Electrolysis device and method for efficiently extracting slag inclusion in steel

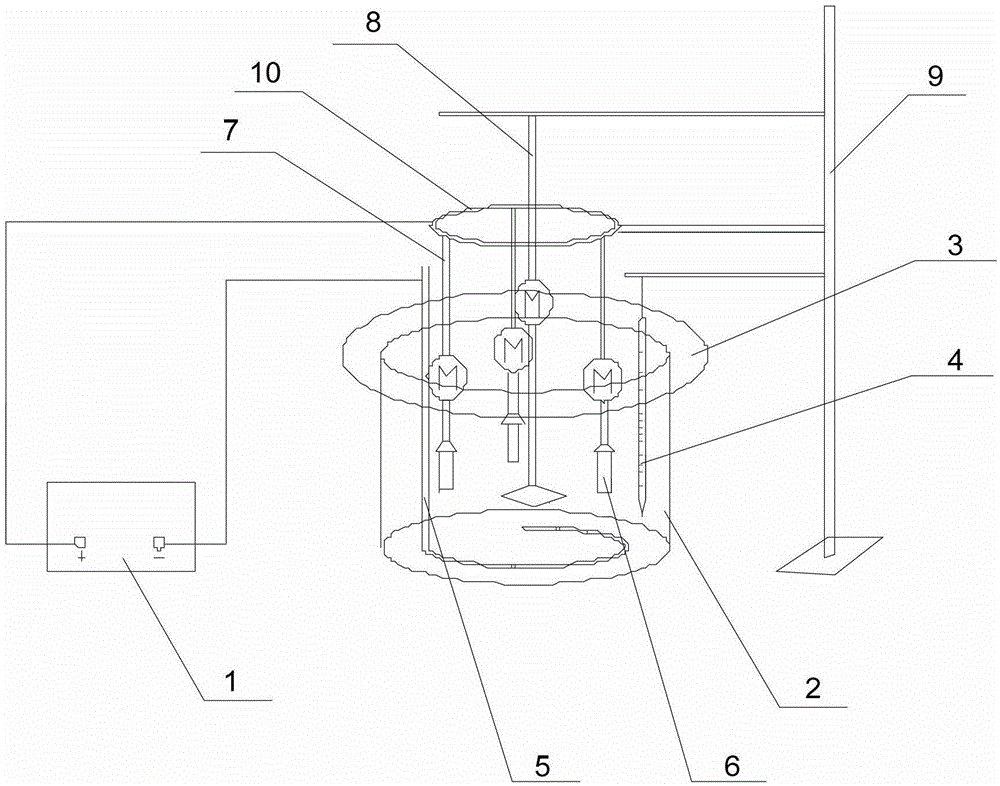

An electrolysis device and a technology for inclusions, applied in the field of metallurgical engineering, can solve the problems of inability to meet production needs, the solution cannot meet the requirements, and the electrolysis time is long, and achieve the effects of improving electrolysis efficiency, increasing stirring effect, and accelerating electrolysis.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0049] In this embodiment, three groups of comparative experiments are set up by controlling the number of anodes.

