High-efficiency electrolytic water catalyst HRu4O8 microrod and preparation method thereof

A technology of micro-rods and water electrolysis, which is applied in chemical instruments and methods, water/sewage treatment equipment, water/sludge/sewage treatment, etc. The effect of excellent catalytic activity, excellent stability and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

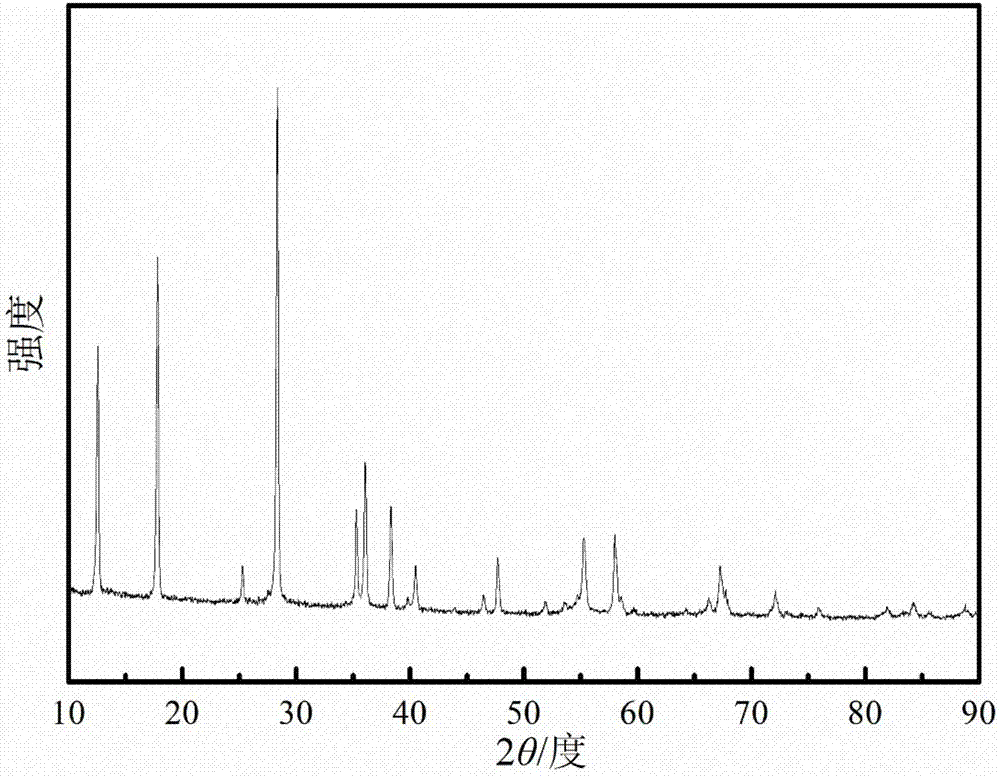

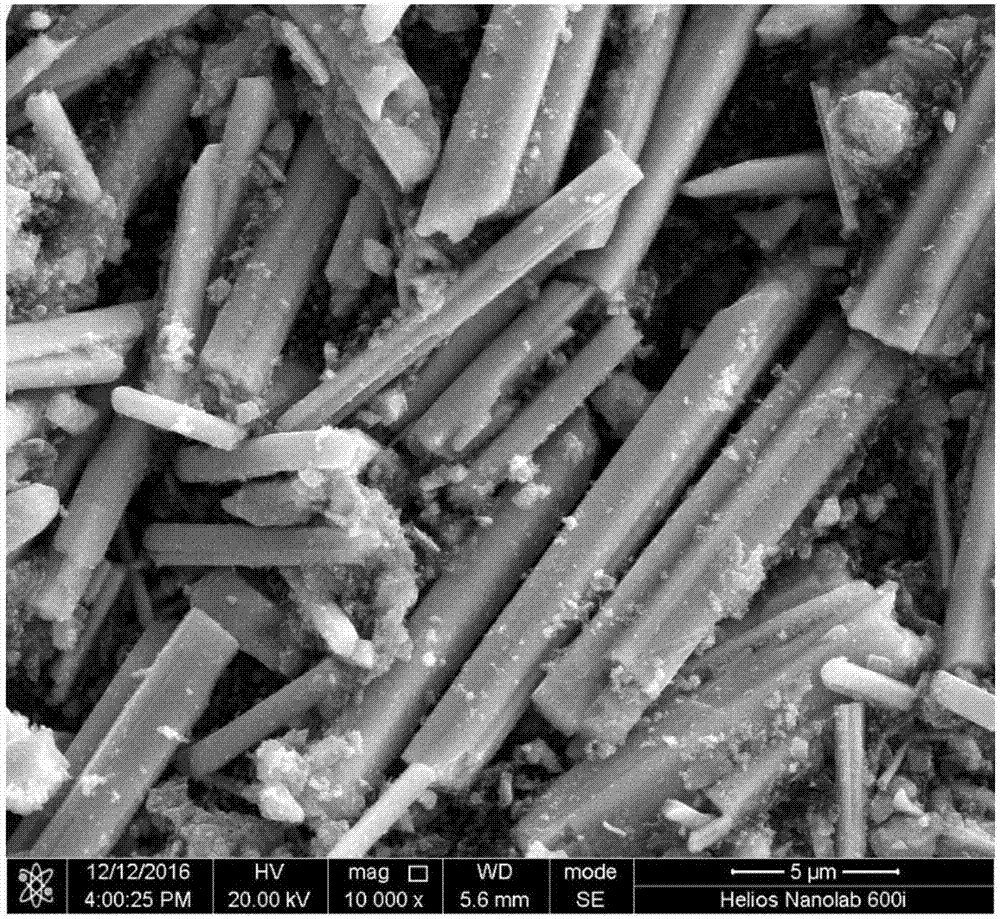

[0019] Specific implementation mode 1: In this implementation mode, a high-efficiency electrolytic water catalyst HRu 4 o 8 The atomic ratio of H:Ru:O in the microrods is 1:4:8, HRu 4 o 8 The diameter of the microrod is 1-10 μm, and the length is 5-100 μm.

