Automatic feeding controller of milling system

A technology of automatic feeding and control devices, applied in grain processing, etc., can solve problems such as unqualified products, unfavorable grinding, uncontrollable and processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

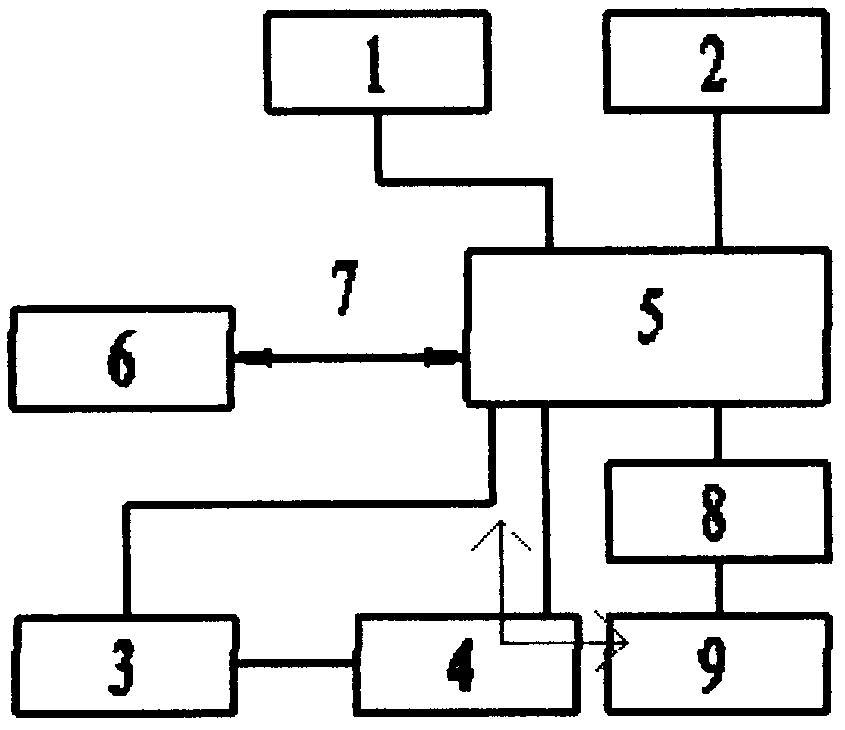

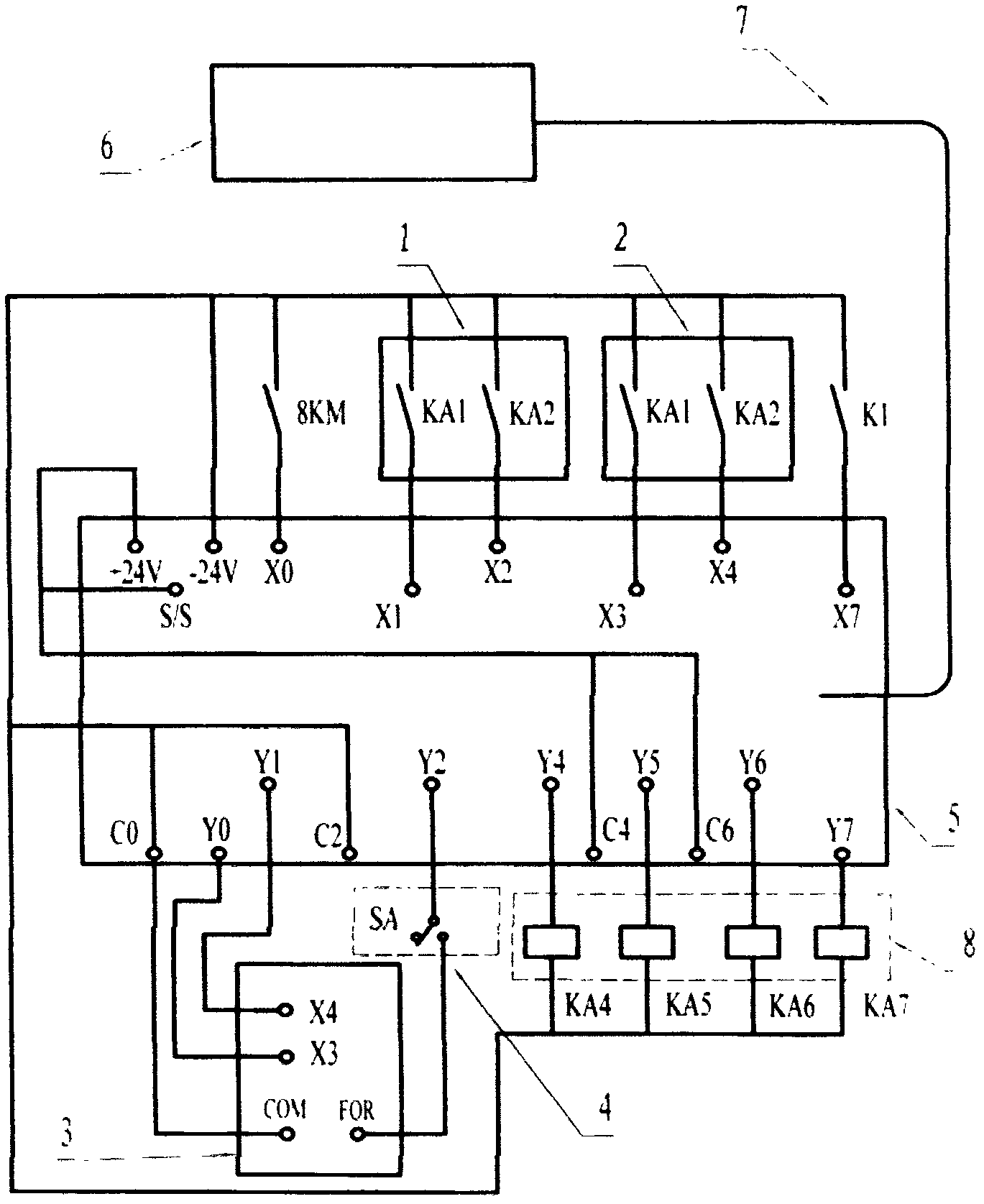

[0041] An automatic feeding control device for a powder milling system, including a programming controller PLC, a text display, a communication cable, an intelligent ammeter for a host machine, an intelligent ammeter for a fan, a feeding screw frequency converter, an extended relay, an alarm, and a manual control switch for the frequency converter. The whole device as figure 1 shown.

