Full-automatic online labeling machine and labeling method

A labeling machine, fully automatic technology, applied in labeling machine, labeling, packaging and other directions, can solve the problems of different handwritten wire number fonts, inconsistent length of offline, inconsistent size of white tape, etc., to achieve easy operation, The effect of improving production efficiency and diversifying processing methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

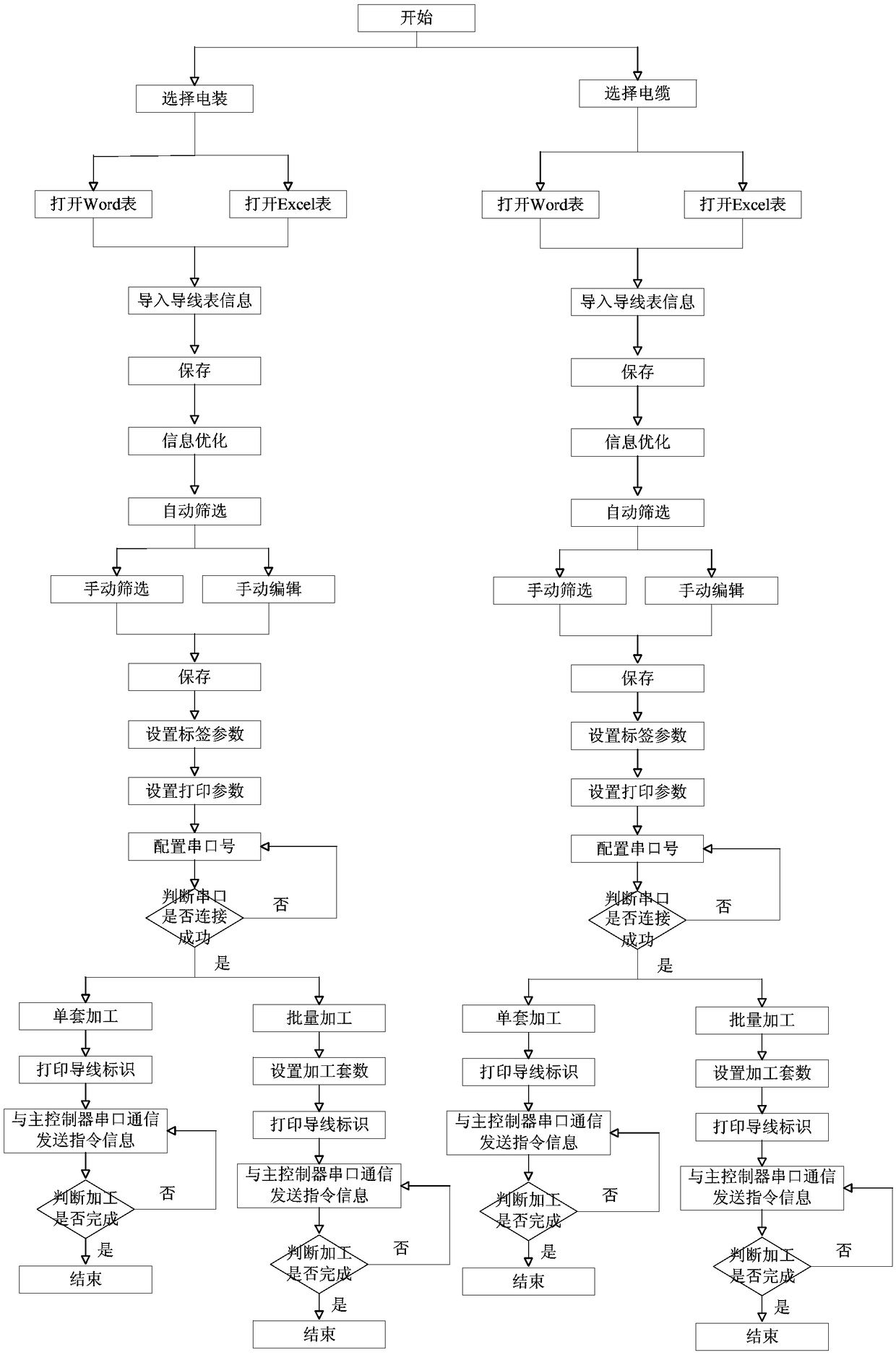

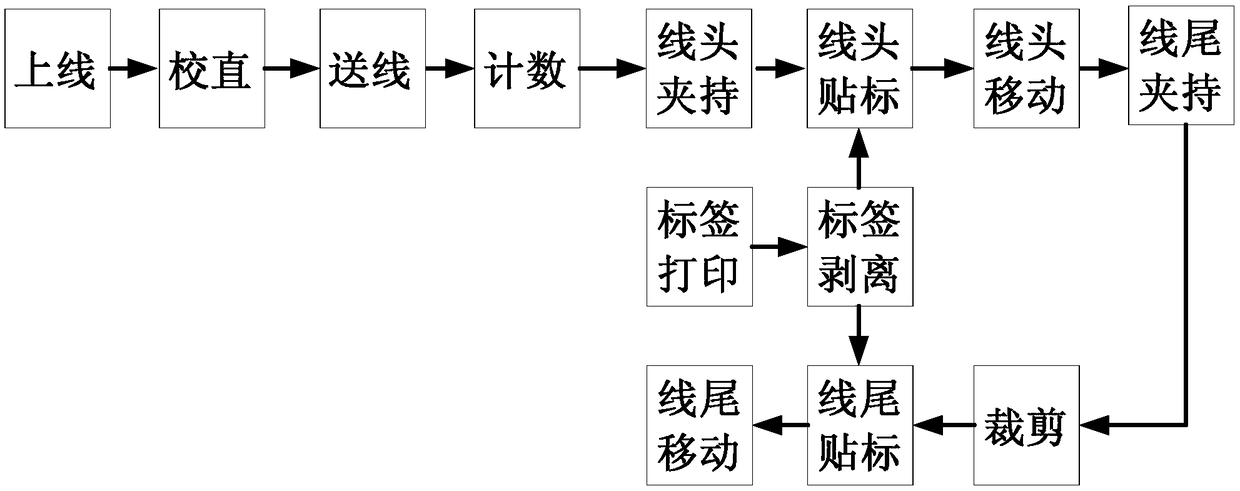

[0045] The invention is a fully automatic on-line labeling machine and labeling method. Aiming at the shortcomings of the current similar products, the invention has the characteristics of