Method for preparing CuCoO2 nanocrystal material based on MOFs material at low temperature

A nanocrystalline material, low temperature technology, applied in the field of synthesis and preparation of nanoscale delafossite structure CuCoO2 crystal material, can solve the problems of restricting the application research of optoelectronic devices, the activity of electrolyzed water needs to be improved, and the crystal material has not been found yet, so as to promote the application The effect of development, easy control of process parameters and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

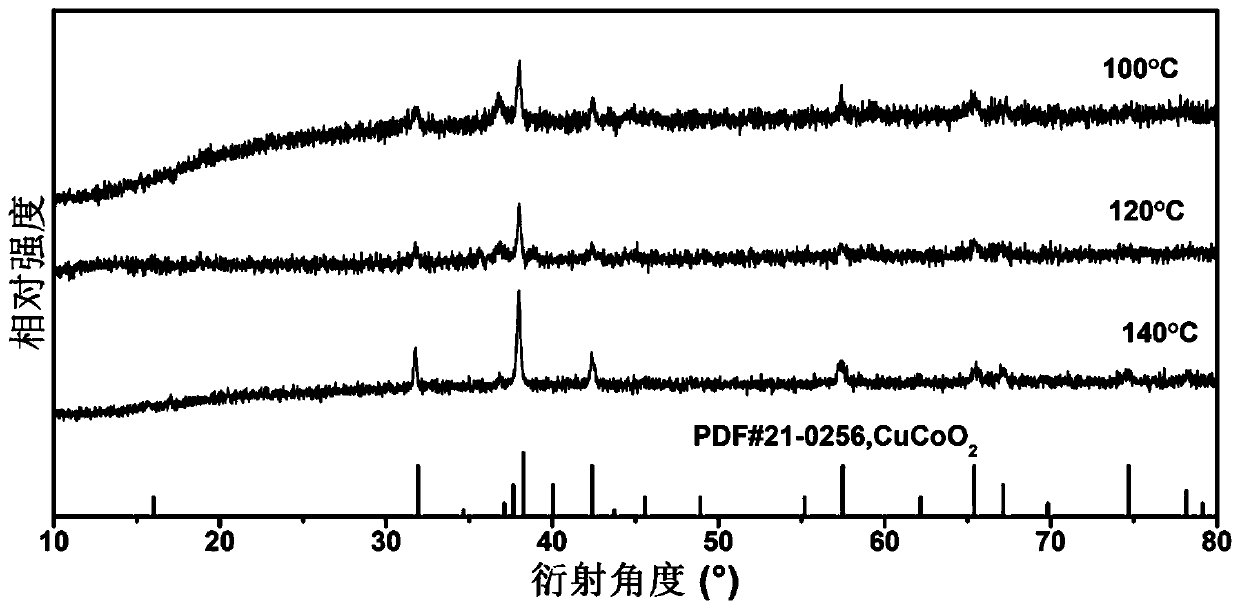

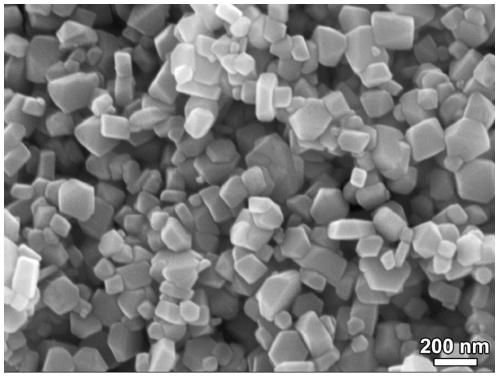

[0035] A low-temperature preparation of CuCoO with nanoscale delafossite structure 2 A method for crystal materials, comprising the steps of:

[0036] First prepare the reaction precursor (or hydrothermal reaction precursor): the Co MOFs crystal material (ZIF-67) and Cu(NO 3 ) 2 Add it into the reaction solution according to the mass ratio of 1:1 (the reaction solution is a mixed solution of deionized water and absolute ethanol, and the volume ratio of deionized water and absolute ethanol is 1:2.5), stir in a magnetic stirrer for 10 to 15 minutes to dissolve Finally, add NaOH 10 times the mass of ZIF-67 as a mineralizer, and continue stirring for 10 to 15 minutes until completely dissolved to obtain a reaction precursor.

[0037] Transfer the above reaction precursor to a hydrothermal reaction kettle (generally polytetrafluoroethylene), control the reaction solution (the reaction solution in the hydrothermal reaction kettle is a mixed solution of deionized water and absolute...

Embodiment 2

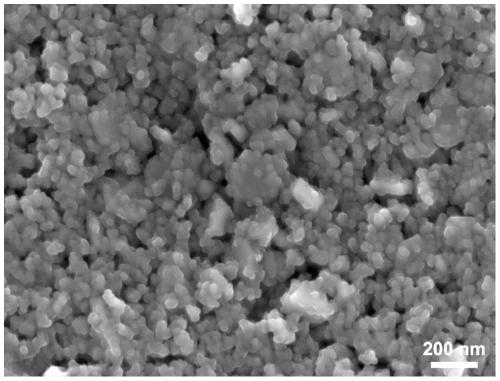

[0040] A low-temperature preparation of CuCoO with nanoscale delafossite structure 2 A method for crystal materials, comprising the steps of:

[0041] First prepare the reaction precursor (or hydrothermal reaction precursor): combine ZIF-67 and Cu(NO 3 ) 2 Add it into the reaction solution according to the mass ratio of 1:1.2 (the reaction solution is a mixed solution of deionized water and absolute ethanol, and the volume ratio of deionized water and absolute ethanol is 1:2.5), fully stir the solution with a magnetic stirrer for 10-15 After decomposing for 1 minute, add NaOH 50 times the mass of ZIF-67 as a mineralizer, and continue stirring for 10-15 minutes until completely dissolved to obtain a reaction precursor.

[0042] Transfer the above reaction precursor to a hydrothermal reaction kettle (generally polytetrafluoroethylene), control the reaction solution (the reaction solution in the hydrothermal reaction kettle is a mixed solution of deionized water and absolute et...

Embodiment 3

[0045] A low-temperature preparation of CuCoO with nanoscale delafossite structure 2 A method for crystal materials, comprising the steps of:

[0046] First prepare the reaction precursor (or hydrothermal reaction precursor): the Co-based MOF material ZIF-67 and Cu(NO 3 ) 2 Add it into the reaction solution according to the mass ratio of 1:1.2 (the reaction solution is a mixed solution of deionized water and absolute ethanol, and the volume ratio of deionized water and absolute ethanol is 1:2.5), and stir fully on a magnetic stirrer for 10 to 15 minutes After dissolving, add Cu(NO 3 ) 2 10 times the mass of NaOH is used as a mineralizer, and the stirring is continued for 10 to 15 minutes until it is completely dissolved to obtain a reaction precursor.

[0047] Transfer the above reaction precursor to a hydrothermal reaction kettle (generally polytetrafluoroethylene), control the reaction solution (the reaction solution in the hydrothermal reaction kettle is a mixed solutio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com