Electrolytic machining tool enabling flow field period fluctuation and method

A technology for machining tools and flow fields, applied in the field of electrolytic machining tools, can solve problems such as complex equipment, and achieve the effects of improving the quality of the machined surface, improving the stability and uniformity, and improving the stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with accompanying drawing:

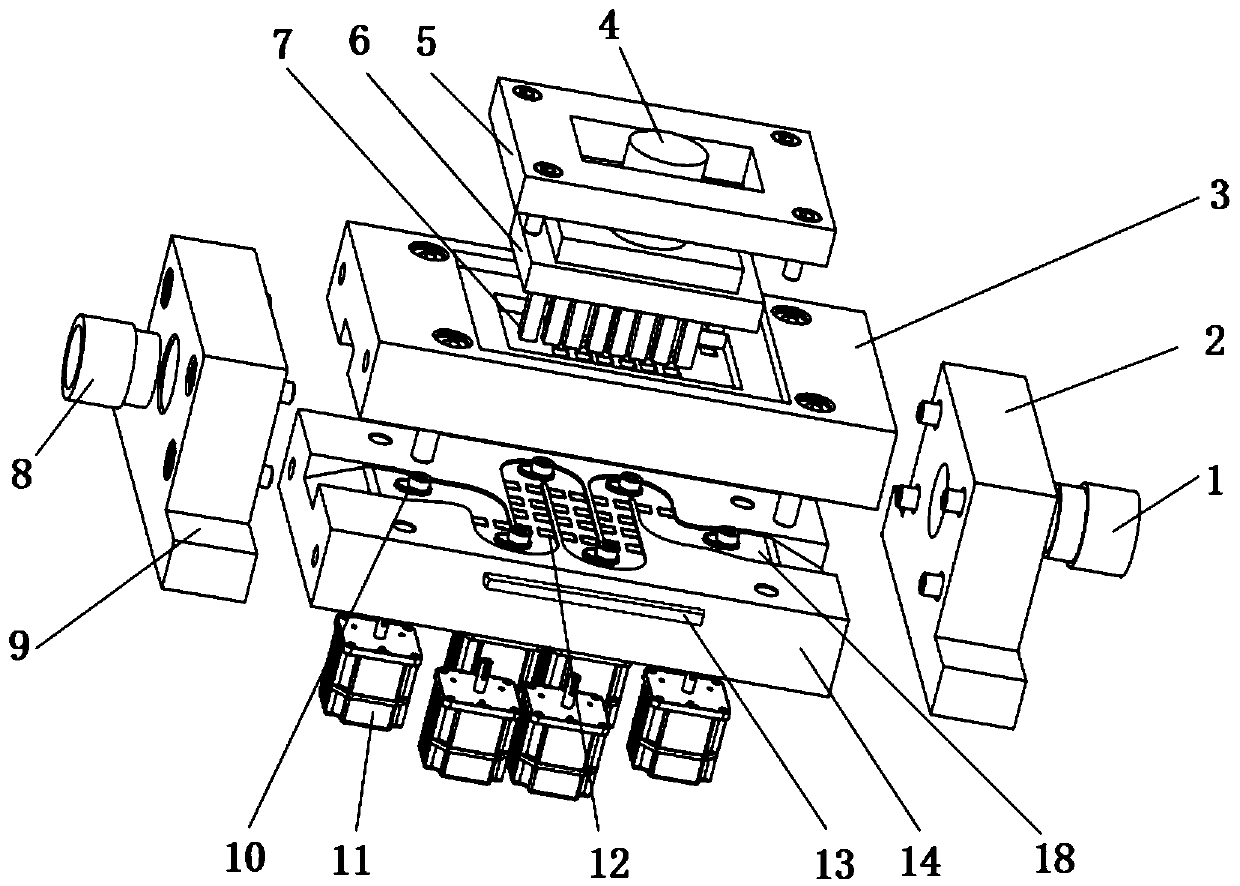

[0030] The present invention proposes an electrolytic machining tool and method in which the rotation of the barbed cam promotes the periodic fluctuation of the flow field, such as figure 1 As shown, the anode workpiece 14 and the cathode block 7 are placed in the clamp body, the electrolyte flows in from the liquid inlet pipe 8, passes through the continuously narrowed inner flow channel, flows through the barbed cam 10 and the processing area 12, and flows from the liquid outlet pipe 1 flow out.

