Laid cloth roll clamping mechanism for wind power blade mold and application of laid cloth roll clamping mechanism

A technology of wind power blade and clamping mechanism, which is applied in the field of wind power blade mold laying roll clamping mechanism, which can solve the problems of gradual change and non-fitting of profiles, etc., and achieve the effects of liberating productivity, good fit, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

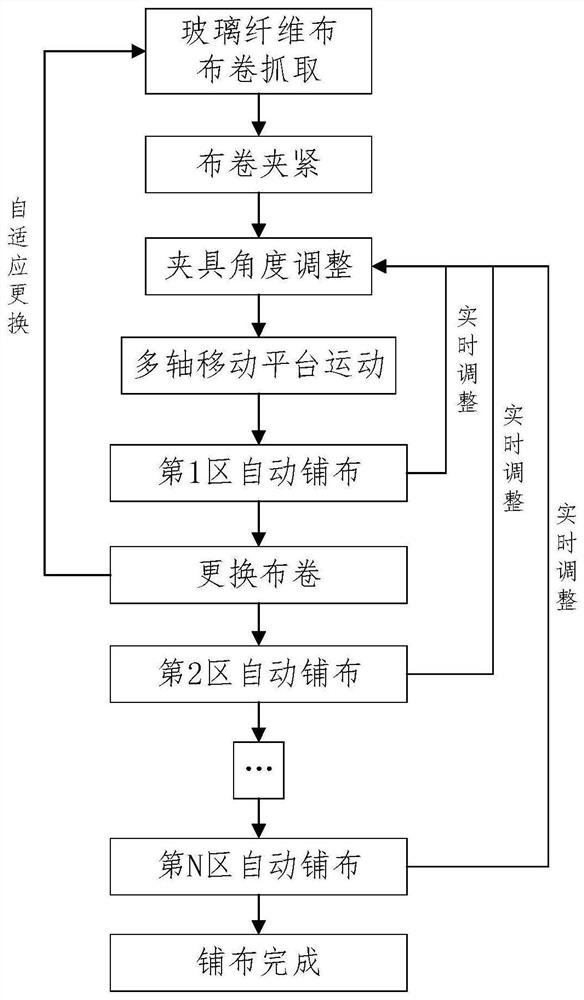

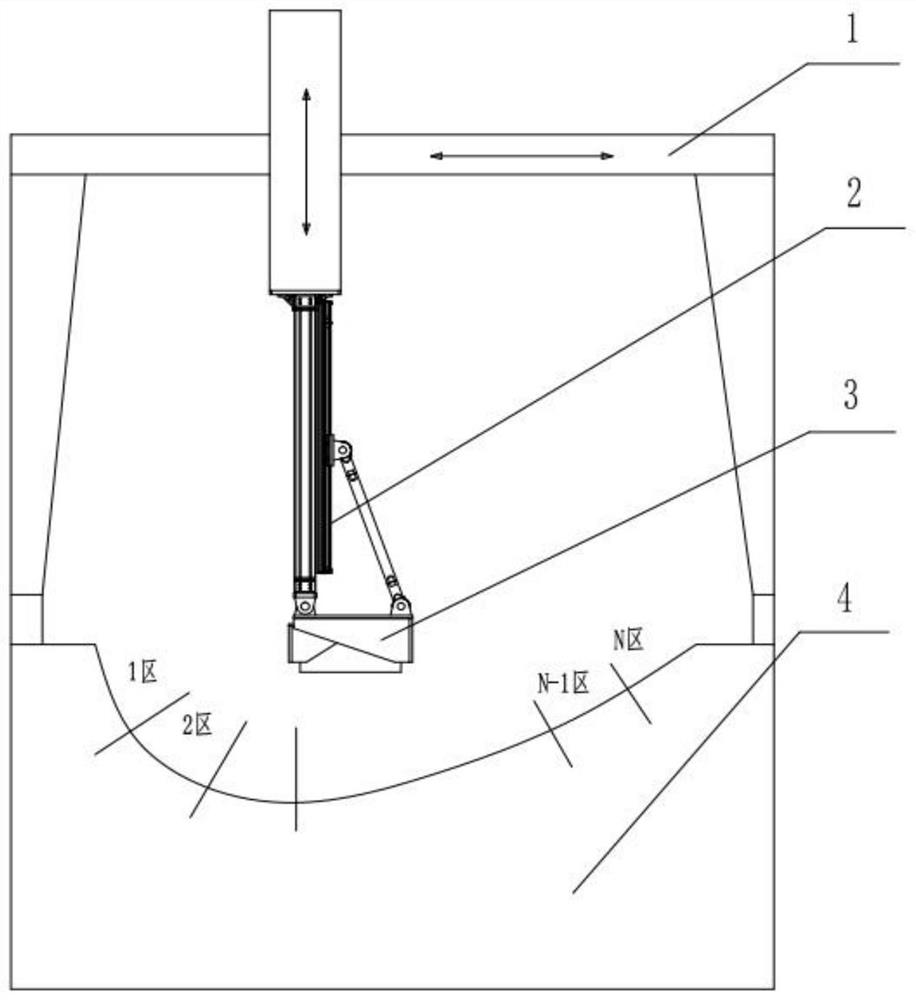

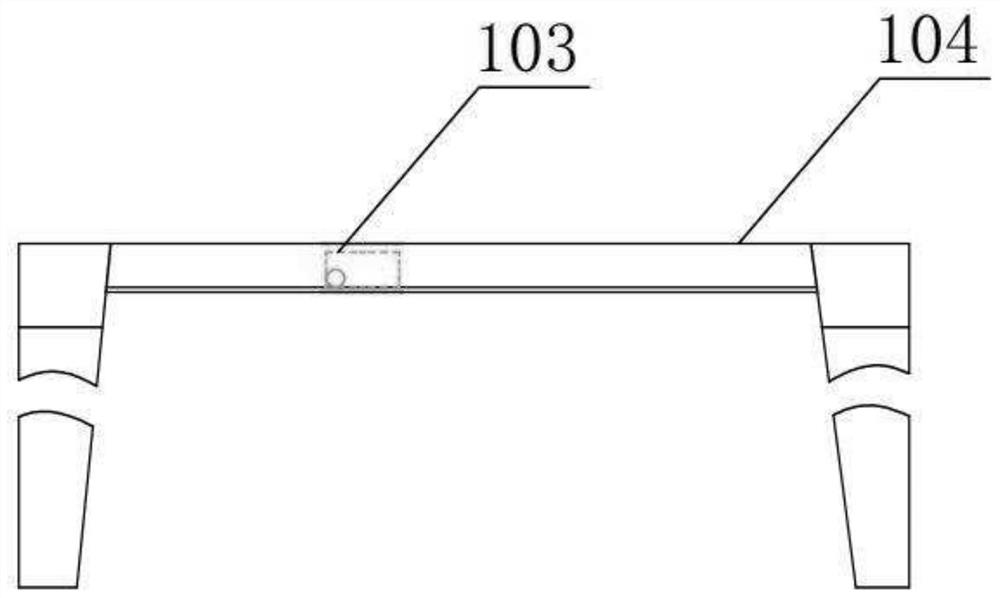

[0056] Step 1: Place the multi-axis mobile platform 1 on the mold 100, and manually transport the glass fiber cloth roll of one blade to the designated place around the mold 100. After the central control terminal turns on the switch for changing the cloth roll, the glass fiber cloth roll After the cylinder 305 in the fixture 3 receives the power-on work button sent by the PLC circuit, the piston rod on the cylinder 305 connected to the L-shaped clamping plate 308 pushes the L-shaped clamping plate 308 to stretch out from the support frame 306. At this time, The support bearing A309 moves under the drive of the L-shaped clamping plate 308 until the position sensor on the support frame 306 sends the limit position of the L-shaped clamping plate 308 to the PLC circuit, and the PLC circuit sends a power-off stop signal to the cylinder 305 Signal, fix one end of the glass fiber cloth roll on the support bearing B307 by manual or mechanical arm, and the other end of the glass fiber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com