High-efficiency high-pressure sensor test machine

A high-pressure sensor and testing machine technology, applied in instruments, measuring fluid pressure, measuring devices, etc., can solve the problems of complex detection steps, low accuracy, high detection cost, etc., and achieve perfect alarm function, high accuracy, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

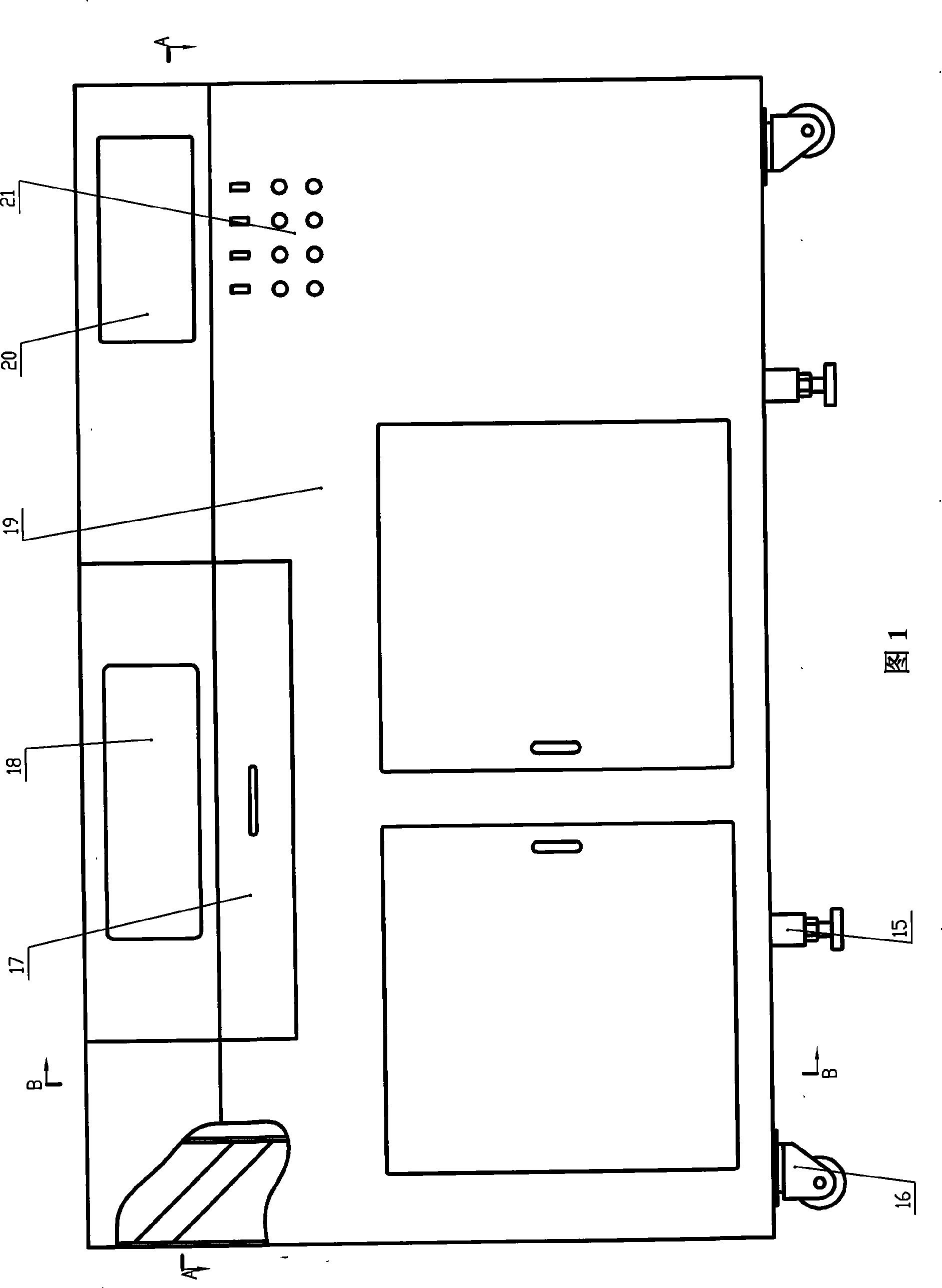

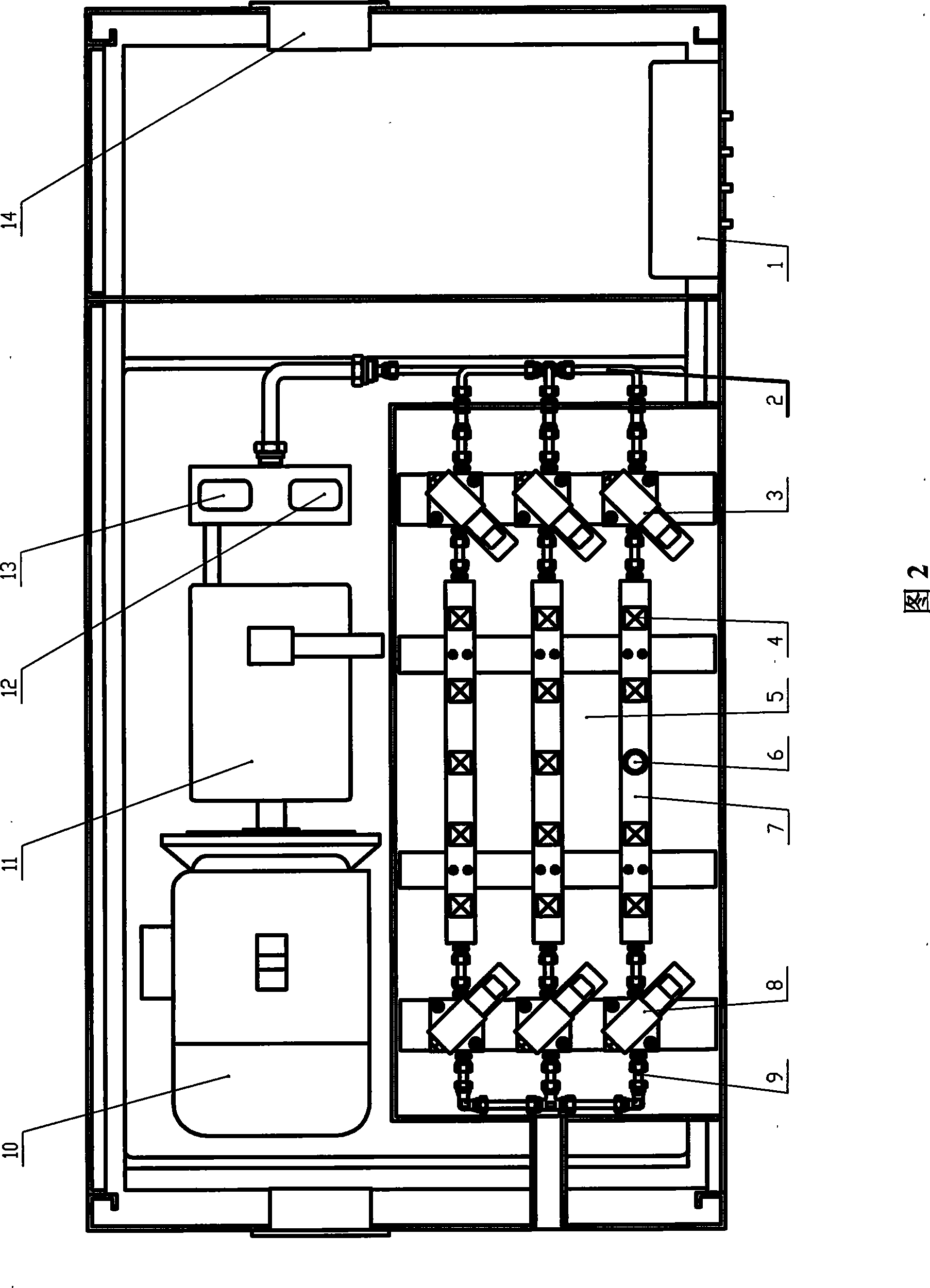

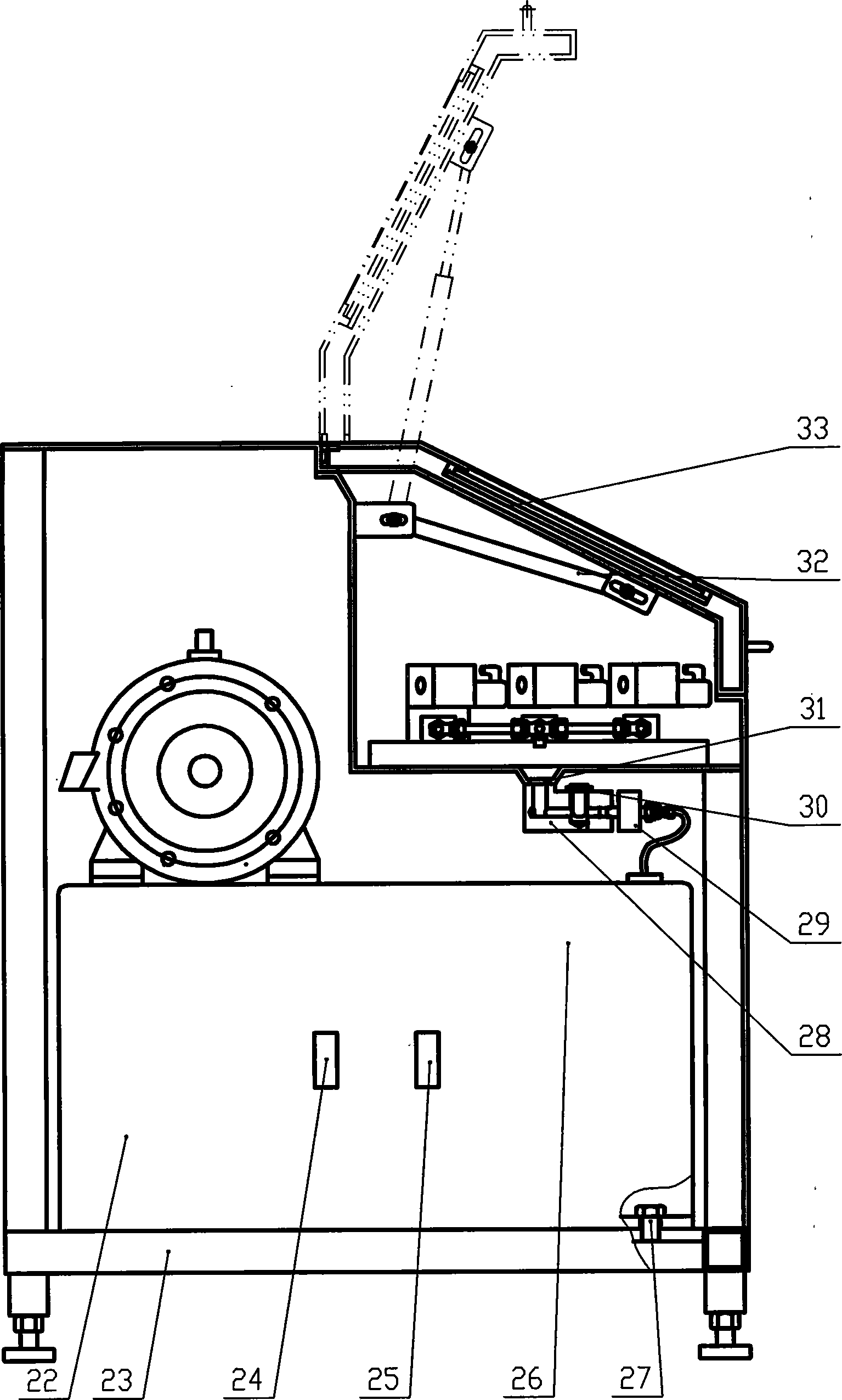

[0031] As shown in Figures 1 to 3, the complete machine is supported by four shock-absorbing adjustment pad irons 15 below the base plate 23, and four casters 16 are set at the same time to facilitate movement. The cabinet 19 and the pressure generating system 26 are connected on the bottom plate 23 .

[0032] The pressure generating system 26 is mainly composed of a fuel tank 22, a motor 10, a variable pump 11, a servo relief valve 12, an electromagnetic pressure regulating valve 13, a liquid level sensor 24, a temperature sensor 25, etc., which are fixed on the base plate 23 by a positioning device 27. The variable displacement pump 11 is connected to the motor 10 , and its pressure outlet is connected to the pipeline 2 through the electromagnetic pressure regulating valve 13 and the servo overflow valve 12 . After the pipeline 2 is connected in parallel to three routes, it leads to the test area 5 which can be kept closed, and is connected to the installation fixture 7 thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com