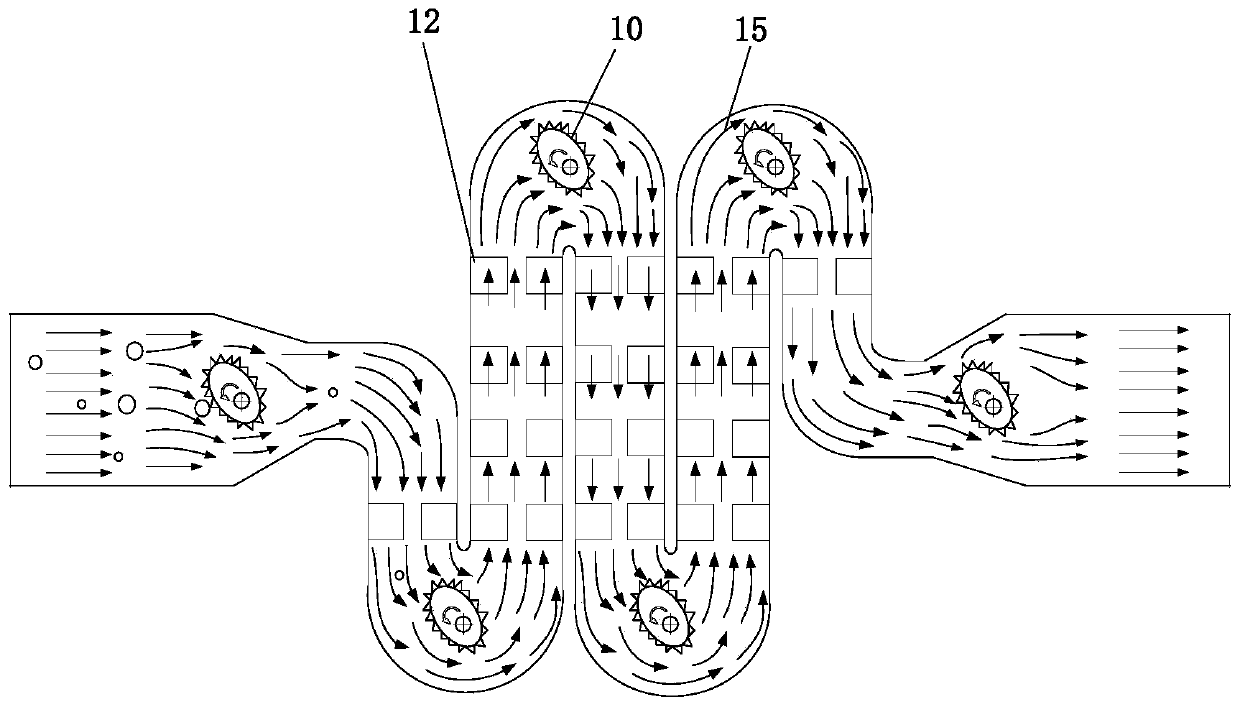

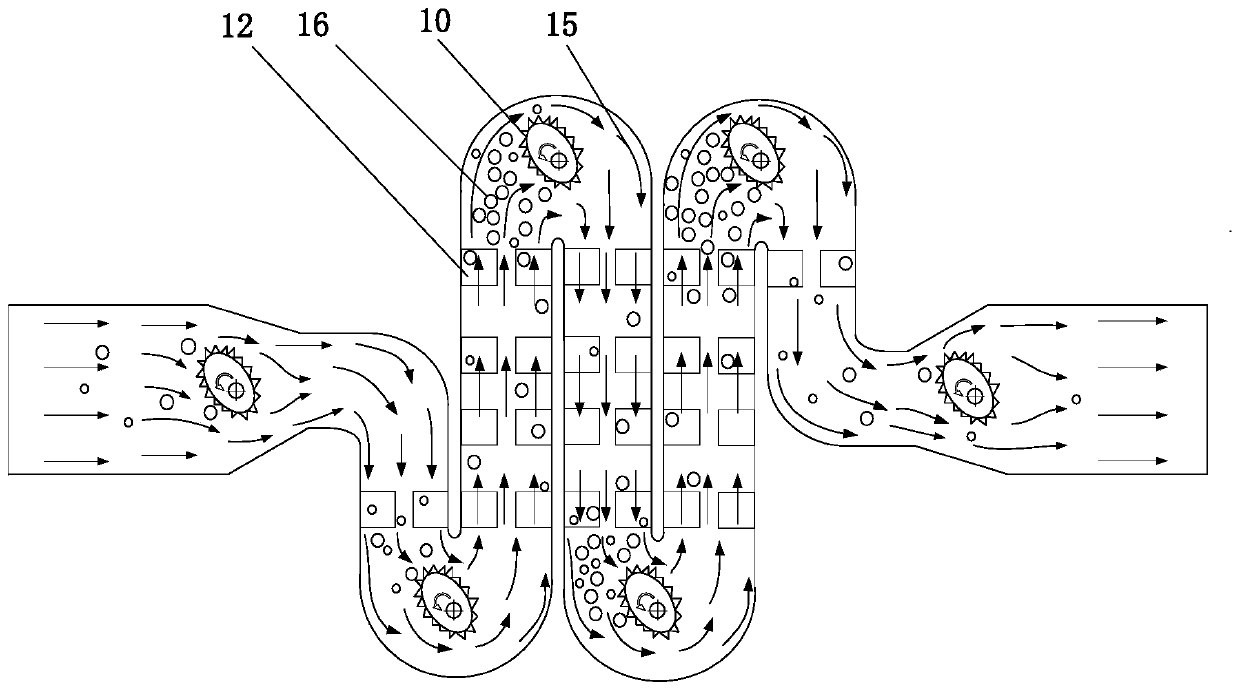

[0031] Such as image 3 As shown, at the constricted section of the flow channel and the corner of the flow channel, the barbed cam 10 mechanism rotates at high speed under the control of the drive motor 11, and the spikes on the surface of the cam can pierce continuous air bubbles to prevent them from affecting the subsequent processing area.

[0032] Such as figure 2 , F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com