Automatic welding production line system for industrial filter

An automatic welding and filter technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of time-consuming, labor-intensive, low-efficiency, etc., and achieve less time-consuming, complete functions, and simplified welding process. the effect of the flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further introduced below in conjunction with the accompanying drawings and specific embodiments.

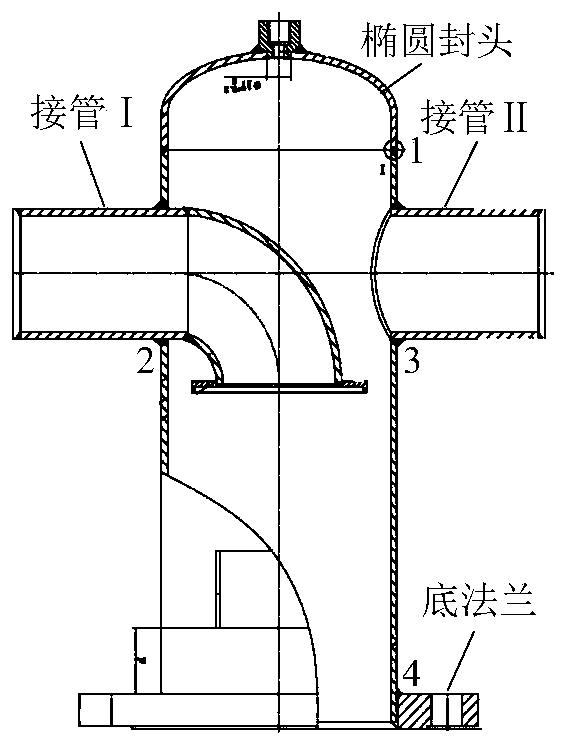

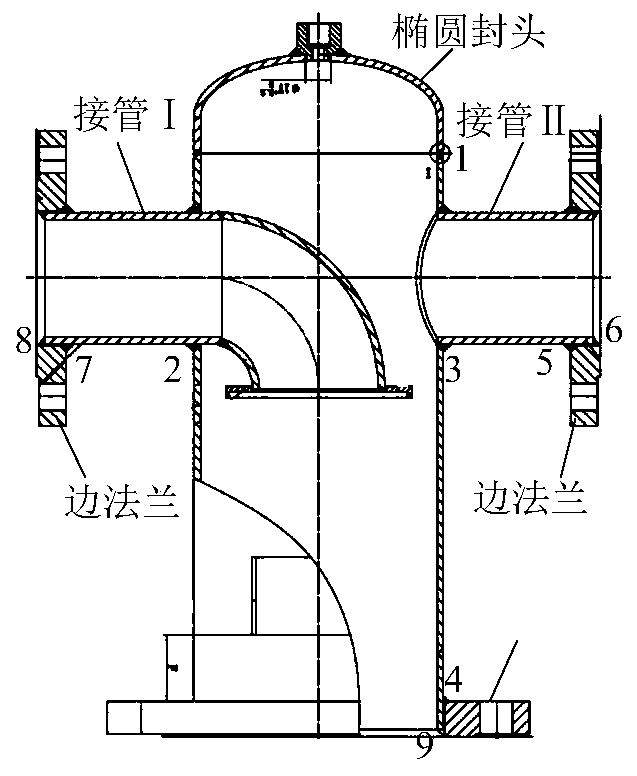

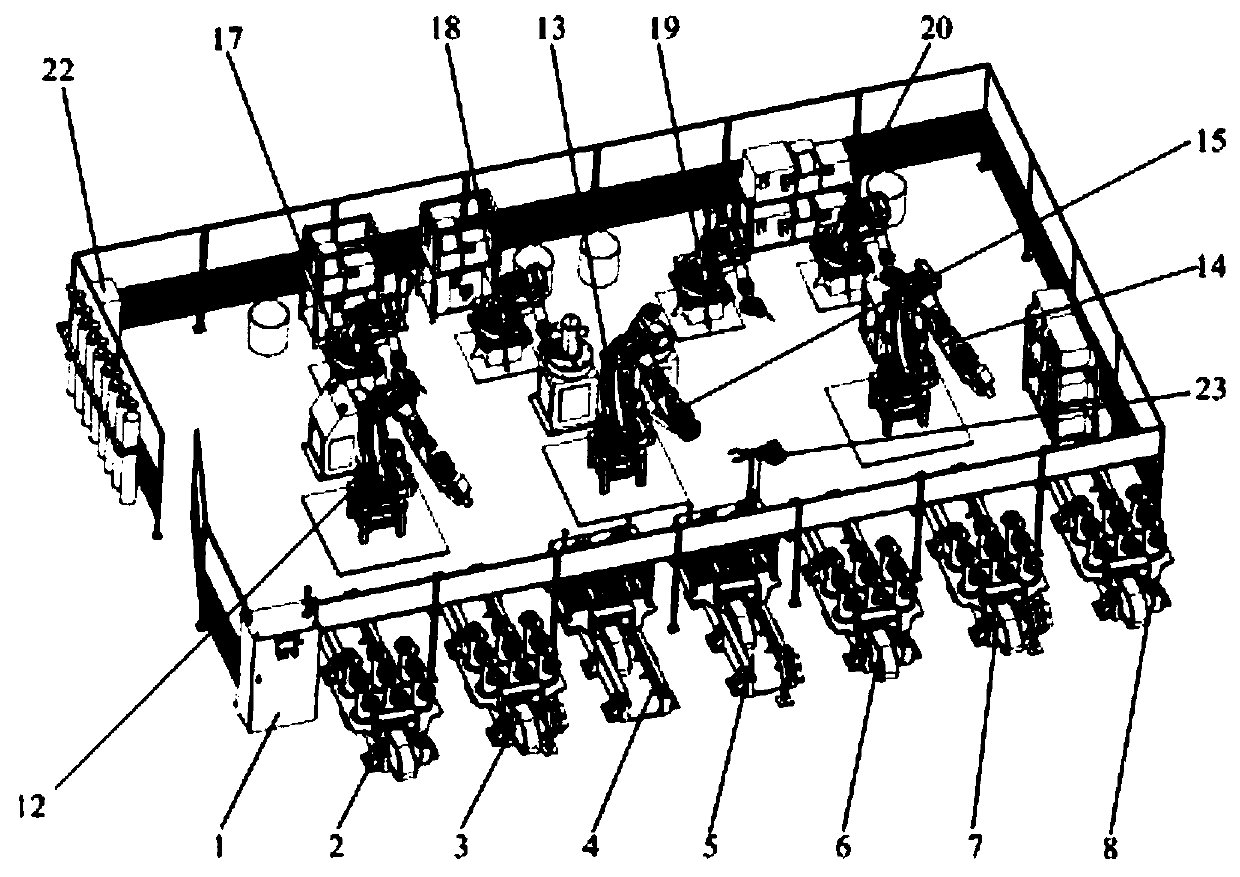

[0022] combine figure 1 It is the blank of the industrial filter to be processed, among which the welding seam between the oval head and the main body of the filter 1, the welding seam between the connecting pipe I and the main body of the filter 2, the welding seam between the connecting pipe II and the main body of the filter 3, the welding seam between the bottom flange and the main body of the filter 4 have been spot welded, and the bottom flange is provided with multiple mounting holes at equal intervals in a week; the welding process to be completed includes (1) full welding of weld 1, weld 2, and weld 3 to form the first semi-finished product ; (2) The full welding of the butt weld 4 constitutes the second semi-finished product; (3) The two side flanges are respectively spot-welded with the connecting pipe I and the connecting pipe II t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com