Method for recovering nickel from electroplating centralized control wastewater

A waste water recovery and centralized control technology, which is applied in the direction of metallurgical waste water treatment, chemical instruments and methods, and process efficiency improvement, can solve the problems of unsatisfactory recovery effect, complicated treatment methods, and high treatment costs, so as to protect the environment and improve The effect of electrolysis rate and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0028] Treatment of nickel-containing wastewater containing 0.5g / L nickel, pH 5-6, water temperature 20-30 degrees, and adsorption flow 10BV / H:

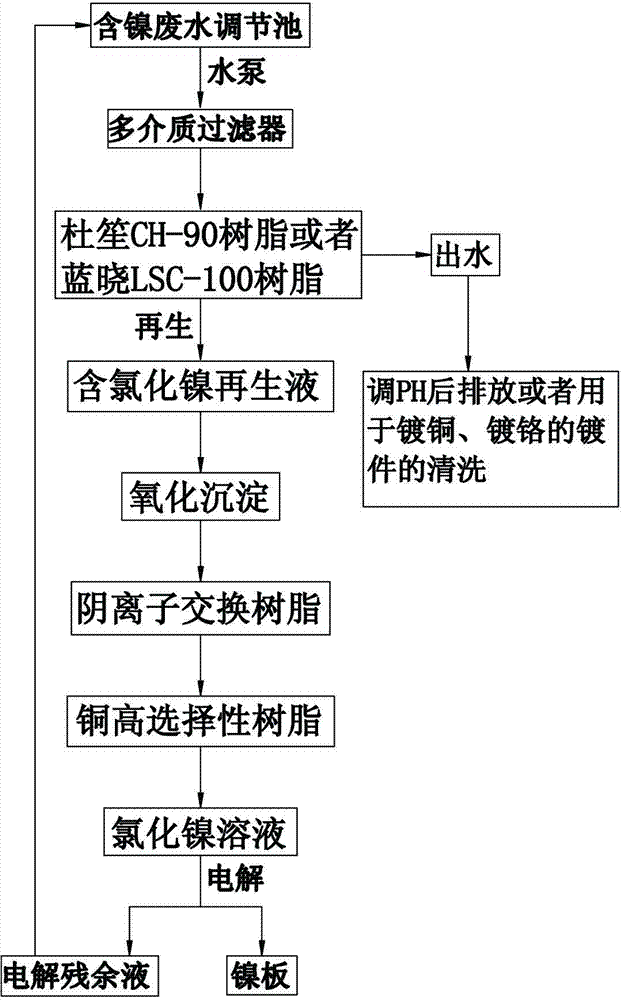

[0029] refer to figure 1 A method for recycling nickel from electroplating centralized wastewater treatment, comprising the following steps carried out in sequence:

[0030] a. Collection: collect nickel-containing wastewater and homogenize;

[0031] b. Filtration: Wastewater enters the multi-media filter for filtration treatment to remove solid particle impurities;

[0032] c. Adsorption: after the filtrate in step b is adjusted to PH to 3, it passes through an adsorption device filled with nickel high-selectivity resin, so that most of the nickel ions are adsorbed on the nickel high-selectivity resin; the adsorption device is composed of two resin columns connected in series, That is, the liquid outlet of the first resin column is connected with the liquid inlet of the second resin column, and the two resin columns are filled wit...

Embodiment approach 2

[0041] The method for reclaiming nickel from electroplating centralized control wastewater comprises the following steps carried out in sequence:

[0042] a. Collection: collect nickel-containing wastewater and homogenize;

[0043] b. Filtration: Wastewater enters the multi-media filter for filtration treatment to remove solid particle impurities;

[0044]c. Adsorption: After the filtrate in step b is adjusted to pH 3, it passes through the resin column filled with Lanxiao LSC-100 (amino carboxylic acid) resin, so that most of the nickel ions are adsorbed on Lanxiao LSC-100 resin; the resin column After adjusting the PH to PH = 6 ~ 9, the effluent can be directly discharged or used for cleaning nickel-plated and chrome-plated parts;

[0045] d. Regeneration: Wash the nickel ions adsorbed on Lanxiao LSC-100 resin with 10% hydrochloric acid to obtain a regeneration solution. The concentration of nickel ions in the regeneration solution is about 20g / L;

[0046] e. Impurity remo...

Embodiment approach 3

[0049] The method for reclaiming nickel from electroplating centralized control wastewater comprises the following steps carried out in sequence:

[0050] a. Collection: collect nickel-containing wastewater and homogenize;

[0051] b. Filtration: Wastewater enters the multi-media filter for filtration treatment to remove solid particle impurities;

[0052] c. Adsorption: after the filtrate of step b is adjusted to PH to 3, pass through the resin column filled with Dusheng CH-90 resin, so that most of the nickel ions are adsorbed on the Dusheng CH-90 resin; the flow rate of the filtrate entering the resin column is 40m 3 / h; the effluent of the resin column can be directly discharged after adjusting the PH to PH=6~9 or used for cleaning nickel-plated and chrome-plated parts;

[0053] d. Regeneration: Wash the nickel ions adsorbed on Dusheng CH-90 resin with 10% hydrochloric acid to obtain a regeneration solution. The concentration of nickel ions in the regeneration solution i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com