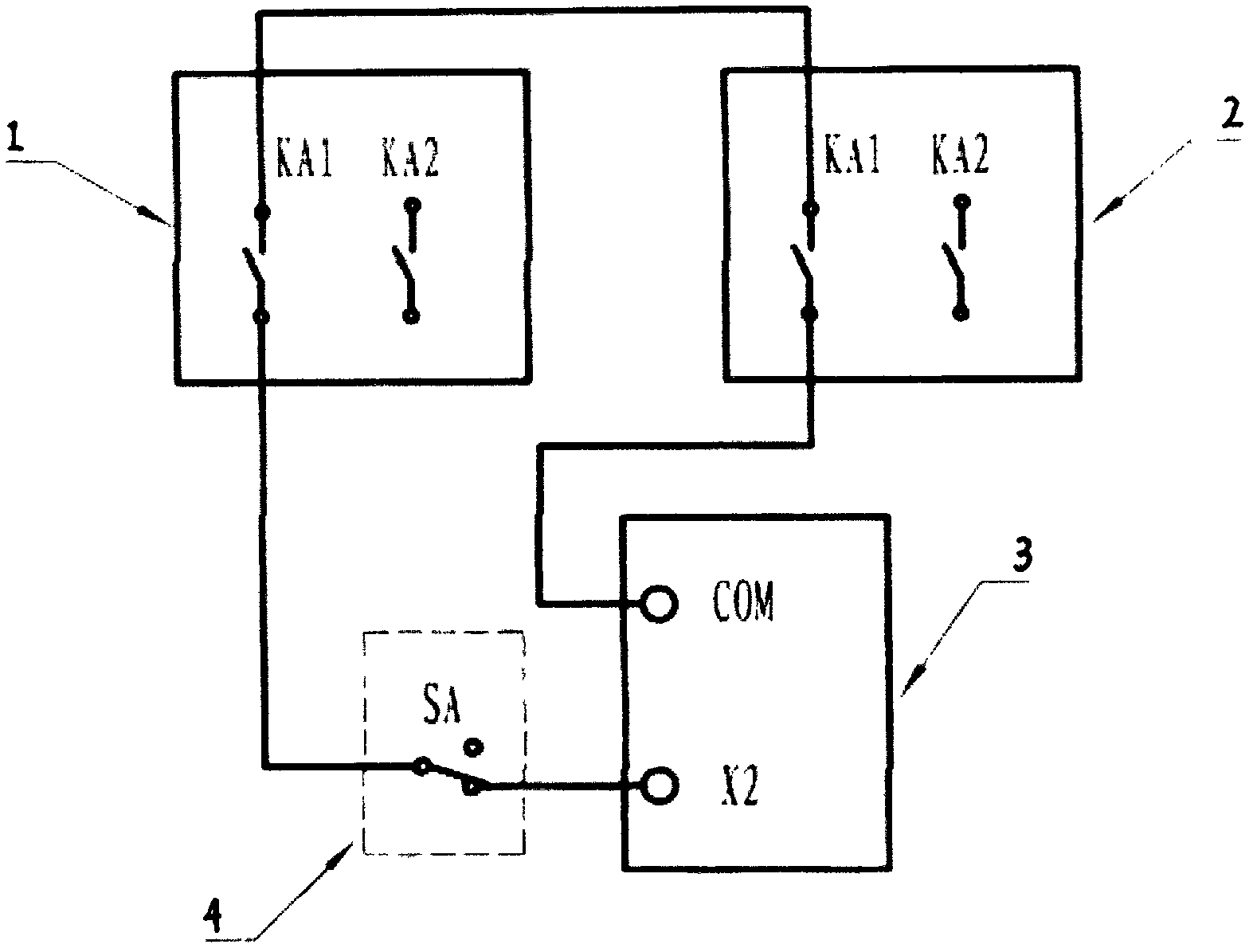

[0042] The manufacture method of the automatic feeding control device of the present invention is: programmable controller PLC is connected to text display with communication cable, host intelligent ammeter, blower fan intelligent ammeter are connected to the input terminal of programmable controller PLC; The relay is connected to the "frequency" control terminal of the feeding screw inverter, the output relay of the programmable controller PLC is connected to the "running" control terminal of the feeding screw inverter through the series inverter manual control switch, and the programmable con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com