[0020] The beneficial effect of this implementation mode:

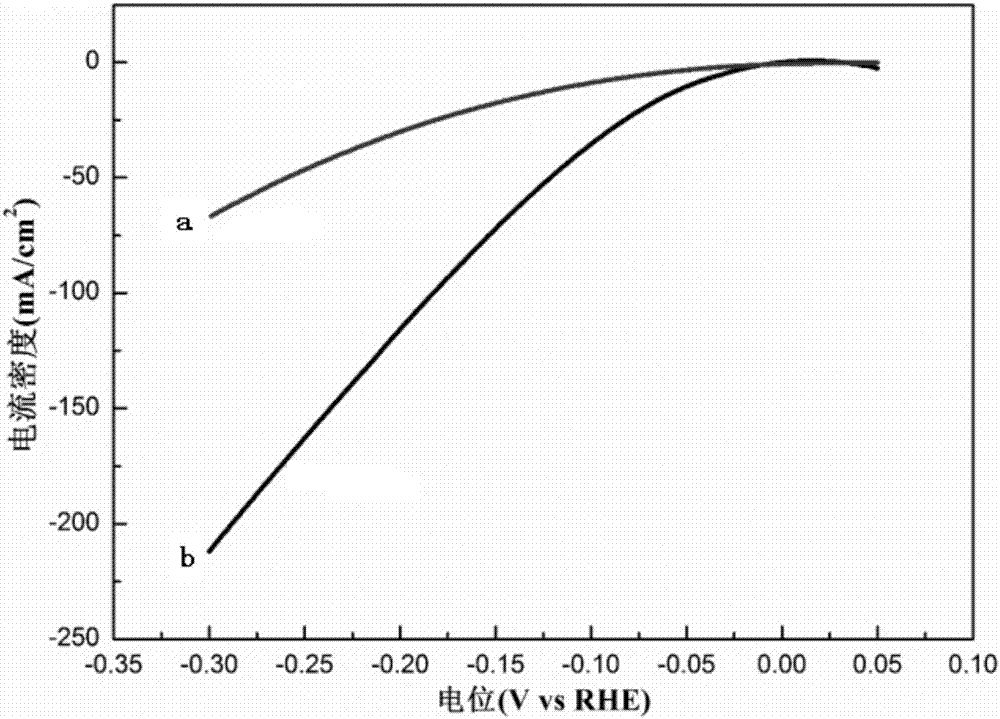

[0021] 1. The HRu of this embodiment 4 o 8 Microrods are applied to HER and OER, and have excellent performance. A dual-functional electrocatalyst with excellent catalytic activity for HER and OER in alkaline electrolyte system is obtained, which can electrolyze water efficiently;

[0022] 2. The HRu of this embodiment 4 o 8 HER at 10mA / cm for microrods, commercial Pt / C in 1M KOH 2 The overpotentials are 50mV and 108mV (without IR correction), respectively, and the performance is much better than that of commercial Pt / C. HRu 4 o 8 Microrods, Commercial RuO 2 OER in 1M KOH at 10mA / cm 2 The overpotential at low temperature is only 300mV, 323mV (both wit...

specific Embodiment approach 2

[0024] Specific implementation mode 2: In this implementation mode, a high-efficiency electrolytic water catalyst HRu 4 o 8 The preparation method of microrod is carried out according to the following steps:

[0025] 1. RuO 2Preparation of nanoparticles: dissolving the ruthenium precursor and nitrate in water with a molar ratio of 1:(1-20), stirring until evenly mixed to obtain a mixed solution, the concentration of the ruthenium precursor in the mixed solution is 1-100g / L, dry the mixed solution to obtain a solid, then put the solid into a container, then keep it in an inert atmosphere at 200-400°C for 0.5-10h, then keep it at 400-700°C for 1-10h, take it out after cooling down , washed 3 to 10 times, and dried to obtain RuO 2 Nanoparticles;

[0026] 2. Preparation of ruthenate microrods: the RuO 2 Nanoparticles and carbonate or bicarbonate are mixed in a molar ratio (0.5-10):1, then put into a container, and then kept in an inert atmosphere at 300-1200°C for 2-30 hours...

specific Embodiment approach 3

[0028] Specific embodiment three: the difference between this embodiment and specific embodiment two is that the ruthenium precursor in step one is RuCl 3 ·nH 2 O, Ru(acac) 3 、Ru 2 (CO) 6 Cl 4 、K 2 RuCl 5 ·nH 2 One or more of O and tris(2,2-bipyridyl)ruthenium chloride hexahydrate are mixed in any ratio. Others are the same as in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com