Method for gradient separation of titanium copper and titanium silicon from titaniferous slag through liquid copper cathode electrolysis

A technology for cathodic electrolysis and titanium slag, which is applied in the field of liquid copper cathode electrolysis of titanium-containing slag to separate titanium copper and titanium silicon by steps, can solve the problems of energy consumption, high cost, low titanium content, poor electronic conductivity, etc. The effect of electrolysis process safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

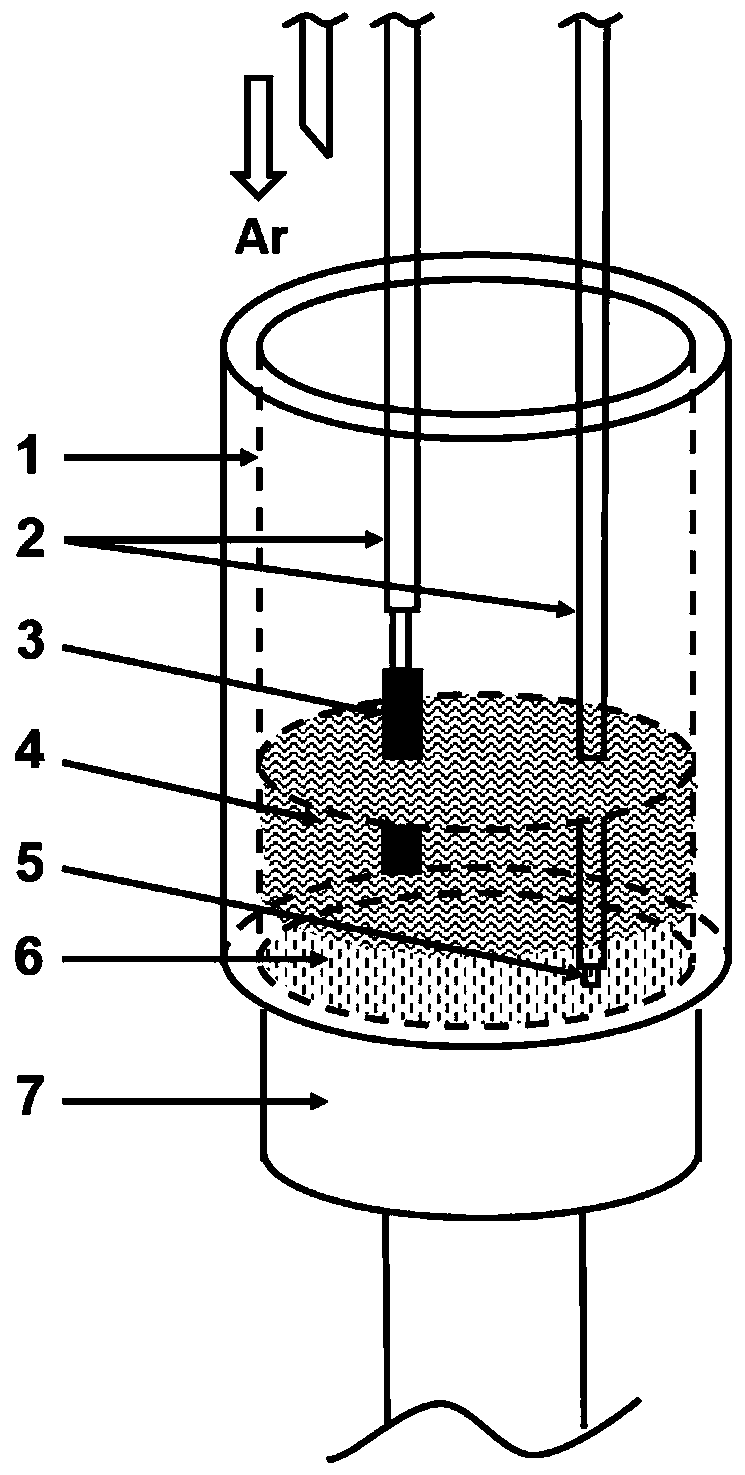

[0025] Step 1: Select a silicon nitride crucible for electrolysis, place copper powder with a purity of 99.9% at the bottom of the crucible, and use it as a cathode; place titanium-containing slag (26.46wt% CaO, 15.35wt% Al 2 o 3 , 9.40wt% MgO, 26.76wt% SiO 2 and 22.03 wt% TiO 2 ), use it as the electrolyte, choose graphite as the anode, and connect it with the conductive rod. A tungsten rod with a diameter of 4mm and a length of 1000mm is selected as the conductive rod, and is wrapped with a silicon nitride protective sleeve.

[0026] Step 2: Place the silicon nitride crucible with copper powder cathode and titanium slag in the high temperature furnace, and install the anode and conductive rod. Pass high-purity argon for protection, and raise the furnace temperature to 1500°C. When the furnace temperature reaches 1500°C, keep it warm for 2 hours, lower the cathode conductive rod to 0.2 cm from the bottom of the crucible, and lower the graphite anode to immerse in the oxid...

Embodiment 2

[0029] Step 1: Select a zirconia crucible for electrolysis, place a copper block with a purity of 99% at the bottom of the crucible, and use it as a cathode; place a titanium-containing slag (38.09wt% CaO, 25.55wt% Al 2 o 3 , 15.69wt% MgO, 8.00wt% SiO 2 and 12.67wt% TiO 2 ), use it as the electrolyte, choose Cr-Fe alloy as the anode, and connect it with the conductive rod. A tungsten rod with a diameter of 3 mm and a length of 1100 mm is selected as the conductive rod, and is wrapped with a silicon nitride protective sleeve.

[0030] Step 2: Place the zirconia crucible with copper block cathode and titanium slag in the high temperature furnace, and install the anode and conductive rod. Common argon is used for protection, and the furnace temperature is raised to 1550°C. When the furnace temperature reaches 1550°C, keep it warm for 1 hour, lower the cathode conductive rod to a distance of 0.1 cm from the bottom of the crucible, and lower the graphite anode to immerse in the...

Embodiment 3

[0033] Step 1: Select a zirconia crucible for electrolysis, place copper powder with a purity of 99.9% at the bottom of the crucible as the cathode; place titanium-containing slag (17.23wt% CaO, 23.68wt% Al 2 o 3 , 4.70wt% MgO, 10.38wt% SiO 2 ,14.01wt% TiO 2 and 30.00wt% CaF 2 ), use it as the electrolyte, choose Cr-Fe alloy as the anode, and connect it with the conductive rod. A molybdenum rod with a diameter of 3mm and a length of 1000mm is selected as the conductive rod and wrapped with a zirconia protective sleeve.

[0034]Step 2: Place the zirconia crucible with copper powder cathode and titanium-containing slag in the high-temperature furnace, and install the anode and conductive rod. Pass high-purity argon for protection, and raise the furnace temperature to 1400°C. When the furnace temperature reaches 1400°C, keep it warm for 2 hours, lower the cathode conductive rod to a distance of 0.2 cm from the bottom of the crucible, and lower the graphite anode to immerse i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com