high automation, wide application range, high efficiency, small size, and adjustable parameters. It can realize printing , labeling, and online integration functions; import electrical equipment and cable types of wire lists, edit, filter and save Word and Excel two-format wire lists; high equipment reliability, with information prompts, abnormal alarms; streamlined Automated equipment processing flow improves production efficiency, and the equipment is easy to carry, easy to operate, and easy to maintain.

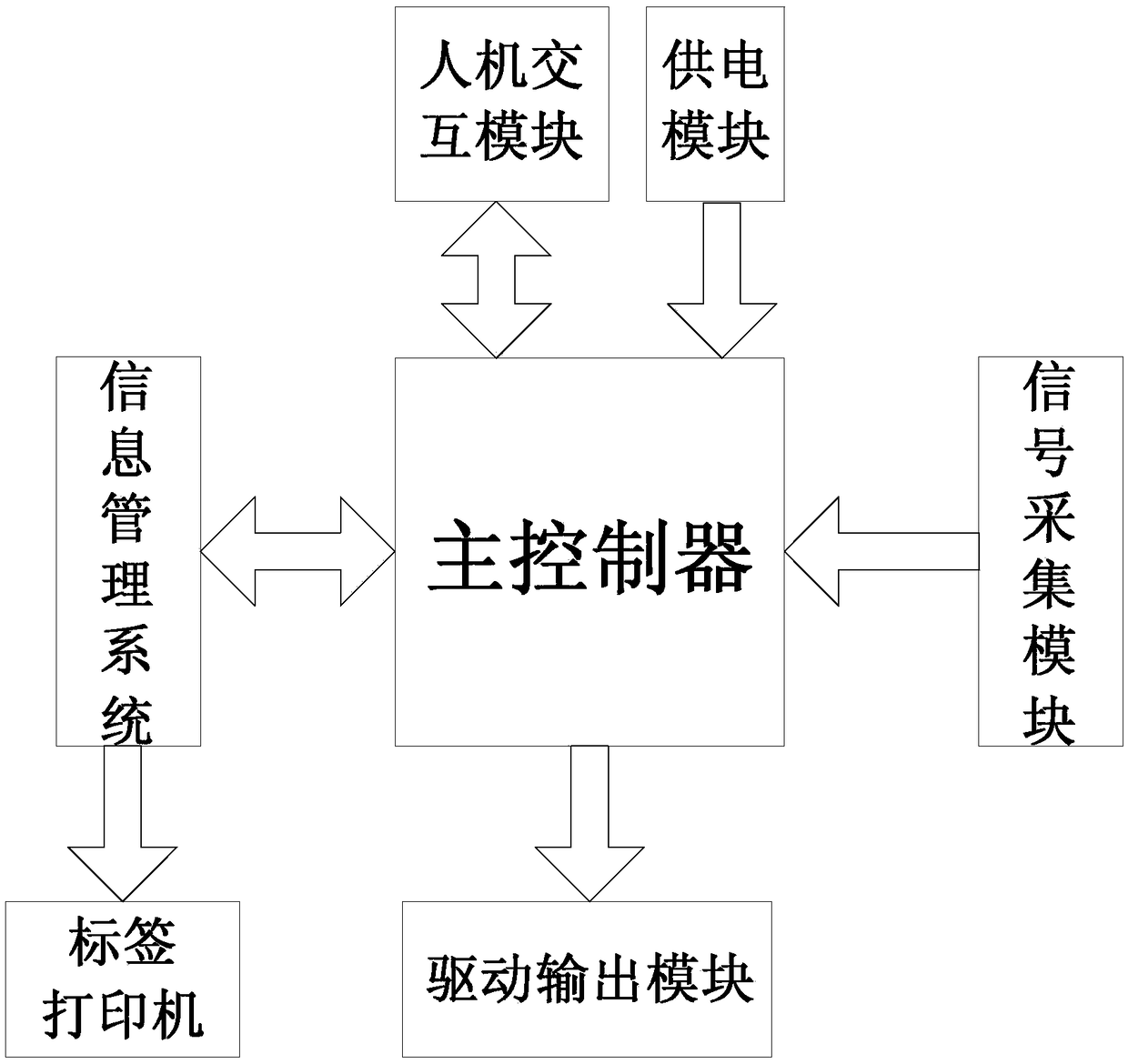

[0046] A fully automatic on-line labeling machine of the present invention, comprising: a main controller, an information management system, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com