Electrochemical sewage treatment apparatus and electrode cleaning mechanism thereof

A sewage treatment device, electrochemical technology, applied in water/sewage treatment, water/sewage treatment equipment, water/sludge/sewage treatment, etc., can solve problems affecting the effect of sewage electrolysis treatment, etc., to achieve easy cleaning, high efficiency and fast speed The effect of electrolysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

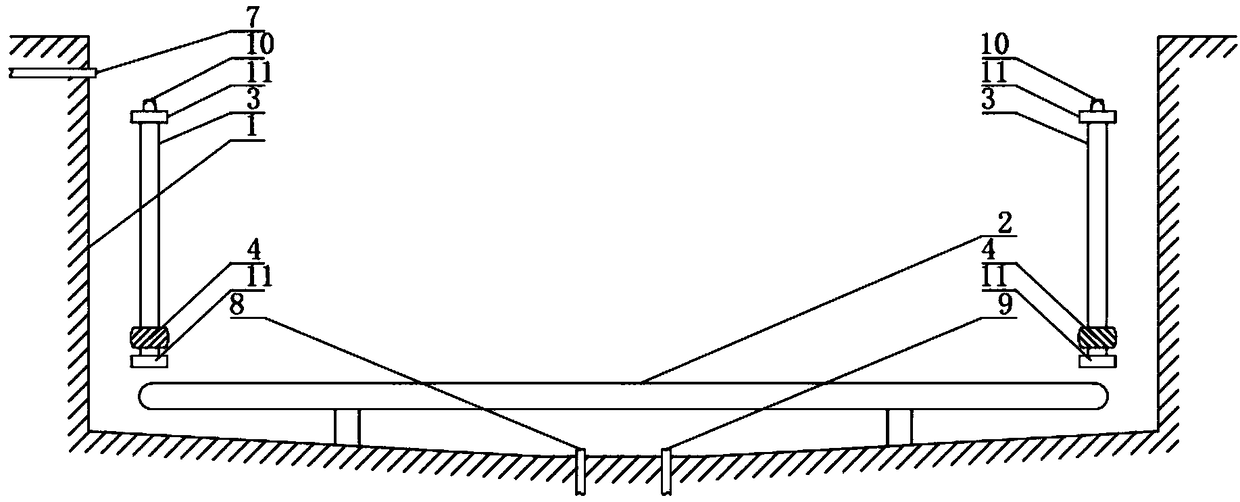

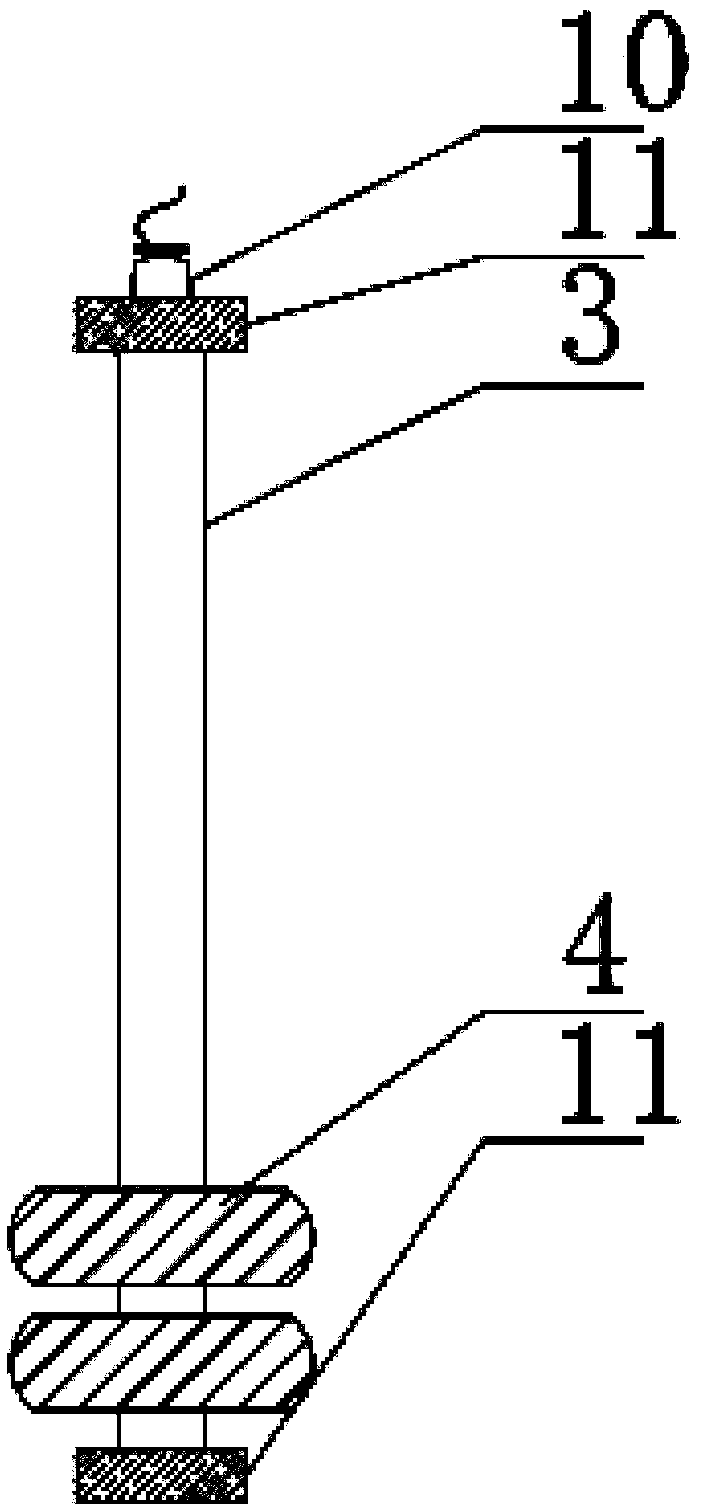

[0021] see Figure 1-4 , an electrochemical sewage treatment device and an electrode cleaning mechanism thereof, comprising a treatment tank 1, an aeration device 2, an electrode plate 3, and decontamination beads 4, characterized in that: the bottom of the treatment tank 1 is evenly equipped with an aeration device 2, and the treatment Electrode plates 3 are installed on opposite sides of the pool 1 and the lowest end of the electrode plates 3 is higher than the installation position of the aeration device 2. The electrodes of the electrode plates 3 on both sides of the treatment pool 1 are opposite, and the electrode plates 3 installed on both sides of the treatment pool 1 The number is the same and arranged opposite to each other. When multiple sets of electrode plates 3 are installed on both sides of the treatment pool 1, the multiple sets of electrode plates 3 are vertically arranged parallel to each other and the distances between adjacent two sets of electrode plates 3 a...

Embodiment 2

[0024] see figure 1 , figure 2 , the working principle of the present invention is: when in use, when the same number of electrode plates 3 are installed on both sides of the treatment pool 1 and the decontamination beads 4 are installed on the electrode plates 3, the sewage is discharged into the sewage pool through the water inlet pipeline 7, Connect each electrode plate 3 to the power supply and power it on, and at the same time turn on the aeration device 2 to aerate the sewage while performing electrolytic treatment on the sewage. The air bubbles generated during the aeration process can drive the decontamination beads 4 upward along the electrode plate 3 Move to clean up the remaining dirt on the electrode plate 3, when the aeration device 2 stops working, the bubbles stop to be generated, and the decontamination beads 4 move down along the electrode plate 3 under the action of gravity to further clean up the dirt.

[0025] Multiple groups or a group of decontamination...

