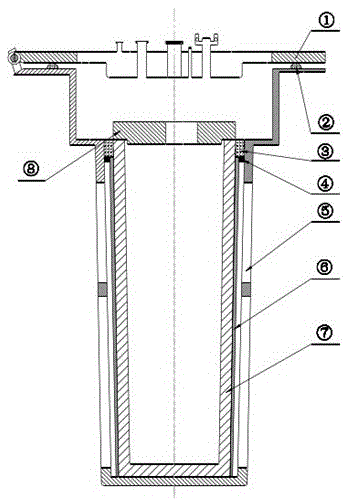

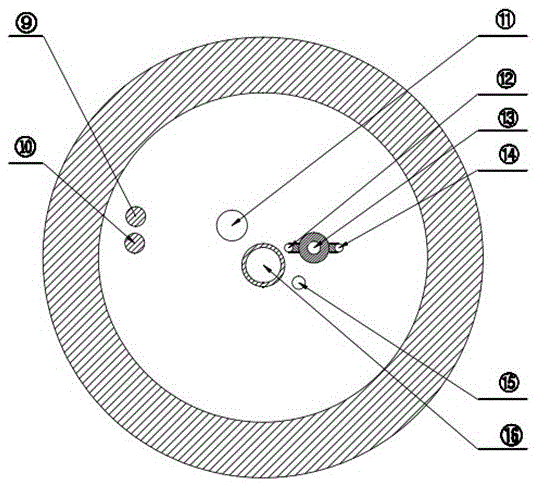

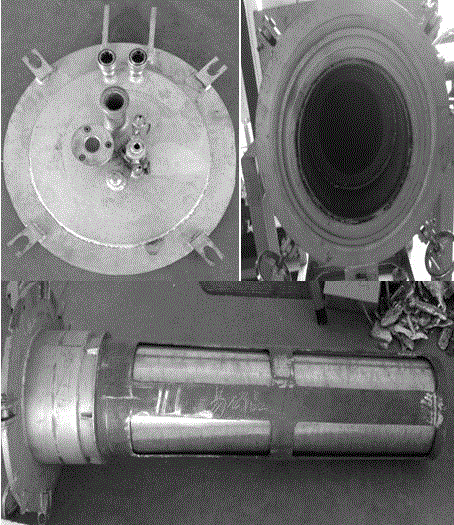

A furnace device and method for preparing ultra-high-purity aluminum

A furnace liner and pure aluminum technology, applied in the field of metal purification, can solve the problems of the internal structure of the purification furnace without specifying the sealing method of the purification furnace, affecting the purification effect of high-purity aluminum, and high power of vacuum equipment, so as to reduce the temperature and prevent oxidation. , the effect of small furnace space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1: select the refined aluminum that purity is 4N3,

[0025] (1) Loading requirements: In the crucible, the aluminum material should be packed densely from the bottom up, and the aluminum material must not be stuck in the graphite crucible so that the aluminum material cannot reach the bottom of the crucible.

[0026] (2) Cover the graphite cover, install a rubber sealing strip on the surface of the side wall sealing ring sleeve, and then cover the furnace cover to ensure the tightness inside the furnace cover.

[0027] (3) Close the exhaust valve and argon inlet valve, and open the vacuum pump valve.

[0028] (4) Turn on the vacuum pump, and after 10 minutes, make the pressure measurement display 0.0015Mpa.

[0029] (5) Open the argon inlet valve, close the vacuum pump valve, and turn on the argon inlet switch until the pressure indication is 0.1Mpa.

[0030] (6) Close the argon inlet valve, and then start heating the molten aluminum.

[0031] (7) After th...

Embodiment 2

[0033]Embodiment 2: select the refined aluminum that purity is 4N6,

[0034] (1) Loading requirements: In the crucible, the aluminum material should be packed densely from the bottom up, and the aluminum material must not be stuck in the graphite crucible so that the aluminum material cannot reach the bottom of the crucible.

[0035] (2) Cover the graphite cover, install a rubber sealing strip on the surface of the side wall sealing ring sleeve, and then cover the furnace cover to ensure the tightness inside the furnace cover.

[0036] (3) Close the exhaust valve and argon inlet valve, and open the vacuum pump valve.

[0037] (4) Turn on the vacuum pump, and after 12 minutes, make the pressure measurement display 0.001Mpa.

[0038] (5) Open the argon inlet valve, close the vacuum pump valve, and turn on the argon inlet switch until the air pressure indication is 0.15Mpa.

[0039] (6) Close the argon inlet valve, and then start heating the molten aluminum.

[0040] (7) After...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com