Board grinding method for removing orifice burrs of printed circuit board (PCB)

A PCB board, grinding board technology, applied in grinding machines, grinding/polishing equipment, machine tools suitable for grinding workpiece edges, etc., can solve problems such as affecting the reliability of PCB boards, and avoid unidirectional removal of holes by grinding The effect of copper on the bottom of the mouth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

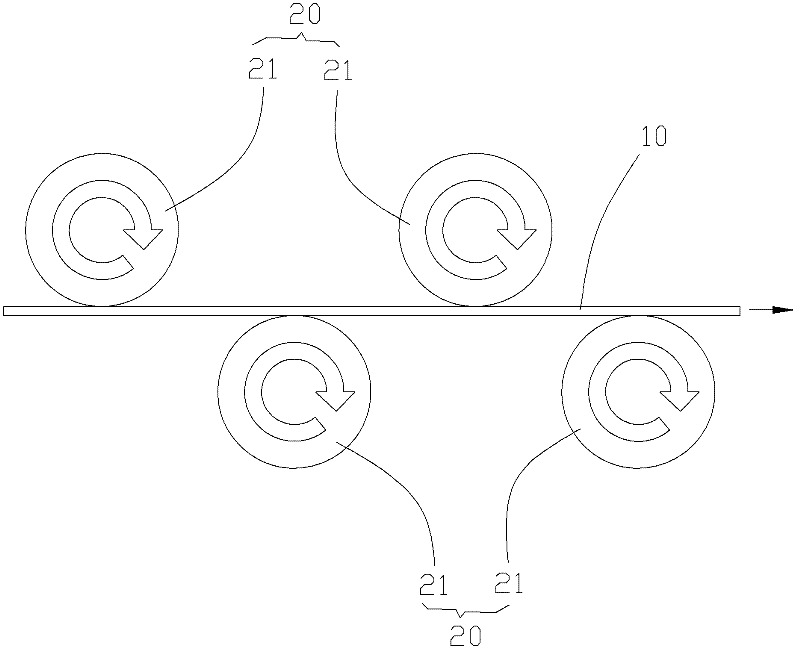

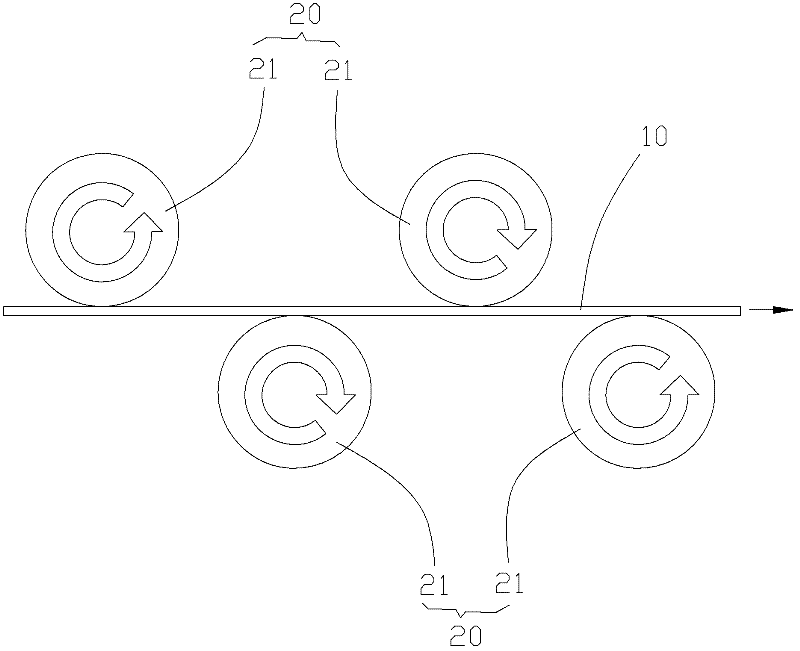

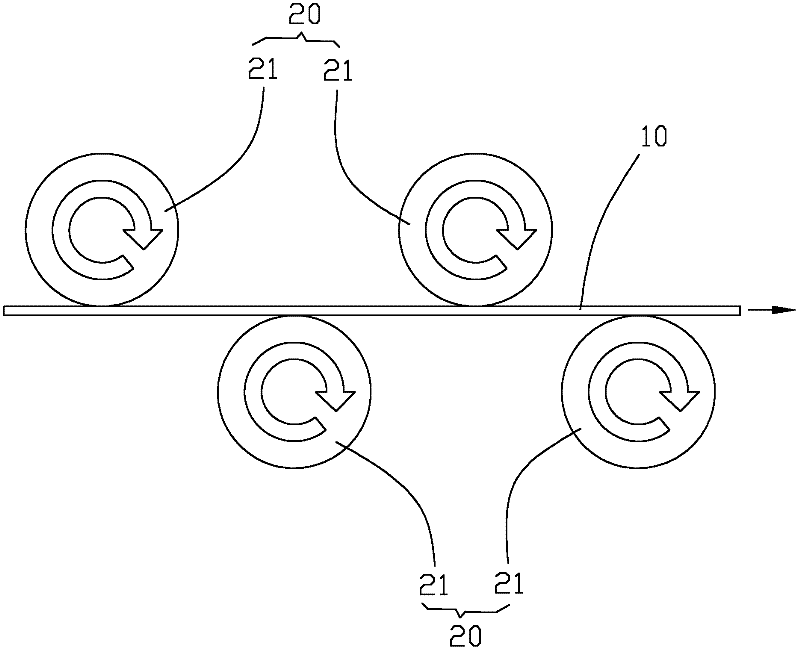

[0015] Such as figure 1 As shown, it is a schematic diagram of a preferred embodiment of a grinding method for removing orifice burrs from a PCB board of the present invention.

[0016] The grinding plate method of this PCB board removal orifice burr, comprises the steps:

[0017] Step 1: Provide a grinding machine and the drilled PCB board 10, the grinding machine includes two pairs of grinding wheels 20, upper and lower, and two grinding wheels 21 of each pair of grinding wheels 20 are respectively provided with grinding brushes;

[0018] Step 2: grinding the PCB board 10, the PCB board 10 is located between the upper and lower pairs of grinding wheels 20, and the upper and lower sides of the PCB board 10 are respectively brushed by the grinding brushes of the upper and lower pairs of grinding wheels 20. The lower two sides carry out grinding plate processing, to remove the orifice burr of drilling, during grinding plate, the rotation direction of two grinding wheels 21 of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com