Embodiment 3

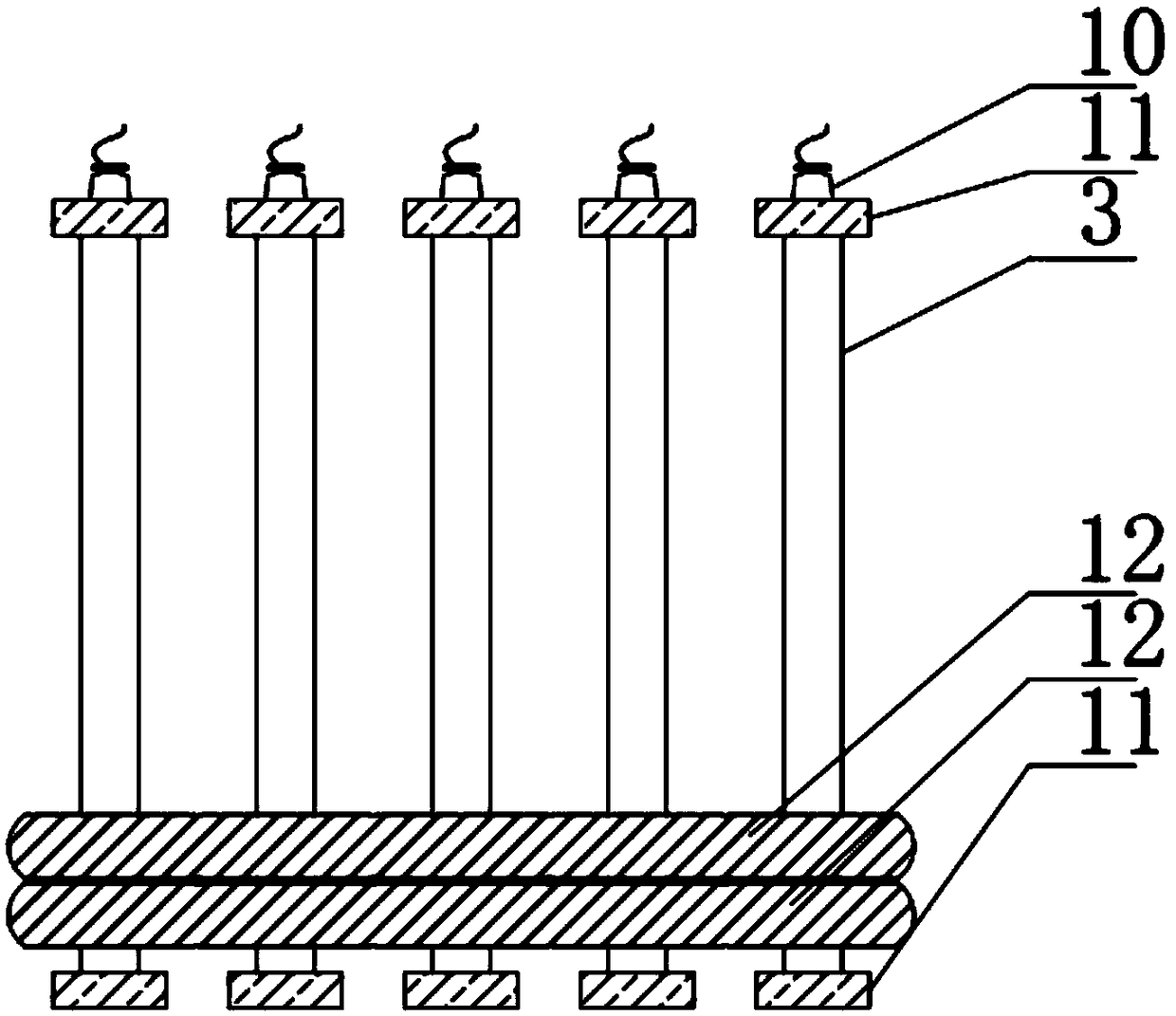

[0027] see figure 1 , image 3 When the same number of electrode plates 3 are installed on both sides of the treatment pool 1 and the decontamination beads 4 installed on each group of electrode plates 3 on one side are made as a complete whole to form the decontamination plate 12, the water inlet pipeline 7 will Sewage is discharged into the sewage tank, and each electrode plate 3 is connected to the power supply to energize the sewage. At the same time, the aeration device 2 is turned on to aerate the sewage, and the air bubbles generated during the aeration process can drive the decontamination plate. 12 moves upward along the electrode plate 3 to clean up the remaining dirt on the electrode plate 3. When the aeration device 2 stops working, the bubbles stop to be generated, and the decontamination plate 12 moves down along the electrode plate 3 under the action of gravity to remove the dirt. Clean up further.

[0028] Multi-layer or one-layer decontamination plate 12 can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com