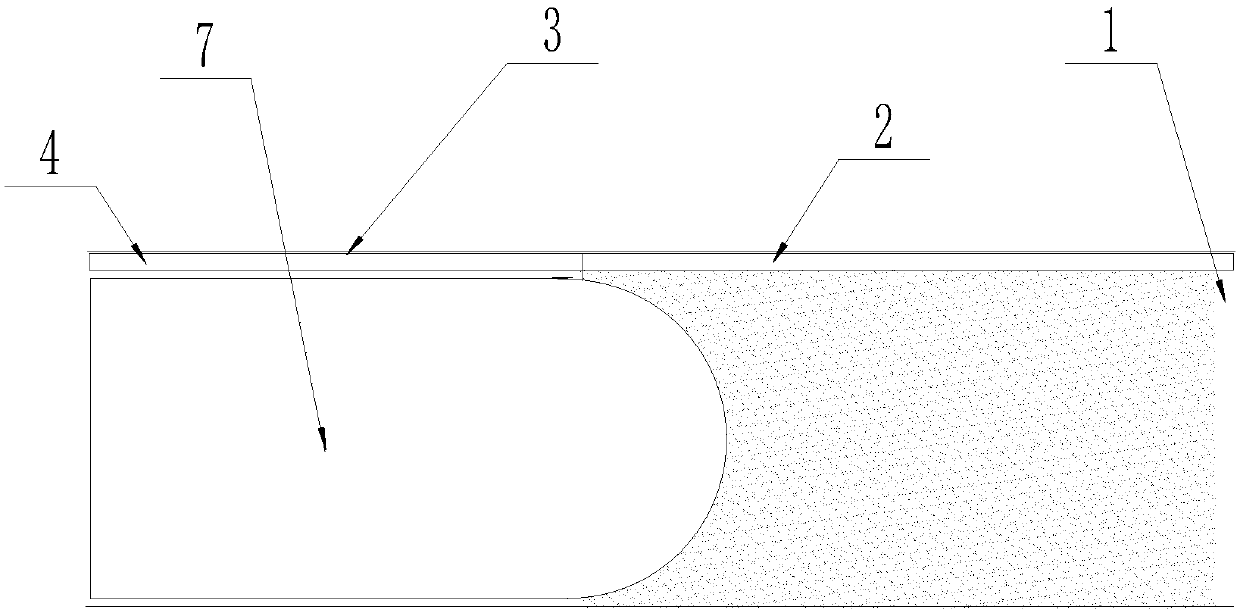

[0046] Replace the joint pipe and joint box with a two-in-one joint box, and the two-in-one joint box can be pulled out once and then enter the next process for construction, which improves the construction efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com