Coal reservoir permeability increasing agent based on aqueous solution of sodium hypochlorite

A sodium hypochlorite solution and sodium hypochlorite technology, applied in the direction of drilling composition, production fluid, wellbore/well components, etc., can solve the problems of low power and difficult realization, reduce the probability of gas exceeding the limit, and increase the drainage radius , The effect of shortening the gas drainage time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

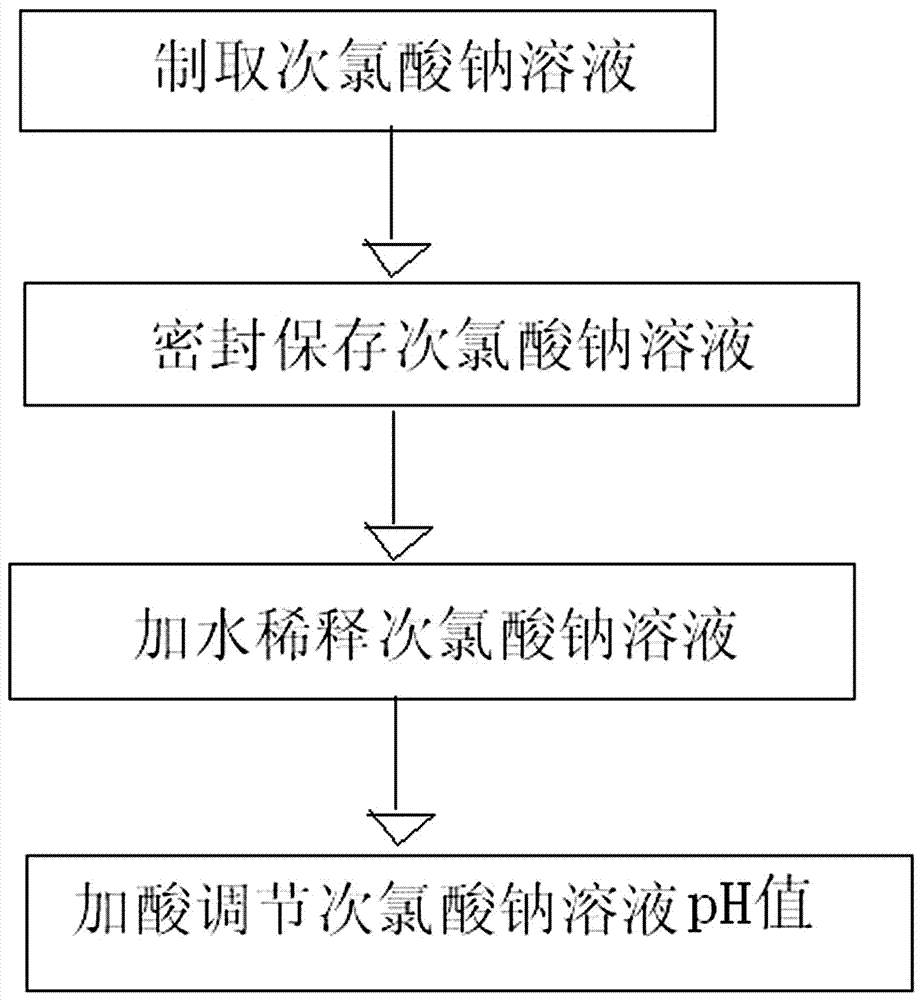

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1: a kind of coal reservoir antipermeability agent based on sodium hypochlorite aqueous solution, is made up of component A, component B and water, and wherein component A is sodium hypochlorite solid, and component B is pH regulator, and described pH regulator It is hydrochloric acid with a concentration of less than 10%; the mass ratio of sodium hypochlorite solid, pH regulator and water is: sodium hypochlorite solid: pH regulator: water=1:5:100; The effective chloride ion concentration is 1%, and the pH value is 13.

Embodiment 2

[0027] Embodiment 2: a kind of coal reservoir antipermeability agent based on sodium hypochlorite aqueous solution, is made up of component A, component B and water, and wherein component A is sodium hypochlorite solid, and component B is pH adjuster, and described pH adjuster It is sulfuric acid with a concentration of less than 10%; the mass ratio of sodium hypochlorite solid, pH regulator and water is: sodium hypochlorite solid: pH regulator: water=5:10:100; the coal reservoir anti-permeability agent based on sodium hypochlorite aqueous solution The effective chloride ion concentration is 3%, and the pH value is 10.

Embodiment 3

[0028] Embodiment 3: a kind of coal reservoir antipermeability agent based on sodium hypochlorite aqueous solution, is made up of component A, component B and water, and wherein component A is sodium hypochlorite solid, and component B is pH adjuster, and described pH adjuster It is hydrochloric acid with a concentration of less than 10%; the mass ratio of sodium hypochlorite solid, pH regulator and water is: sodium hypochlorite solid: pH regulator: water=7:1:100; The effective chloride ion concentration is 5%, and the pH value is 12.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Permeability | aaaaa | aaaaa |

| Permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com