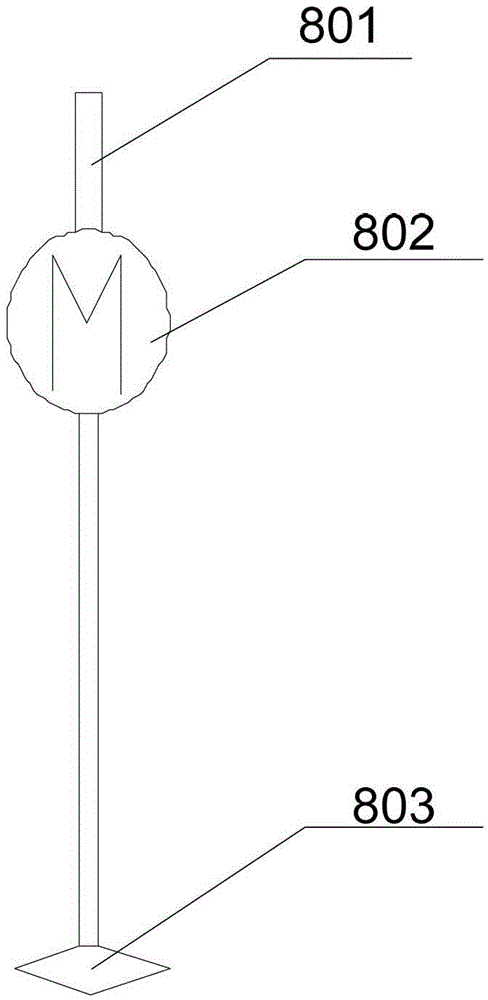

[0050] In the test, the power supply voltage of the three groups of experiments was controlled to be 5V, the steel samples were not rotated, the central stirring was 4s / rotation, the temperature was controlled at about 0°C, and the electrolysis time was 12 hours. The only variable in the three sets of experiments was the number of anodes. The number of anodes is 1, 2 and 3 respectively and numbered 1, 2 and 3 respectively.

[0051] The following are the experimental results:

[0052]

[0053] It can be seen from the experimental results in the above table that the present invention can not only extract the inclusions in the steel sample, observe its complete three-dimensional structure and composition, but also greatly improve the electrolysis efficiency by adopting the method of parallel connection of anodes.

example 2

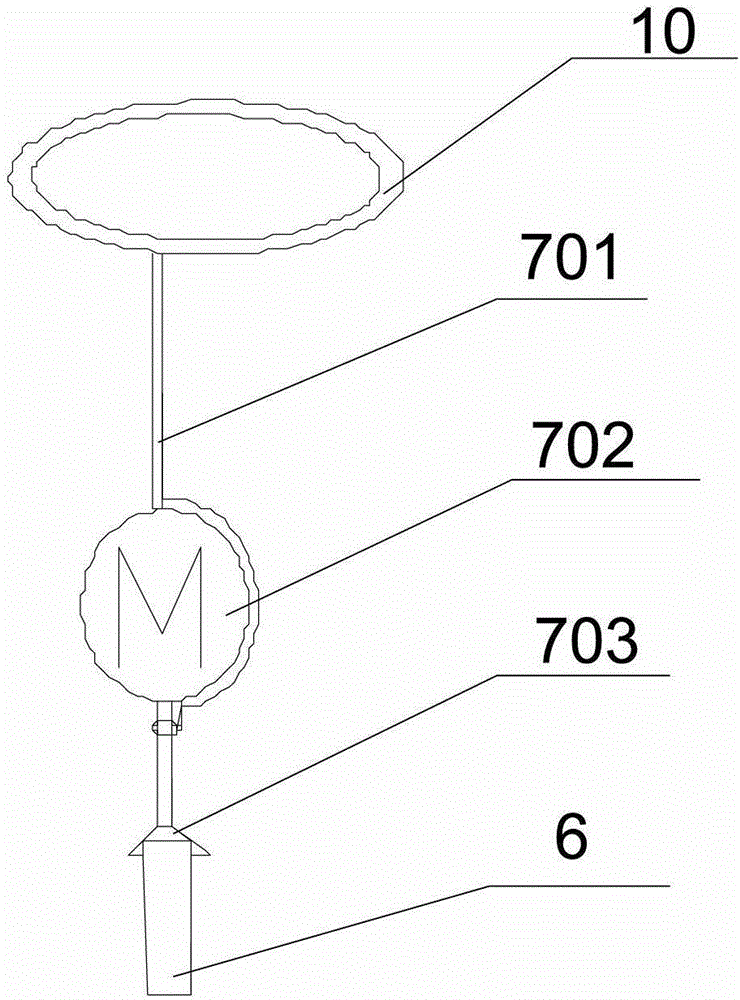

[0055] In this embodiment, three groups of experiments are set up by controlling the relationship between the anode rotation and the center rotation.

[0056] In the test, the power supply voltage of the three groups of experiments was controlled to be 5V, three anodes were connected in parallel, the central stirring was 4s / revolution, the temperature was controlled at about 0°C, and the electrolysis time was 12 hours. The only variable for the three sets of experiments was the anode rotation versus center rotation. They are normal center agitation without anode rotation, same direction anode rotation and center agitation, reverse anode rotation and center agitation, and are numbered 4, 5, and 6 in sequence.

[0057] If the rotation speed of the anode is 6s / revolution. The following are the experimental results:

[0058]

[0059] It can be seen from the experimental results in the above table that the present invention can not only extract the inclusions in the steel samp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com